Comprehensive Guide to Repairing John Deere 5065E

Maintaining heavy equipment is essential for ensuring optimal performance and longevity. This section delves into the various aspects of upkeep for a specific model, highlighting key components and procedures necessary for effective servicing. Proper knowledge and application of maintenance techniques can significantly enhance the functionality of agricultural machinery.

Users will discover the importance of regular inspections, troubleshooting common issues, and executing necessary adjustments to maintain peak efficiency. Emphasis will be placed on understanding the operational characteristics and mechanical systems involved, allowing operators to identify potential problems before they escalate.

Additionally, this guide offers detailed instructions for conducting routine tasks, ensuring that the machinery remains in top condition throughout its lifespan. By adhering to these practices, owners can achieve improved performance and reduced downtime, ultimately leading to increased productivity in the field.

Understanding John Deere 5065E Features

The model in question is designed with a range of attributes that enhance functionality and efficiency for various agricultural tasks. Its robust construction and advanced engineering make it suitable for demanding environments, ensuring optimal performance for operators.

Key Functionalities

This machine boasts an impressive array of capabilities, including powerful engine performance and excellent torque characteristics. Versatility is a hallmark of this unit, allowing it to tackle numerous attachments and implements, thereby expanding its usability across different farming operations.

User-Friendly Design

The design incorporates ergonomic elements that promote ease of use. Intuitive controls and a spacious operator station enhance comfort during extended periods of operation, making it a preferred choice for many users in the field.

Common Issues with John Deere 5065E

This section explores prevalent challenges faced by operators of a specific model of agricultural machinery. Understanding these issues can help in diagnosing problems early and maintaining optimal performance. Knowledge of these common malfunctions is essential for ensuring smooth operation and longevity of the equipment.

Engine Performance Problems

One of the frequent concerns involves engine efficiency. Operators may notice a decrease in power output or unusual noises during operation. Regular maintenance checks, including fuel system inspections and air filter replacements, can mitigate these issues and enhance overall performance.

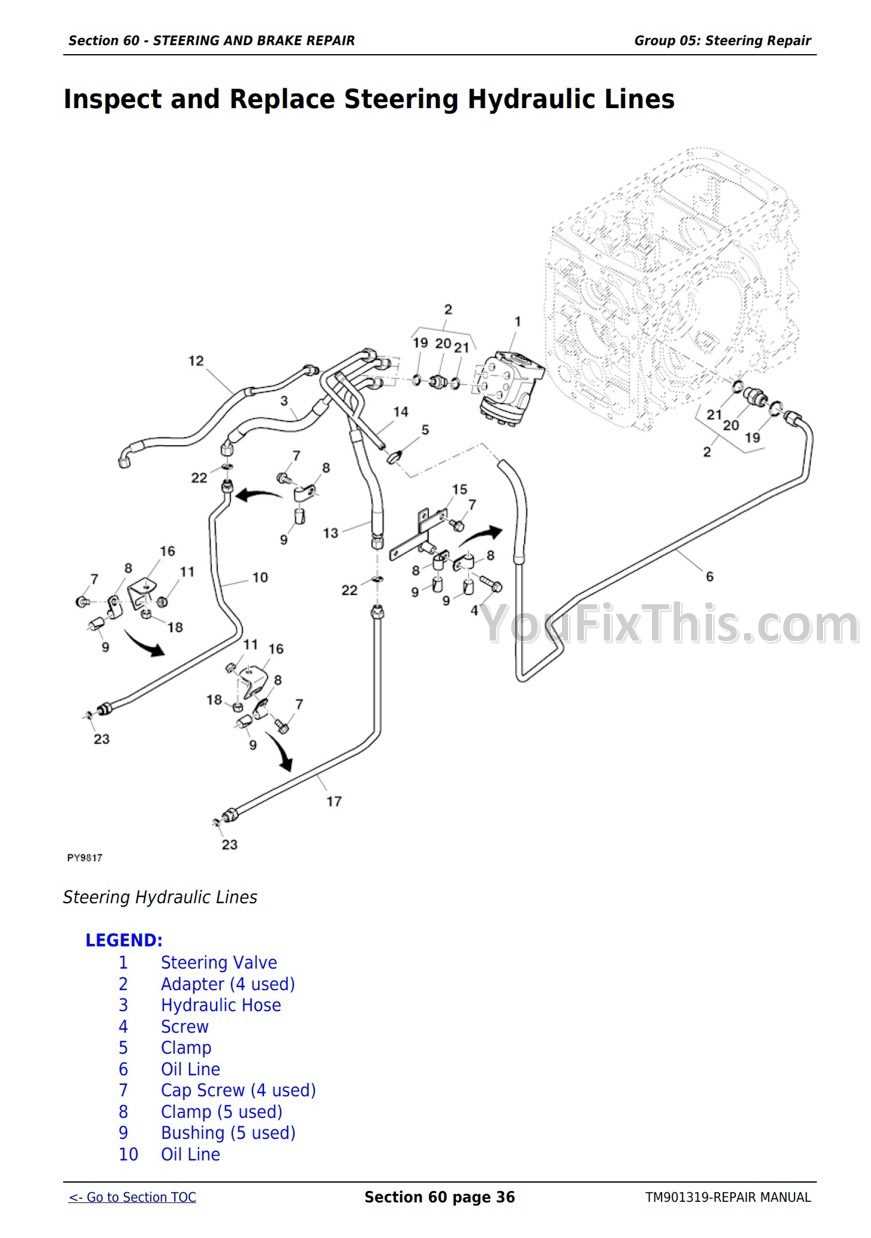

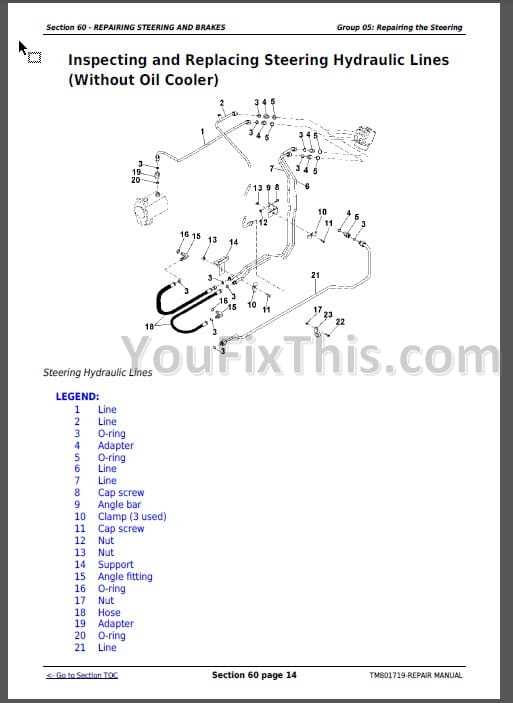

Hydraulic System Failures

Another significant area of concern is the hydraulic system. Users often report leaks or sluggish response from hydraulic components. Ensuring that seals are intact and that the fluid is at the proper level can prevent most of these complications. Regular system diagnostics can also help identify underlying issues before they escalate.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of machinery. Adopting a systematic approach to care can significantly enhance functionality and reduce the likelihood of unexpected breakdowns. This section outlines key practices that will help maintain peak operational standards.

Firstly, it is crucial to adhere to the recommended service intervals. This includes checking fluid levels, inspecting filters, and replacing worn components as necessary. Staying proactive can prevent minor issues from escalating into major repairs.

Moreover, proper cleaning should not be overlooked. Accumulated dirt and debris can hinder performance and cause premature wear. Regularly cleaning the exterior and key components helps in maintaining optimal airflow and cooling.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check oil levels | Every 50 hours | Ensure levels are within recommended range. |

| Inspect air filter | Every 100 hours | Replace if dirty or damaged. |

| Clean cooling system | Monthly | Prevent overheating issues. |

| Lubricate moving parts | Every 200 hours | Use recommended lubricants for best results. |

Implementing these guidelines will contribute to the overall reliability and efficiency of the equipment, ensuring it remains in prime condition for various tasks. Consistent maintenance ultimately leads to better performance and reduced operational costs.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues that may arise with machinery. By following a systematic method, users can identify problems efficiently, ensuring optimal performance and longevity of equipment.

1. Identify Symptoms: Begin by observing the machinery for any unusual signs, such as strange noises or performance drops. Take note of specific behaviors that deviate from normal operation.

2. Check Basics: Ensure that all fundamental components are functioning correctly. This includes examining fuel levels, fluid quality, and battery charge, as these can often be the root cause of malfunctions.

3. Consult Documentation: Refer to available resources for troubleshooting advice related to specific symptoms. Manuals and guides often provide valuable insights and recommended procedures.

4. Conduct Visual Inspection: Perform a thorough examination of the equipment. Look for signs of wear, damage, or loose connections that could contribute to operational issues.

5. Test Components: Isolate and test individual parts using appropriate tools. This step can help determine whether a specific component is faulty and requires replacement.

6. Implement Solutions: Once the problem has been identified, proceed with necessary repairs or adjustments. Follow the recommended procedures to ensure the effectiveness of the solution.

7. Monitor Performance: After completing repairs, observe the equipment during operation to verify that the issue has been resolved. Consistent monitoring can help catch any potential recurring problems early.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are completed safely and accurately. Various instruments cater to different needs, from basic adjustments to complex overhauls.

First and foremost, a comprehensive set of wrenches is indispensable for tackling various fasteners. Ratchet sets allow for quick loosening and tightening, making them ideal for both tight and accessible areas. Additionally, screwdrivers in multiple sizes and types are essential for addressing a wide range of components.

Another vital inclusion is a multimeter, which aids in diagnosing electrical issues. This device helps in measuring voltage, current, and resistance, providing valuable insights into the system’s health. Alongside this, pliers and wire cutters facilitate handling wiring tasks and securing connections.

Lastly, a reliable jack and stands are necessary for lifting and supporting machinery safely. These tools provide the stability required to perform work underneath or on elevated sections, promoting a secure working environment. Investing in high-quality equipment not only saves time but also contributes to the longevity of the machinery.

Fluid Types and Specifications

Understanding the various liquid types and their specific requirements is crucial for optimal performance and longevity of machinery. Proper selection of these substances ensures smooth operation and prevents potential damage due to incompatible materials.

Engine Oil: The choice of lubricant for the engine is vital. Look for oils that meet industry standards, ensuring adequate viscosity and thermal stability. It is recommended to follow the manufacturer’s guidelines for oil grades and change intervals to maintain peak efficiency.

Hydraulic Fluid: This type of liquid is essential for the proper functioning of hydraulic systems. Selecting a fluid that provides adequate protection against wear and corrosion is important. Ensure that the fluid complies with the required specifications to maintain optimal pressure and response times.

Coolant: The cooling system relies on a suitable mixture to prevent overheating. Using a fluid with appropriate freeze and boil-over protection is necessary to safeguard engine components. Regular checks and replacements can help avoid costly repairs.

Fuel: The type of fuel used directly affects engine performance and efficiency. It is essential to choose fuel that meets the recommended specifications for the unit, ensuring smooth combustion and reducing emissions.

Regular monitoring and maintenance of these liquids will contribute to the overall health and efficiency of the equipment, ensuring it operates effectively under various conditions.

Electrical System Overview and Issues

The electrical system in agricultural machinery plays a crucial role in ensuring optimal performance and reliability. Understanding its components and potential challenges is essential for maintaining efficiency and preventing downtime. This section provides insights into the common issues faced and the significance of proper upkeep.

Key Components

The electrical framework comprises various elements, including the battery, alternator, wiring harnesses, and electronic control units. Each part works synergistically to deliver power and control signals throughout the machine. Regular checks on these components can help identify wear and tear that may lead to malfunctions.

Common Challenges

Issues such as corroded connections, damaged wires, and failing batteries can disrupt the functioning of the system. Frequent inspections and timely repairs are vital to address these challenges. Maintaining a clean and secure environment for electrical components can significantly enhance their longevity and performance.

Engine Components and Maintenance

Understanding the vital elements of a powertrain and their upkeep is essential for optimal performance. Regular attention to these components can enhance longevity and efficiency, ensuring that the machinery operates smoothly under various conditions.

Key Components

Among the most crucial parts are the cylinders, pistons, and crankshaft, each playing a significant role in the internal combustion process. The cylinder head contains vital mechanisms for air and fuel management, while the valves regulate intake and exhaust. Routine inspections can help identify wear and tear early on.

Maintenance Practices

Implementing a systematic maintenance schedule is paramount. This includes regular oil changes, checking fluid levels, and replacing filters to keep the engine functioning efficiently. Utilizing high-quality lubricants and adhering to manufacturer recommendations can significantly enhance performance and reduce the risk of breakdowns.

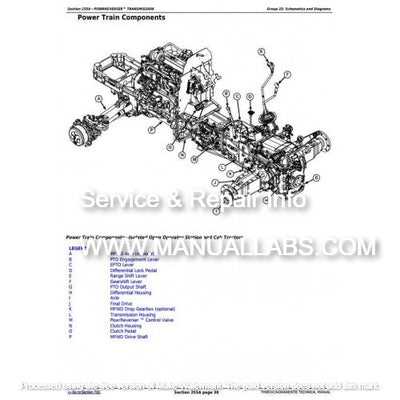

Transmission Care and Repair Techniques

Maintaining and servicing the transmission system is crucial for ensuring the optimal performance and longevity of machinery. This section outlines essential practices and strategies to effectively manage transmission components, focusing on preventative measures and troubleshooting techniques.

Regular Maintenance Practices

Consistent upkeep is vital for a smoothly operating system. Routine checks should include fluid levels, filter conditions, and the integrity of seals. Regularly replacing the transmission fluid helps in removing contaminants, while inspecting the filters ensures that the system remains clean and free from debris. Additionally, checking for leaks and wear can prevent more significant issues down the line.

Troubleshooting Common Issues

Understanding typical problems that may arise is key to effective management. Symptoms such as unusual noises, difficulty in shifting gears, or fluid discoloration should not be overlooked. Identifying the source of these issues often involves examining the linkage and the condition of the internal components. Employing diagnostic tools can aid in pinpointing faults, facilitating timely interventions and reducing downtime.

Hydraulic System Functionality Explained

The hydraulic system is a vital component that plays a significant role in the operation of machinery. It utilizes fluid under pressure to transfer power, allowing various functions to be performed efficiently and effectively. Understanding its workings is essential for maintaining optimal performance and ensuring the longevity of equipment.

This system comprises several key elements that work in unison to facilitate movement and control. Below is an overview of the primary components and their functions:

| Component | Function |

|---|---|

| Hydraulic Pump | Generates pressure by drawing fluid from the reservoir and pushing it into the system. |

| Actuators | Convert hydraulic energy into mechanical energy, enabling movement of various parts. |

| Valves | Regulate the flow and direction of the hydraulic fluid, controlling operations. |

| Reservoir | Holds hydraulic fluid, ensuring a steady supply to the pump and components. |

| Hoses and Tubing | Transport fluid between the different components of the system. |

Effective operation of the hydraulic system depends on regular maintenance and monitoring of fluid levels, ensuring all components are in good working condition. By understanding the functionality of each element, operators can troubleshoot issues more efficiently and enhance the overall performance of the machinery.

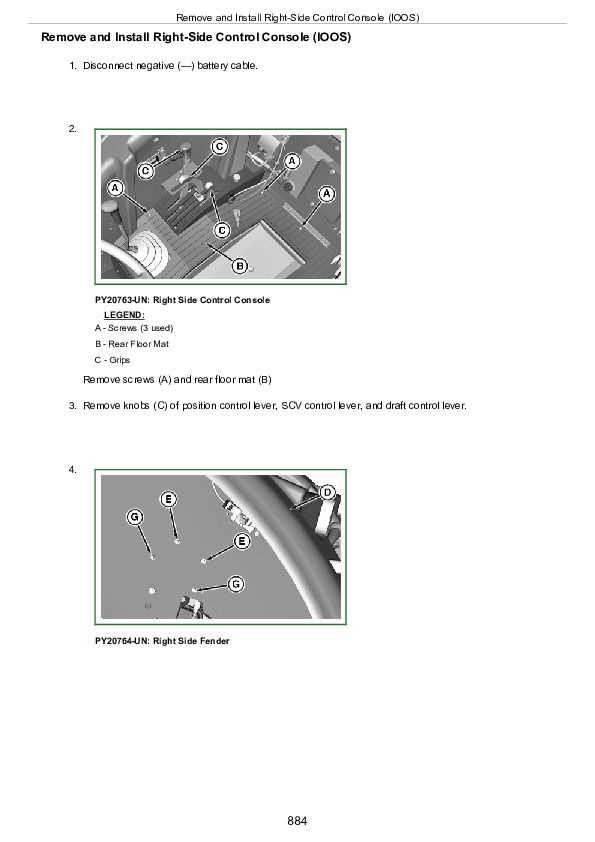

Replacing Parts: A How-To Guide

Maintaining machinery often requires the replacement of various components to ensure optimal performance. This guide aims to provide a systematic approach to swapping out parts effectively and efficiently.

Before commencing any work, it’s essential to gather the necessary tools and components. Familiarize yourself with the specific parts that need replacement and refer to your machine’s documentation for precise instructions. Below is a basic overview of the tools typically needed for such tasks:

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening or loosening bolts and nuts |

| Screwdriver | Removing screws from covers and panels |

| Pliers | Gripping and manipulating small parts |

| Jack | Raising the machine for easier access |

Once you have everything prepared, start by disconnecting any power sources to avoid accidents. Carefully remove the old component, taking note of how it is installed. This observation will help you install the new part correctly. After securing the replacement, reassemble the machine by reversing the steps taken during disassembly.

Finally, perform a thorough check to ensure everything is securely fastened and functioning as intended before resuming use. Regular maintenance and timely replacements contribute significantly to the longevity of your equipment.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance on heavy machinery. Proper precautions not only protect the individual performing the work but also enhance the overall effectiveness of the task. This section outlines essential guidelines to follow during maintenance activities to minimize risks and ensure a secure working environment.

Essential Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the equipment is turned off and securely positioned before starting any work.

- Keep work areas clean and free of obstructions to prevent accidents.

- Use tools and equipment correctly to avoid injury or damage.

Emergency Preparedness

- Familiarize yourself with emergency procedures and the location of first aid kits.

- Have a fire extinguisher readily accessible in case of emergencies.

- Report any hazards or unsafe conditions immediately to a supervisor.

By adhering to these safety measures, individuals can significantly reduce the likelihood of accidents and create a safer environment during maintenance tasks.

Resources for Further Assistance

When facing challenges with your machinery, having access to reliable resources can significantly ease the troubleshooting process. This section outlines various avenues for support that can enhance your understanding and resolution of issues.

| Resource Type | Description | Link |

|---|---|---|

| Official Support | Contact the manufacturer’s support team for expert guidance and specific inquiries related to your equipment. | Visit Support |

| Online Forums | Engage with other users in dedicated forums where you can share experiences and seek advice on common problems. | Join Forums |

| Instructional Videos | Access video tutorials that demonstrate maintenance techniques and problem-solving strategies for similar equipment. | Watch Videos |

| Local Dealers | Visit authorized dealers for professional services, parts, and expert advice tailored to your specific model. | Find a Dealer |

Utilizing these resources can empower you to effectively address any operational difficulties, ensuring your equipment remains in optimal condition.