Comprehensive Guide to Repairing the 2001 Chevy Silverado 2500HD

Owning a robust vehicle designed for heavy tasks requires an understanding of its intricate systems and components. Proper upkeep is essential to ensure optimal performance and longevity. This guide aims to provide essential insights and information for enthusiasts and owners alike, facilitating informed decisions about their vehicle’s care and service.

Through detailed explanations and step-by-step procedures, readers will gain valuable knowledge on troubleshooting common issues and executing necessary maintenance tasks. The focus will be on empowering vehicle owners to take charge of their maintenance practices, ultimately leading to improved reliability and safety.

Whether dealing with mechanical challenges or routine checks, a well-organized reference can be a game-changer. This resource serves as a foundation for those who wish to delve deeper into their vehicle’s mechanics and enhance their maintenance skills.

2001 Chevy Silverado 2500HD Overview

This section provides a comprehensive insight into a robust vehicle designed for heavy-duty performance. Known for its strength and reliability, this model has become a staple for those requiring a dependable workhorse.

The vehicle is characterized by:

- Sturdy construction, enabling it to handle demanding tasks with ease.

- A powerful engine that delivers impressive torque and towing capabilities.

- A spacious interior, designed for comfort during long journeys.

- Advanced safety features, ensuring peace of mind for both drivers and passengers.

Overall, this vehicle stands out in its class, making it an excellent choice for both work and recreation.

Common Issues and Solutions

When dealing with heavy-duty trucks, owners often encounter a range of typical problems that can affect performance and reliability. Understanding these challenges can help in maintaining optimal function and extending the vehicle’s lifespan. Here are some frequent concerns along with effective solutions.

Engine Performance Issues: One of the most common complaints relates to the engine’s performance, including rough idling and decreased power. Regular maintenance, such as changing the air filter and ensuring proper fuel quality, can often resolve these issues. If the problem persists, checking the fuel injectors and spark plugs may be necessary.

Transmission Problems: Difficulties in shifting gears or slipping can indicate transmission issues. Ensuring that the transmission fluid is at the correct level and in good condition is crucial. If low fluid levels are not the cause, a professional inspection may be required to assess for potential internal damage.

Electrical System Failures: Electrical components can sometimes malfunction, leading to issues like battery drain or faulty lights. Inspecting wiring for corrosion and ensuring connections are secure can mitigate these problems. In some cases, replacing worn-out batteries or faulty alternators may be necessary.

Suspension and Steering Concerns: A bumpy ride or difficulty steering often points to suspension or steering system problems. Regularly inspecting components like shock absorbers and control arms can help identify wear and tear. Replacing these parts as needed can greatly improve driving comfort and safety.

Addressing these common issues promptly not only enhances performance but also prevents more significant complications in the future. Regular inspections and maintenance are key to keeping a heavy-duty truck in excellent condition.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of a heavy-duty vehicle involves regular upkeep and attention to detail. Implementing effective maintenance strategies not only extends the lifespan of the vehicle but also enhances its overall reliability and safety on the road.

- Regular Fluid Checks: Monitor and maintain all essential fluids, including engine oil, coolant, brake fluid, and transmission fluid. Regular changes and top-ups are crucial for preventing overheating and mechanical failures.

- Tire Maintenance: Ensure proper tire pressure and alignment. Rotate tires regularly and inspect them for signs of wear to maintain traction and fuel efficiency.

- Brake System Inspection: Periodically check the brake pads, rotors, and fluid levels. Timely replacements and repairs are vital for safe stopping power.

- Battery Care: Inspect the battery for corrosion and ensure connections are tight. Regularly check its charge to avoid unexpected failures.

- Filter Replacements: Change air and fuel filters at recommended intervals to ensure optimal engine performance and fuel efficiency.

Incorporating these practices into a regular maintenance routine can significantly improve the vehicle’s reliability and longevity, ultimately leading to a more enjoyable driving experience.

Understanding the Repair Manual Structure

The layout of a maintenance guide is essential for effectively navigating the content and accessing the necessary information. Each section is designed to facilitate the user’s experience, ensuring that vital details are easy to locate. This structured approach aids both novices and experienced individuals in addressing various tasks related to vehicle upkeep and troubleshooting.

Typically, these guides are organized into several key components:

| Section | Description |

|---|---|

| Introduction | An overview of the vehicle, highlighting its features and specifications. |

| Tools and Equipment | A list of necessary tools and equipment required for maintenance tasks. |

| Maintenance Schedules | Detailed timelines for routine inspections and services to ensure optimal performance. |

| Troubleshooting | Guidelines for diagnosing common issues and finding solutions. |

| Specifications | Technical data regarding engine performance, fluid capacities, and other critical parameters. |

This organized format promotes efficiency and enhances understanding, enabling users to tackle a wide range of service tasks with confidence.

Essential Tools for Repairs

Having the right equipment is crucial when it comes to maintaining and servicing your vehicle. A well-equipped workspace can significantly enhance efficiency and ensure that tasks are completed safely and effectively. Below are some fundamental instruments that every automotive enthusiast should consider for their toolkit.

Basic Hand Tools

Hand tools form the backbone of any repair endeavor. These instruments are essential for various tasks, from minor adjustments to more extensive projects. A comprehensive selection typically includes:

| Tool | Purpose |

|---|---|

| Wrenches | Loosening or tightening nuts and bolts. |

| Screwdrivers | Fastening or removing screws in various sizes. |

| Pliers | Gripping, bending, or cutting wire and other materials. |

Power Tools

In addition to hand tools, power tools can greatly enhance productivity and reduce manual effort. They are particularly useful for repetitive tasks and heavier components. Key power tools include:

| Tool | Purpose |

|---|---|

| Impact Wrench | Applying high torque for loosening stubborn fasteners. |

| Drill | Creating holes and fastening components efficiently. |

| Angle Grinder | Cutting, grinding, and polishing various materials. |

Engine Specifications and Troubleshooting

This section delves into the vital aspects of engine performance, detailing the specifications necessary for optimal functioning. Understanding these details is crucial for effective diagnostics and ensuring that the powertrain operates smoothly.

The following table outlines essential engine specifications, providing a quick reference for various components and their measurements.

| Component | Specification |

|---|---|

| Engine Type | V8 |

| Displacement | 6.0 L |

| Horsepower | 300 hp |

| Torque | 360 lb-ft |

| Compression Ratio | 9.4:1 |

Regular assessments and familiarity with the engine’s specifications can significantly aid in identifying common issues. Common troubleshooting methods include checking fluid levels, inspecting for leaks, and evaluating performance metrics to pinpoint potential problems.

Transmission System Insights

The transmission system plays a vital role in the overall performance of heavy-duty vehicles. It facilitates the transfer of power from the engine to the wheels, enabling the vehicle to move efficiently across various terrains. Understanding the intricacies of this system is essential for ensuring optimal operation and longevity.

Modern transmission systems often employ advanced technologies that enhance functionality and reliability. These include automatic gear shifting, which allows for smoother transitions between gears, and electronic controls that improve response times. Proper maintenance of these systems is crucial, as neglect can lead to issues such as slipping gears or difficulty in shifting, ultimately affecting driving experience.

Regular inspections and timely interventions can prevent common problems associated with the transmission. Monitoring fluid levels, checking for leaks, and addressing any unusual noises can help maintain the system’s health. Additionally, utilizing quality lubricants tailored to the vehicle’s specifications can enhance performance and reduce wear.

In summary, a well-maintained transmission system not only ensures the vehicle operates smoothly but also contributes to safety and efficiency. Awareness of its components and functions empowers vehicle owners to take proactive measures, ensuring their heavy-duty trucks remain in peak condition.

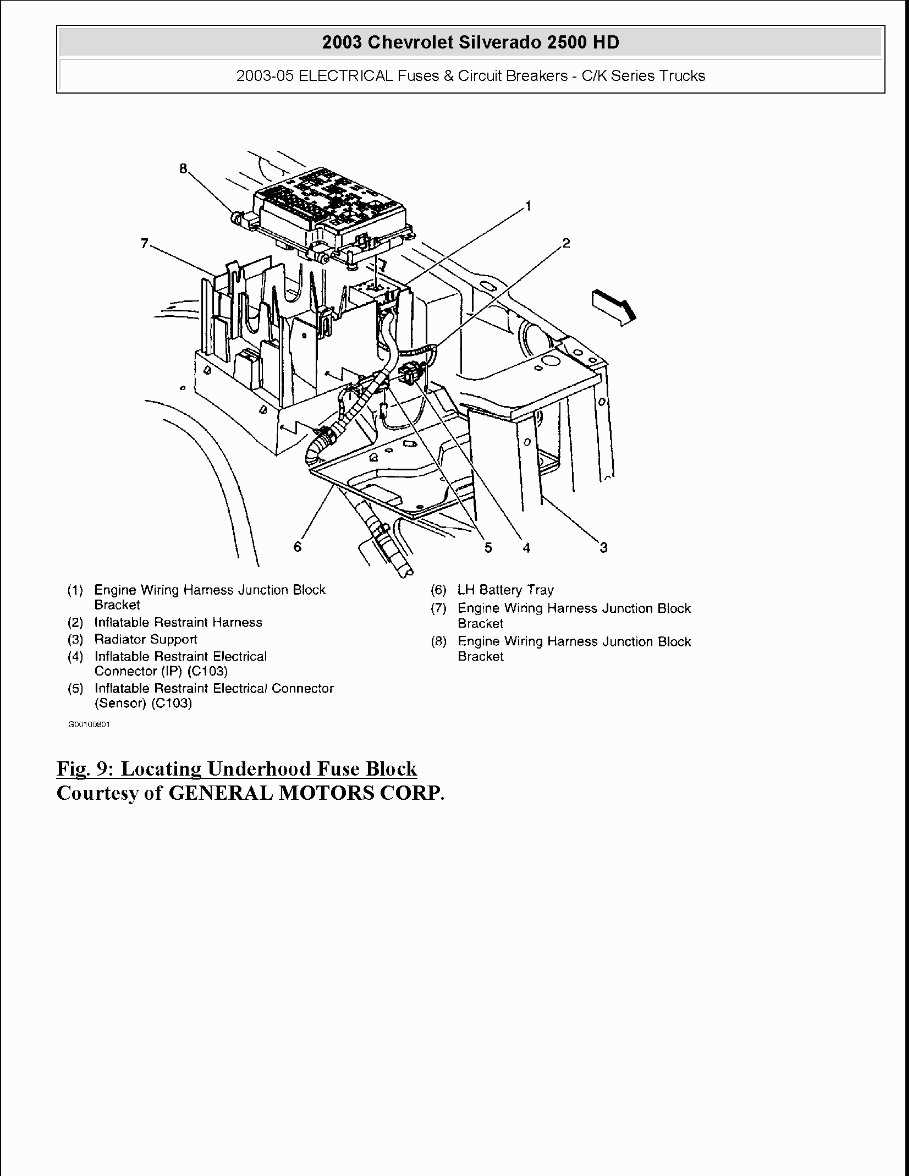

Electrical System Diagnostics

Diagnosing the electrical system of a heavy-duty vehicle requires a systematic approach to identify issues affecting performance and reliability. Understanding the various components and their functions is essential for effective troubleshooting. A thorough examination can help pinpoint malfunctions and ensure the vehicle operates efficiently.

Common Electrical Components

- Batteries

- Alternators

- Starter Motors

- Wiring Harnesses

- Fuses and Relays

Diagnostic Steps

- Inspect the battery for corrosion and secure connections.

- Test the alternator output using a multimeter.

- Examine starter motor functionality and connections.

- Check the integrity of wiring harnesses for any signs of damage.

- Verify that fuses and relays are functioning properly.

By following these steps, one can efficiently diagnose and address electrical issues, leading to improved vehicle performance and longevity.

Bodywork and Frame Repairs

This section provides essential guidance on restoring the exterior and structural components of heavy-duty vehicles. Proper attention to these areas ensures longevity and safety, enhancing both aesthetics and functionality. Whether addressing minor dents or significant frame damage, understanding the fundamental processes involved is crucial for effective outcomes.

Common Issues and Solutions

Various problems can arise related to body and frame integrity, often caused by wear and tear, accidents, or environmental factors. Below are some typical issues along with recommended approaches for resolution:

| Issue | Recommended Action |

|---|---|

| Dents and Scratches | Utilize body filler and sanding techniques to smooth the surface, followed by repainting to match the original color. |

| Rust Damage | Remove affected areas, treat with anti-corrosive solutions, and apply protective coatings to prevent further deterioration. |

| Frame Misalignment | Employ alignment equipment to restore proper geometry, ensuring all components fit correctly and safely. |

Tools and Materials Needed

For effective bodywork and frame repairs, having the right tools and materials is essential. Here is a list of commonly used items:

- Wrenches and Socket Sets

- Body Hammers and Dollies

- Sanders and Polishers

- Welding Equipment

- Protective Coatings and Paints

Suspension and Steering Adjustments

The suspension and steering systems are crucial for vehicle stability and handling. Proper adjustments in these systems can enhance driving comfort and improve overall performance. Ensuring these components are finely tuned is essential for a smooth ride and effective maneuverability.

Importance of Proper Alignment

Alignment affects tire wear and steering response. Regular checks are necessary to maintain optimal angles and settings. Here are some key points to consider:

- Misalignment can lead to uneven tire wear.

- Correct alignment improves fuel efficiency.

- Proper settings enhance overall safety and handling.

Suspension System Adjustments

Adjusting the suspension system involves checking various components to ensure they function correctly. Consider the following aspects:

- Shocks and Struts: Inspect for leaks and wear, replacing them as needed.

- Spring Tension: Adjust the spring tension to maintain desired ride height and load capacity.

- Bushings and Joints: Regularly check for wear and replace them to prevent noise and improve handling.

Routine maintenance and adjustments in these areas will significantly enhance the driving experience and prolong the life of your vehicle’s components.

Brake System Maintenance Procedures

Proper upkeep of the braking system is essential for ensuring the safety and performance of any vehicle. Regular checks and maintenance of components such as pads, rotors, and fluid levels contribute to optimal functionality. This section outlines key procedures for maintaining the braking system, promoting longevity and reliability.

Key maintenance tasks include inspecting brake pads for wear, checking fluid levels, and ensuring that all components are free from corrosion or damage. Following a systematic approach can help identify issues before they become serious problems.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Inspect Brake Pads | Every 10,000 miles | Check for thickness and wear indicators; replace if necessary. |

| Check Brake Fluid | Monthly | Ensure fluid is at the recommended level; top up if needed. |

| Examine Brake Lines | Every 20,000 miles | Look for leaks, cracks, or corrosion in the lines and fittings. |

| Test Brake Performance | Annually | Assess responsiveness and noise; seek professional help if issues arise. |

Implementing these procedures will help maintain a reliable braking system, ensuring the vehicle remains safe and effective in various driving conditions.

Heating and Air Conditioning Repairs

Ensuring a comfortable driving experience involves maintaining the heating and cooling systems in your vehicle. These systems are crucial for regulating the interior temperature and ensuring proper air circulation. When issues arise, it’s essential to address them promptly to avoid discomfort and potential damage to other components.

Common problems may include insufficient heating or cooling, strange noises, or unpleasant odors. Regular inspections can help identify wear and tear on various parts, leading to more efficient operation and enhanced comfort.

| Common Issues | Possible Causes | Recommended Actions |

|---|---|---|

| Poor heating performance | Low coolant levels, faulty thermostat | Check coolant levels, replace thermostat |

| Insufficient cooling | Low refrigerant, blocked condenser | Recharge refrigerant, clean condenser |

| Strange noises from vents | Loose components, debris in system | Inspect components, remove debris |

| Unpleasant odors | Mold growth, dirty filters | Clean or replace filters, disinfect system |

By addressing these concerns proactively, you can maintain a pleasant environment within your vehicle. Regular maintenance not only improves comfort but can also extend the lifespan of your heating and air conditioning systems.

Aftermarket Modifications and Upgrades

Enhancing the performance and appearance of your vehicle can be an exciting venture for enthusiasts and everyday drivers alike. Various enhancements are available to improve efficiency, handling, and aesthetics, allowing owners to tailor their vehicles to suit personal preferences and needs. These modifications range from simple cosmetic changes to comprehensive performance upgrades.

One popular avenue for customization involves upgrading the suspension system. This can improve ride quality, increase ground clearance, and enhance off-road capabilities. Additionally, investing in high-performance exhaust systems can not only improve engine efficiency but also produce a more aggressive sound that appeals to many drivers.

Another significant area for enhancement is the vehicle’s electronic systems. Upgrading the audio system, integrating modern navigation, or installing advanced driver-assistance features can greatly enhance the driving experience. Furthermore, many owners choose to customize their vehicle’s exterior with aftermarket wheels, body kits, or custom paint jobs, which can significantly impact the overall look and style.

While aftermarket modifications can provide numerous benefits, it’s crucial to ensure that any upgrades are compatible with the vehicle’s existing systems. Consulting with professionals and researching product specifications can help avoid potential issues and ensure a seamless integration of new components.