Comprehensive Guide to Repairing John Deere 2130

Ensuring the optimal performance of agricultural machinery is crucial for enhancing productivity and minimizing downtime. This section aims to provide an in-depth exploration of effective strategies for maintaining and resolving common issues associated with a specific model of tractor. By understanding the intricacies of this equipment, users can extend its lifespan and improve its efficiency.

In the realm of machinery upkeep, possessing detailed knowledge of operational procedures and troubleshooting techniques is invaluable. This guide serves as a resource for individuals seeking to enhance their familiarity with essential components, as well as offering step-by-step instructions for various tasks. Whether it’s routine maintenance or addressing specific challenges, having access to reliable information can make a significant difference.

Throughout this guide, readers will discover a wealth of information designed to empower them in their maintenance efforts. From understanding key features to implementing practical solutions, each section will focus on fostering a deeper comprehension of the machinery. Ultimately, this resource aims to equip users with the necessary tools to tackle maintenance tasks with confidence and proficiency.

Overview of John Deere 2130

This section provides a comprehensive look at a specific agricultural machine designed for versatility and efficiency in various farming tasks. Known for its reliability and ease of use, this model has become a favored choice among many operators in the agricultural sector.

Key Features

The machine is equipped with a robust engine that ensures powerful performance while maintaining fuel efficiency. Its intuitive controls and ergonomic design contribute to a user-friendly experience, allowing operators to work comfortably over extended periods. Additionally, the model includes various attachments and implements, enhancing its functionality for tasks ranging from plowing to planting.

Maintenance and Care

Regular upkeep is essential for sustaining optimal performance and longevity. Operators should adhere to the recommended service intervals and check vital components such as the engine, transmission, and hydraulic systems. By following proper maintenance practices, users can ensure that the machine remains in excellent working condition, minimizing downtime and costly repairs.

Common Issues and Troubleshooting

This section aims to address frequent problems encountered with agricultural machinery and provides effective solutions to enhance performance and reliability. Understanding these common issues can assist operators in maintaining optimal functionality and minimizing downtime.

Frequent Problems

- Engine not starting

- Unusual noises during operation

- Poor fuel efficiency

- Hydraulic system failure

- Electrical system malfunctions

Troubleshooting Steps

- Engine Issues: Check battery connections, fuel levels, and ignition components. Inspect for any leaks or obstructions in the fuel lines.

- Unusual Noises: Listen for abnormal sounds indicating mechanical wear. Check belts and pulleys for proper tension and alignment.

- Poor Performance: Verify fuel quality and cleanliness of the air filter. Replace any worn spark plugs and ensure regular maintenance of the engine.

- Hydraulic Failures: Inspect hydraulic fluid levels and check for leaks in hoses and fittings. Replace filters as needed to maintain flow efficiency.

- Electrical Issues: Examine fuses and wiring for damage. Ensure all connections are secure and corrosion-free.

By following these guidelines and addressing potential issues promptly, operators can ensure their equipment remains in excellent working condition, ultimately enhancing productivity.

Engine Maintenance Guidelines

Regular upkeep of the power unit is essential for optimal performance and longevity. Proper care not only enhances efficiency but also reduces the likelihood of breakdowns. Following systematic procedures can ensure that the engine operates smoothly and reliably over time.

Routine Checks

Frequent inspections should be conducted to identify any potential issues early. Check oil levels, coolant, and other fluids regularly. Ensure that the filters are clean and replace them as needed. Listening for unusual sounds can also indicate underlying problems that may require attention.

Cleaning and Lubrication

Keeping components clean is vital. Remove dirt and debris from the engine exterior to prevent overheating. Ensure that moving parts are well-lubricated to minimize wear and tear. Use high-quality lubricants that are suitable for the specific type of engine to achieve the best results.

Following these guidelines will help maintain the engine’s performance and extend its lifespan. Proper care is an investment in reliability and efficiency.

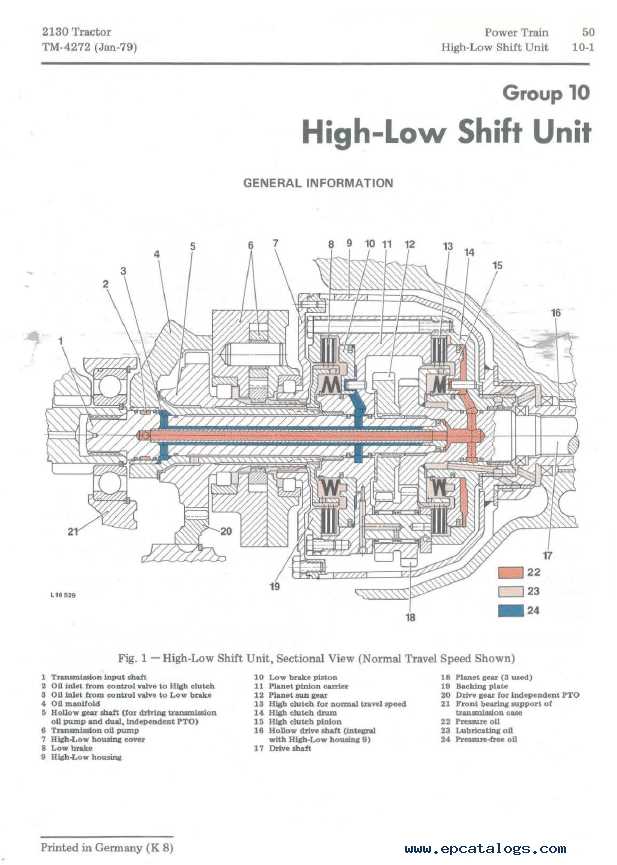

Transmission System Insights

The transmission system is a vital component of any machinery, playing a crucial role in transferring power from the engine to the wheels. Understanding its intricacies can significantly enhance performance and longevity. This section delves into the various elements of the transmission system, highlighting their functions and importance.

At its core, the transmission system consists of several key parts that work in harmony to facilitate smooth operation. These components include gears, clutches, and control mechanisms, each contributing to the overall efficiency of the vehicle. Regular maintenance and timely adjustments can prevent common issues that arise within the system.

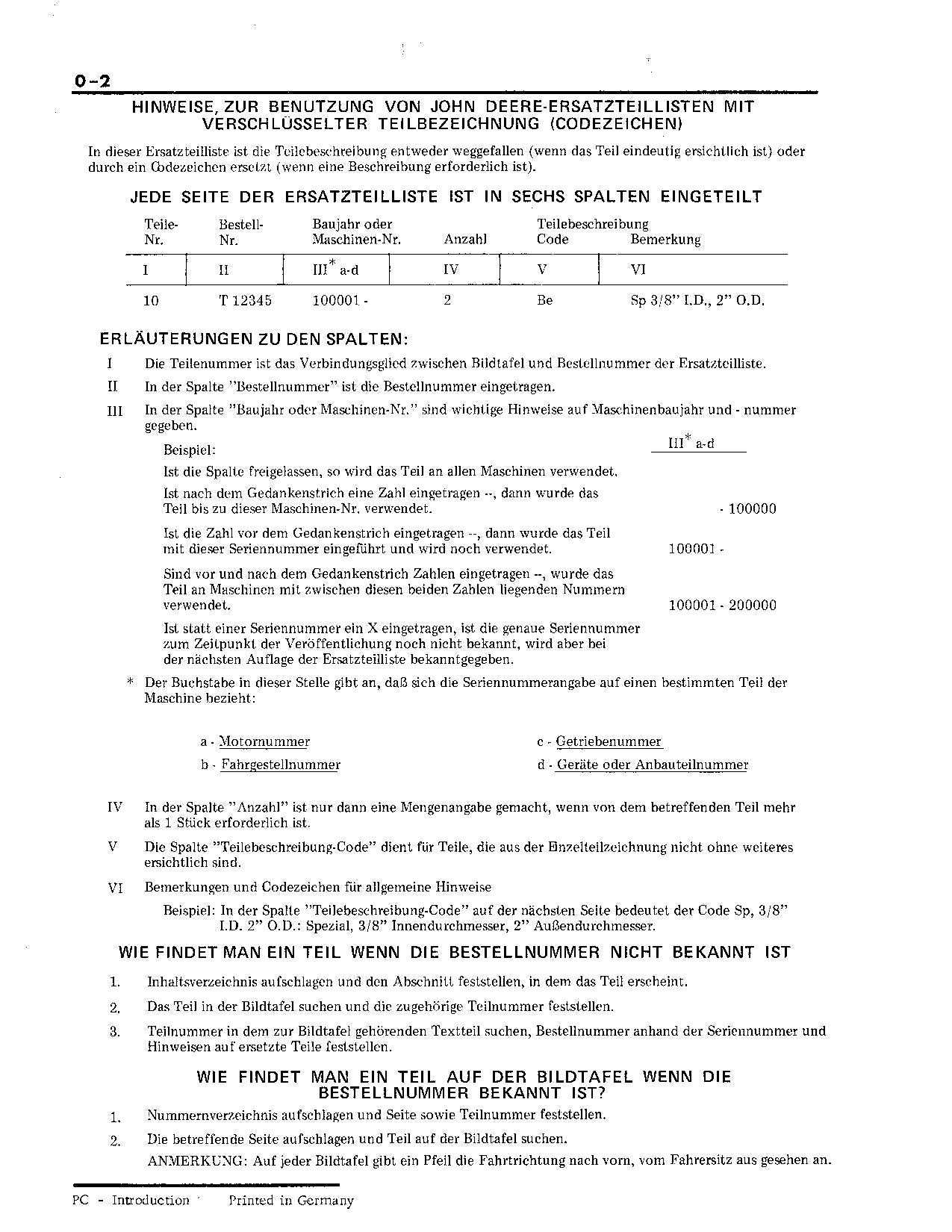

| Component | Function |

|---|---|

| Gears | Change the torque and speed of the vehicle. |

| Clutch | Engages and disengages the engine from the transmission. |

| Control Mechanism | Allows the operator to select gears and control speed. |

In conclusion, a comprehensive understanding of the transmission system can lead to better handling and efficiency. Regular checks and preventative measures ensure optimal performance, allowing for seamless operation in various conditions.

Hydraulic System Repair Techniques

Understanding the methods for maintaining and troubleshooting hydraulic systems is crucial for ensuring optimal performance and longevity. These systems play a vital role in the functioning of machinery, and a thorough approach to their upkeep can prevent significant downtime and costly repairs.

When addressing issues within hydraulic systems, it is essential to follow a systematic approach. Below are key techniques to consider:

- Visual Inspection: Regularly examine the hydraulic components for signs of wear, leaks, or damage. Pay close attention to hoses, fittings, and connections.

- Fluid Quality Check: Ensure that the hydraulic fluid is clean and at the correct level. Contaminated or low fluid can lead to system failures.

- Pressure Testing: Use a pressure gauge to assess the hydraulic pressure within the system. This can help identify blockages or issues with pumps.

- Seal Replacement: If leaks are detected, replacing worn seals and gaskets can restore system integrity. Ensure proper fitting to prevent future leaks.

- Component Overhaul: In cases of significant wear, disassembling and refurbishing major components like pumps and cylinders may be necessary to restore functionality.

- System Bleeding: Removing air from the hydraulic system is vital for maintaining efficiency. Follow manufacturer guidelines to bleed the system properly.

Implementing these techniques systematically can enhance the reliability and efficiency of hydraulic systems. Consistent maintenance will ultimately lead to improved performance and extended service life.

Electrical Components Overview

This section delves into the essential elements that constitute the electrical system of agricultural machinery. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Key Electrical Components

- Batteries: Store electrical energy and provide the necessary power for starting the engine and operating electrical systems.

- Alternators: Generate electricity while the engine is running, replenishing the battery and powering electrical components.

- Wiring Harnesses: Facilitate the distribution of electrical power to various systems, ensuring proper connectivity and functionality.

- Fuses: Protect electrical circuits by preventing overloads and short circuits, safeguarding sensitive components.

- Relays: Act as switches to control larger electrical loads, allowing for efficient operation of various systems.

Maintenance Tips

- Regularly inspect battery terminals for corrosion and ensure a secure connection.

- Check the alternator’s output to confirm it is functioning correctly.

- Examine wiring harnesses for wear and tear, replacing any damaged sections.

- Test fuses periodically to prevent electrical failures.

- Ensure relays are clean and operational to maintain system efficiency.

By familiarizing oneself with these electrical components and adhering to maintenance guidelines, operators can enhance the reliability and efficiency of their machinery.

Regular Service Intervals Explained

Maintaining optimal performance of agricultural machinery is crucial for ensuring longevity and efficiency. Routine check-ups and timely interventions not only enhance functionality but also prevent costly repairs down the line. Understanding the recommended servicing schedules can help operators and technicians maintain their equipment in peak condition, thus maximizing productivity.

Importance of Scheduled Maintenance

Adhering to a structured maintenance timetable allows for early detection of potential issues, thereby reducing downtime and enhancing the overall lifespan of the equipment. Scheduled service is designed to address various components, ensuring that every aspect of the machinery is functioning properly. This proactive approach minimizes the risk of unexpected failures and costly repairs.

Typical Service Intervals

| Service Type | Interval (Hours) | Notes |

|---|---|---|

| Oil Change | 100 | Replace oil and filter to maintain engine health. |

| Air Filter Inspection | 200 | Check and clean or replace as necessary for optimal airflow. |

| Coolant Level Check | 250 | Ensure proper coolant levels to prevent overheating. |

| Brake Inspection | 300 | Examine brake components for wear and proper function. |

| Tire Inspection | 500 | Check tire pressure and tread condition for safety. |

Parts Replacement Procedures

Effective maintenance of machinery requires a clear understanding of how to replace components efficiently and safely. This section outlines the essential steps and best practices for substituting various parts in agricultural equipment, ensuring optimal performance and longevity.

Before starting the replacement process, it is crucial to gather all necessary tools and components. Ensure the work area is clean and organized, minimizing the risk of accidents or losing small parts. Always refer to the specifications of the replacement parts to confirm compatibility with the equipment.

Begin by disconnecting any power sources to prevent accidental activation during the procedure. Carefully remove any coverings or barriers that may obstruct access to the component. Use appropriate tools to detach the old part, taking note of the installation method for reference during reassembly.

Once the old component is removed, inspect surrounding areas for signs of wear or damage. If needed, clean the installation site to remove any debris or residue that may interfere with the new part. Position the new component carefully, aligning it according to the manufacturer’s guidelines.

After securing the new part in place, reattach any coverings and reconnect the power sources. Conduct a thorough inspection to ensure everything is installed correctly. Finally, test the machinery to verify that the new component is functioning as intended and that the equipment operates smoothly.

Tools Needed for Repairs

When undertaking maintenance on agricultural machinery, having the right equipment is essential for ensuring efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also enhances safety and precision during tasks. Understanding the necessary implements can greatly influence the outcome of any maintenance endeavor.

Essential Hand Tools: A variety of hand tools are vital for any maintenance job. Commonly used items include wrenches, pliers, and screwdrivers, which aid in loosening or tightening various components. It’s advisable to have both metric and imperial sizes available to accommodate different fasteners.

Power Tools: For more demanding tasks, power tools can significantly reduce labor time. Drills and impact wrenches provide the extra torque needed to tackle stubborn bolts and screws. Ensure that all power tools are well-maintained and inspected before use to prevent malfunctions.

Diagnostic Equipment: Utilizing diagnostic devices can help identify issues within the machinery quickly. Tools such as multimeters and diagnostic scanners can provide valuable insights into electrical systems, allowing for targeted repairs.

Safety Gear: Always prioritize safety when working on machinery. Appropriate gear, such as gloves, safety glasses, and hearing protection, is crucial to minimize risks while performing maintenance tasks. Ensuring a safe working environment is paramount for successful outcomes.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for preventing accidents and injuries. Proper guidelines and precautions play a crucial role in safeguarding both the individual performing the work and the machinery being serviced. Following recommended safety practices helps create a more efficient and productive atmosphere.

Before starting any maintenance activities, it is vital to wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. These items help shield against potential hazards such as sharp edges, moving parts, and harmful substances. Additionally, securing the workspace by removing clutter and ensuring adequate lighting contributes to a safer working environment.

It is also important to disconnect any power sources and release stored energy before attempting to work on equipment. This step minimizes the risk of unexpected starts or movements during the maintenance process. Always refer to relevant documentation for specific guidelines related to the machinery involved, as each model may have unique requirements and safety measures.

Furthermore, maintaining clear communication with others nearby is essential. Alerting coworkers about ongoing tasks can help prevent accidents caused by miscommunication. In case of an emergency, knowing the location of first-aid supplies and emergency contact numbers is crucial for quick response and assistance.

Resources for Further Assistance

For individuals seeking additional guidance and support, a variety of resources are available to enhance knowledge and facilitate troubleshooting. Accessing reliable information can make a significant difference in effectively addressing issues that may arise with agricultural machinery.

Here are some valuable resources to consider:

- Online Forums: Engage with communities where experienced users share insights and solutions.

- Manufacturer Websites: Visit official sites for comprehensive documentation, specifications, and product updates.

- Instructional Videos: Explore platforms that offer visual demonstrations of maintenance techniques and repair processes.

- Local Workshops: Participate in hands-on workshops conducted by professionals, offering practical experience and expert advice.

- Technical Support Hotlines: Utilize customer service lines to receive direct assistance from knowledgeable representatives.

These avenues provide a wealth of information that can aid in understanding and resolving mechanical challenges, ensuring optimal performance of your equipment.