Comprehensive Guide to 2011 Chevy Cruze Repair Manual

Maintaining a vehicle is essential for ensuring optimal performance and longevity. Understanding the intricacies of automotive systems allows owners to navigate common challenges effectively. This section aims to provide valuable insights into various aspects of vehicle upkeep, empowering enthusiasts and everyday drivers alike.

From routine checks to more complex procedures, having access to detailed information is crucial. Whether addressing minor issues or tackling significant repairs, the right knowledge equips individuals to make informed decisions. By exploring systematic approaches to diagnostics and maintenance, readers can enhance their understanding and confidence in managing their vehicle’s needs.

In this guide, we will delve into specific techniques, essential tools, and best practices that facilitate successful interventions. With a focus on practical advice and straightforward explanations, this resource serves as a reliable companion for anyone seeking to navigate the world of automotive care.

This section provides a comprehensive look at a specific compact vehicle model known for its efficiency and modern features. It highlights essential aspects, including performance metrics, design elements, and technological advancements, aimed at enhancing user experience and ensuring reliable operation.

Understanding the vehicle’s key components and functionality is crucial for maintenance and troubleshooting. Below is a table summarizing significant features and specifications relevant to this model:

| Feature | Description |

|---|---|

| Engine Type | Available in various configurations, offering a balance of power and fuel economy. |

| Transmission Options | Equipped with both automatic and manual transmission choices to suit different driving preferences. |

| Fuel Efficiency | Designed to achieve high miles per gallon, making it economical for daily commuting. |

| Safety Features | Incorporates advanced safety technologies to enhance occupant protection. |

| Interior Comfort | Offers a well-designed cabin with modern amenities for a pleasant driving experience. |

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and restoring vehicles effectively. A well-equipped workspace not only enhances efficiency but also ensures safety while working on various tasks. Below are some of the indispensable tools that every automotive enthusiast should consider having at their disposal.

Basic Hand Tools

- Wrenches: A set of both standard and metric sizes is essential for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will cover most fasteners encountered.

- Plier Set: Includes needle-nose and adjustable pliers for gripping and manipulating components.

- Socket Set: A range of sockets is vital for accessing nuts and bolts in tight spaces.

Specialized Equipment

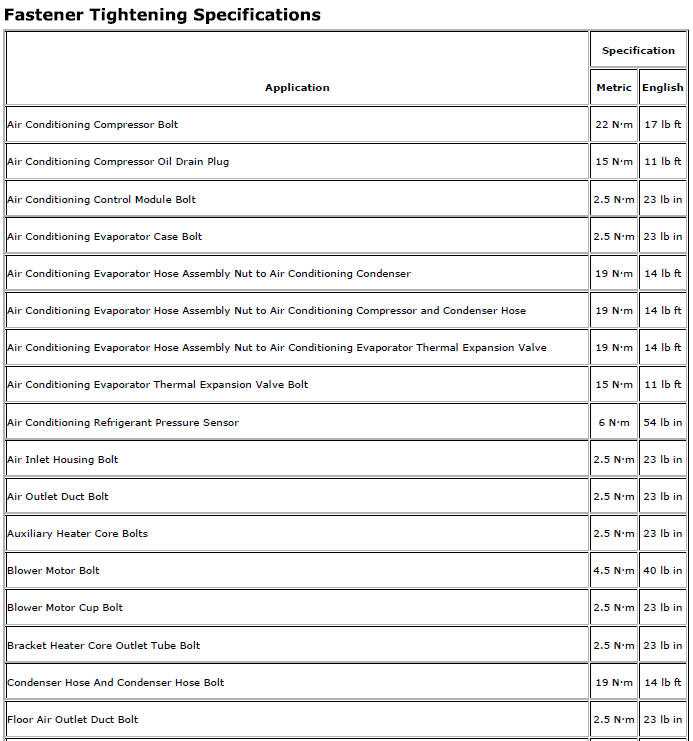

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Jack and Jack Stands: Necessary for safely lifting the vehicle during maintenance tasks.

- Diagnostic Scanner: Useful for reading error codes and troubleshooting electronic systems.

- Oil Filter Wrench: Facilitates the removal of oil filters during fluid changes.

Common Issues and Solutions

When it comes to vehicle maintenance, certain challenges are frequently encountered by owners. Addressing these concerns promptly can enhance performance and prolong the lifespan of the automobile. This section highlights typical problems along with effective remedies.

Frequent Concerns

- Engine performance issues

- Electrical system malfunctions

- Transmission difficulties

- Suspension-related noises

Effective Remedies

-

Engine Performance: Regularly check and replace air filters and spark plugs to ensure optimal engine function.

-

Electrical System: Inspect battery connections and fuses; clean or replace as needed to maintain proper electrical flow.

-

Transmission Problems: Regular fluid changes and checks can prevent slippage and overheating issues.

-

Suspension Noises: Inspect struts and shocks for wear; replace any damaged components to eliminate unwanted sounds.

Engine Maintenance Guidelines

Ensuring the longevity and efficiency of an engine involves regular attention and care. Adhering to systematic maintenance practices can significantly enhance performance while preventing costly issues down the line. Below are essential recommendations to keep in mind for optimal engine upkeep.

Regular Inspections

Consistent evaluations of engine components are crucial. Pay attention to the following elements:

- Check fluid levels: Ensure oil, coolant, and transmission fluid are at appropriate levels.

- Inspect belts and hoses: Look for signs of wear, cracking, or leaks.

- Monitor for unusual noises: Listen for any irregular sounds that may indicate underlying problems.

Fluid Changes

Routine fluid changes are vital for engine health. Follow these guidelines:

- Oil and filter: Replace every 5,000 to 7,500 miles or as recommended by the manufacturer.

- Coolant: Flush and refill every 30,000 miles to prevent overheating and corrosion.

- Transmission fluid: Change according to the vehicle’s specifications to ensure smooth shifting.

By adhering to these practices, you can maintain engine efficiency and reliability for years to come.

Electrical System Troubleshooting

The functionality of a vehicle’s electrical components is crucial for optimal performance. Diagnosing issues within the electrical system requires a methodical approach to identify the root causes of malfunctions. This section outlines effective strategies for troubleshooting common electrical concerns that may arise.

Common Symptoms of Electrical Issues

Recognizing signs of electrical faults is the first step in addressing potential problems. Common symptoms include flickering lights, difficulty starting the engine, and malfunctioning accessories. These indicators can often signal underlying issues with wiring, connections, or battery health. Observing these symptoms promptly can prevent further complications.

Step-by-Step Diagnostic Process

To effectively diagnose electrical issues, follow a systematic approach. Start by inspecting the battery for proper voltage and secure connections. Next, check fuses and relays to ensure they are functioning correctly. Use a multimeter to measure voltage at various points within the system, as this can reveal areas of concern. Documenting each step will aid in identifying recurring problems and assist in formulating solutions.

Transmission Service Tips

Maintaining the efficiency of your vehicle’s power transfer system is essential for optimal performance. Regular attention to this component can enhance longevity and ensure smooth operation. Here are some essential guidelines for servicing this critical system.

Fluid Maintenance

Proper fluid management is crucial for the functionality of the power transfer mechanism. Regular checks and changes of the fluid can prevent potential issues.

| Fluid Type | Change Interval | Notes |

|---|---|---|

| Automatic Transmission Fluid | Every 30,000 miles | Check for discoloration and odor. |

| Manual Transmission Fluid | Every 50,000 miles | Ensure correct viscosity is used. |

Inspection Procedures

Conducting routine inspections can help identify potential issues before they escalate. Pay attention to any irregularities during your check-ups.

- Look for leaks around seals and gaskets.

- Monitor the performance for unusual noises or shifting issues.

- Ensure that the cooler lines are in good condition.

Brake System Inspection Techniques

Ensuring the safety and functionality of the braking apparatus is crucial for any vehicle. Regular evaluation of this critical component helps in identifying wear and tear, potential issues, and necessary adjustments. This section discusses effective methods for examining the braking system, ensuring optimal performance and safety on the road.

Visual Examination

A thorough visual assessment is the first step in inspecting the braking system. Begin by checking for any visible signs of wear on brake pads, rotors, and calipers. Look for cracks, uneven surfaces, or excessive rust. Additionally, inspect the brake lines and hoses for any leaks or deterioration. Promptly addressing any noticeable damage can prevent more serious complications later.

Functional Testing

After the visual inspection, conducting functional tests is essential. Engage the brake pedal to assess its responsiveness and feel. Listen for any unusual noises, such as grinding or squeaking, which may indicate underlying issues. Brake fluid level should also be checked to ensure it is within the recommended range. Regular functional testing contributes significantly to maintaining the reliability of the braking mechanism.

Suspension and Steering Adjustments

This section outlines the essential modifications and calibrations needed for optimal handling and ride quality. Proper alignment and suspension settings play a crucial role in enhancing vehicle stability, ensuring a smooth driving experience, and prolonging component lifespan.

Regular assessments and adjustments to the suspension and steering systems can prevent premature wear and improve overall performance. Understanding the various angles and settings will assist in achieving precise control and comfort during operation.

| Adjustment Type | Description | Recommended Specifications |

|---|---|---|

| Camber | The angle of the wheels in relation to the vertical axis. | -0.5° to -1.5° |

| Toe | The direction in which the tires point relative to the centerline of the vehicle. | 0.0° to +0.1° |

| Caster | The angle of the steering pivot point, influencing stability and steering effort. | 3.0° to 5.0° |

Regular inspections should be conducted to ensure that all components remain within the specified parameters. Adjustments may require specialized tools and should ideally be performed by trained professionals for the best outcomes.

Interior Features and Repairs

This section delves into the various characteristics and maintenance considerations of the cabin space, emphasizing the importance of functionality and aesthetics. Understanding the layout and components will enhance both comfort and usability, providing an enjoyable experience for all occupants.

Common Interior Components

The interior of the vehicle boasts a range of essential features designed for convenience and comfort. These elements require periodic inspection and maintenance to ensure optimal performance and longevity. Below are some of the critical components along with their typical issues and suggested solutions.

| Component | Common Issues | Suggested Solutions |

|---|---|---|

| Dashboard | Cracks, fading | Use dashboard protectants, consider replacement |

| Seats | Wear, stains | Regular cleaning, reupholstering |

| Door Panels | Loose fittings, scratches | Reattach or replace panels |

| Infotainment System | Software glitches, connectivity issues | Update software, check connections |

Maintenance Tips

To maintain the interior in peak condition, regular upkeep is essential. Here are some recommendations to follow:

- Clean surfaces routinely to prevent build-up.

- Inspect all components periodically for wear and tear.

- Address minor repairs promptly to avoid escalation of issues.

Safety Recommendations for DIY Repairs

Engaging in do-it-yourself maintenance tasks can be rewarding and cost-effective, but it is crucial to prioritize safety throughout the process. Understanding proper precautions not only protects individuals from potential hazards but also ensures a smooth and efficient workflow.

Before commencing any task, it is advisable to gather the necessary tools and familiarize oneself with the specific equipment involved. Wearing appropriate personal protective equipment, such as gloves and safety glasses, is essential to prevent injuries. Furthermore, ensuring a well-ventilated workspace can mitigate the risks associated with harmful fumes or dust.

| Recommendation | Description |

|---|---|

| Read Documentation | Familiarize yourself with the equipment’s specifications and guidelines to understand the procedures better. |

| Use Quality Tools | Invest in reliable and appropriate tools to reduce the risk of accidents and ensure effective results. |

| Secure the Vehicle | Ensure the vehicle is on a flat surface and use wheel chocks to prevent rolling. |

| Disconnect Power | Always disconnect the battery or power source before working on electrical components to avoid shocks. |

| Seek Assistance | Do not hesitate to ask for help or consult a professional if unsure about any procedure. |

By adhering to these guidelines, individuals can enhance their safety while performing maintenance tasks and increase the likelihood of successful outcomes.