Note any grinding, whining, or clunking sounds that might

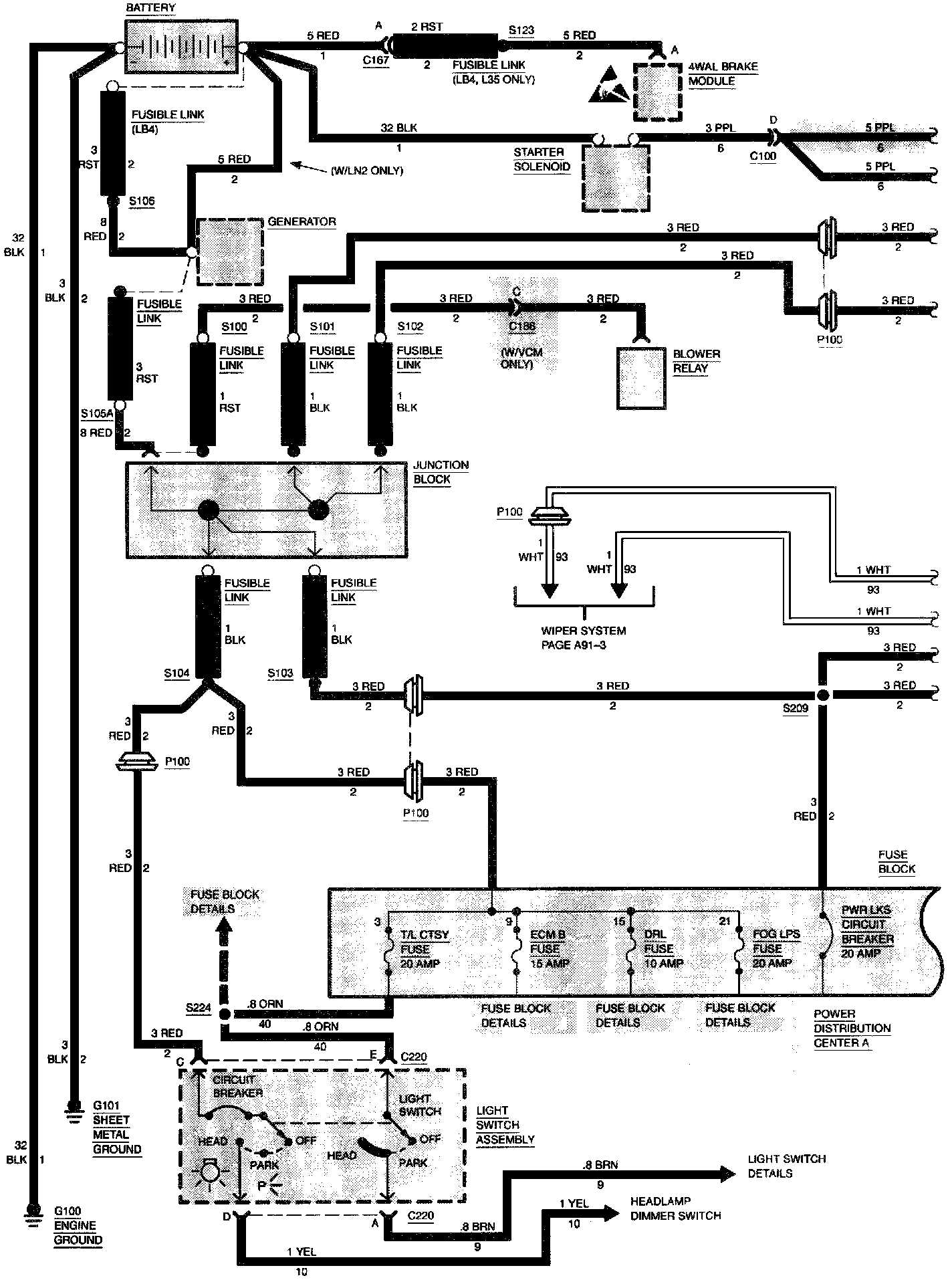

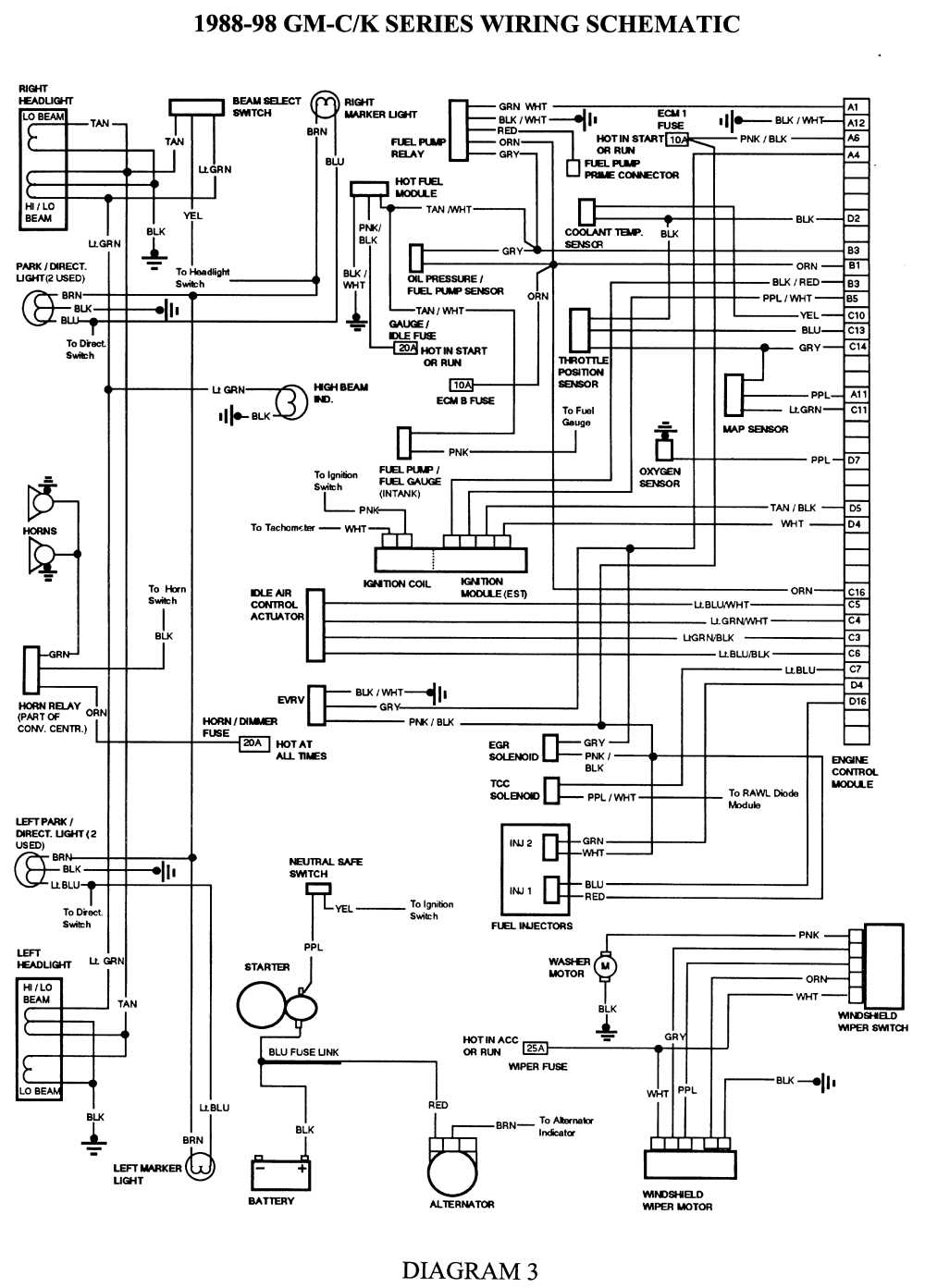

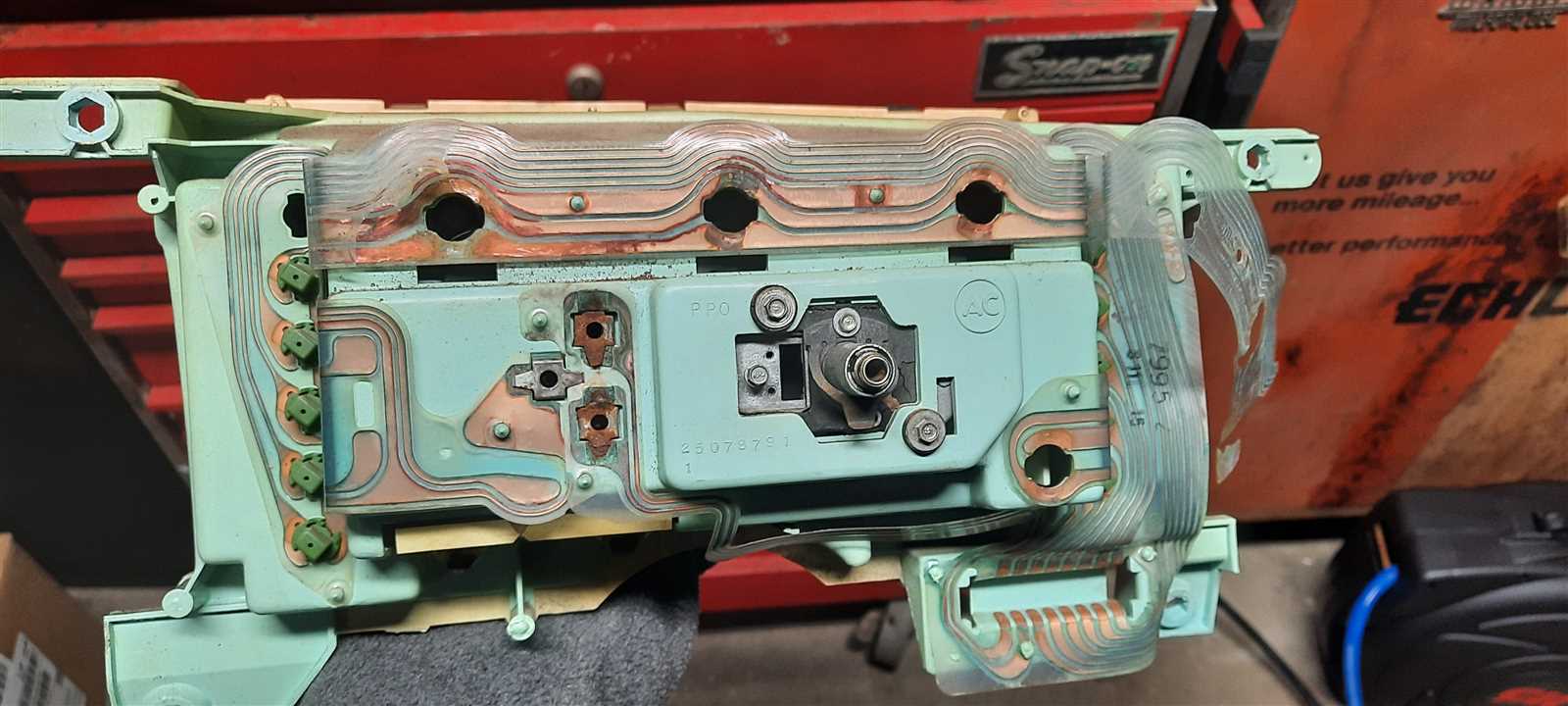

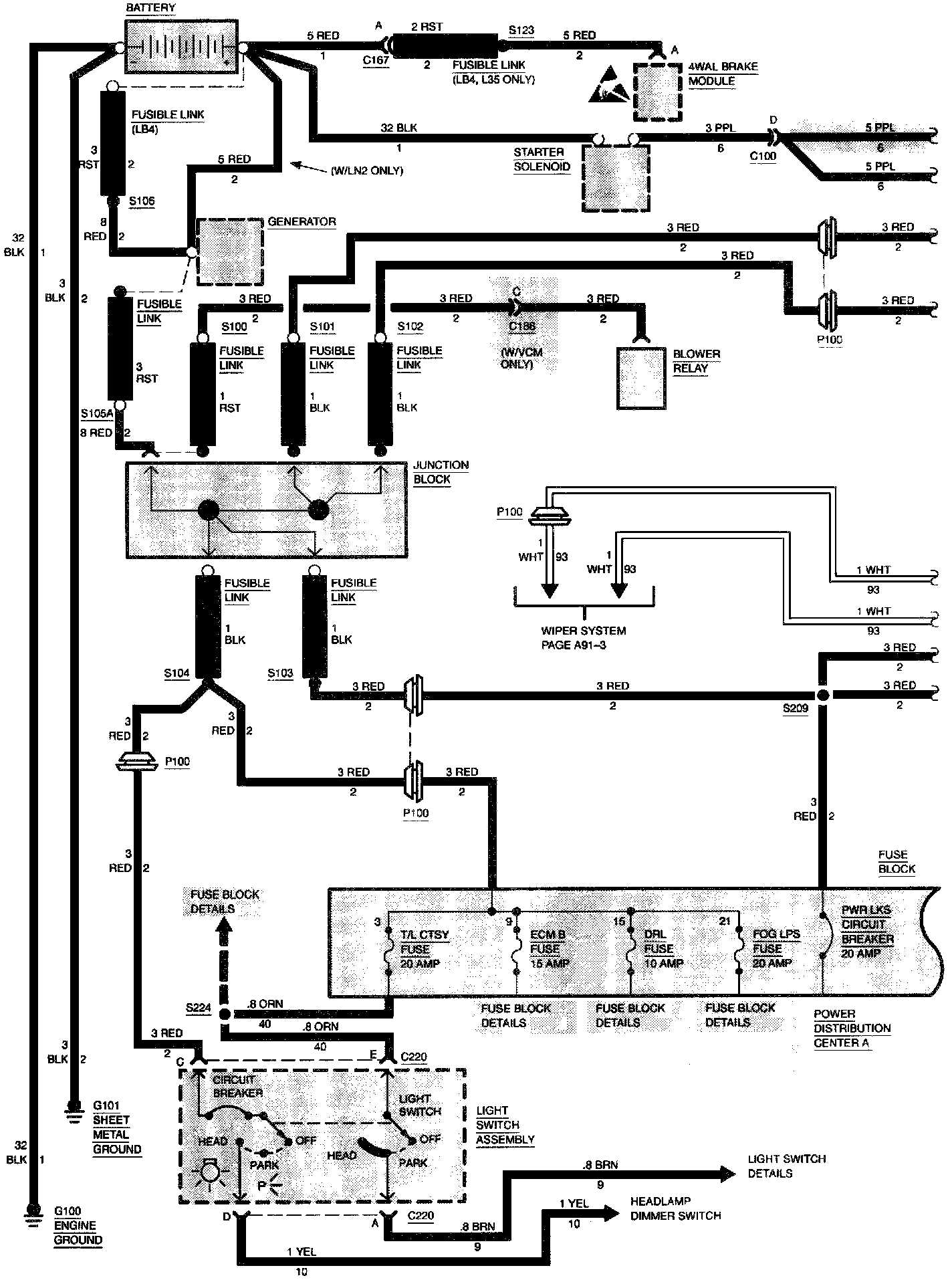

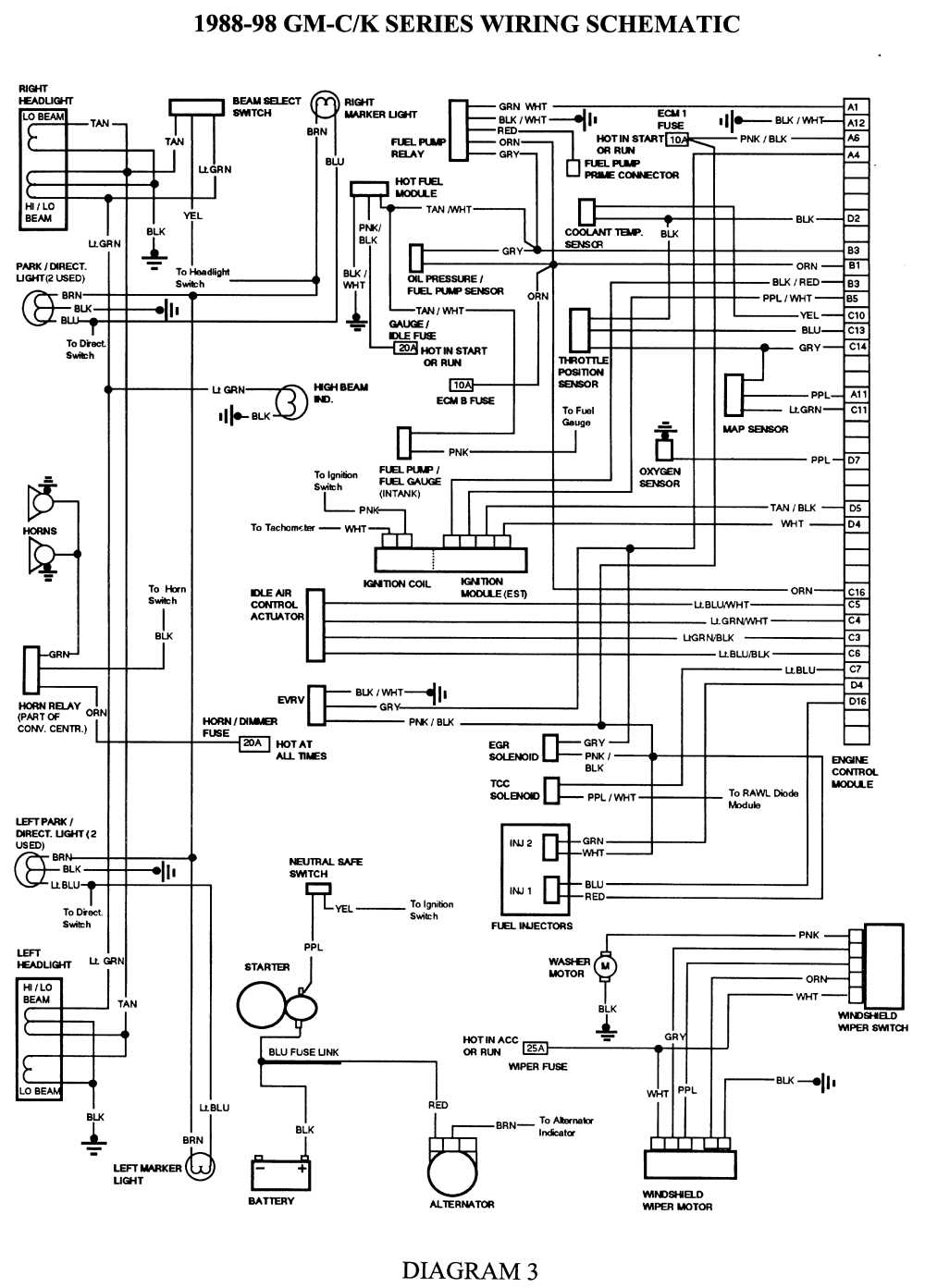

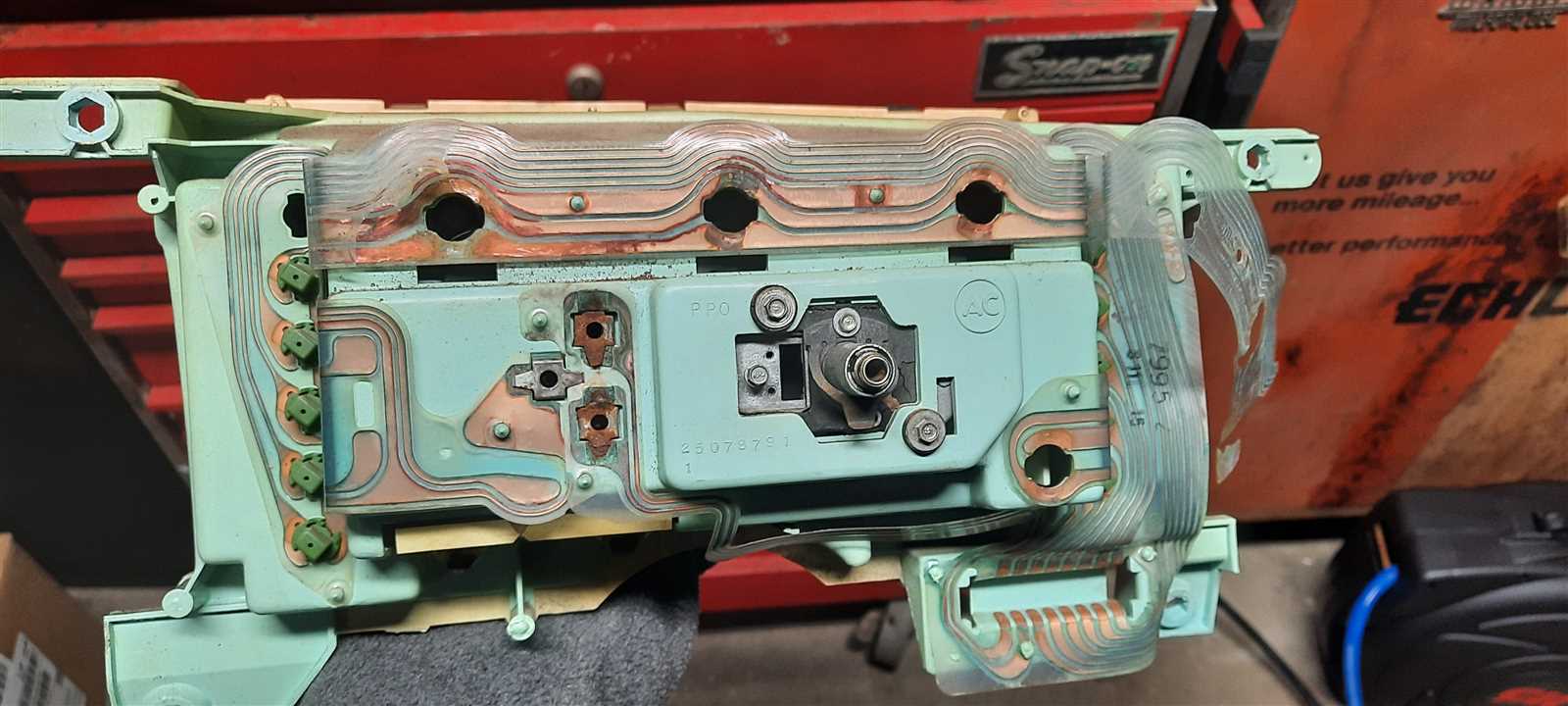

Basic Electrical System Maintenance

Regular upkeep of a vehicle’s electrical components is essential for consistent performance and longevity. Proper attention to this area ensures reliable starting, smooth functioning of electronic accessories, and overall operational safety. The electrical setup comprises several key parts, all requiring routine checks and minor servicing to prevent issues.

| Component |

Maintenance Action |

Frequency |

| Battery |

Inspect terminals for corrosion and ensure a secure fit. Test charge levels regularly. |

Every 3 months |

| Alternator |

Check the belt for wear and proper tension. Monitor charging output. |

Every 6 months |

| Fuses |

Inspect and replace any blown fuses to protect the electrical circuits. |

As needed |

| Wiring |

Look for frayed or damaged wires, especially near connectors and high-vibration areas. |

Annually |

| Ground Connections |

Ensure ground points are clean and free from rust or dirt buildup. |

Annually |

Consistent inspection and simple upkeep practices for these components help prevent electrical issues, support efficient energy use, and enhance the overall reliability of the vehicle’s electronic systems. Staying proactive with these routine checks can save time and cost over the long term.

Brake System Inspection Tips

Maintaining a reliable and effective braking system is essential for vehicle safety. Regular inspections help identify any wear or potential issues that might compromise performance, ensuring a smooth and secure driving experience. Understanding key areas to inspect and recognizing early signs of wear are crucial steps in keeping your vehicle’s brake system in optimal condition.

Check Brake Pads and Rotors

Brake pads and rotors play a central role in stopping power. Inspect brake pads for wear, paying attention to the thickness. Thin pads may indicate the need for replacement. Rotors should be checked for smoothness and thickness. Any grooves, warping, or significant wear on the rotor’s surface can affect braking efficiency and may require resurfacing or replacement.

Examine Brake Lines and Fluid

Brake lines should be inspected for any cracks, leaks, or signs of corrosion, as these issues can compromise the flow of brake fluid. The fluid itself should be checked for clarity and proper levels. If the fluid appears dark or has particles, it may indicate contamination, necessitating a flush. Regularly maintaining clean and sufficient brake fluid ensures proper hydraulic pressure throughout the braking system.

Remember to include regular checks of other components, such as the calipers and drums, if applicable. Addressing any irregularities early can prevent costly repairs and extend the lifespan of the brake system, contributing to safer and more reliable operation.

Exhaust System Repairs and Care

The exhaust system is a crucial component of any vehicle, responsible for directing harmful gases away from the engine and ensuring optimal performance. Regular maintenance and timely interventions can prevent costly damage and enhance efficiency. Understanding the common issues that may arise and knowing how to address them can significantly prolong the lifespan of the exhaust components.

Common Issues and Solutions

Over time, various problems may occur within the exhaust system, leading to decreased performance and potential hazards. Below are some frequent issues and their corresponding remedies:

| Issue |

Description |

Solution |

| Rust and Corrosion |

Oxidation can weaken exhaust pipes and joints, causing leaks. |

Inspect regularly and replace affected sections. |

| Loose Connections |

Components may become loose over time, resulting in noise and inefficiency. |

Tighten clamps and bolts; replace any damaged parts. |

| Blocked Catalytic Converter |

A clogged converter can hinder exhaust flow and decrease performance. |

Clean or replace the catalytic converter as necessary. |

Maintenance Tips

Proper care is essential for the longevity of the exhaust system. Consider the following tips for maintaining its functionality:

- Conduct visual inspections for any signs of damage or wear.

- Listen for unusual noises while the vehicle is running.

- Ensure all components are securely fastened and free from rust.

- Seek professional help for comprehensive checks at regular intervals.

Cooling System Maintenance Essentials

Maintaining the cooling system is crucial for ensuring optimal performance and longevity of your vehicle. Regular checks and timely servicing can prevent overheating, which could lead to significant engine damage. This section covers essential practices to keep your cooling system in top shape, ensuring your engine runs smoothly and efficiently.

Regular Inspection

Consistent inspection of the cooling system components is vital. Check for leaks in hoses, the radiator, and the water pump. Examine the coolant level and ensure it is within the recommended range. If you notice any signs of corrosion or wear, it may be time to replace parts to maintain system integrity.

Coolant Quality and Replacement

Using the correct coolant and replacing it at specified intervals is essential for effective temperature regulation. Over time, coolant can become contaminated, losing its ability to protect against freezing and corrosion. Regularly flushing the cooling system helps remove debris and old fluid, ensuring optimal performance. Always refer to your vehicle’s specifications for the appropriate type and mixture of coolant.

Suspension and Steering Adjustments

Proper alignment and adjustment of the suspension and steering systems are crucial for optimal vehicle performance and handling. Ensuring that these components are in excellent condition not only enhances ride quality but also improves safety and stability during operation. Regular inspections and necessary adjustments can help maintain the longevity of the vehicle and provide a smooth driving experience.

Suspension Adjustments

Maintaining the suspension system involves several key adjustments that can significantly affect the vehicle’s handling and comfort. Below are essential aspects to consider:

- Ride Height: Adjusting the height of the suspension can impact overall vehicle handling and appearance. Ensure that the height is consistent across all four corners.

- Spring Preload: Proper preload settings on coil springs can influence ride quality and responsiveness. Adjust as needed to achieve the desired stiffness.

- Shock Absorber Settings: Many shock absorbers offer adjustable damping. Fine-tune these settings based on driving conditions and personal preferences.

Steering Adjustments

Steering alignment is vital for vehicle control and tire longevity. Consider the following adjustments:

- Toe Alignment: Ensuring the front wheels are parallel is essential. Adjust the toe angle to prevent uneven tire wear and improve handling.

- Camber Angle: Adjusting the camber helps in managing tire contact with the road surface, which can affect cornering stability.

- Steering Wheel Centering: Ensure the steering wheel is centered while driving straight. Adjustments may be necessary to achieve proper alignment.

Regularly checking and adjusting these systems will contribute to a safer and more enjoyable driving experience. It is advisable to consult with a professional technician for comprehensive inspections and adjustments as needed.

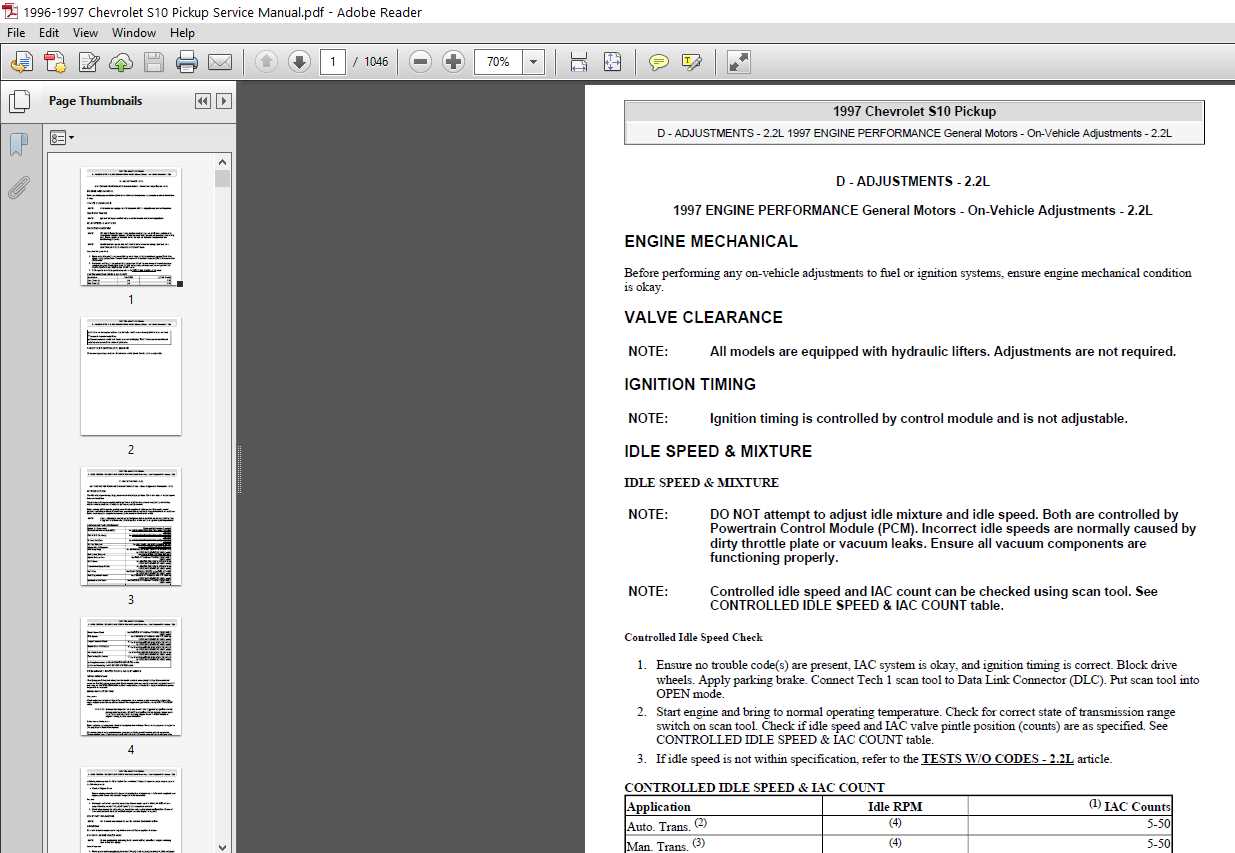

Fuel System Diagnostics

Effective troubleshooting of the fuel system is essential for ensuring optimal engine performance. Identifying issues related to fuel delivery and quality can prevent more serious complications and enhance vehicle reliability. This section outlines key steps and considerations for diagnosing problems within the fuel system.

When beginning the diagnostic process, it is important to assess various components that contribute to fuel delivery. The following steps can guide you through effective evaluation:

- Check Fuel Level: Ensure there is sufficient fuel in the tank, as low levels can lead to performance issues.

- Inspect Fuel Lines: Examine the fuel lines for leaks, cracks, or blockages that may impede flow.

- Test Fuel Pump: Verify that the fuel pump is operating correctly by listening for noise when the ignition is turned on and checking fuel pressure with a gauge.

- Evaluate Fuel Filter: Replace the fuel filter if it appears clogged or has not been changed in a significant time, as this can restrict fuel flow.

- Analyze Fuel Injectors: Inspect fuel injectors for clogs or improper spray patterns, and clean or replace them if necessary.

- Examine Fuel Quality: Check for contaminants or water in the fuel, as poor-quality fuel can cause performance issues.

After completing these initial checks, additional diagnostics may involve using specialized equipment to analyze fuel pressure and flow rates. Following these guidelines will assist in pinpointing fuel system issues and facilitate appropriate solutions.

Body and Interior Restoration Basics

Restoring the exterior and interior of a vehicle is an essential aspect of automotive refurbishment that combines aesthetics with functionality. This process involves meticulous attention to detail and a thorough understanding of various materials and techniques. Whether enhancing the visual appeal or improving the overall comfort of the cabin, proper restoration practices can breathe new life into an aging vehicle.

Assessing the Condition: Before diving into restoration, it’s crucial to evaluate the current state of the vehicle’s body and interior. Inspect for any signs of rust, damage, or wear. This assessment helps in planning the necessary repairs and upgrades effectively.

Preparation Steps: Preparing the surfaces is vital. This may involve stripping old paint, cleaning, and sanding surfaces to create a suitable foundation for new finishes. For interiors, removing old upholstery and cleaning the underlying materials ensures a fresh start.

Materials and Tools: Selecting the right materials is key to a successful restoration. Choose quality paints, primers, and upholstery fabrics that match the desired aesthetic. Additionally, having the correct tools, such as sanders, spray guns, and sewing kits, will facilitate the process.

Finishing Touches: Once the restoration work is complete, adding finishing touches can significantly enhance the overall look. This includes detailing the exterior, installing new trims, or adding modern conveniences to the interior. These elements contribute to both the visual appeal and functionality of the vehicle.

Headlight and Taillight Replacement Guide

Replacing your vehicle’s lighting components is an essential maintenance task that enhances visibility and safety on the road. Properly functioning headlights and taillights are crucial for signaling your presence to other drivers and ensuring compliance with traffic regulations. This guide will provide you with step-by-step instructions to help you efficiently change both types of lights.

Before starting the replacement process, gather the necessary tools and materials. You will typically need a screwdriver, a socket wrench set, and the appropriate replacement bulbs for your specific vehicle. Always refer to your vehicle’s specifications to ensure you purchase the correct parts.

To replace the headlights, begin by opening the hood and locating the back of the headlight assembly. Disconnect the power connector from the bulb, then unclip or unscrew the assembly to remove it from the housing. Insert the new bulb, ensuring it is securely in place before reassembling the unit and reconnecting the power.

For taillight replacement, access the taillight assembly by opening the trunk or tailgate. Locate the screws or clips holding the taillight in place and remove them. Once the assembly is loose, pull it out gently and disconnect the bulb socket. Replace the bulb, reattach the socket, and carefully position the assembly back into place, securing it with the screws or clips.

After completing both replacements, test the lights to ensure they function correctly. Regularly checking and maintaining your vehicle’s lighting system is vital for safe driving conditions and can prevent potential accidents on the road.

Preventive Care and Routine Checks

Regular maintenance and thorough inspections are essential for ensuring optimal performance and longevity of your vehicle. By adhering to a systematic approach to upkeep, you can identify potential issues before they escalate, thereby saving time and reducing costs associated with major repairs.

Regular Inspections

Conducting routine inspections is crucial for the overall health of your vehicle. This includes checking fluid levels, examining belts and hoses for wear, and ensuring that tires are properly inflated. Regular assessments not only help in maintaining efficiency but also enhance safety during drives.

Scheduled Maintenance

Following a scheduled maintenance plan is vital for sustaining your vehicle’s reliability. This involves changing the oil, replacing filters, and rotating tires at specified intervals. Keeping up with these tasks can significantly extend the life of your automobile and improve its performance on the road.

Remember: Preventive measures can help avoid unexpected breakdowns and ensure a smooth driving experience. Prioritizing maintenance is an investment in the future of your vehicle.

|