Comprehensive Guide to Repairing Your 1966 Chevy C10

For enthusiasts of vintage vehicles, keeping these automotive treasures in top condition is both an art and a science. Understanding the intricacies of older models not only enhances their performance but also preserves their nostalgic charm. A well-structured approach to upkeep can make all the difference in ensuring longevity and reliability.

In this guide, we delve into the critical components that require attention in these classic trucks. From engine tuning to bodywork, each aspect plays a vital role in maintaining functionality and aesthetic appeal. By following comprehensive instructions and tips, owners can confidently tackle various tasks, whether they are seasoned mechanics or newcomers to automotive care.

Equipped with the right knowledge, any enthusiast can embark on the journey of restoration and maintenance. The combination of practical advice and detailed insights will empower readers to foster a deeper connection with their vehicles, transforming routine upkeep into a fulfilling experience.

Essential Tools for C10 Repair

When working on vintage vehicles, having the right equipment is crucial for effective maintenance and restoration. This section outlines the fundamental implements that will aid in the process, ensuring that enthusiasts can tackle various tasks with confidence.

Here are some indispensable tools to consider:

- Socket Set: A comprehensive set of sockets will enable you to loosen and tighten a variety of fasteners efficiently.

- Wrenches: Both standard and metric wrenches are necessary for different bolt sizes throughout the vehicle.

- Jack and Jack Stands: Safe lifting equipment is essential for working under the chassis.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, is important for numerous components.

- Torque Wrench: To ensure bolts are tightened to the correct specifications, a torque wrench is vital.

In addition to these basics, consider the following specialized tools:

- Multimeter: Useful for diagnosing electrical issues.

- Impact Wrench: This tool speeds up the removal of stubborn bolts.

- Brake Bleeder Kit: Essential for maintaining the brake system.

- Paint Sprayer: For restoring the vehicle’s exterior finish.

Equipping yourself with these tools will make the journey of working on your classic vehicle not only easier but also more enjoyable.

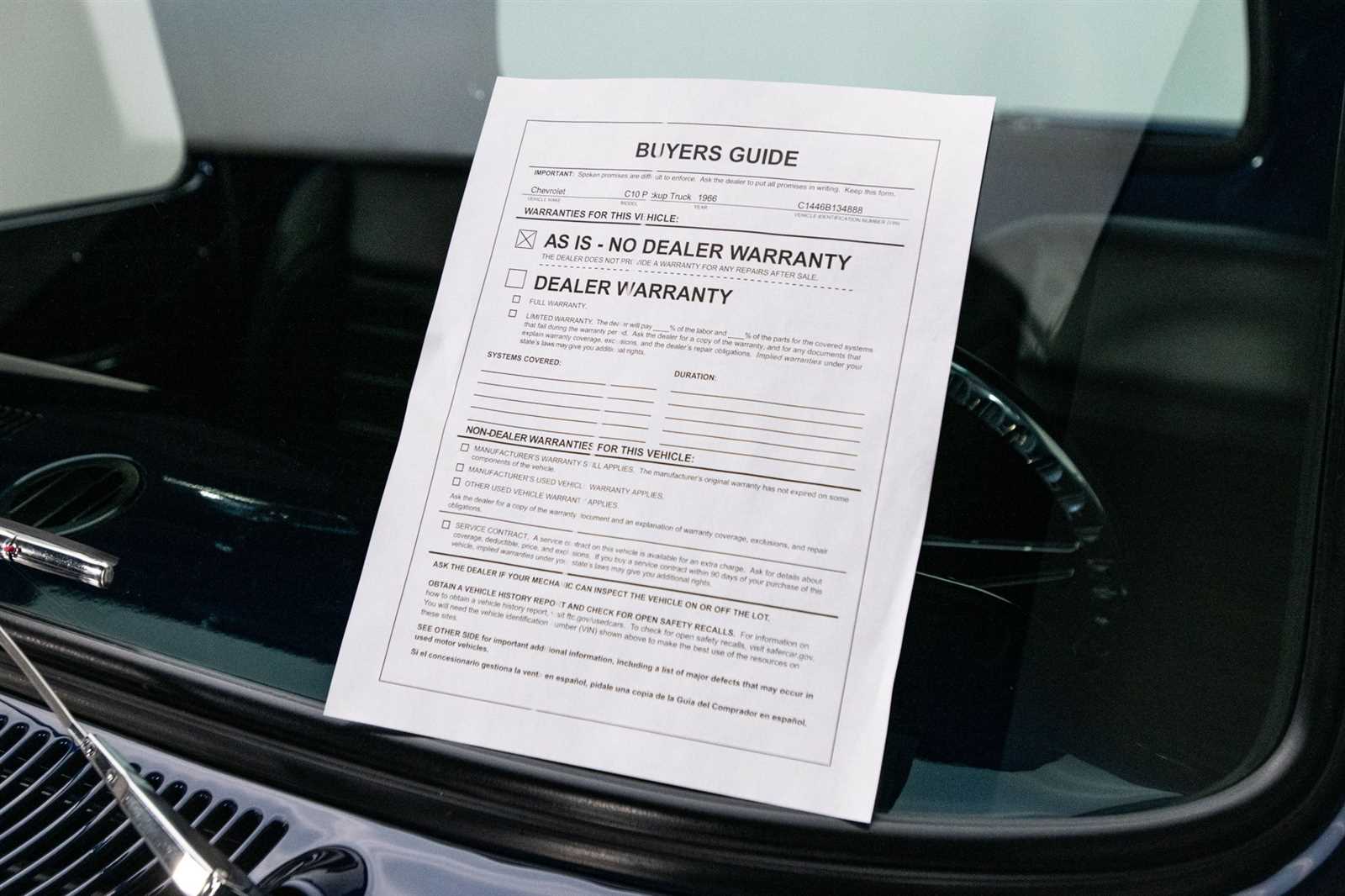

Common Issues in 1966 Chevy C10

The classic truck from the mid-60s is beloved for its robust design and nostalgic appeal, but like any vintage vehicle, it comes with its own set of challenges. Owners often encounter specific problems that can affect performance, safety, and overall enjoyment of the ride. Understanding these common issues can help in maintaining the vehicle and preserving its charm.

Electrical System Problems

One frequent concern is related to the electrical system. Owners may experience difficulties with starting the engine due to faulty wiring or corroded connections. Additionally, issues with the lighting system, such as dim or non-functioning headlights, are also common. Regular checks and updates to the wiring harness can mitigate these problems.

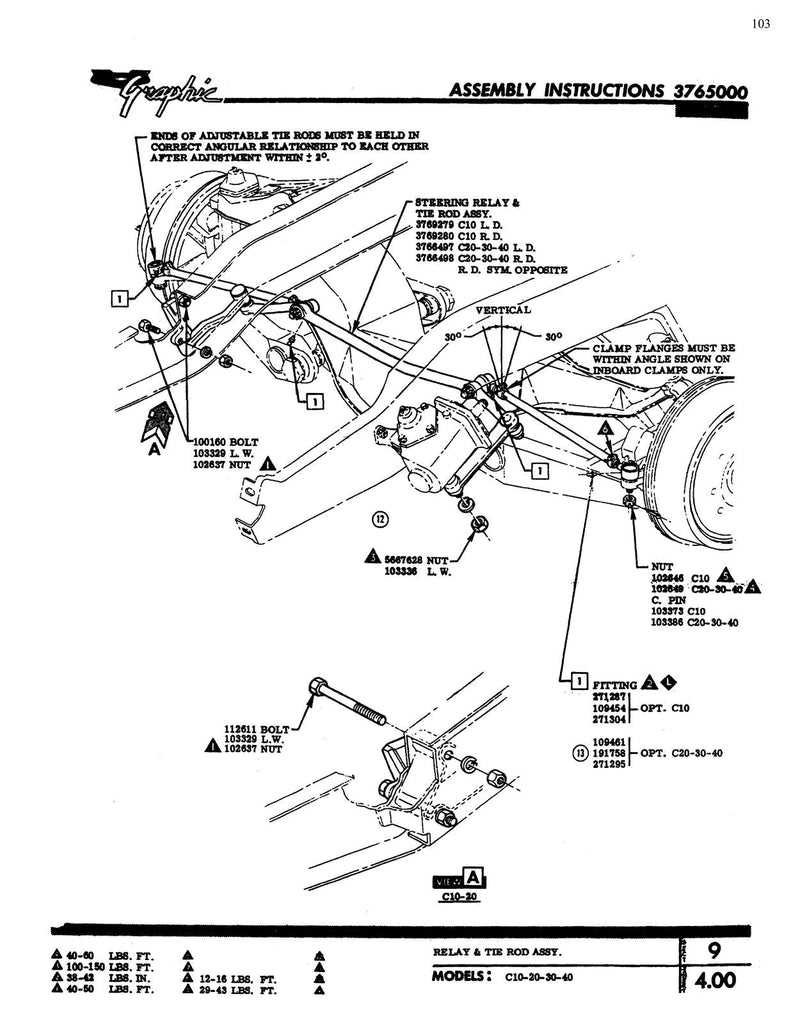

Suspension and Steering Wear

Another area that often requires attention is the suspension and steering components. Over time, parts such as bushings, ball joints, and tie rods may wear out, leading to a less responsive steering feel and uneven tire wear. Regular inspections and timely replacements of these parts can enhance handling and safety.

Step-by-Step Maintenance Guide

Maintaining your vehicle is essential for ensuring its longevity and optimal performance. A systematic approach to care not only prevents unexpected issues but also enhances your driving experience. This guide outlines key procedures to help you keep your automobile in excellent condition.

Routine Checks

Regular inspections are vital for identifying potential problems early. Here are some fundamental tasks to include in your maintenance routine:

- Check fluid levels (engine oil, coolant, brake fluid).

- Inspect tire pressure and tread depth.

- Examine the battery for corrosion and charge status.

- Assess the condition of belts and hoses.

Periodic Maintenance Tasks

Beyond routine checks, certain tasks should be performed at specific intervals to ensure everything is functioning smoothly:

- Oil Change: Replace engine oil and filter every 3,000 to 5,000 miles.

- Brake Inspection: Examine brake pads and rotors for wear every 10,000 miles.

- Transmission Service: Change transmission fluid according to manufacturer recommendations.

- Coolant Flush: Replace coolant every two years to prevent overheating.

By adhering to these guidelines, you can maintain your vehicle’s performance and safety, ensuring a reliable driving experience for years to come.

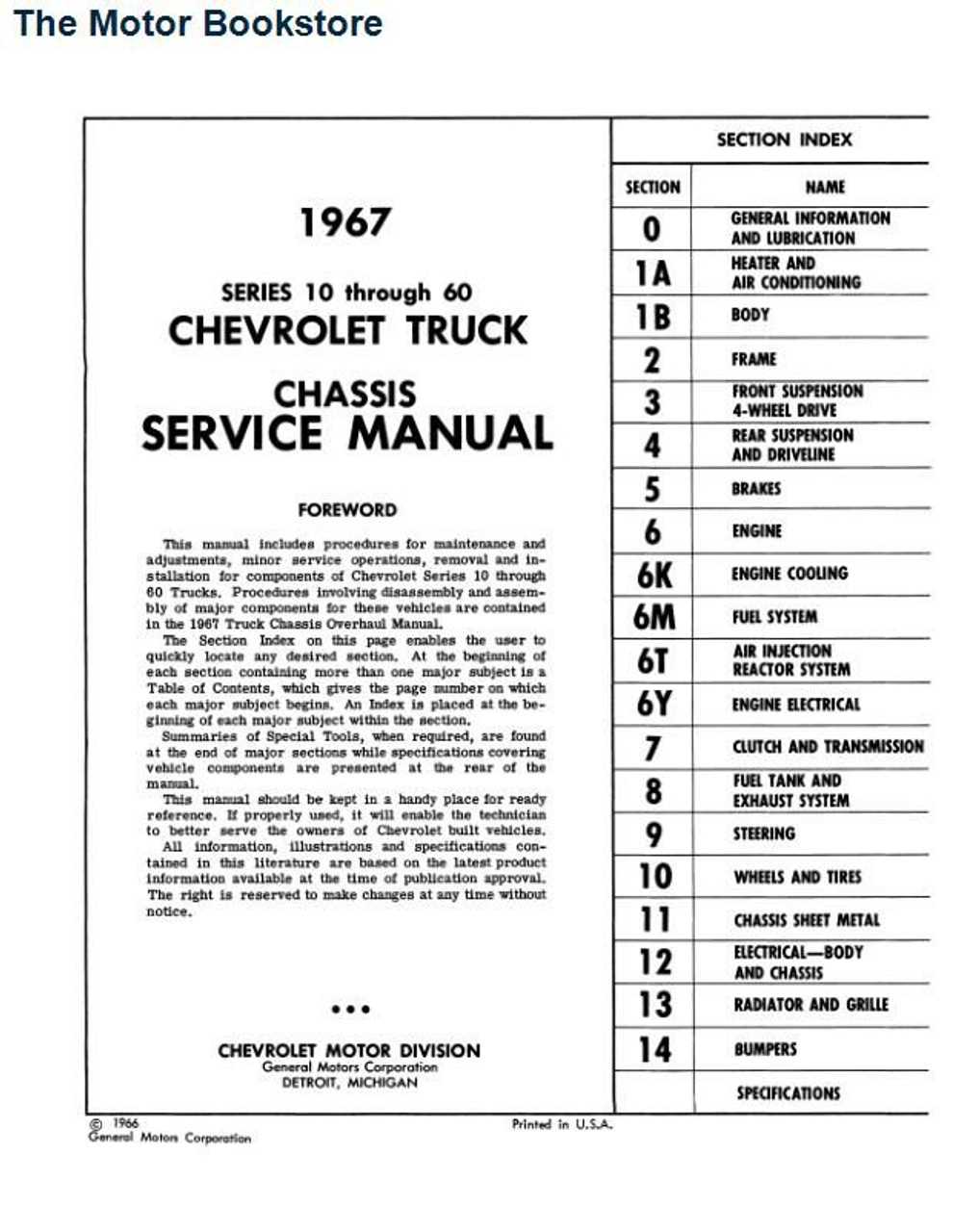

Understanding C10 Engine Components

When delving into the intricacies of a classic pickup’s powertrain, it’s essential to grasp the various elements that contribute to its functionality and performance. Each component plays a pivotal role, ensuring that the engine operates smoothly and efficiently. Familiarizing oneself with these parts not only aids in maintenance but also enhances overall vehicle appreciation.

1. Engine Block: The core structure of the powerplant, housing the cylinders and providing the foundation for other components. Its durability is crucial for supporting engine performance and longevity.

2. Cylinder Head: This component sits atop the engine block, containing essential elements like valves and spark plugs. It plays a vital role in controlling airflow and facilitating combustion.

3. Crankshaft: A key player in transforming the linear motion of pistons into rotational force, the crankshaft is integral to the vehicle’s ability to move. Its design directly influences engine balance and efficiency.

4. Camshaft: Responsible for timing the opening and closing of valves, the camshaft is essential for optimal airflow into and out of the cylinders. Variations in its design can significantly impact engine performance.

5. Fuel System: Comprising the fuel tank, lines, pump, and injectors or carburetors, this system ensures that the engine receives the necessary fuel-air mixture for combustion. Its efficiency can greatly affect power output and fuel economy.

6. Exhaust System: This system channels exhaust gases away from the engine, preventing back pressure that could hinder performance. Proper functioning of the exhaust system is crucial for engine health and efficiency.

Understanding these essential components empowers owners and enthusiasts alike to engage more meaningfully with their vehicles, whether for routine upkeep or performance enhancements.

Electrical System Troubleshooting Tips

Tackling issues within the electrical system can often seem daunting, yet understanding the basics can lead to effective resolutions. Identifying common problems and employing systematic approaches can significantly simplify the process, ensuring your vehicle’s components function harmoniously.

Start by checking the battery condition. A weak or dead battery is often the root cause of electrical failures. Ensure all connections are clean and secure, as corrosion can impede performance.

Next, inspect fuses and relays. A blown fuse can disrupt circuits, while faulty relays may prevent components from operating. Replace any damaged parts promptly to restore functionality.

Wiring integrity is crucial. Look for frayed wires, loose connections, or signs of damage. Repair or replace any compromised sections to maintain a reliable electrical flow.

Utilize a multimeter to diagnose issues accurately. Measuring voltage, resistance, and continuity can help pinpoint faults within the system, guiding you toward the ultimate solution.

Bodywork and Paint Restoration Techniques

Restoring the exterior of a classic vehicle involves meticulous attention to detail and a solid understanding of various techniques. From addressing rust and dents to achieving a flawless paint finish, each step is crucial for preserving the integrity and aesthetics of the automobile.

Here are some essential techniques to consider for bodywork and paint restoration:

- Rust Repair:

- Identify rust spots and assess damage.

- Use a wire brush or grinder to remove rust.

- Apply a rust-inhibiting primer to prevent future corrosion.

- Dent Removal:

- Utilize a suction cup or dent puller for minor dents.

- For more severe damage, consider the PDR (Paintless Dent Repair) method.

- Fill deeper dents with body filler, ensuring it’s smooth and level.

- Surface Preparation:

- Wash the surface thoroughly to remove dirt and grease.

- Sand the area to create a smooth surface for painting.

- Use a tack cloth to eliminate dust particles.

- Painting Techniques:

- Select high-quality paint and primer suited for automotive applications.

- Apply primer evenly and allow proper drying time.

- Spray multiple coats of paint, allowing each layer to dry before applying the next.

- Finish with a clear coat for protection and shine.

- Polishing and Finishing:

- Use a polishing compound to restore the shine.

- Buff the surface to achieve a high-gloss finish.

- Inspect for imperfections and touch up as necessary.

Employing these methods will not only enhance the appearance of the vehicle but also extend its lifespan. A well-executed restoration project can bring new life to any classic ride, making it a source of pride and joy for years to come.

Suspension Upgrades for Better Handling

Improving your vehicle’s suspension system can significantly enhance its handling and overall performance. By upgrading various components, drivers can experience a smoother ride, better cornering stability, and increased safety on the road. Whether it’s for daily driving or competitive use, a well-tuned suspension is essential for maximizing your vehicle’s potential.

Upgrading shock absorbers is one of the most effective ways to achieve better handling. High-performance shocks provide superior damping control, allowing the tires to maintain better contact with the road surface. This results in improved traction and responsiveness, especially during sharp turns and abrupt maneuvers.

Additionally, swapping out the springs for stiffer alternatives can help reduce body roll and improve cornering capabilities. Performance springs are designed to maintain optimal ride height and enhance stability, giving the driver more confidence in the vehicle’s handling characteristics.

Another important aspect to consider is adding sway bars. These components help minimize body roll during cornering by linking the left and right sides of the suspension. Upgraded sway bars can significantly improve handling dynamics, making your ride feel more balanced and controlled.

Finally, upgrading to performance bushings can further enhance the suspension system. High-quality bushings reduce deflection and improve feedback from the road, allowing for a more connected driving experience. This upgrade can lead to a more responsive and agile feel when navigating through curves.

In summary, investing in suspension upgrades can lead to noticeable improvements in handling and stability. By carefully selecting components such as shock absorbers, springs, sway bars, and bushings, drivers can transform their vehicle’s performance, making every journey more enjoyable and secure.

Brake System Overhaul Procedures

The effective functioning of the braking mechanism is crucial for vehicle safety and performance. A comprehensive approach to revitalizing this system ensures optimal stopping power and reliability. This segment will guide you through essential steps and considerations necessary for overhauling the braking system.

Initial Inspection

Begin with a thorough examination of the entire braking system. Check for signs of wear, leaks, and corrosion on components such as brake lines, calipers, and drums. Pay special attention to the condition of the brake pads and shoes, as these are critical for effective operation.

Disassembly

Once the inspection is complete, carefully disassemble the braking components. Take notes or photographs to assist in reassembly. Remove the wheels and detach the brake calipers or drums, ensuring to support any hanging components securely.

Cleaning

Clean all disassembled parts with a suitable solvent to remove dust, grease, and debris. A clean surface is essential for effective reinstallation and performance. Inspect each part for damage during this process, replacing any worn or broken components as necessary.

Component Replacement

Replace brake pads and shoes as required, ensuring they meet the manufacturer’s specifications. Additionally, consider renewing brake lines and hoses to enhance safety and performance. When installing new components, follow the recommended torque specifications for all fasteners.

Reassembly

Carefully reassemble the braking system in reverse order of disassembly. Ensure all parts are correctly aligned and secured. Reattach the wheels, and do not forget to recheck all fasteners for proper tightness.

Fluid Replacement and Bleeding

Finally, refill the brake fluid reservoir with the appropriate type of fluid. Bleed the system to remove any air that may have entered during disassembly. This step is vital for restoring the responsiveness of the braking mechanism.

By following these steps diligently, you can ensure that the braking system operates at its best, enhancing both safety and driving experience.

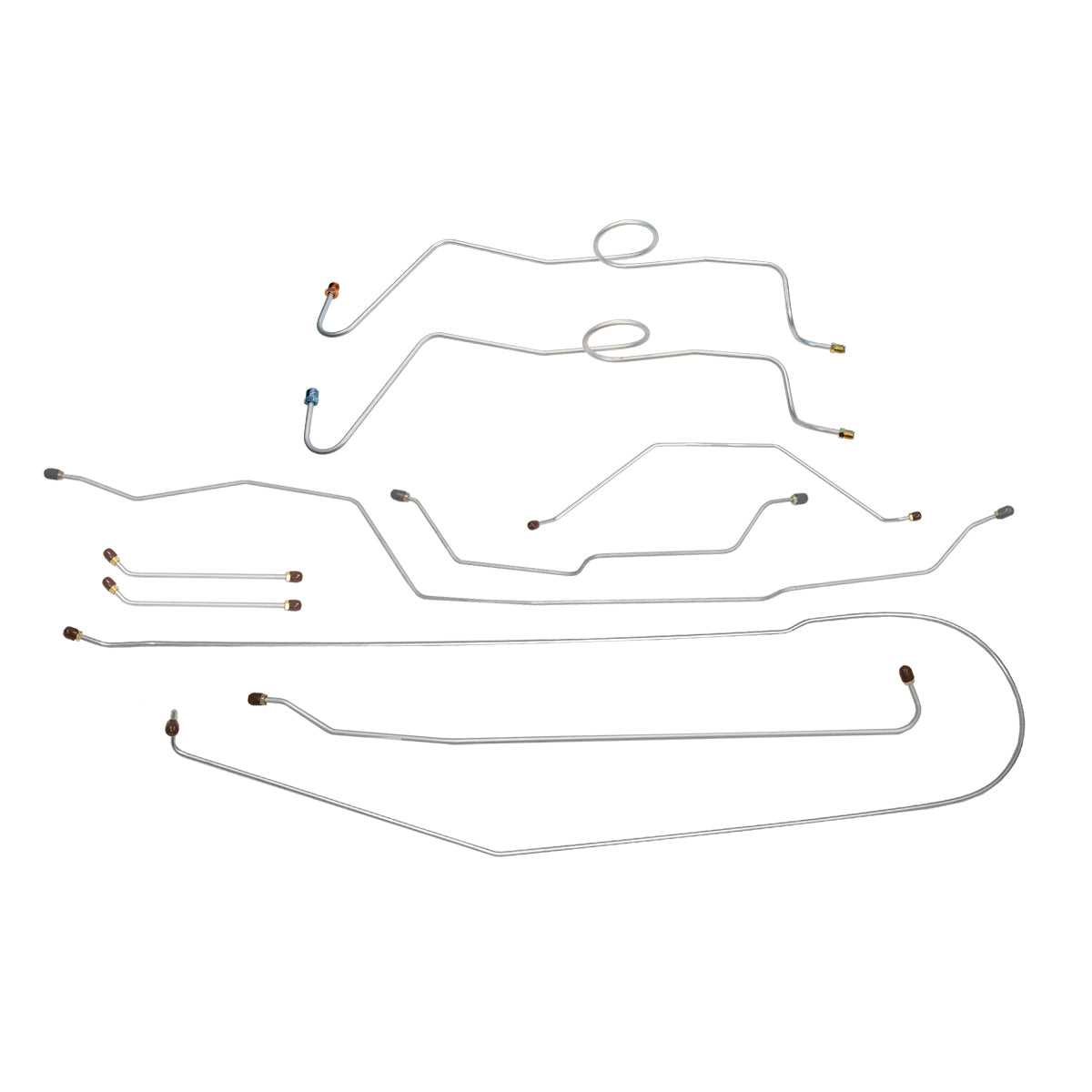

Fuel System Inspection and Repair

Ensuring optimal performance of the fuel delivery system is essential for any vehicle’s efficiency and reliability. This section focuses on the critical components involved in the fuel system and the steps needed to assess their condition and functionality. Regular inspections and timely interventions can prevent more severe issues down the line, ensuring a smooth driving experience.

Key Components to Inspect

Begin by examining the fuel tank, lines, and pump. Check for signs of corrosion, leaks, or blockages that may hinder fuel flow. Fuel filters should also be inspected and replaced as necessary, as they play a vital role in maintaining the purity of the fuel entering the engine. Additionally, the carburetor or fuel injection system must be evaluated for proper operation and cleanliness.

Testing and Maintenance Procedures

Utilize a pressure gauge to measure the fuel pressure and confirm that it falls within the manufacturer’s specifications. Any discrepancies may indicate a malfunctioning pump or a clogged filter. Furthermore, ensure that all electrical connections to the pump and injectors are secure and free of corrosion. Regular maintenance, such as cleaning components and replacing worn parts, is crucial for the longevity of the fuel system.

Interior Restoration Best Practices

Reviving the inside of a classic vehicle can significantly enhance its overall appeal and value. This process involves careful planning and execution to ensure every element, from upholstery to dashboard components, is restored to its former glory. Adopting best practices in this endeavor not only preserves authenticity but also improves functionality.

Assessing Condition and Planning

Before diving into restoration, thoroughly evaluate the current state of the interior. Identify areas needing attention, such as worn upholstery or damaged trim. Creating a detailed plan will help prioritize tasks and allocate resources effectively, ensuring a smoother restoration journey.

Choosing Quality Materials

Utilizing high-quality materials is crucial for achieving lasting results. Select fabrics and finishes that closely match the original specifications. Investing in top-notch supplies can make a substantial difference in the final appearance and durability of the interior, ultimately enhancing the vehicle’s charm.