Comprehensive Guide to Repairing John Deere 325 Skid Steer

This section provides essential insights into the upkeep of your versatile compact loader, ensuring optimal performance and longevity. Understanding the intricacies of maintenance can significantly enhance the efficiency of your machine, allowing it to tackle various tasks effectively.

Regular attention to key components and systems is vital for preventing potential issues. By following best practices and recommendations, operators can minimize downtime and maintain peak functionality. This guide offers a comprehensive overview of troubleshooting methods and upkeep procedures tailored specifically for your equipment.

Furthermore, embracing a proactive approach to maintenance can lead to significant cost savings over time. Utilizing this resource will equip you with the knowledge necessary to handle common challenges, ensuring that your compact loader remains in excellent working condition throughout its lifespan.

This section explores frequently encountered challenges and their corresponding signs that may indicate underlying problems with the machinery. Understanding these issues can facilitate timely troubleshooting and enhance operational efficiency.

Mechanical Failures

Several mechanical failures can arise during the use of the equipment, often characterized by specific symptoms. Operators should be vigilant and address these signs promptly to prevent further damage.

| Issue | Symptoms |

|---|---|

| Hydraulic Leaks | Fluid puddles under the machine; reduced lifting capability. |

| Engine Overheating | Unusual engine noises; warning lights; steam from the hood. |

| Starting Problems | Unresponsive ignition; clicking sounds; erratic engine cranking. |

Electrical Issues

Electrical problems may also arise, often manifesting through erratic behavior or failure to operate. Identifying these signs early can prevent more significant disruptions.

| Issue | Symptoms |

|---|---|

| Battery Drain | Frequent jump-starts needed; dimming lights. |

| Sensor Malfunctions | Inaccurate readings; warning lights; erratic machine response. |

| Faulty Wiring | Intermittent power loss; blown fuses; unusual electrical smells. |

Maintenance Practices for Longevity

Ensuring the extended life of your machinery requires a commitment to regular upkeep and attention to detail. Implementing effective maintenance routines not only enhances performance but also reduces the likelihood of costly breakdowns. By following systematic procedures, operators can keep equipment in optimal condition, ultimately extending its operational lifespan.

Key practices include regular inspections, timely servicing, and careful monitoring of fluid levels. These actions help identify potential issues before they escalate, enabling more efficient problem-solving and minimizing downtime.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Daily | Detects visible wear or damage early. |

| Fluid Level Check | Weekly | Ensures optimal performance and prevents overheating. |

| Filter Replacement | Every 250 hours | Maintains cleanliness and efficiency of operation. |

| Full Service | Annually | Comprehensive assessment and preventative measures. |

By adhering to these maintenance guidelines, operators can significantly enhance the reliability and efficiency of their equipment, ensuring it remains a valuable asset for years to come.

Step-by-Step Repair Procedures

This section provides a detailed guide for troubleshooting and fixing issues with your machinery. Following these systematic instructions will help ensure that you can effectively address common problems, enhancing performance and longevity.

-

Identify the Issue:

Begin by observing any unusual sounds or behaviors. Take note of symptoms and any warning indicators on the display panel.

-

Gather Necessary Tools:

Collect all essential tools and replacement parts. Ensure you have the following:

- Wrenches

- Screwdrivers

- Pliers

- Diagnostic equipment

-

Access the Area:

Remove any covers or panels to gain access to the components needing attention. Ensure safety measures are in place before proceeding.

-

Perform the Fix:

Follow the specific steps for the identified problem. This may involve:

- Replacing damaged parts

- Tightening loose connections

- Cleaning filters or screens

-

Reassemble the Unit:

After completing the necessary adjustments, carefully reattach any removed components. Ensure everything is secured properly.

-

Test the Functionality:

Start the machinery and observe its operation. Check for any remaining issues and ensure everything functions smoothly.

By following these comprehensive procedures, you can efficiently resolve common challenges, keeping your equipment in optimal condition.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing machinery effectively. A well-equipped toolkit can make the difference between a simple task and a complicated procedure. Understanding which instruments are necessary ensures that you can address issues promptly and efficiently.

Basic Hand Tools: A variety of hand tools should be the foundation of your kit. Wrenches, pliers, and screwdrivers in different sizes are essential for accessing various components. Having a good set of sockets can also enhance your ability to work on intricate areas.

Power Tools: Electric drills and impact wrenches significantly speed up the process of disassembly and reassembly. These tools provide the power needed to tackle stubborn bolts and screws that may be difficult to manage manually.

Diagnostic Equipment: Utilizing diagnostic devices helps identify underlying issues quickly. These tools can provide vital information about performance, allowing for targeted interventions rather than guesswork.

Safety Gear: Personal protective equipment is non-negotiable. Gloves, safety goggles, and appropriate footwear ensure that you remain safe while performing tasks, reducing the risk of injury in a demanding environment.

Investing in these essential tools will not only simplify your maintenance efforts but also extend the lifespan of the machinery you work with.

Electrical System Troubleshooting Guide

This section provides a comprehensive overview of identifying and resolving issues within the electrical framework of your equipment. Understanding the various components and their interactions is crucial for effective problem-solving.

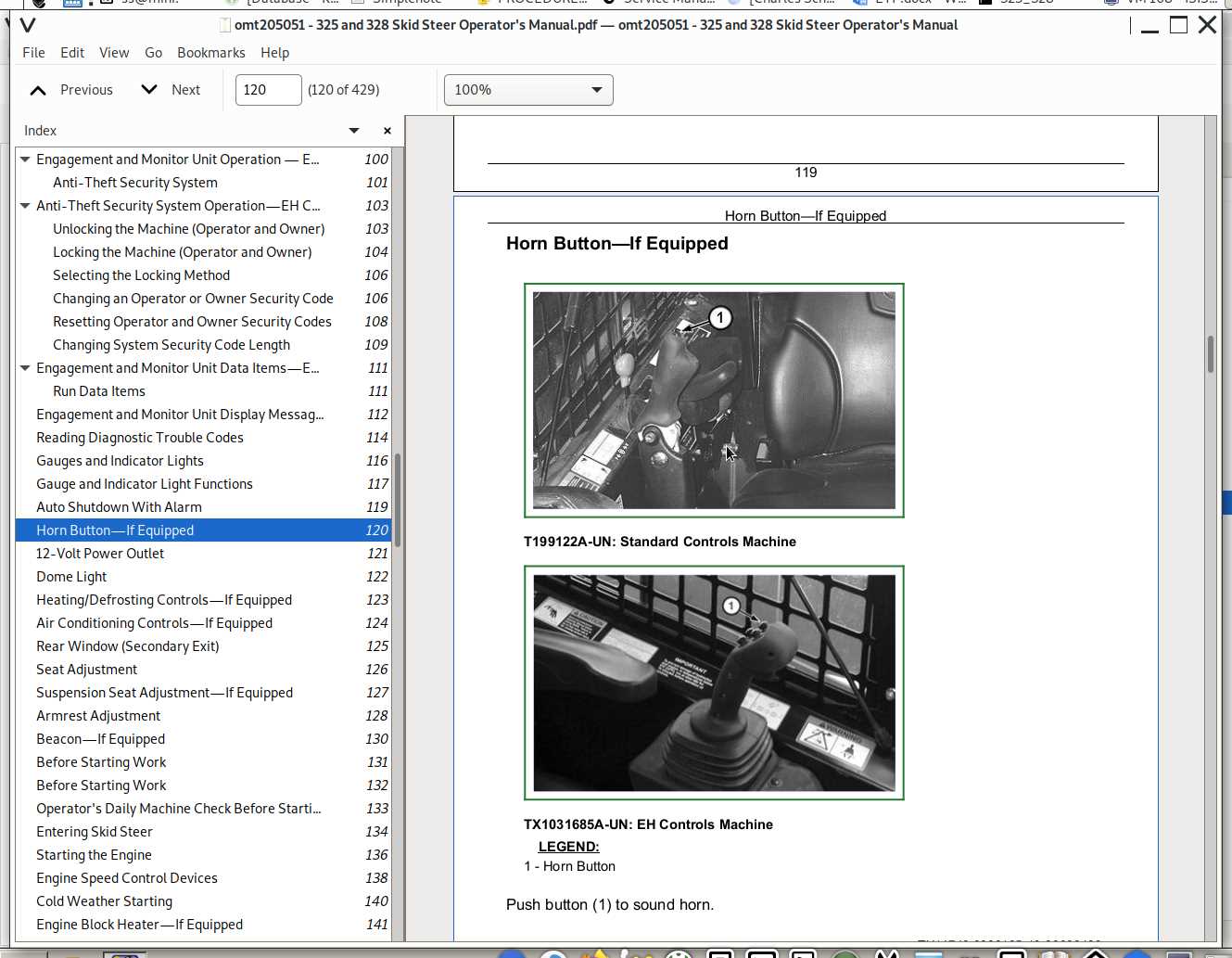

Common Symptoms: Users may encounter several indicators that suggest electrical malfunctions. These can include failure to start, intermittent operation, or warning lights illuminating on the dashboard. Recognizing these signs early can prevent more severe damage.

Initial Checks: Begin troubleshooting by inspecting the battery and connections. Ensure that terminals are clean and securely fastened. A weak or dead battery is often the root cause of many electrical issues.

Fuses and Relays: Check for blown fuses or faulty relays, as these can disrupt the flow of electricity to essential components. Replacing damaged parts may resolve the problem effectively.

Wiring Inspection: Conduct a thorough examination of the wiring harness for any signs of wear, fraying, or disconnections. Damaged wires can lead to shorts and erratic behavior in the electrical system.

Testing Components: Use a multimeter to test various electrical components, such as switches and sensors, for proper functionality. This will help identify any malfunctioning parts that may need replacement.

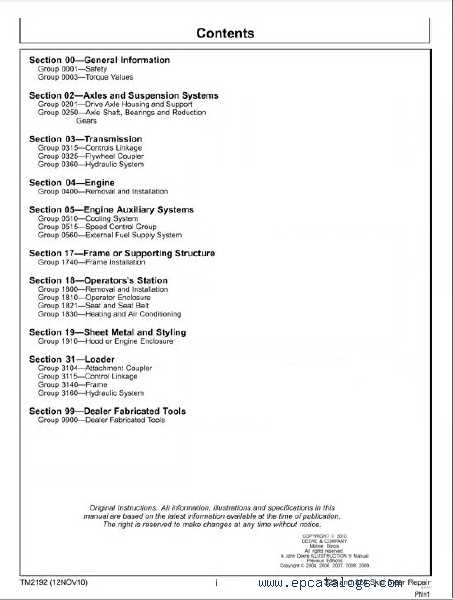

Consulting Documentation: Reference the appropriate service guides or technical documentation for specific wiring diagrams and component locations. This information can be invaluable when pinpointing issues.

By systematically following these steps, you can effectively troubleshoot electrical problems and restore functionality to your equipment.

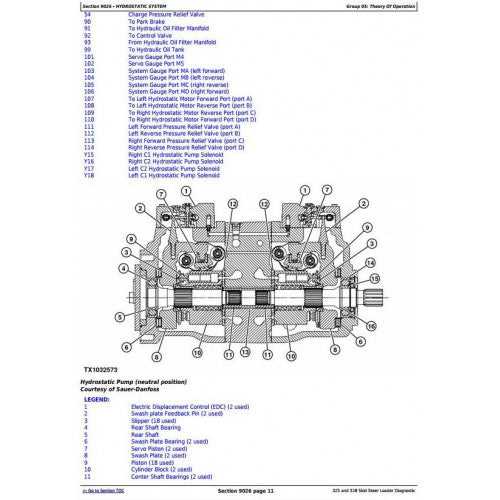

Hydraulic System Maintenance Tips

Ensuring the longevity and optimal performance of hydraulic systems is crucial for effective machinery operation. Regular upkeep can prevent costly breakdowns and enhance efficiency. This section outlines essential practices to maintain the hydraulic components of your equipment.

Regular Fluid Checks

Maintaining proper fluid levels is fundamental. Regularly inspect the hydraulic fluid for contamination and leaks. Clean fluid is vital for the system’s efficiency and helps prevent wear on internal components. Always follow the manufacturer’s recommendations for fluid types and intervals for replacement.

Inspecting Hoses and Fittings

Frequent inspections of hoses and connections can prevent unexpected failures. Look for signs of wear, cracking, or leaks. Ensure that all fittings are tight and secure, as loose connections can lead to pressure loss and inefficiencies. Replace any damaged components promptly to maintain system integrity.

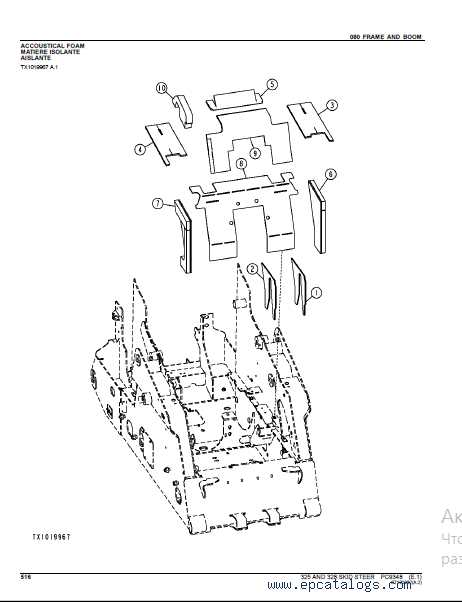

Engine Components and Care

Understanding the essential parts of an engine and their maintenance is crucial for ensuring optimal performance and longevity. Regular care and attention to these components can prevent malfunctions and enhance efficiency. This section outlines the key elements that contribute to the proper functioning of the power unit and the best practices for their upkeep.

Key Components

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and forms the core of the engine. |

| Piston | Moves up and down within the cylinder, creating pressure for combustion. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Camshaft | Controls the opening and closing of the intake and exhaust valves. |

Maintenance Tips

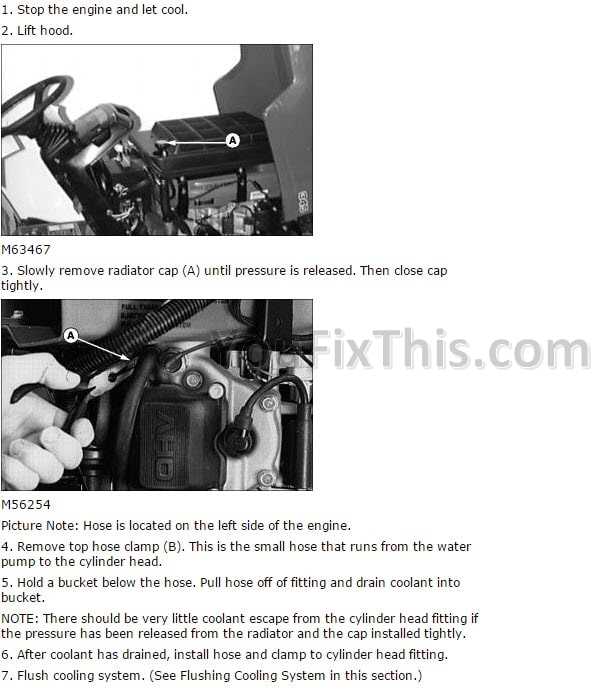

Regular inspection and maintenance of engine parts are vital. Check oil levels frequently and change the oil as recommended to ensure proper lubrication. Clean or replace air filters to maintain airflow and efficiency. Additionally, monitor the cooling system to prevent overheating, and inspect belts and hoses for wear and tear. Following these guidelines will help maintain the engine in excellent condition, enhancing its performance and lifespan.

Operational Safety Guidelines

Ensuring a secure working environment is essential when operating heavy machinery. Adhering to safety protocols minimizes risks and promotes effective operations. Operators should familiarize themselves with best practices to safeguard themselves and others while using equipment.

Pre-Operation Checks

Before commencing work, thorough inspections are crucial. Verify that all components are functioning correctly and that safety features are operational. This includes checking fluid levels, ensuring attachments are secure, and confirming that all safety gear is in place.

Safe Operating Practices

During operation, maintain a clear focus on surroundings and potential hazards. Follow guidelines for load limits and never exceed capacity. Ensure proper visibility and utilize spotters when maneuvering in tight spaces to prevent accidents.

| Safety Procedure | Description |

|---|---|

| Wear Protective Gear | Always use appropriate personal protective equipment, including helmets, gloves, and steel-toed boots. |

| Maintain Distance | Keep a safe distance from other workers and obstacles to avoid collisions. |

| Secure Loads | Ensure that all loads are properly secured before moving to prevent shifting during transport. |

| Follow Emergency Procedures | Be aware of emergency protocols and know the location of first aid kits and emergency shut-off switches. |

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and troubleshooting for a popular compact loader model. Here, you will find valuable insights that can assist users in understanding and resolving typical challenges associated with their machinery.

What should I do if my equipment won’t start?

If your machine fails to initiate, first check the battery connections for corrosion or looseness. Additionally, ensure that the fuel supply is adequate and that the ignition system is functioning correctly. If the issue persists, consulting a professional may be necessary.

How often should routine checks be performed?

Regular inspections are crucial for optimal performance. It is recommended to conduct a thorough examination at least every 50 operating hours. This includes checking fluid levels, inspecting belts, and ensuring all components are secure. Following these guidelines can prolong the lifespan of your equipment.