Comprehensive Guide to 2002 Chevy Malibu Repair

Understanding the intricacies of automotive care is essential for any car owner. This section delves into the various aspects of vehicle upkeep, ensuring your automobile operates smoothly and efficiently. By following well-structured guidelines, you can extend the lifespan of your vehicle and enhance its overall performance.

From troubleshooting common issues to performing routine inspections, having access to detailed instructions is invaluable. This resource empowers you to take charge of your automobile’s health, enabling you to tackle challenges with confidence. Whether you’re a seasoned mechanic or a novice enthusiast, the insights provided here will aid in fostering a deeper connection with your vehicle.

Additionally, knowing the essential components and their functions helps in making informed decisions during maintenance tasks. As you embark on this journey of discovery, you’ll gain a clearer understanding of how to keep your vehicle in prime condition, ensuring a safer and more enjoyable driving experience.

Overview of the 2002 Chevy Malibu

This section provides an in-depth look at a mid-size sedan known for its reliability and comfort. Designed to cater to everyday drivers, this vehicle combines practicality with a sleek aesthetic, making it a popular choice among families and commuters alike.

Key Features

Equipped with a range of features, this model offers an inviting interior and a selection of engine options. The spacious cabin is complemented by user-friendly technology, ensuring both convenience and enjoyment during journeys. Safety is also a priority, with several systems designed to protect occupants.

Performance and Efficiency

The driving experience is characterized by a smooth ride and responsive handling. With a focus on fuel efficiency, this model stands out in its class, providing a balance between power and economical operation. Whether navigating city streets or cruising on highways, it delivers a dependable performance that meets the needs of diverse drivers.

Common Issues and Troubleshooting Tips

This section provides insights into frequent challenges encountered by vehicle owners, along with practical advice for resolution. Understanding these typical problems can save time and enhance overall performance.

Frequent Challenges

- Engine performance fluctuations

- Electrical system malfunctions

- Brake responsiveness issues

- Suspension irregularities

- Overheating concerns

Troubleshooting Strategies

- Conduct regular inspections of fluid levels.

- Examine the battery connections and charge state.

- Listen for unusual sounds from the engine compartment.

- Check tire pressure and tread condition.

- Investigate warning lights on the dashboard.

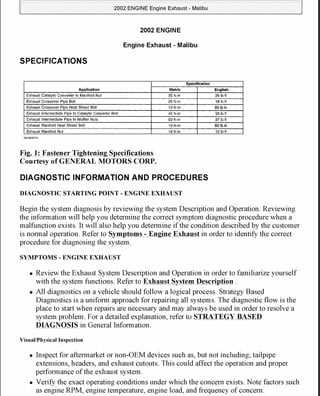

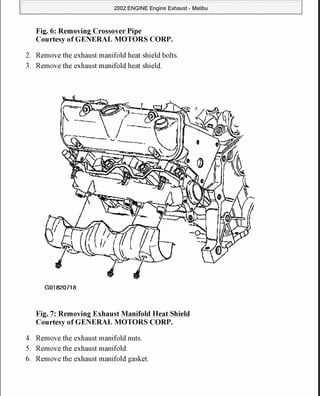

Engine Maintenance and Repairs

Proper upkeep of the engine is vital for ensuring optimal performance and longevity. Regular attention to various components not only enhances efficiency but also helps prevent costly breakdowns. This section outlines essential practices for maintaining and addressing common issues related to the engine.

Key aspects to focus on include:

- Regular oil changes to ensure smooth operation and prevent wear.

- Checking and replacing air filters to maintain airflow and improve fuel efficiency.

- Inspecting belts and hoses for signs of wear or damage.

- Monitoring coolant levels to prevent overheating.

- Keeping the ignition system in top shape for reliable starting and performance.

When faced with engine troubles, consider the following troubleshooting steps:

- Check for warning lights on the dashboard and refer to the corresponding signals.

- Inspect for unusual noises or vibrations during operation.

- Look for leaks around seals, gaskets, and hoses.

- Conduct a visual inspection of the engine bay for any obvious issues.

By adhering to these maintenance practices and being proactive in addressing concerns, the engine can remain in peak condition, contributing to the overall reliability and performance of the vehicle.

Transmission Problems and Solutions

Addressing issues related to vehicle gear systems is crucial for ensuring optimal performance and longevity. Common symptoms of transmission difficulties can include slipping gears, delayed engagement, and unusual noises. Understanding these problems can help owners take timely action and avoid more significant complications.

Common Issues

- Slipping Gears: This may manifest as the engine revving without a corresponding increase in speed.

- Delayed Engagement: A noticeable lag when shifting from park to drive or reverse can indicate underlying problems.

- Noisy Operation: Grinding or whining sounds while the vehicle is in gear are red flags.

Possible Solutions

- Check and Replace Fluid: Low or contaminated fluid levels can cause many transmission issues. Regular maintenance can help prevent this.

- Inspect for Leaks: Look for signs of fluid leakage under the vehicle, which can lead to insufficient lubrication.

- Examine Electrical Components: Faulty sensors or wiring can disrupt the transmission’s operation, requiring diagnostic testing.

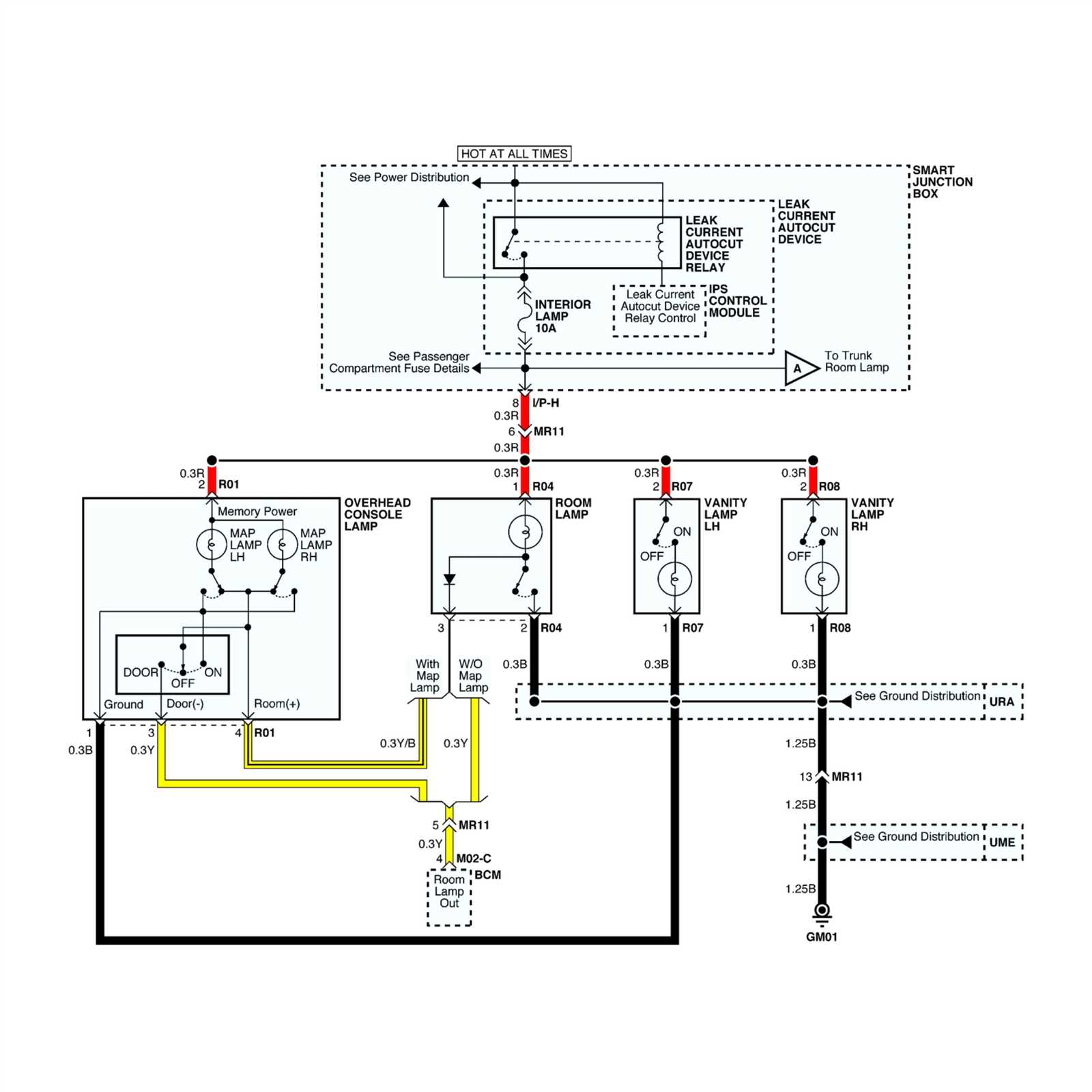

Electrical System Diagnostics

Diagnosing the electrical framework of a vehicle is crucial for maintaining optimal performance and ensuring safety. This process involves identifying issues within the wiring, connectors, and components that could affect the functionality of the system.

Step 1: Preliminary Checks should begin with a visual inspection of the wiring harnesses and connections. Look for signs of wear, corrosion, or loose connections that might disrupt electrical flow. Ensuring that battery terminals are clean and tightly secured is essential.

Step 2: Utilizing Diagnostic Tools allows for more precise identification of problems. A multimeter can measure voltage, resistance, and continuity, while a scan tool can retrieve error codes from the vehicle’s onboard computer. These tools help pinpoint the root of electrical issues more efficiently.

Step 3: Systematic Testing of individual components such as fuses, relays, and sensors should follow. Testing each part can reveal faulty components that may be causing malfunctions. Replacing these defective elements can restore proper function to the electrical system.

In summary, a thorough examination and methodical approach to troubleshooting the electrical system will enhance reliability and performance, ensuring a safe driving experience.

Cooling System Care and Repair

The efficient functioning of an engine relies heavily on its cooling system, which prevents overheating and maintains optimal performance. Proper maintenance is crucial to ensure longevity and reliability. This section outlines essential practices and common issues related to this vital system.

Routine Maintenance Practices

Regular inspections of hoses, clamps, and the radiator are vital for identifying wear or leaks. Flushing the coolant system periodically helps to remove debris and prevents corrosion. Checking coolant levels and quality ensures effective heat transfer and protects against freezing in colder climates.

Troubleshooting Common Issues

Signs of overheating, unusual noises, or coolant leaks can indicate serious problems. Identifying these issues early can prevent costly damage. Monitoring temperature gauges and investigating any warning lights can provide insights into potential failures, allowing for timely interventions.

Brake System Inspection and Service

The braking system is crucial for vehicle safety and performance. Regular examination and maintenance ensure that all components function optimally, preventing potential hazards on the road. This section outlines essential procedures for evaluating and servicing the braking mechanism.

Inspection Procedures

Conducting a thorough inspection involves several key steps:

- Examine brake pads for wear and damage.

- Check the condition of brake rotors, looking for signs of scoring or warping.

- Inspect brake fluid levels and quality, ensuring there are no leaks in the lines.

- Assess the overall performance of the brake pedal, checking for responsiveness.

Maintenance and Service Tips

Proper maintenance can extend the lifespan of the braking system. Consider the following suggestions:

- Replace brake pads as needed, typically every 20,000 to 50,000 miles.

- Flush and refill brake fluid every two years to prevent moisture buildup.

- Regularly clean components to remove dust and debris that can hinder performance.

- Consult a professional if any unusual sounds or sensations occur during braking.

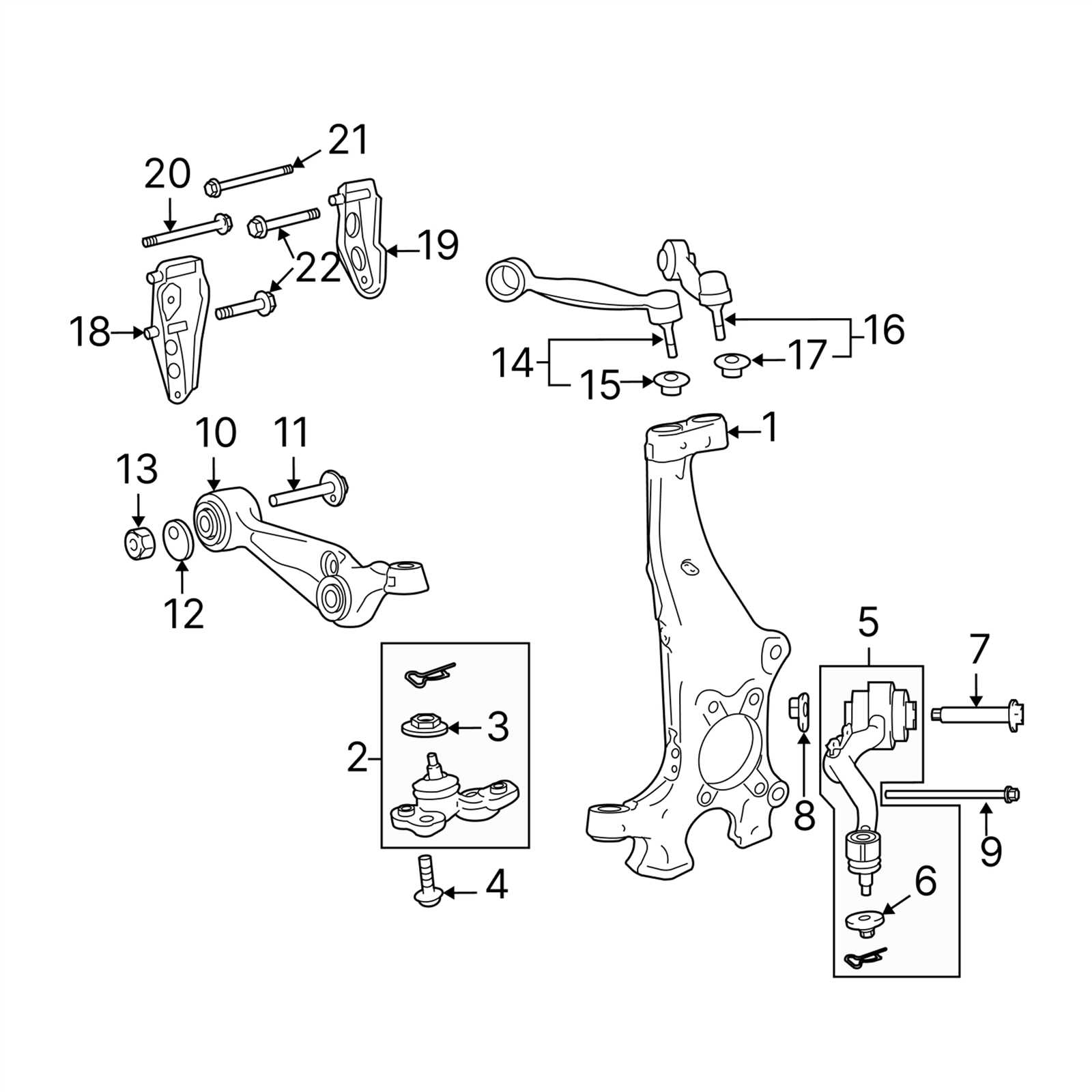

Suspension and Steering Adjustments

Proper alignment and tuning of the suspension and steering systems are crucial for ensuring optimal vehicle performance and safety. Adjustments in these areas can significantly enhance handling, ride comfort, and overall driving experience. Understanding the various components involved and the methods for their calibration allows for effective maintenance and troubleshooting.

To achieve the desired handling characteristics, it is essential to regularly check and adjust parameters such as camber, toe, and caster angles. These settings influence tire wear and steering responsiveness, directly impacting the vehicle’s stability during maneuvers. A precise alignment helps maintain straight-line tracking and minimizes unnecessary strain on suspension components.

Furthermore, the steering system must be examined for proper function and responsiveness. Adjustments to the steering gear and linkage can help eliminate play and ensure a direct connection between the driver’s input and the vehicle’s direction. Regular maintenance of these systems not only prolongs their lifespan but also contributes to a more enjoyable driving experience.

Bodywork and Interior Repairs

Maintaining the exterior and interior of a vehicle is essential for both aesthetics and functionality. Addressing issues such as dents, scratches, and upholstery damage not only enhances the overall appearance but also contributes to the longevity of the vehicle. Proper techniques and materials are crucial for achieving professional results.

When dealing with exterior imperfections, it’s important to assess the damage thoroughly. Techniques such as paintless dent removal can be effective for minor dings, while more severe damage may require panel replacement or traditional bodywork methods. Selecting the right paint and tools is vital for ensuring a seamless finish.

Interior upkeep focuses on preserving comfort and safety. Replacing worn-out seats or fixing damaged dashboard components can rejuvenate the cabin environment. Utilizing appropriate cleaning products and repair kits ensures that materials remain in good condition and function properly over time.

Routine Maintenance Schedule Recommendations

Regular upkeep is essential for the longevity and optimal performance of any vehicle. Establishing a consistent maintenance plan helps to ensure that all critical components function effectively, reducing the likelihood of unexpected breakdowns and costly repairs. This section outlines a suggested schedule for routine servicing to keep your automobile in peak condition.

| Service | Frequency | Notes |

|---|---|---|

| Oil Change | Every 5,000 miles | Use high-quality oil and filter. |

| Tire Rotation | Every 6,000 miles | Ensures even wear and extends tire life. |

| Brake Inspection | Every 12,000 miles | Check pads, rotors, and fluid levels. |

| Fluid Checks (coolant, transmission) | Every 30,000 miles | Top off or replace as necessary. |

| Battery Check | Annually | Inspect terminals and test charge. |

Tools Required for DIY Repairs

Undertaking vehicle maintenance can be a rewarding experience, allowing owners to save on costs while gaining valuable skills. To successfully complete various tasks, it’s essential to have the right set of instruments at hand. This section outlines the basic tools needed to tackle common issues, ensuring that each project runs smoothly and efficiently.

A comprehensive toolkit typically includes items such as wrenches, sockets, and screwdrivers, which are fundamental for most mechanical jobs. Additionally, having a reliable jack and jack stands is crucial for safely lifting the vehicle when accessing the undercarriage or changing tires. Pliers and wire cutters can assist in a variety of tasks, from disconnecting wires to removing stubborn clips.

For more advanced repairs, specialized tools like torque wrenches and diagnostic equipment may be necessary. These instruments help ensure that parts are secured to the correct specifications and allow for the identification of issues through onboard systems. Investing in quality tools not only enhances performance but also contributes to a safer working environment.