John Deere 261 Grooming Mower Repair Guide

Maintaining outdoor equipment ensures its longevity and optimal performance. Regular checks, component adjustments, and proper care contribute significantly to the reliable functioning of machinery used in land management and upkeep. Consistent attention to these aspects helps avoid unexpected downtimes and costly repairs.

Diagnosing common issues can reveal underlying mechanical problems that may affect operational efficiency. Addressing wear and tear on essential components, such as blades and bearings, as well as inspecting hydraulic systems, ensures the equipment runs smoothly. Preventative measures not only extend the lifespan of the machine but also improve safety during use.

Following a detailed maintenance schedule allows for timely identification of potential problems. This approach ensures that all mechanical and structural elements are in top condition, which in turn enhances overall productivity and reduces the risk of long-term damage.

John Deere 261 Grooming Mower Repair Manual

Maintaining equipment to ensure optimal performance is essential for long-term functionality. Proper upkeep can prevent common issues, extend the lifespan, and ensure efficient operation. Understanding the intricacies of the machinery and addressing any arising problems promptly can save significant time and effort.

Routine inspections and component assessments are crucial to detect early signs of wear. Regularly examining key parts helps identify potential failures before they escalate. Paying close attention to signs like unusual vibrations or changes in operation will provide insight into the machine’s condition.

When performing preventive maintenance, thorough cleaning and lubrication of moving parts should not be overlooked. Dirt and debris accumulation can hinder movement and cause premature wear, while proper lubrication ensures smoother functioning. Additionally, securing bolts and tightening loose connections will help maintain stability during use.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure machinery runs smoothly and maintains its efficiency over time. By following a consistent maintenance routine, you can extend the lifespan of the equipment and avoid unexpected issues. Here are some practical suggestions to keep your machine in peak condition and maximize its functionality.

Regular Lubrication

Applying the appropriate amount of lubricant to moving parts helps reduce friction and wear. Make sure to check the lubrication points frequently and use suitable oils or greases to keep components running efficiently. Proper lubrication not only ensures smoother operation but also helps prevent overheating and unnecessary strain on the equipment.

Inspection of Wear and Tear

Periodically examine the machinery for signs of wear, such as damaged parts or loosened bolts. Addressing these issues early can prevent more severe damage and costly repairs in the future. Tighten loose hardware and replace any worn-out elements to maintain optimal safety and functionality.

Clean After Use – To preserve the equipment’s condition, thoroughly clean it after each use. This helps prevent the buildup of dirt, grass, or debris, which can interfere with moving parts and affect performance. Use a brush or compressed air to reach difficult areas and ensure the machinery is free from obstructions.

Check for Proper Adjustments – Regularly inspect the settings and alignments of the machine. Incorrect adjustments can le

Common Issues and Their Solutions

Over time, equipment used for maintaining landscapes may encounter various problems that can affect performance and efficiency. Understanding these potential issues and knowing how to address them can help extend the lifespan of the equipment and ensure consistent operation.

Frequent Mechanical Problems

- Engine Trouble: Poor performance or difficulty starting can be linked to fuel system blockages or dirty air filters. Regularly cleaning or replacing these components can prevent such issues.

- Blade Malfunctions: Blades may become dull or misaligned due to frequent use. Sharpening or adjusting them ensures a clean cut and prevents strain on the engine.

- Transmission Slips: Slipping transmission may be caused by low fluid levels or worn belts. Checking and refilling fluids or replacing damaged belts can resolve this.

Hydraulic and Electrical Issues

- Hydraulic Leaks: Leaks can arise from cracked hoses or loose fittings. Regularly inspecting these components and tightening connections helps avoid fluid loss.

- Electrical Failures: Malfunctioning electrical systems may result from corroded connections or faulty wiring. Cleaning contacts and replacing damaged wires can restore functionality.

Addressing these common issues proactively ensures reliable equipment operation and reduces the need for extensive repairs.

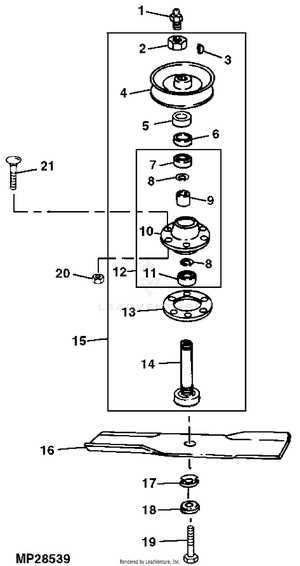

Blade Sharpening and Replacement Guide

Maintaining sharp and properly balanced blades is crucial for ensuring efficient cutting and prolonging the equipment’s lifespan. Regular sharpening or replacing the blades can significantly improve performance and prevent uneven cuts or damage to the grass. This section outlines the steps for sharpening, balancing, and replacing blades to keep your equipment operating smoothly.

Steps for Sharpening Blades

To sharpen the blades, begin by safely removing them from the machine. Secure the blade in a vise to prevent movement during sharpening. Use a metal file or a grinding tool to sharpen the cutting edge, following the original angle of the blade. Make smooth, even strokes to maintain a consistent edge. After sharpening, it is essential to check the blade balance by placing it on a balancer. If one side is heavier, file it down until the blade is balanced.

Blade Replacement Process

If the blades are chipped, bent, or too worn to sharpen, they should be replaced. When installing new blades, ensure they are aligned correctly and securely fastened. Refer to the equipment’s specifications for torque requirements and double-check for tightness to avoid any safety hazards. Always replace blades in sets to maintain balance and consistency during operation.

| Task | Tools Required | Frequency | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sharpening | Metal file, grinding tool,

Engine Troubleshooting TechniquesDiagnosing engine issues can be a challenging task, requiring careful observation and systematic approaches to identify the underlying causes of malfunctions. Understanding the symptoms and how they relate to various components allows for efficient problem-solving and helps restore optimal performance. By following step-by-step methods, one can address common problems and ensure the engine operates smoothly. Start by inspecting the fuel system, as blockages or contaminants can affect proper function. Ensuring a clean fuel flow may resolve performance inconsistencies. Additionally, check for any signs of leaks, which could indicate issues with connections or components. The ignition system is another critical area to evaluate. Examine spark plugs for wear or residue buildup, which can cause misfires or difficulty starting. Replacing damaged plugs or cleaning connections may improve the engine’s responsiveness. Also, verify the condition of electrical wiring to rule out any faults that could disrupt the ignition sequence. Finally, consider mechanical aspects, such as compression levels and valve operation. Low compression might signal worn parts, while irregular valve movement can lead to poor efficiency. Regular maintenance checks help detect these concerns early, allowing for timely adjustments or part replacements to maintain consistent engine function. Adjusting Cutting Height SettingsProperly managing the height of the cutting mechanism is essential for achieving optimal results in lawn care. The height at which grass is cut can significantly impact its health, growth, and overall appearance. Ensuring the correct settings allows for a well-maintained landscape that meets both aesthetic and functional needs. Understanding Cutting Height OptionsDifferent grass types and environmental conditions require specific cutting heights. Familiarizing yourself with the available height settings is crucial for tailoring the cutting process. Below are common height levels and their benefits:

Steps for Adjusting Cutting HeightsFollow these steps to modify the cutting height effectively:

Regular adjustments based on seasonal changes or grass growth can enhance the health and appearance of your lawn. Maintaining awareness of cutting height is vital for effective landscape management. Lubrication Points and Recommended GreaseProper maintenance is essential for ensuring the longevity and optimal performance of any landscaping equipment. This section highlights the critical areas that require lubrication and suggests the best types of grease to use for effective operation. Regular attention to these points will help prevent wear and enhance the efficiency of the machinery. Key Lubrication Areas

Recommended Grease TypesUtilizing the appropriate lubricant is crucial for the maintenance of equipment. Here are some recommended types of grease:

Regularly checking and replenishing grease in these areas will significantly contribute to the overall functionality and lifespan of the equipment. Replacing Drive Belt and TensioningMaintaining optimal performance in your equipment often involves the timely replacement of essential components, such as the drive belt. A worn or damaged belt can lead to decreased efficiency and increased wear on other parts. This section provides guidance on how to effectively remove the old belt and install a new one, ensuring proper tension for smooth operation. Tools and Materials Needed

Procedure for Replacement

Regular checks on the drive belt’s condition can prevent operational issues and extend the lifespan of your equipment. Ensure to consult the specifications for any unique requirements related to the model in use. Electrical System Maintenance ProceduresProper upkeep of the electrical framework in your equipment is essential for optimal performance and longevity. This section outlines critical practices that ensure all components function effectively, minimizing the risk of faults and enhancing reliability. Regular checks and timely interventions are vital in preventing costly repairs and ensuring smooth operation. Routine InspectionsConducting regular inspections is the first step in maintaining the electrical system. Look for signs of wear or damage in wiring and connectors. Ensure that all connections are secure and free from corrosion. Attention to detail during these checks can identify potential issues before they escalate, saving time and resources in the long run. Component TestingTesting individual components, such as switches and relays, is crucial in assessing the system’s health. Utilize appropriate diagnostic tools to measure voltage and continuity. This process not only verifies that each part is functioning as intended but also helps pinpoint any irregularities that may affect overall performance. How to Align the Mower DeckAchieving the correct alignment of the cutting apparatus is crucial for optimal performance and even grass trimming. Proper setup ensures that the blades operate effectively, reducing wear and tear while providing a clean cut. This section outlines the necessary steps for adjusting the height and positioning of the cutting unit, allowing for efficient operation and improved results. Before starting the alignment process, gather the required tools and materials. This may include a measuring tape, leveling tool, and wrenches. Ensure the equipment is parked on a flat, stable surface to facilitate accurate adjustments.

Regularly inspecting and maintaining the alignment of the cutting apparatus will enhance its efficiency and prolong its lifespan. Following these steps ensures that the equipment operates at its best, providing a superior cutting experience. Cleaning and Storing After UseMaintaining equipment in optimal condition is crucial for its longevity and performance. Proper cleaning and storage after each session ensure that all components remain functional and free from debris that can cause wear or damage. This process not only enhances the efficiency of the machinery but also contributes to safety during its operation. Steps for Effective CleaningBegin by removing any accumulated grass clippings and dirt from the exterior surfaces. Utilize a soft brush or cloth to gently scrub areas that may have stubborn residue. For a thorough cleaning, follow these steps:

Storage RecommendationsAfter cleaning, proper storage is essential to protect the machinery from environmental factors. Store in a dry, sheltered location to avoid moisture and direct sunlight. Ensure that the equipment is placed on a flat surface to prevent any structural damage. Additionally, consider the following tips:

Safety Precautions for RepairsWhen undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the safety of any project. By following established guidelines and employing appropriate protective measures, individuals can ensure a secure environment while addressing equipment issues. Essential Protective GearUtilizing the right personal protective equipment (PPE) is vital for safeguarding oneself during maintenance activities. Recommended items include sturdy gloves to protect hands from sharp edges, safety goggles to shield eyes from debris, and hearing protection if working with loud machinery. Wearing appropriate footwear can also minimize the risk of slips and falls in the workspace. Work Area OrganizationA well-organized work area can greatly contribute to a safer environment. Ensure that tools and materials are neatly arranged and easily accessible to avoid unnecessary distractions. Keeping the floor free of clutter reduces the likelihood of tripping hazards. Additionally, ensure adequate lighting to improve visibility during tasks, allowing for better concentration and minimizing the risk of errors. Tools Needed for Mower RepairWhen it comes to maintaining lawn equipment, having the right instruments is essential for efficient and effective work. The appropriate tools not only streamline the process but also ensure safety and precision. Whether tackling minor adjustments or more extensive servicing, familiarity with the necessary gear can significantly enhance the experience. Basic Hand Tools: A reliable set of hand tools forms the foundation for any maintenance task. This includes items like wrenches, screwdrivers, and pliers. These tools are vital for loosening and tightening various components and facilitating adjustments as needed. Specialized Equipment: In addition to standard tools, certain specialized instruments are crucial for specific tasks. For instance, a torque wrench ensures that bolts are tightened to the manufacturer’s specifications, while a blade sharpening kit helps maintain cutting efficiency. Safety Gear: It is equally important to prioritize safety. Utilizing protective gear such as gloves, goggles, and ear protection can help prevent injuries during the maintenance process. Investing in quality safety equipment is a prudent decision for anyone working with machinery. Cleaning Supplies: Maintaining a clean working environment contributes to overall efficiency. Cleaning agents, brushes, and cloths are necessary for removing debris and ensuring that all components function smoothly. Regular cleaning helps prolong the lifespan of the equipment. |