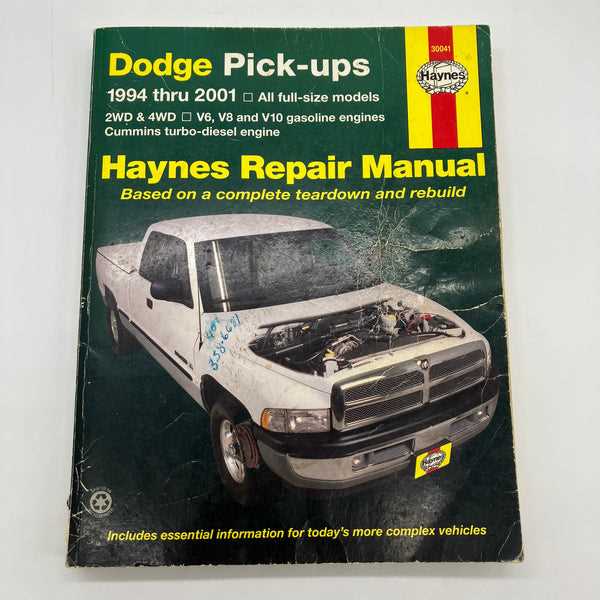

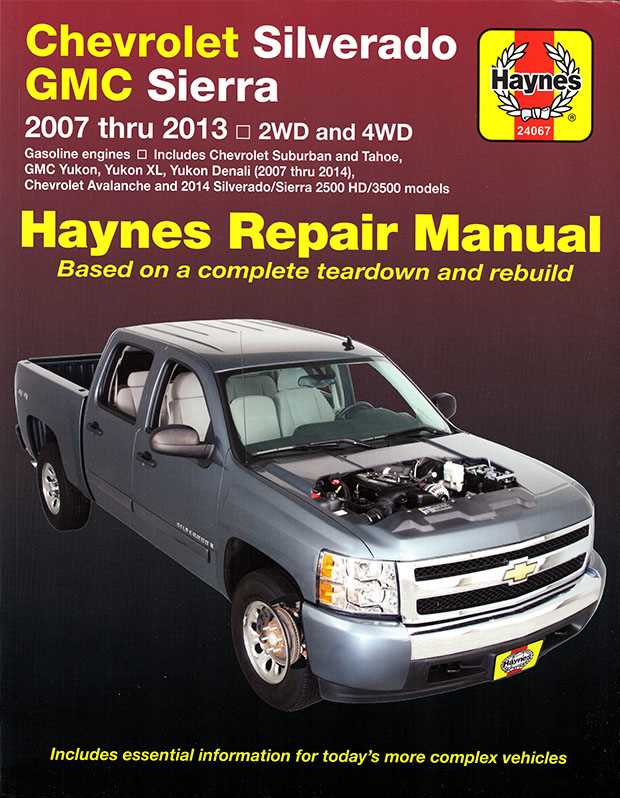

2001 Chevy Silverado 1500 Repair Guide

Maintaining a vehicle is essential for ensuring its longevity and optimal performance. This section offers valuable insights and instructions that can assist owners in navigating common issues and routine upkeep. A thorough understanding of the system components and their functions is crucial for effective troubleshooting and enhancement of vehicle efficiency.

Accessing detailed information regarding specific models can greatly facilitate the maintenance process. Comprehensive guidelines and step-by-step procedures enable individuals to tackle various challenges confidently. Whether addressing mechanical issues or performing regular checks, being well-informed can lead to better decision-making and prevent costly repairs.

Furthermore, familiarity with recommended practices and potential pitfalls can empower owners to take a proactive approach. Knowledge of the vehicle’s intricacies not only promotes safety but also enhances the overall driving experience. Embracing these principles will undoubtedly lead to a more reliable and enjoyable ride.

2001 Chevy Silverado 1500 Repair Manual

This section provides essential guidance for the maintenance and troubleshooting of a popular pickup truck model. Understanding the key components and systems is crucial for effective handling and ensuring longevity. A comprehensive resource can facilitate both novice and experienced users in addressing common issues and performing necessary upkeep.

Overview of Key Systems

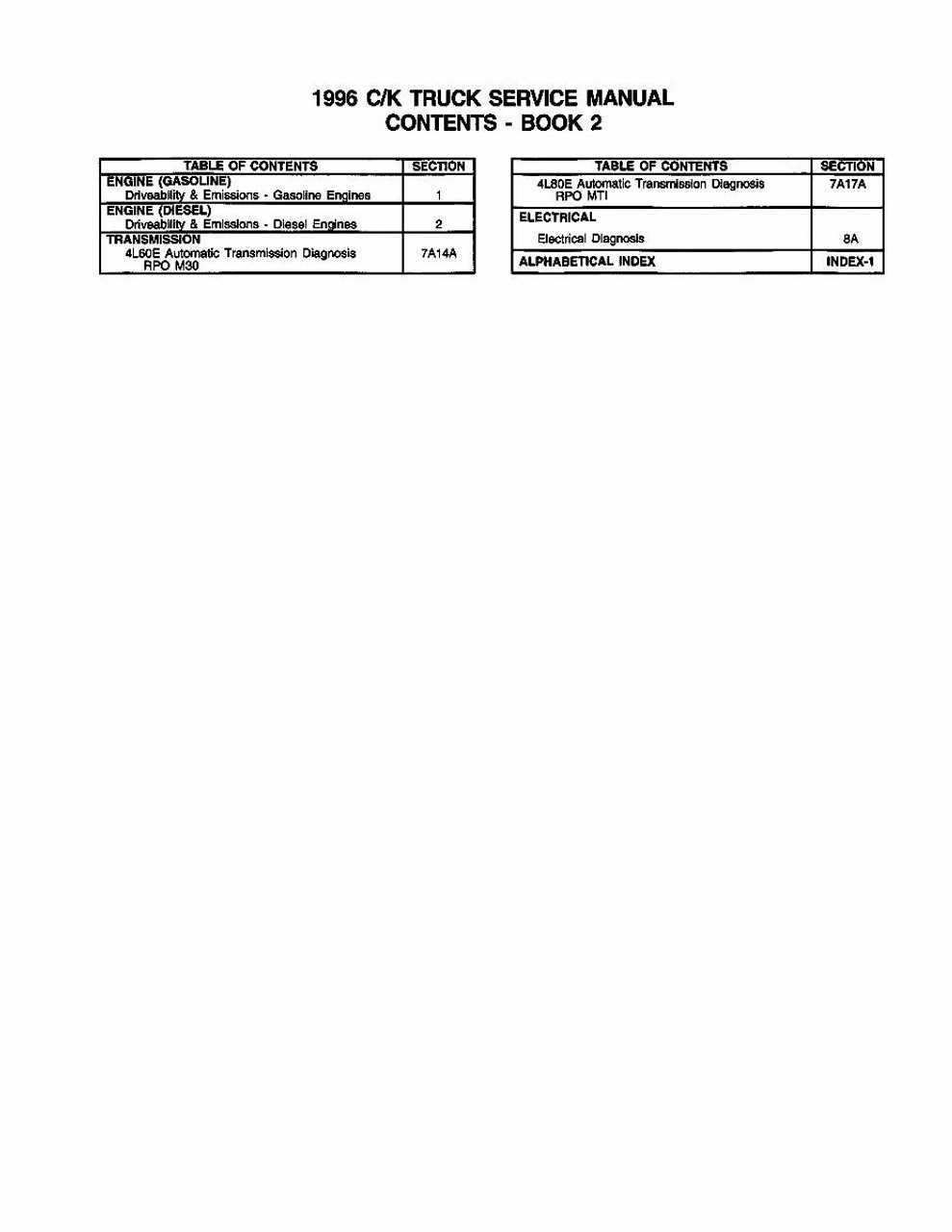

Familiarity with the major systems, such as the engine, transmission, and electrical components, allows for more informed decisions regarding repairs and upgrades. Knowing the specifications and functions of each part can streamline the process and reduce the likelihood of errors.

Troubleshooting Common Problems

Identifying frequent complications is essential for prompt resolution. Common issues may include performance inconsistencies, electrical failures, and wear-related concerns. A systematic approach to diagnostics can help pinpoint the source of a problem effectively.

Maintenance Best Practices

Regular maintenance is vital for optimal performance and reliability. Adhering to a schedule for oil changes, fluid checks, and part replacements can prevent larger issues from developing. Investing time in routine inspections contributes to the vehicle’s overall health and functionality.

Essential Tools for Repairs

When undertaking maintenance or troubleshooting tasks, having the right instruments at your disposal is crucial. A well-equipped toolkit can significantly enhance efficiency and effectiveness, allowing for smoother processes and better outcomes.

Basic Hand Tools

Fundamental hand tools are the backbone of any mechanical work. These instruments should be readily available:

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Hammers (claw and rubber mallet)

Diagnostic Equipment

In addition to hand tools, diagnostic instruments help identify issues effectively:

- Multimeter for electrical measurements

- OBD-II scanner for troubleshooting error codes

- Pressure gauge for checking fluid systems

- Torque wrench for precise tightening

Common Issues and Fixes

This section addresses typical challenges encountered with this vehicle model, providing insights into effective solutions. Understanding these common problems can help owners maintain performance and enhance reliability.

One frequent issue involves electrical system malfunctions, often leading to difficulties in starting or erratic behavior of dashboard indicators. Regular inspections and prompt replacement of faulty components can mitigate these concerns.

Another prevalent problem is related to the suspension, which may exhibit unusual noises or a rough ride. Checking for worn-out bushings or shocks and addressing them promptly can significantly improve driving comfort.

Finally, engine performance can sometimes falter due to fuel delivery issues. Ensuring the fuel system is clean and functional will help maintain optimal efficiency and responsiveness.

Understanding Vehicle Components

A thorough comprehension of the various elements that make up a motor vehicle is essential for effective maintenance and troubleshooting. Each part plays a specific role, contributing to the overall performance and safety of the automobile.

The main components can be categorized into several key groups:

- Engine: The powerhouse that generates the necessary energy for movement.

- Transmission: Transfers power from the engine to the wheels, affecting speed and torque.

- Braking System: Ensures safe stopping by controlling the vehicle’s speed.

- Suspension: Provides stability and comfort by absorbing shocks from the road.

- Electrical System: Powers various features and controls within the vehicle.

Understanding these components allows for better diagnostics and enhances the ability to perform maintenance tasks. Familiarity with each part’s function will enable owners to identify issues and make informed decisions regarding repairs.

Maintenance Schedules and Tips

Regular upkeep is essential for the longevity and performance of your vehicle. Adhering to a well-structured maintenance plan can prevent potential issues and enhance driving safety. Here are key practices to consider for optimal care.

Recommended Maintenance Intervals

- Engine oil and filter change: every 3,000 to 5,000 miles

- Air filter replacement: every 15,000 to 30,000 miles

- Brake inspection: at least once a year

- Tire rotation: every 5,000 to 7,500 miles

- Fluid checks (coolant, transmission, brake): every 30,000 miles

Maintenance Tips for Longevity

- Keep tires properly inflated for better fuel efficiency and handling.

- Wash and wax the exterior regularly to protect the paint and finish.

- Address warning lights immediately to prevent further damage.

- Use high-quality parts and fluids during replacements to ensure reliability.

- Consult a professional for any unfamiliar repairs or diagnostics.

Safety Precautions During Repairs

Ensuring safety during vehicle maintenance is crucial for both the technician and the surroundings. Implementing appropriate measures can prevent accidents and injuries, allowing for a smooth and effective process. A careful approach to tools, components, and the working environment significantly contributes to overall safety.

First, always wear suitable personal protective equipment, including gloves, goggles, and sturdy footwear. This gear safeguards against potential hazards such as sharp edges, hot surfaces, and harmful substances. Additionally, ensure that the workspace is well-ventilated to minimize exposure to toxic fumes and dust.

Before starting any task, make sure to disconnect the battery to avoid electrical shocks or short circuits. Secure the vehicle properly using jack stands to prevent it from rolling or collapsing while working underneath. Following these precautions not only protects individuals but also enhances the efficiency of the task at hand.

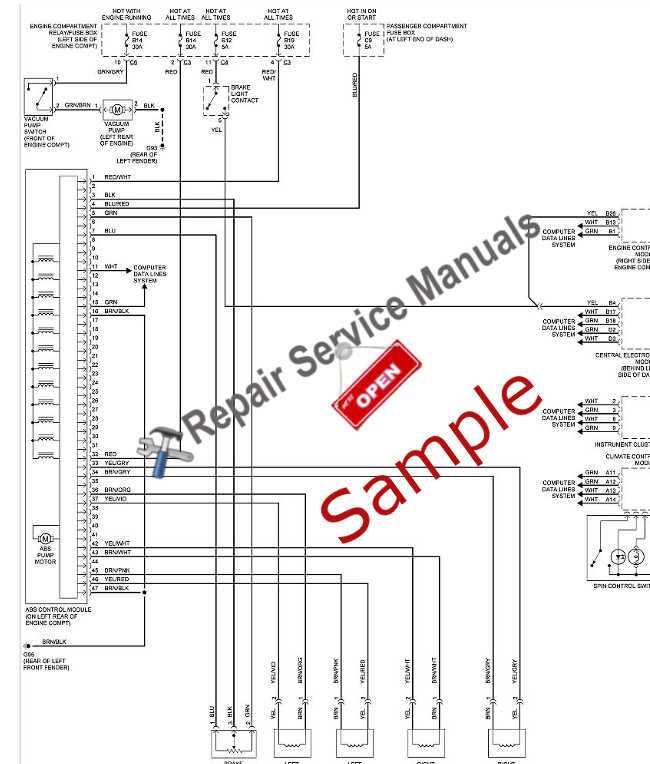

Electrical System Troubleshooting Guide

This section aims to assist in diagnosing and resolving issues related to the electrical framework of a vehicle. Understanding the intricacies of the electrical components can help identify common problems and streamline the repair process.

Identify Symptoms: Begin by observing any unusual behaviors, such as flickering lights, non-functioning accessories, or starting difficulties. Documenting these symptoms will provide valuable information during troubleshooting.

Check Connections: Inspect all wiring and connectors for signs of corrosion or damage. Ensuring that connections are secure and free from debris is essential for optimal performance.

Utilize Testing Tools: Employ a multimeter to measure voltage levels and continuity in the circuit. This can help pinpoint faulty components, such as relays, fuses, or switches.

Consult Wiring Diagrams: Reference electrical schematics to understand the layout of the system. This will aid in tracing circuits and identifying the source of issues effectively.

Seek Professional Assistance: If problems persist despite thorough investigation, consider consulting a certified technician. Their expertise can provide additional insights and solutions.

Engine Performance Enhancements

Improving the efficiency and power of a vehicle’s engine involves a variety of modifications and upgrades that can significantly boost performance. These enhancements not only increase horsepower but also improve throttle response and overall drivability. Various approaches can be employed, ranging from simple adjustments to comprehensive upgrades.

Common Modification Techniques

Several popular techniques can enhance engine output. These include upgrading the air intake system to allow for better airflow, installing a high-performance exhaust system to reduce back pressure, and reprogramming the engine control unit (ECU) for optimized fuel delivery. Each of these modifications contributes to a more powerful engine and can be tailored to suit specific performance goals.

Benefits of Performance Enhancements

Incorporating performance enhancements leads to noticeable improvements in driving experience. Enhanced acceleration, improved fuel efficiency, and greater torque are just a few advantages. Moreover, investing in such upgrades can increase the vehicle’s overall value and longevity, making it a worthwhile consideration for any enthusiast.

Transmission Service and Maintenance

Ensuring the longevity and optimal performance of a vehicle’s transmission system requires regular upkeep and attention. Proper servicing not only enhances driving experience but also prevents costly repairs down the line. Understanding the essential maintenance tasks can help vehicle owners extend the lifespan of this critical component.

Routine maintenance should include checking fluid levels, inspecting for leaks, and replacing filters as needed. A well-maintained transmission system operates smoothly, contributing to overall vehicle efficiency.

| Service Task | Frequency | Notes |

|---|---|---|

| Check fluid level | Every 30,000 miles | Use manufacturer-recommended fluid. |

| Change transmission fluid | Every 50,000 miles | Flush system for best results. |

| Inspect for leaks | Monthly | Look for signs of fluid under the vehicle. |

| Replace transmission filter | Every 50,000 miles | Essential for clean fluid circulation. |

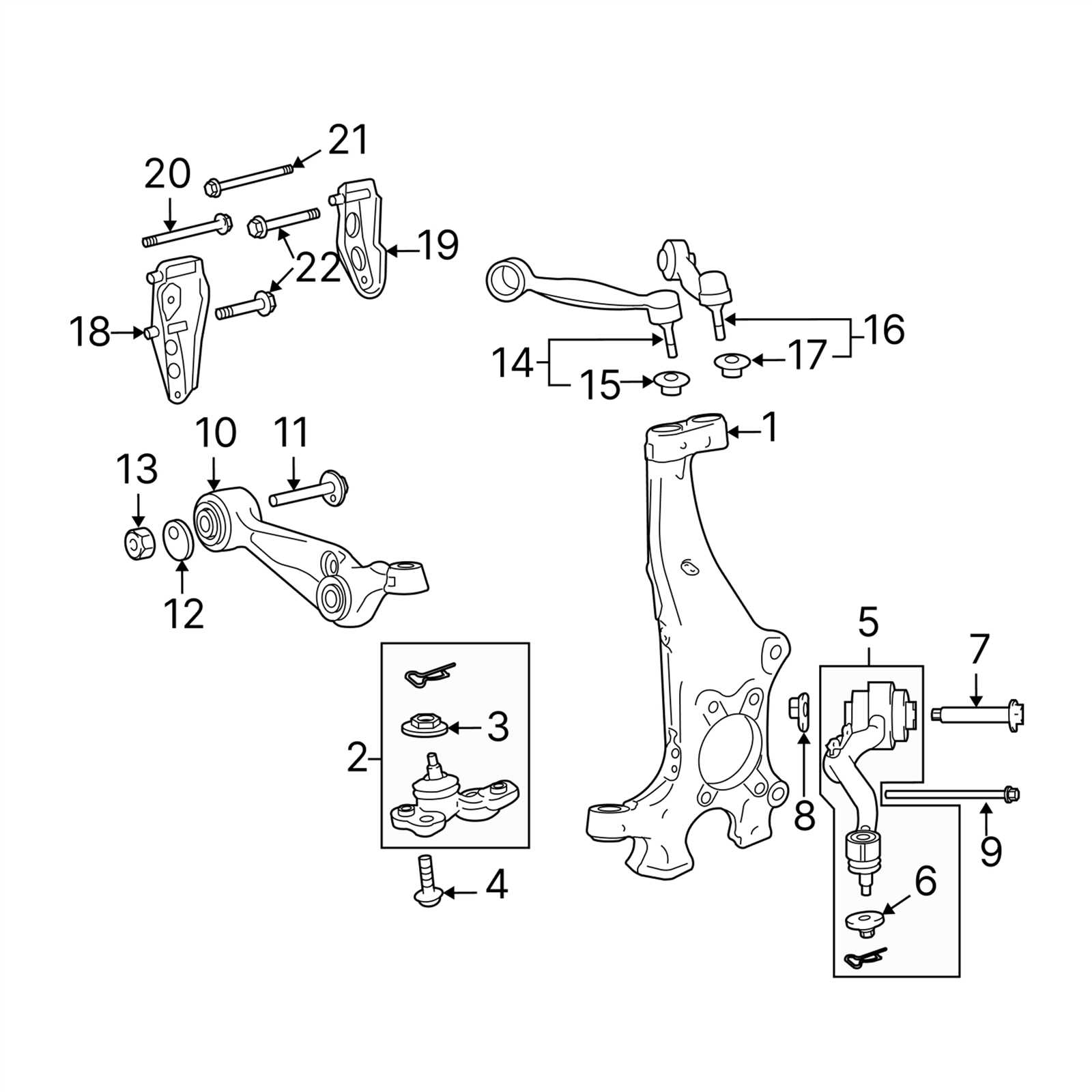

Suspension and Steering Adjustments

Proper alignment and adjustment of the suspension and steering systems are crucial for maintaining vehicle performance and safety. These elements play a significant role in how the vehicle handles, ensuring stability and comfort during operation. Regular checks and modifications can prevent uneven tire wear and enhance driving dynamics.

Importance of Suspension Adjustments

Suspension modifications can significantly affect ride quality and handling. Consider the following key points:

- Improved stability on uneven surfaces

- Enhanced load distribution for better handling

- Increased comfort for passengers

Steering System Calibration

Accurate steering calibration is essential for precise vehicle control. The following adjustments should be monitored:

- Alignment settings to ensure straight tracking

- Steering fluid levels for responsive handling

- Inspection of tie rods and joints for wear

Regular maintenance and adjustment of these systems will contribute to optimal vehicle performance and longevity.

Brake System Diagnostics

Effective evaluation of the stopping mechanism is crucial for vehicle safety and performance. This section outlines the key steps to identify and resolve common issues related to the braking system, ensuring optimal functionality and reliability.

Common Symptoms of Brake Issues

- Unusual noises during braking, such as squeaking or grinding

- Soft or spongy brake pedal feel

- Vibration or pulsation when applying brakes

- Warning lights on the dashboard

- Uneven wear on brake pads

Diagnostic Steps

- Inspect the brake fluid level and condition.

- Examine the brake pads and rotors for wear and damage.

- Check for leaks in the brake lines and connections.

- Test the functionality of the anti-lock braking system (ABS).

- Evaluate the brake master cylinder for proper operation.

By following these diagnostic steps, vehicle owners can effectively troubleshoot brake-related problems and ensure a safe driving experience.

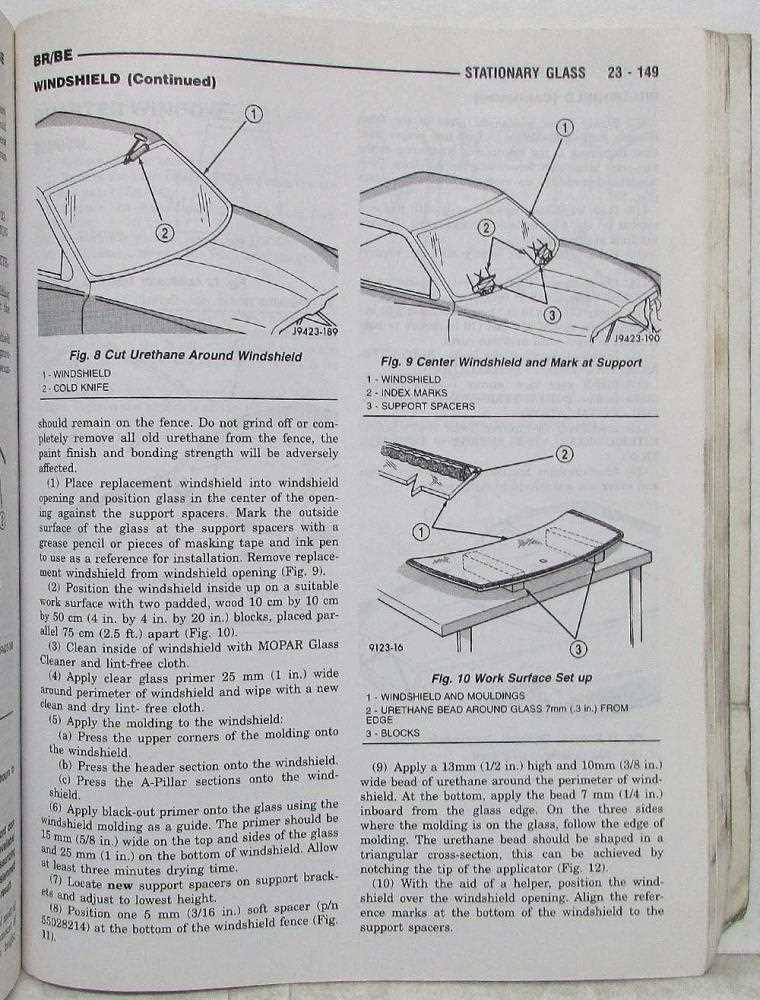

Body and Interior Repair Techniques

Maintaining the aesthetics and functionality of a vehicle’s exterior and interior is essential for both appearance and safety. This section covers various methods and approaches to effectively address common issues that may arise in these areas. Whether dealing with minor dents, upholstery damage, or structural concerns, understanding the techniques can significantly enhance the overall condition of the vehicle.

Assessing Damage: The first step in any restoration process is a thorough evaluation. Inspecting for scratches, dents, or interior wear can help identify the necessary interventions. Utilizing appropriate tools for measuring and assessing damage will ensure accurate repairs.

Surface Preparation: Proper preparation of surfaces is crucial before applying any finishes or repairs. Cleaning, sanding, and priming surfaces will create an ideal base for paint or adhesive applications, ensuring longevity and durability. Attention to detail during this phase can prevent future complications.

Upholstery Care: Maintaining the interior involves regular cleaning and potential reupholstering. Using suitable cleaning products tailored for various materials can preserve the integrity and appearance of seats and panels. In cases of severe damage, replacement of upholstery may be necessary to restore comfort and aesthetics.

By employing these techniques, vehicle owners can maintain the condition of both the body and interior, contributing to the longevity and value of their vehicle.