Comprehensive Repair Manual for the 2003 Chevy Avalanche

In the realm of automotive care, having a reliable resource at your fingertips is crucial for effective maintenance and problem-solving. This section serves as a valuable tool for enthusiasts and owners alike, aiming to enhance understanding of vehicle functionality and address common issues.

By delving into detailed procedures and insights, individuals can gain the confidence to tackle a variety of challenges. Whether it’s routine upkeep or more complex repairs, a thorough knowledge base can streamline the process and improve the longevity of the vehicle.

Equipped with step-by-step instructions and practical tips, this guide emphasizes the importance of preventative measures. A proactive approach to vehicle care not only ensures optimal performance but also fosters a deeper connection between the owner and their automobile.

2003 Chevy Avalanche Overview

This section provides a comprehensive look at a versatile and rugged vehicle designed for both utility and comfort. With a blend of robust engineering and refined features, this model is crafted to meet the needs of diverse drivers, whether for work or leisure.

Key Features

The model boasts a unique configuration that allows for impressive cargo capacity, along with an array of modern amenities. Notable attributes include a spacious interior, advanced safety systems, and the ability to adapt to various driving conditions. These elements contribute to its reputation as a reliable choice for families and adventurers alike.

Performance and Capabilities

Under the hood, this vehicle is equipped with a powerful engine that delivers a smooth driving experience. Its performance is complemented by features that enhance handling and stability, making it suitable for both on-road and off-road adventures. Overall, this model exemplifies a perfect blend of functionality and style.

Essential Maintenance Tips

Regular upkeep is crucial for ensuring the longevity and reliability of your vehicle. By adhering to a consistent maintenance schedule, you can prevent major issues and enhance overall performance. Here are some fundamental practices that every owner should consider.

Regular Fluid Checks

Monitoring fluid levels is essential for optimal functioning. This includes engine oil, coolant, brake fluid, and transmission fluid. Regular checks can help you identify leaks early and ensure your vehicle runs smoothly.

Tire Care

Proper tire maintenance contributes significantly to safety and efficiency. Ensure that tires are correctly inflated and rotated regularly to promote even wear and extend their lifespan.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000-7,500 miles |

| Brake Inspection | Every 10,000 miles |

| Tire Rotation | Every 6,000-8,000 miles |

| Air Filter Replacement | Every 15,000-30,000 miles |

Common Issues and Solutions

This section addresses frequent challenges faced by vehicle owners and offers practical solutions to enhance performance and longevity. Understanding these common problems can assist in maintaining the functionality of your automobile.

Electrical Problems

One of the typical concerns involves electrical systems, which may manifest as intermittent failures or complete malfunctions. Issues often arise from worn-out wiring or faulty connectors. To resolve these problems, inspect all electrical connections and replace any damaged components. Ensuring proper grounding and checking fuses can also prevent future disruptions.

Engine Performance

Another prevalent issue is related to engine efficiency. Symptoms such as rough idling, reduced power, or unusual noises can indicate underlying troubles. Regular maintenance, including timely oil changes and air filter replacements, can significantly enhance engine performance. Additionally, using high-quality fuel can prevent deposits from accumulating and support smoother operation.

Understanding the Electrical System

The electrical system in a vehicle plays a crucial role in ensuring all components function harmoniously. This intricate network is responsible for powering essential features, from lighting to advanced infotainment systems, and requires careful consideration during troubleshooting and maintenance.

Key Components

At the heart of the electrical system are several vital components, including the battery, alternator, and various wiring harnesses. The battery stores energy, providing the necessary power to start the engine and operate accessories when the engine is off. The alternator recharges the battery and powers electrical systems while the engine is running. Proper understanding of these elements is essential for effective diagnostics and repairs.

Troubleshooting Electrical Issues

Identifying electrical problems often involves a systematic approach. Begin by inspecting fuses and relays, as these components are common failure points. Utilize a multimeter to measure voltage and continuity, ensuring that all connections are secure and free of corrosion. Being methodical in your approach will help in pinpointing issues and restoring functionality to the electrical system.

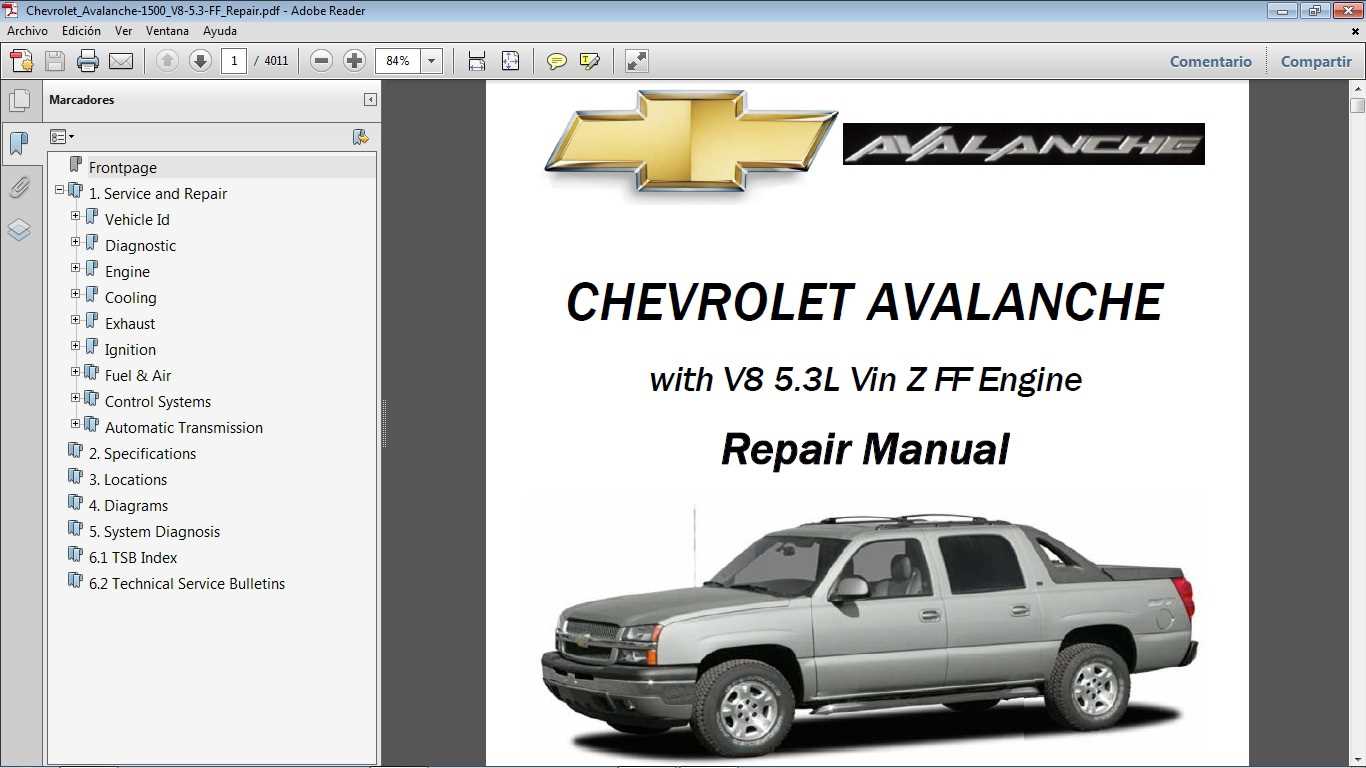

Engine Specifications and Troubleshooting

This section focuses on key details regarding the powertrain and offers guidance on common issues that may arise. Understanding the specifications and potential problems can greatly enhance maintenance efforts and ensure optimal performance.

Below are the critical specifications:

- Engine Type: V8

- Displacement: 5.3 liters

- Horsepower: Approximately 295 hp

- Torque: Around 335 lb-ft

- Fuel System: Sequential fuel injection

When troubleshooting engine-related concerns, consider the following common symptoms:

- Poor Fuel Economy: Check for proper tire inflation and regular maintenance.

- Rough Idling: Inspect the spark plugs and ignition system.

- Overheating: Ensure the cooling system is functioning efficiently and check for leaks.

- Check Engine Light: Utilize a diagnostic tool to read trouble codes.

Regular monitoring and timely interventions can prevent more serious complications, leading to a smoother and more efficient driving experience.

Transmission Repair Procedures

This section outlines essential steps for addressing issues related to the vehicle’s transmission system. Proper maintenance and timely intervention can significantly enhance performance and longevity.

Before beginning any procedures, ensure that you have the necessary tools and parts. A clean workspace will facilitate a smoother process.

- Gather tools: sockets, wrenches, screwdrivers, and transmission fluid.

- Ensure safety: disconnect the battery and wear protective gear.

Follow these procedures for effective intervention:

- Identify the symptoms of transmission issues, such as slipping or unusual noises.

- Drain the existing fluid from the transmission pan.

- Remove the pan and filter, inspecting for debris or wear.

- Replace the filter and gasket, ensuring a tight seal.

- Refill with the appropriate type and amount of transmission fluid.

Regular checks and maintenance can prevent major failures and extend the life of the transmission.

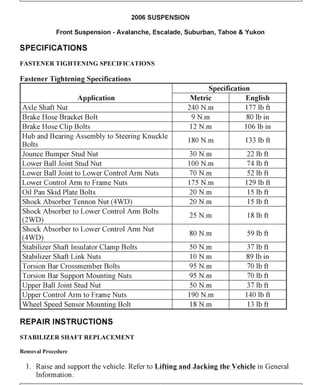

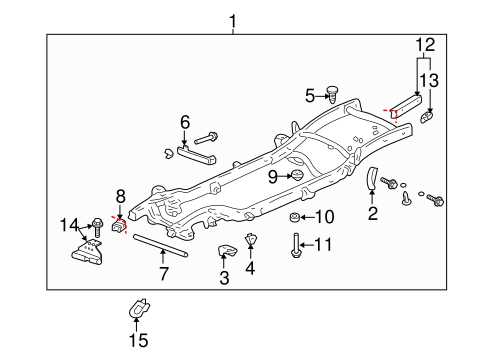

Suspension System Insights

The suspension system plays a crucial role in ensuring a smooth and comfortable ride. It absorbs shocks from the road, maintaining tire contact with the surface and enhancing vehicle stability. Understanding the components and functionality of this system is essential for optimal performance and safety.

This system comprises various elements, including springs, shock absorbers, and control arms. Each part contributes to the overall dynamics, affecting handling and comfort. Regular inspection and maintenance are vital to prevent wear and tear, which can lead to decreased performance and potential safety hazards.

Drivers should be aware of signs indicating suspension issues, such as uneven tire wear, excessive bouncing, or difficulty steering. Addressing these concerns promptly can prolong the lifespan of the suspension system and enhance the overall driving experience.

Brake System Maintenance Guidelines

Regular upkeep of the braking system is essential for ensuring safety and performance. Proper maintenance not only enhances the effectiveness of the brakes but also prolongs their lifespan. Following a systematic approach to care can prevent costly repairs and improve overall driving experience.

Key maintenance practices include:

- Routine inspection of brake pads and rotors for wear and tear.

- Checking brake fluid levels and quality, replacing if necessary.

- Monitoring the condition of brake lines and hoses for leaks or damage.

- Cleaning and lubricating components to prevent rust and improve function.

It is advisable to adhere to the following schedule for maintenance:

- Inspect brake pads and rotors every 6,000 miles or as recommended by the manufacturer.

- Change brake fluid every two years to maintain optimal performance.

- Examine brake lines and connections for signs of wear during every oil change.

By consistently following these guidelines, you can ensure your braking system remains reliable and efficient, contributing to overall vehicle safety.

Cooling System Performance Checks

Ensuring optimal operation of the cooling system is essential for maintaining engine efficiency and preventing overheating. Regular assessments help identify potential issues before they escalate into more serious problems.

Begin by inspecting the coolant level. Proper fluid levels are crucial for effective heat dissipation. Follow these steps for a comprehensive evaluation:

- Check the coolant reservoir for the appropriate level, ensuring it meets the manufacturer’s specifications.

- Inspect the radiator for any signs of leaks, corrosion, or damage.

- Examine hoses and connections for wear, cracks, or looseness that could lead to fluid loss.

Next, evaluate the performance of the thermostat and water pump:

- Test the thermostat by observing the engine temperature gauge during operation.

- Monitor the water pump for unusual noises or vibrations, which may indicate a failure.

Finally, ensure that the cooling fans operate correctly. This can be checked by:

- Listening for the fans to activate as the engine reaches the designated temperature.

- Verifying that fans operate at full speed during high-temperature conditions.

Regularly conducting these checks will help maintain the integrity of the cooling system, ensuring a reliable and efficient engine performance.

Bodywork and Exterior Repairs

This section provides essential guidance for addressing exterior maintenance and restoration tasks. Whether it’s minor scratches or significant damage, understanding the techniques involved in maintaining the vehicle’s appearance is crucial for longevity and aesthetics.

Common Issues and Solutions

Exterior components often face wear and tear from various environmental factors. Common issues include dents, scratches, and rust formation. To effectively address these concerns, start by thoroughly cleaning the affected areas. For scratches, applying touch-up paint can restore the finish, while dents may require specialized tools to pull them back into shape. Rust should be treated promptly to prevent further deterioration.

Painting and Finishing Techniques

When it comes to enhancing or restoring the exterior finish, proper painting techniques are vital. Before applying new paint, ensure that the surface is smooth and clean. Utilize primer to create a good base for paint adhesion. After the primer dries, apply several thin coats of paint, allowing adequate drying time between applications. A clear coat can further protect the finish and provide a glossy appearance, ensuring the vehicle maintains its visual appeal.

Interior Component Replacement Guide

This section provides essential guidance for the removal and installation of various internal parts within your vehicle. Whether you’re addressing wear and tear or upgrading features, understanding the process is crucial for maintaining optimal functionality and aesthetics.

Tools and Materials Needed

Before starting, gather the necessary tools and materials to ensure a smooth process. Common items include a screwdriver set, pliers, socket wrenches, and a trim removal tool. Having replacement components ready will also expedite your project.

Step-by-Step Procedure

Begin by carefully disconnecting the battery to prevent electrical issues. Remove the trim panels gently to access the underlying components. Follow the manufacturer’s guidelines for each part you intend to replace, ensuring proper alignment and securing all fasteners. Once completed, reconnect the battery and test the functionality of the newly installed elements.

Note: Always consult available resources or seek professional assistance if unsure about any steps in the process.

Tools Required for Repairs

When undertaking maintenance tasks on your vehicle, having the right equipment is essential for efficiency and effectiveness. Proper tools not only facilitate the process but also ensure that tasks are completed safely and accurately. From basic hand tools to specialized equipment, each plays a crucial role in successful interventions.

Commonly needed items include wrenches, screwdrivers, pliers, and socket sets, which cover a wide range of applications. Additionally, diagnostic tools can provide insights into the vehicle’s systems, helping to identify issues more precisely. Always ensure that your toolkit is organized and stocked with the necessary implements to handle various situations.

Investing in quality tools can significantly enhance your overall experience. Not only do they make tasks easier, but they also improve the longevity of the components being worked on. Familiarizing yourself with the tools available can lead to more efficient problem-solving and maintenance practices.

Safety Protocols During Repairs

When undertaking maintenance tasks on vehicles, adhering to established safety measures is essential to prevent accidents and ensure a secure working environment. Proper preparation and awareness can significantly reduce risks associated with mechanical work.

Before commencing any work, it is crucial to wear appropriate personal protective equipment, such as gloves, goggles, and steel-toed boots. These items shield against potential hazards, including sharp objects and chemical spills. Additionally, ensuring a well-ventilated workspace minimizes exposure to harmful fumes and allows for better concentration.

Always disconnect the battery before working on electrical systems to avoid shocks or short circuits. When lifting heavy components, utilize proper lifting techniques or tools to prevent injury. It’s also advisable to keep a fire extinguisher nearby, especially when dealing with flammable materials.

Regularly inspect tools and equipment for any damage, and use them according to the manufacturer’s guidelines. Maintaining a clean workspace can further minimize accidents, as clutter can lead to slips and falls. Lastly, never hesitate to seek assistance when needed, as teamwork can enhance safety and efficiency.