Comprehensive Guide to John Deere 4630 Repair Manual

In the realm of agricultural machinery, understanding the intricacies of your equipment is essential for optimal performance and longevity. Proper care and attention can significantly enhance the efficiency of your machinery, ensuring that it operates at peak capacity. This section delves into the critical aspects of upkeep and problem-solving techniques that every operator should be familiar with.

Maintaining high standards of functionality requires a systematic approach to identifying and addressing potential issues. This includes a thorough examination of components and systems, which is crucial for preventing costly breakdowns. Operators are encouraged to familiarize themselves with various procedures that can assist in diagnosing common complications and implementing effective solutions.

Moreover, being equipped with the right knowledge can empower users to tackle challenges confidently. By following established protocols and leveraging detailed information, you can ensure that your machinery remains reliable and ready for the demands of daily tasks. This guide serves as a valuable resource, offering insights that enhance both understanding and capability in machinery management.

Understanding the John Deere 4630

This section delves into the intricacies of a particular agricultural machinery model, focusing on its features, functionalities, and common issues. Grasping the fundamentals of this equipment is essential for optimal performance and longevity. Operators and technicians alike will benefit from an in-depth understanding of its components and maintenance requirements.

Key Features and Specifications

This machine is renowned for its robust design and efficiency. It boasts a powerful engine that ensures high productivity, making it a reliable choice for various farming tasks. The hydraulic system plays a crucial role in enhancing performance, enabling seamless operation with attachments and implements. Moreover, its user-friendly controls facilitate ease of use, even for those new to operating such machinery.

Common Challenges and Solutions

While this equipment is built to withstand rigorous conditions, users may encounter specific challenges over time. Issues such as fuel system clogs, electrical faults, and hydraulic leaks can arise. Recognizing these potential problems early can save time and resources. Implementing regular checks and adhering to maintenance protocols can significantly mitigate these issues, ensuring that the machinery operates efficiently.

Understanding this equipment’s nuances not only enhances operational effectiveness but also contributes to safe and responsible usage in the field.

Key Features of the 4630 Model

This model stands out in the agricultural machinery landscape due to its robust design and advanced capabilities. It combines power, efficiency, and user-friendly features, making it a reliable choice for various farming tasks.

Performance and Power

- Equipped with a high-output engine that ensures optimal performance across different terrains.

- Advanced transmission system provides smooth gear shifting, enhancing operational efficiency.

- Strong hydraulic capabilities allow for seamless attachment of various implements.

User Comfort and Convenience

- Spacious cab design offers excellent visibility and reduces operator fatigue during long working hours.

- Intuitive control layout facilitates ease of use, making it accessible for both seasoned operators and newcomers.

- Efficient climate control system ensures a comfortable working environment, regardless of weather conditions.

Common Issues Faced by Owners

Many individuals encounter a range of challenges while operating their agricultural machinery. Understanding these frequent problems can aid in better maintenance and enhance overall performance.

- Hydraulic System Failures:

Issues with the hydraulic system can lead to decreased efficiency and functionality. Common symptoms include:

- Slow response time

- Unusual noises during operation

- Fluid leaks

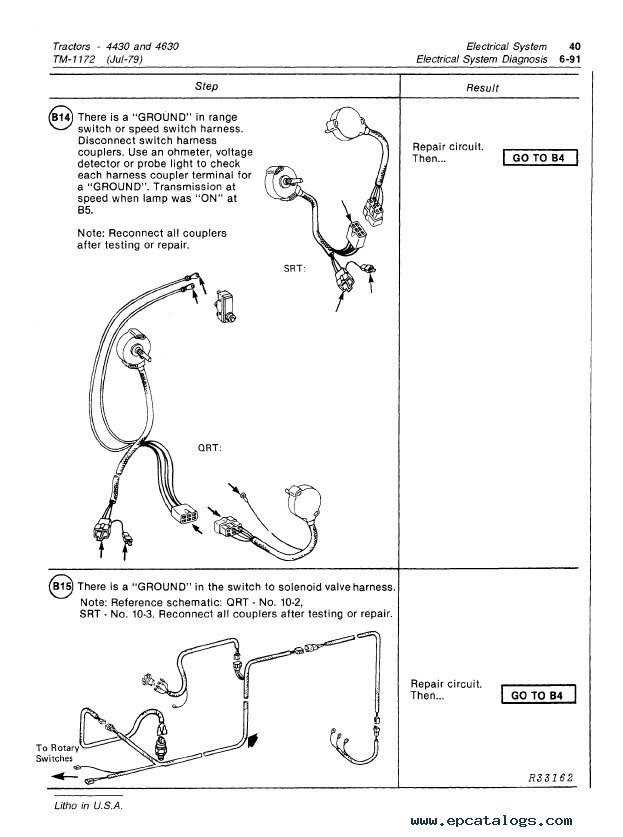

- Electrical Problems:

Electrical malfunctions can disrupt operations and may present in various forms:

- Faulty wiring connections

- Malfunctioning starter motor

- Dashboard warning lights

- Engine Performance Issues:

Engine-related complications can severely impact productivity. Common indicators include:

- Difficulty starting

- Excessive smoke from the exhaust

- Unusual vibrations during operation

- Transmission Difficulties:

Transmission problems can hinder mobility and efficiency. Symptoms often include:

- Slipping gears

- Unresponsive shifting

- Unusual noises when changing gears

By recognizing these common issues, owners can take proactive steps to maintain their equipment, ensuring reliable performance for years to come.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your machinery requires consistent care and attention. Regular maintenance not only extends the lifespan of the equipment but also enhances its reliability in demanding tasks. Here are essential practices to consider for optimal upkeep.

- Regular Inspections: Conduct thorough checks to identify any wear and tear early. Pay attention to critical components like the engine, transmission, and hydraulic systems.

- Fluid Changes: Change oils and fluids as recommended. Fresh fluids prevent contaminants from causing damage and ensure smooth operation.

- Filter Maintenance: Replace air, oil, and fuel filters regularly to maintain optimal performance and prevent blockages.

- Tire Care: Regularly inspect tires for proper inflation and tread wear. Rotate and replace them as necessary to ensure stability and efficiency.

Incorporating these strategies into your routine can significantly improve performance and longevity. Consider scheduling maintenance tasks to align with operational downtime for maximum efficiency.

- Cleaning: Keep the exterior and interior clean to prevent buildup of dirt and debris. This not only maintains aesthetics but also prevents overheating.

- Storage: Store equipment in a sheltered location to protect it from harsh weather conditions. Use covers if stored outdoors.

- Operator Training: Ensure that all operators are well-trained in the correct usage and handling of the machinery to avoid misuse and accidents.

By following these maintenance tips, you can help ensure your equipment remains in peak condition, ready to meet the challenges of any job.

Essential Tools for Repairs

When it comes to maintaining machinery, having the right equipment is crucial for ensuring efficiency and longevity. Whether tackling routine maintenance or addressing specific issues, a well-equipped toolkit can make all the difference in achieving optimal performance.

Basic Toolkit Components

A comprehensive toolkit should include a variety of instruments designed for different tasks. Below are the essential items every technician should consider:

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening and tightening bolts and nuts. |

| Screwdrivers | Essential for fastening and removing screws. |

| Pliers | Helpful for gripping and twisting wires or small objects. |

| Socket Set | Provides various sizes for efficient fastening of different fasteners. |

| Torque Wrench | Ensures bolts are tightened to the specified torque level. |

Specialized Equipment

In addition to basic tools, certain specialized equipment can enhance repair capabilities. These instruments help in diagnosing issues and making precise adjustments:

| Tool | Purpose |

|---|---|

| Multimeter | Measures voltage, current, and resistance for electrical troubleshooting. |

| Oil Filter Wrench | Aids in the removal and installation of oil filters. |

| Diagnostic Scanner | Interfaces with machinery to read error codes and performance data. |

| Jack and Stands | Allows safe lifting of machinery for undercarriage access. |

| Cleaning Supplies | Essential for maintaining a clean workspace and ensuring optimal performance. |

Step-by-Step Repair Procedures

This section outlines a systematic approach to address various mechanical issues that may arise with agricultural machinery. By following a structured process, operators can ensure effective troubleshooting and resolution of common problems.

Begin by identifying the symptoms of the malfunction. Gather necessary tools and materials before proceeding to disassemble the components that require attention. It’s crucial to document each step, noting any specific adjustments or replacements needed during the process.

Next, inspect each part meticulously for wear and damage. Cleaning components is essential, as it helps in assessing their condition more accurately. Replace any faulty elements with appropriate parts, ensuring they match the specifications required for optimal functionality.

Once the repairs are made, reassemble the machinery carefully, following the reverse order of disassembly. Check all connections and fittings to prevent leaks or malfunctions. Finally, conduct thorough testing to confirm that the issues have been resolved and the equipment operates smoothly.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is paramount. Proper precautions can prevent accidents, protect both the individual and the equipment, and promote a productive environment. Adhering to safety guidelines helps mitigate risks and ensures that all operations proceed smoothly.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and steel-toed boots.

- Ensure the work area is well-lit and free from clutter to avoid tripping hazards.

- Disconnect the power source before beginning any servicing to prevent unexpected starts.

- Use tools and equipment as intended, following the manufacturer’s instructions closely.

Emergency Preparedness

- Familiarize yourself with the location of emergency shut-off switches and first aid kits.

- Have a clear emergency plan in place, including contact numbers for medical assistance.

- Report any hazards or unsafe conditions to the supervisor immediately.

By implementing these safety precautions, individuals can significantly reduce the likelihood of accidents and create a safer work environment during maintenance tasks.

Finding Genuine Replacement Parts

When it comes to maintaining the efficiency and longevity of your machinery, sourcing authentic components is crucial. Using original parts ensures optimal performance, reliability, and compatibility, ultimately saving time and costs associated with frequent repairs. This section will guide you on how to locate and acquire these essential items effectively.

Benefits of Using Authentic Components

Opting for genuine parts offers numerous advantages. Firstly, they are designed specifically for your equipment, guaranteeing a perfect fit and superior functionality. Secondly, authentic components often come with warranties, providing peace of mind regarding their quality. Lastly, using original parts helps maintain the resale value of your machinery.

Where to Find Genuine Parts

To locate authentic replacement components, consider the following options:

| Source | Description |

|---|---|

| Authorized Dealers | These vendors are certified to sell genuine parts and often provide expert advice on the best options for your machinery. |

| Manufacturer’s Website | Many manufacturers have online catalogs where you can browse and order original components directly. |

| Reputable Online Retailers | Look for trusted e-commerce platforms that specialize in equipment parts, ensuring they offer authenticity guarantees. |

| Local Repair Shops | Many repair services stock genuine parts and can help you identify the right components for your needs. |

By exploring these avenues, you can ensure that you are investing in quality parts that will support the efficiency and durability of your equipment for years to come.

Utilizing Online Repair Resources

In the digital age, accessing information for machinery maintenance has never been easier. Numerous online platforms offer valuable insights, tutorials, and community support, allowing users to troubleshoot and fix issues with their equipment efficiently. Leveraging these resources can significantly enhance the repair process, saving both time and money.

Websites dedicated to equipment support often host extensive databases filled with guides and troubleshooting tips. These sites are designed to cater to both novice and experienced operators, ensuring that everyone can find relevant information tailored to their needs. Utilizing search functions and categorization helps streamline the process of locating specific content.

Video tutorials are another powerful resource, providing step-by-step demonstrations that can clarify complex procedures. By watching experienced professionals tackle various challenges, users gain practical knowledge that can be applied directly to their own projects. This visual format can be particularly beneficial for those who prefer hands-on learning.

Forums and online communities also play a crucial role in problem-solving. Engaging with fellow enthusiasts and experts allows users to ask questions, share experiences, and gain insights that may not be available through traditional manuals. Building connections within these communities fosters a collaborative atmosphere where knowledge is freely exchanged.

Lastly, social media platforms have emerged as valuable tools for accessing tips and advice. Following relevant pages or groups can provide a continuous stream of information, updates, and expert recommendations. By staying connected, users can remain informed about the latest trends and solutions in machinery upkeep.

Comparing Repair Costs Effectively

When maintaining heavy machinery, understanding expenses is crucial for effective budgeting and planning. By evaluating different service options and parts, operators can make informed decisions that enhance performance while managing financial outlays. A strategic approach to comparing costs allows for more efficient resource allocation and better long-term maintenance strategies.

Assessing Parts and Labor Expenses

To accurately gauge total expenses, it’s important to break down both component and labor charges. Researching various suppliers for components can reveal significant price differences, while obtaining quotes from multiple service providers ensures competitive labor rates. Documenting these expenses will facilitate better comparisons and promote cost-effective choices.

Evaluating Long-Term Value

While initial costs are essential, considering the longevity and reliability of parts and services is equally important. Investing in higher-quality components may result in reduced maintenance frequency and lower long-term costs. Analyzing the total cost of ownership, including potential downtime and repair frequency, will provide a clearer picture of true value.

Owner Experiences and Testimonials

This section aims to share insights and reflections from individuals who have had firsthand experience with their machinery. Their narratives often highlight the challenges faced and the solutions discovered through practical use, offering valuable lessons to current and prospective owners.

Many users express appreciation for the reliability of their equipment, noting that it has significantly contributed to their productivity. One owner mentioned, “This machine has never let me down during crucial farming seasons.” Such feedback underscores the importance of dependability in agricultural operations.

However, some have encountered issues that required attention. A farmer shared, “I had to address a few minor setbacks, but the troubleshooting guides were incredibly helpful.” This highlights the necessity of accessible resources and support for effective maintenance.

Additionally, testimonials often reflect on the value of community and shared knowledge. An experienced operator stated, “Connecting with other users helped me learn shortcuts and techniques that improved my workflow.” This emphasizes the benefit of networking among owners to enhance overall experience.

Where to Seek Professional Help

When faced with mechanical challenges, finding expert assistance can significantly enhance the restoration process. It’s essential to know the right resources to turn to for reliable support, whether you’re dealing with complex issues or routine maintenance.

Authorized Service Centers

One of the most dependable options for professional assistance is visiting authorized service centers. These facilities employ technicians who are specially trained and possess in-depth knowledge of various equipment models. Utilizing their services ensures that your machinery receives the proper care and genuine parts, maximizing performance and longevity.

Local Mechanics and Repair Shops

If you’re seeking more personalized service, consider reaching out to local mechanics or specialized repair shops. These establishments often offer tailored solutions and may be more flexible in terms of scheduling and pricing. Look for those with good reputations and customer reviews to ensure you receive quality assistance.

Regardless of the path you choose, prioritizing professional help can lead to more effective and efficient outcomes in your equipment maintenance journey.