Comprehensive Guide to John Deere 4500 Repair Manual

This section serves as a comprehensive resource for individuals seeking guidance on the upkeep and servicing of a specific agricultural vehicle. Whether you are an experienced operator or a newcomer, understanding the essential aspects of maintaining such machinery can greatly enhance its performance and longevity.

Here, you will find valuable insights into various procedures and techniques designed to address common challenges encountered during operation. From routine inspections to detailed adjustments, the information presented aims to empower users with the knowledge needed to ensure optimal functionality and efficiency.

With clear instructions and helpful tips, this guide facilitates a better understanding of the necessary steps to keep your equipment in top condition. Emphasis is placed on practical approaches that can be easily implemented, making it an essential companion for any owner or operator looking to maximize the utility of their machine.

Overview of John Deere 4500

This section provides a comprehensive look at a well-regarded agricultural machine known for its efficiency and versatility. Designed to meet the diverse needs of users, it stands out in the field of modern farming equipment.

Key Features

- Powerful engine designed for robust performance

- Advanced hydraulic system for improved functionality

- Compact design for maneuverability in various terrains

- User-friendly controls for enhanced operational ease

Applications

- Land cultivation and preparation

- Harvesting crops efficiently

- Transporting materials across the farm

- Assisting in irrigation tasks

Key Features and Specifications

This section outlines the essential attributes and technical details of a prominent agricultural machine, designed to enhance productivity and efficiency. Understanding these aspects can aid users in making informed decisions and optimizing their operations.

- Engine Performance: Equipped with a robust power unit, ensuring reliable operation across various tasks.

- Hydraulic System: Features an advanced hydraulic system, allowing for smooth operation of attachments and implements.

- Transmission: Offers a range of transmission options, enhancing versatility and control.

- Dimensions: Compact size enables maneuverability in tight spaces while maintaining stability.

- Weight: Designed with a balanced weight distribution, contributing to effective traction and reduced soil compaction.

Additional specifications include:

- Operating capacity: Adequately handles various loads.

- Fuel efficiency: Engine optimized for reduced consumption.

- Maintenance requirements: Designed for easy access to key components.

- Operator comfort: Ergonomically designed cab with intuitive controls.

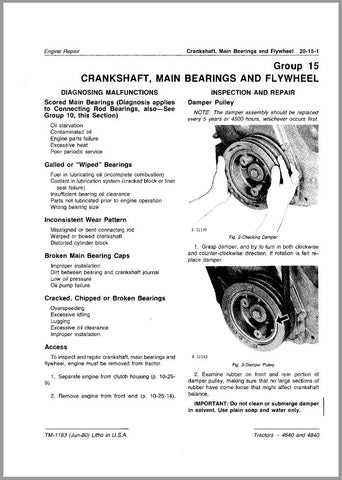

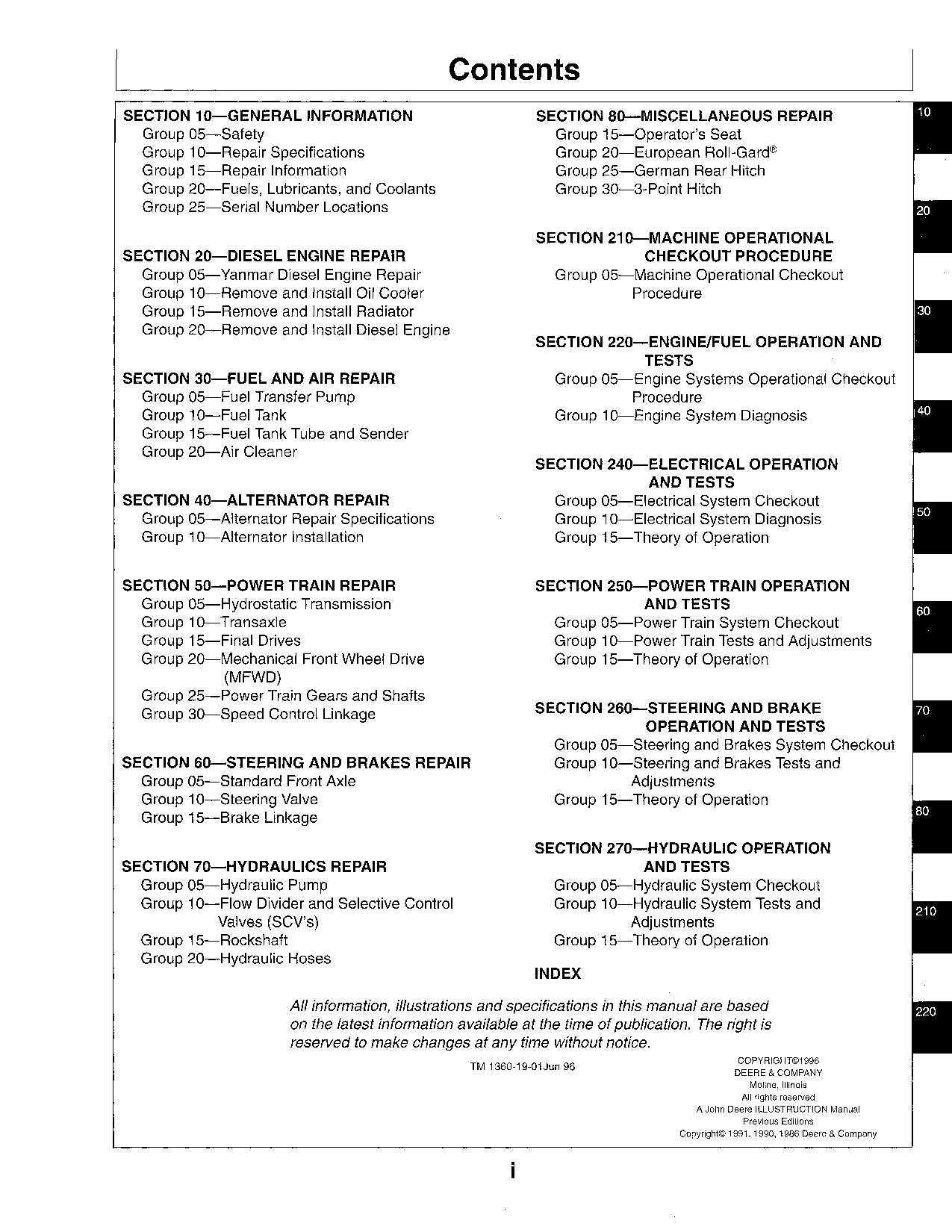

Common Issues with the Model

This section addresses frequent challenges encountered with this specific machinery, providing insights into the typical problems operators might face during its use. Understanding these issues can facilitate better maintenance and ensure efficient performance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Performance | Inconsistent power output and difficulty starting. | Check fuel supply, inspect spark plugs, and assess the air filter. |

| Hydraulic System Failure | Weak or unresponsive hydraulic functions. | Examine hydraulic fluid levels and inspect hoses for leaks. |

| Transmission Issues | Shifting problems and unusual noises during operation. | Ensure proper fluid levels and check for worn components. |

| Electrical Malfunctions | Lights or indicators not functioning correctly. | Inspect wiring connections and test the battery. |

Diagnostic Procedures for Troubleshooting

This section outlines essential strategies for effectively identifying and resolving issues that may arise in agricultural machinery. A systematic approach ensures that all potential problems are addressed, enhancing the overall performance and reliability of the equipment.

Follow these general steps to facilitate efficient troubleshooting:

- Observation:

Begin by carefully observing the machinery during operation. Note any unusual sounds, vibrations, or behaviors that deviate from normal function.

- Consult Documentation:

Refer to available resources to understand the specifications and operational guidelines. This knowledge is crucial for accurate diagnosis.

- Initial Checks:

- Inspect fluid levels, including oil, coolant, and fuel.

- Examine electrical connections for signs of wear or corrosion.

- Look for leaks or physical damage on components.

- Testing Components:

Use appropriate tools to assess the functionality of key components, such as the battery, starter, and alternator. Replace any parts that do not meet the required specifications.

- Evaluate Performance:

After making necessary adjustments or replacements, run the machinery under typical operating conditions. Monitor its performance to determine if the issues have been resolved.

By adhering to these procedures, operators can effectively troubleshoot and maintain optimal functionality of their equipment, ultimately leading to improved productivity.

Essential Tools for Repairs

When addressing maintenance tasks for machinery, having the right equipment is crucial for achieving effective outcomes. A well-equipped workspace can significantly streamline the process, ensuring that every aspect is handled efficiently and safely. Familiarizing oneself with the necessary instruments can save both time and effort in the long run.

Basic Hand Tools

Standard hand tools form the backbone of any maintenance toolkit. Wrenches, screwdrivers, and pliers are fundamental for various tasks, from loosening bolts to tightening connections. Investing in high-quality options will provide durability and reliability, enabling seamless operation during upkeep activities.

Specialized Equipment

In addition to standard tools, specific devices are often required to address unique challenges. This may include diagnostic instruments that assess functionality or replacement components tailored to the machinery. Utilizing the appropriate specialized gear can enhance precision and ensure optimal performance following service tasks.

Maintenance Schedule and Recommendations

A consistent upkeep routine is essential for ensuring optimal performance and longevity of equipment. Adhering to a structured maintenance plan not only prevents unexpected breakdowns but also enhances overall efficiency. Below are key recommendations for maintaining your machinery effectively.

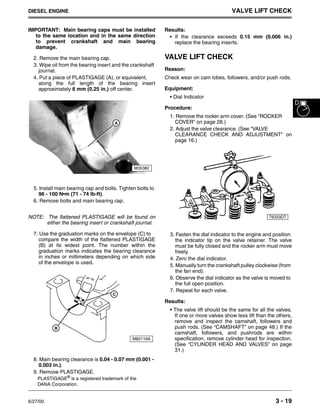

Regular Inspections

Conducting frequent evaluations of critical components is vital. Inspect filters, fluids, and belts to identify wear and tear early. This proactive approach allows for timely replacements, minimizing downtime and maximizing productivity.

Fluid Changes and Lubrication

Changing fluids at recommended intervals is crucial for maintaining engine health. Regularly check and refill oil, coolant, and hydraulic fluids. Additionally, ensure all moving parts are adequately lubricated to reduce friction and prolong equipment life.

Step-by-Step Repair Techniques

This section provides a detailed guide for addressing common issues encountered in agricultural machinery. By following these structured methods, users can efficiently diagnose problems and apply effective solutions, ensuring optimal performance and longevity of the equipment.

Diagnosis Process

Begin by thoroughly examining the equipment to identify any visible signs of wear or malfunction. Listen for unusual sounds and check for fluid leaks. Document your findings for a systematic approach to the next steps.

Execution of Solutions

Once you have identified the issue, proceed with the necessary actions. This often includes disassembling components for a closer inspection. Refer to the following table for common tasks and their corresponding tools needed:

| Task | Required Tools |

|---|---|

| Inspecting Electrical Connections | Multimeter, Wire Strippers |

| Changing Filters | Wrench Set, Oil Filter Wrench |

| Adjusting Belts | Socket Set, Torque Wrench |

Carefully reassemble any components and conduct a final check to ensure everything is functioning properly. Regular maintenance and prompt attention to issues will significantly enhance the reliability of your machinery.

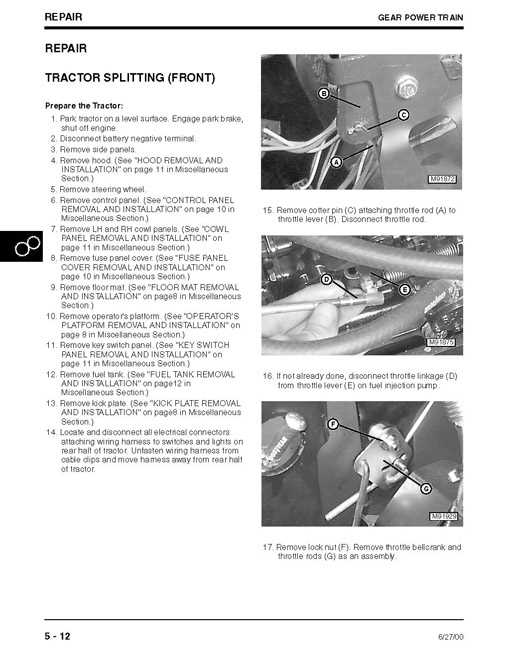

Replacing Major Components Safely

When it comes to servicing heavy machinery, ensuring the safe replacement of key parts is crucial for both performance and longevity. Following proper protocols not only protects the equipment but also safeguards the technician during the process. This section outlines essential practices for effectively handling significant component changes.

Preparation and Planning

Before initiating any replacement, thorough preparation is vital. Begin by gathering all necessary tools and components. Review the specifications and guidelines related to the machinery. Documenting the existing configuration can help avoid confusion during reassembly. Additionally, ensure that the working area is clear of obstacles to minimize risks while performing the task.

Executing the Replacement

During the actual replacement, following safety protocols is paramount. Always wear appropriate personal protective equipment (PPE), such as gloves and goggles. When removing heavy components, utilize lifting aids to prevent strain or injury. Ensure that all fasteners are correctly tightened during reinstallation to maintain structural integrity. Finally, conduct a thorough inspection before returning the equipment to service, confirming that everything is functioning as intended.

Electrical System Troubleshooting

Tackling issues within the electrical framework of agricultural machinery is essential for maintaining optimal performance. Understanding common symptoms and employing systematic techniques can greatly aid in identifying underlying problems. This section will guide you through effective diagnostic practices and solutions.

Common Symptoms

Familiarity with prevalent indicators of electrical faults is crucial. These may include inconsistent starting, dimming lights, or malfunctioning gauges. Recognizing these signs early can prevent further complications.

Diagnostic Techniques

Utilizing a multimeter to measure voltage and continuity is a vital step in troubleshooting. Inspect wiring for any signs of wear or disconnections, and ensure all connections are secure. Consulting schematics can provide clarity on the layout and functionality of the electrical system, allowing for more targeted interventions.

Hydraulic System Maintenance Tips

Proper upkeep of hydraulic systems is crucial for ensuring optimal performance and longevity of machinery. Regular attention to various components can prevent costly breakdowns and enhance efficiency. This section outlines essential practices that can help maintain a well-functioning hydraulic system.

Regular Fluid Checks

Routine inspection of hydraulic fluid levels is vital. Low fluid levels can lead to inadequate lubrication and increased wear on components. Always ensure that the fluid is clean and free from contaminants, as dirty fluid can damage the system and impair its function.

Inspecting Hoses and Connections

Frequent examination of hoses and fittings is essential for identifying signs of wear or leaks. Cracks, abrasions, or loose connections can compromise system integrity. Addressing these issues promptly can prevent fluid loss and potential system failure.

Operator Safety Guidelines

Ensuring a safe working environment is essential for anyone operating heavy machinery. Adhering to proper safety practices minimizes risks and enhances overall efficiency. This section outlines important safety principles that every operator should follow.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Familiarize yourself with the equipment’s controls and features before operation.

- Conduct a pre-operation inspection to identify any potential hazards or mechanical issues.

- Maintain a clear workspace, free of obstacles that could interfere with the machinery’s operation.

- Be aware of your surroundings and watch for other personnel in the area.

Following these guidelines helps ensure not only your safety but also the safety of those around you. Make safety a priority at all times while operating machinery.

- Always follow the manufacturer’s recommendations for operation and maintenance.

- Never operate machinery under the influence of drugs or alcohol.

- Use hand signals or communication devices to maintain clear contact with others in the vicinity.

- Stop the equipment and report any malfunction immediately.

- Stay within the designated operational limits and avoid overloading the machine.

By adhering to these safety practices, operators can significantly reduce the likelihood of accidents and create a safer working environment for everyone involved.

Finding Replacement Parts

When maintaining your machinery, sourcing the right components is crucial for optimal performance. Understanding where to locate high-quality substitutes can significantly enhance the longevity and efficiency of your equipment.

Local Dealerships often have a selection of genuine parts tailored for specific models. Visiting a nearby outlet allows for direct inquiries and the chance to consult knowledgeable staff about your needs.

Online Retailers provide a vast array of options, making it easy to compare prices and specifications. Websites dedicated to heavy machinery components can be particularly useful, often featuring customer reviews and detailed descriptions.

Salvage Yards can be a treasure trove for those seeking budget-friendly alternatives. These locations frequently stock used parts that are still in excellent condition, offering a cost-effective solution.

Finally, connecting with Online Forums or communities focused on similar equipment can yield invaluable recommendations. Members often share their experiences regarding reliable sources for parts and maintenance tips, enhancing your search.

Resources for Further Assistance

When facing challenges with your agricultural machinery, accessing the right information can make a significant difference. This section offers a variety of avenues for obtaining additional help and insights, ensuring that you can effectively address any issues that may arise.

For comprehensive guidance, consider exploring online forums and communities where enthusiasts and professionals share their expertise. These platforms often contain valuable troubleshooting tips and shared experiences that can lead to effective solutions. Additionally, many websites provide access to technical documents and specifications that can enhance your understanding of the equipment.

Another useful option is to contact local dealerships or service centers. These establishments often have knowledgeable staff who can provide assistance tailored to your specific model and its needs. They may also offer workshops or training sessions that can further enhance your skills.

Furthermore, numerous books and publications are dedicated to machinery maintenance and operation. These resources can serve as excellent references for both novice and experienced users, offering detailed insights and practical advice.

By utilizing these various resources, you can ensure that you are well-equipped to handle maintenance tasks and enhance the performance of your equipment.