Comprehensive Guide to John Deere 1010 Repair Manual

Maintaining heavy-duty agricultural equipment is essential for ensuring optimal performance and longevity. This resource aims to provide detailed insights and practical instructions for the upkeep of specific machinery models, helping users navigate common challenges and enhance productivity in the field.

Understanding the intricacies of machinery maintenance is crucial for operators and technicians alike. By familiarizing oneself with essential components and troubleshooting techniques, users can significantly reduce downtime and improve the efficiency of their operations. This guide serves as a valuable reference, empowering individuals to take proactive measures in their equipment care.

In the realm of agricultural technology, regular servicing and timely interventions can lead to substantial savings and a smoother workflow. This comprehensive reference is designed to equip users with the knowledge needed to tackle repairs and enhancements effectively, ensuring that their equipment remains in peak condition for years to come.

Overview of John Deere 1010

This section provides an insight into a well-regarded agricultural machine known for its reliability and versatility. It has earned the trust of many farmers and operators over the years, thanks to its robust design and efficient performance in various tasks.

Key Features

- Powerful engine delivering exceptional torque.

- Durable construction suitable for heavy-duty applications.

- User-friendly controls enhancing ease of operation.

- Versatile attachments available for multiple functions.

Common Applications

- Plowing and tilling fields for crop preparation.

- Hauling materials and equipment across diverse terrains.

- Mowing and landscaping for maintaining properties.

- Assisting in various agricultural tasks, improving productivity.

Overall, this machine stands out for its engineering excellence, making it a valuable asset in the agricultural sector.

Common Issues with the John Deere 1010

When operating a classic agricultural machine, several typical challenges may arise that can affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth workflow.

- Engine Performance:

- Difficulty starting the engine, often due to fuel delivery issues.

- Loss of power during operation, which may result from clogged air filters.

- Transmission Troubles:

- Slipping gears that can lead to unpredictable handling.

- Difficulty shifting, often caused by worn linkage or low fluid levels.

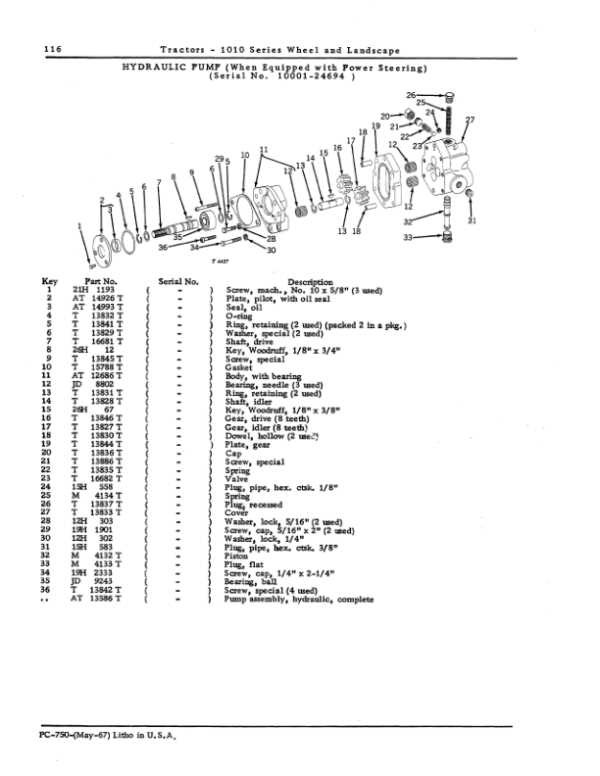

- Hydraulic System Issues:

- Leaks in hydraulic lines that can reduce lifting capability.

- Poor performance of hydraulic components due to contamination.

- Electrical Failures:

- Malfunctioning lights or indicators, typically caused by faulty wiring.

- Battery drain issues that can lead to starting problems.

Identifying and addressing these common issues promptly can significantly enhance the longevity and reliability of the machine, making it an invaluable asset for any farming operation.

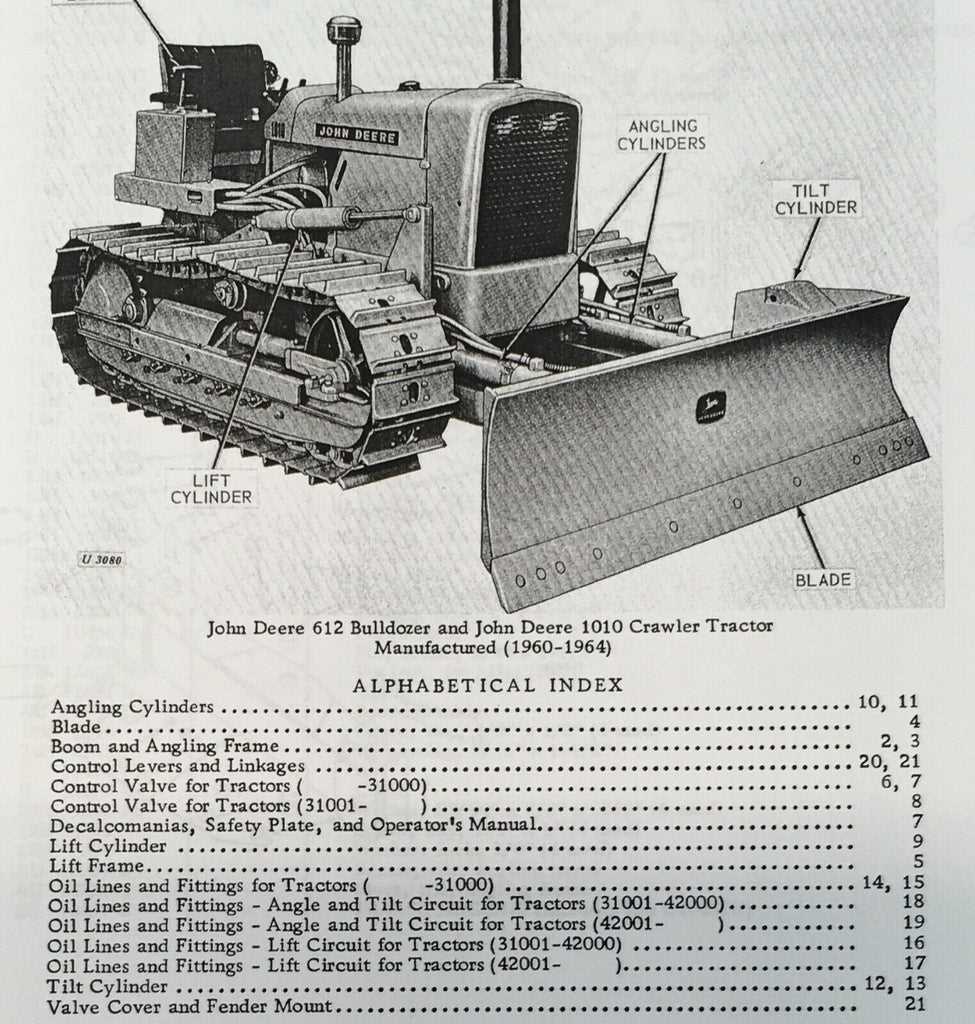

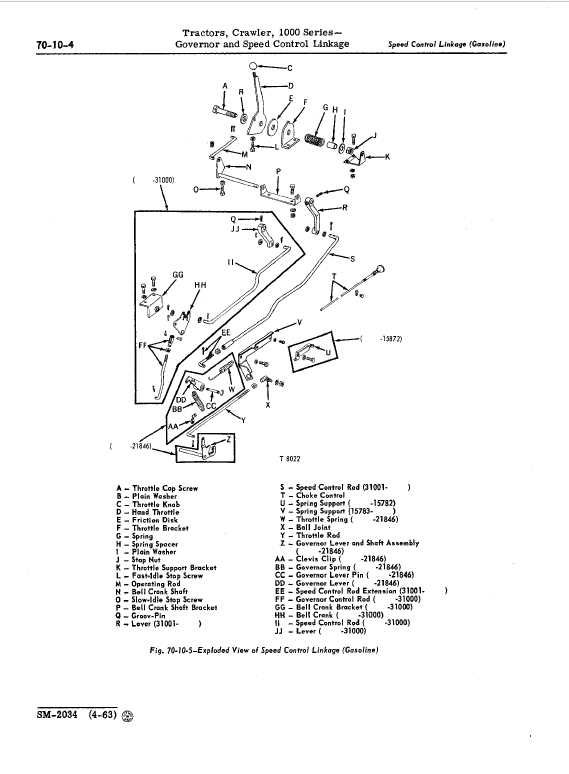

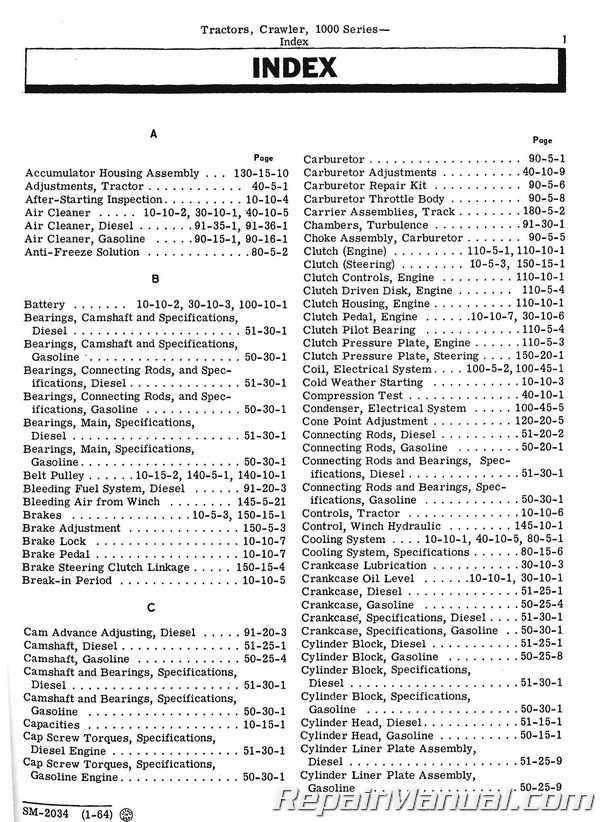

Importance of Repair Manuals

Documentation that guides individuals through the maintenance and restoration of machinery plays a crucial role in ensuring optimal performance and longevity. Such resources provide detailed instructions, diagrams, and troubleshooting advice, which are essential for both novice and experienced users. They enhance understanding of the equipment, fostering confidence in executing repairs or routine checks.

Access to comprehensive guides reduces the risk of errors during service tasks, ultimately saving time and money. Additionally, these resources promote safety by outlining necessary precautions and proper handling procedures. By facilitating informed decision-making, they contribute to the overall efficiency of operations, allowing users to maximize the utility of their equipment.

Furthermore, having reliable documentation on hand supports ongoing education. Users can expand their technical knowledge, adapting to evolving technologies and practices within the industry. This continuous learning not only benefits the individual but also enhances the capabilities of entire teams, driving productivity and innovation in the field.

Tools Required for Repairs

Successful maintenance and troubleshooting of machinery require specific implements and instruments. Having the right tools on hand not only facilitates efficient work but also ensures safety and effectiveness during the process.

Here’s a comprehensive list of essential tools that will aid in the upkeep of your equipment:

- Wrenches: Various sizes are necessary for loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are crucial for handling screws.

- Socket Set: A range of sockets will provide versatility for different fasteners.

- Pliers: Useful for gripping and twisting wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Multimeter: Essential for diagnosing electrical issues and measuring voltage.

- Oil Can: For lubrication of moving parts to prevent wear and tear.

- Diagnostic Tools: Specific electronic devices can assist in troubleshooting more complex issues.

Having these tools readily available will streamline the maintenance process and help achieve optimal performance from your machinery.

Step-by-Step Repair Process

Maintaining machinery in optimal condition requires a systematic approach to troubleshooting and restoration. This section outlines a comprehensive method for addressing common issues, ensuring that operators can efficiently resolve problems and extend the lifespan of their equipment.

Identifying the Problem

The first step involves careful observation and diagnosis. Begin by assessing any unusual noises, performance issues, or warning signals. Document specific symptoms and gather relevant information to narrow down potential causes. Utilizing a checklist can help streamline this phase, ensuring no detail is overlooked.

Executing Repairs

Once the issue has been pinpointed, gather necessary tools and parts. Follow the outlined procedures for disassembly and inspection, taking care to label components for reassembly. Ensure safety measures are in place throughout the process. After replacing or fixing the faulty parts, conduct a thorough reassembly, checking all connections and systems for integrity before testing the machinery.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery involves regular care and attention. Implementing effective maintenance practices not only enhances performance but also prevents costly repairs in the future. By following a few essential guidelines, you can significantly increase the durability and efficiency of your equipment.

1. Regular Inspections: Conduct frequent checks on critical components such as filters, belts, and fluids. Identifying wear and tear early can help avert serious issues.

2. Cleanliness is Key: Keeping your machine clean reduces the risk of dirt and debris causing damage. Regularly wash exterior surfaces and ensure that cooling systems remain free from obstructions.

3. Fluid Maintenance: Always monitor and change fluids according to the manufacturer’s recommendations. Fresh oil and coolant help maintain optimal performance and protect internal parts.

4. Proper Storage: When not in use, store your equipment in a dry, sheltered location. This minimizes exposure to the elements, which can lead to rust and deterioration.

5. Follow the Operating Guidelines: Adhere strictly to the operational guidelines provided. Overloading or improper use can significantly shorten the lifespan of your machinery.

6. Scheduled Servicing: Establish a routine for professional servicing. Regular check-ups by qualified technicians ensure that all systems are functioning correctly and efficiently.

By incorporating these practices into your maintenance routine, you can maximize the longevity and reliability of your machinery, ensuring it continues to perform at its best for years to come.

Safety Precautions During Repairs

Ensuring a secure working environment is essential when performing maintenance tasks on machinery. Proper safety measures not only protect the individual carrying out the work but also contribute to the longevity and efficiency of the equipment being serviced.

Before starting any task, always assess the workspace for potential hazards. Ensure that the area is clean, well-lit, and free from clutter. Proper ventilation is crucial, especially when handling chemicals or working with components that may emit harmful fumes.

Wearing appropriate personal protective equipment (PPE) is vital. This includes gloves, safety glasses, and steel-toed boots to safeguard against physical injuries. In some cases, ear protection and respiratory masks may also be necessary, particularly in noisy or dusty environments.

Always disconnect the power source before working on any machinery. This simple step can prevent accidental start-ups and protect against electric shock. Additionally, familiarize yourself with the location of emergency shut-off switches and first aid kits.

Use tools correctly and ensure they are in good condition. Inspect all equipment for wear and tear before use, and follow manufacturer instructions to avoid accidents. If unfamiliar with a particular tool or procedure, seek guidance or training.

Lastly, never work alone if possible. Having a partner can provide assistance in case of an emergency and help in managing heavy or awkward parts. Prioritizing safety during any maintenance activity is crucial for a successful outcome.

Where to Find Replacement Parts

Locating suitable components for machinery can be a challenging task, but with the right approach, it becomes manageable. Understanding the available sources and options for procurement is essential for maintaining optimal performance. This section outlines various avenues where one can discover the necessary elements to keep equipment in top condition.

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official distributors of the brand. | Guaranteed quality, expert assistance. |

| Online Retailers | Websites specializing in parts sales. | Wide selection, often competitive pricing. |

| Local Repair Shops | Nearby services with parts inventory. | Convenient access, local expertise. |

| Salvage Yards | Recycled parts from decommissioned machines. | Cost-effective options, unique finds. |

| Manufacturer’s Website | Direct source of OEM parts. | Access to the latest updates and parts lists. |

By exploring these resources, one can ensure that their machinery remains reliable and efficient, minimizing downtime and enhancing productivity.

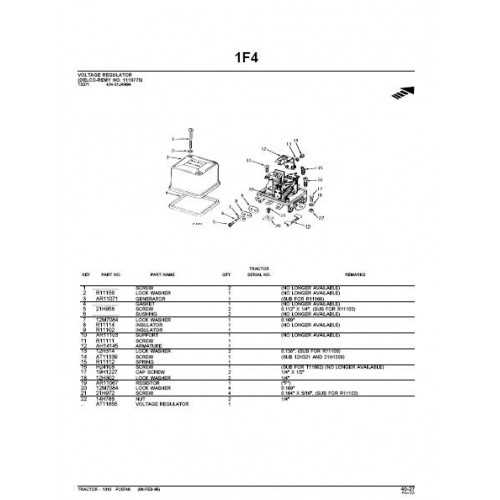

Understanding the Engine Components

Engines are intricate systems composed of various parts that work together to convert fuel into mechanical energy. Each component plays a vital role in ensuring optimal performance and efficiency. By grasping how these elements interact, one can better appreciate the complexities of engine functionality.

The core of any engine is the cylinder, where fuel combustion occurs, generating power. Surrounding the cylinder are critical components such as the piston, which moves up and down, and the crankshaft, converting linear motion into rotational energy. Additionally, the timing system coordinates the opening and closing of valves, ensuring a smooth flow of air and fuel.

Cooling and lubrication systems are equally essential, preventing overheating and reducing friction between moving parts. Understanding these systems enhances one’s ability to maintain and troubleshoot engine issues effectively. In essence, familiarizing oneself with these components provides a comprehensive insight into the overall operation and longevity of the engine.

Customer Support and Resources

When it comes to maintaining and troubleshooting your agricultural machinery, having access to reliable assistance and information is crucial. This section provides an overview of the various support channels and resources available to ensure optimal performance and longevity of your equipment.

Support Options

- Technical Assistance: Reach out to dedicated service teams for expert guidance on operational issues.

- Online Forums: Engage with a community of users to share experiences and solutions.

- Customer Service Hotline: Access real-time support for urgent inquiries.

- In-Person Consultations: Schedule appointments with certified technicians for hands-on assistance.

Additional Resources

- Digital Documentation: Explore a comprehensive library of guides and troubleshooting tips available online.

- Workshops and Training: Attend local sessions to enhance your knowledge and skills regarding equipment maintenance.

- Parts Availability: Identify and order replacement components through official distributors or authorized dealers.

- Maintenance Checklists: Utilize prepared lists to help keep your machinery in peak condition.