Comprehensive Guide for John Deere 6115D Repairs

Understanding the intricacies of agricultural machinery is crucial for optimal performance and longevity. This section offers insights into the various aspects of upkeep, ensuring that the equipment operates smoothly and efficiently throughout its lifespan.

With a focus on troubleshooting and routine care, this guide aims to empower users with the knowledge needed to tackle common issues. By familiarizing yourself with the mechanisms and components, you can enhance productivity and minimize downtime.

Essential tips and procedures are outlined to assist you in navigating maintenance tasks. Regular inspections, timely interventions, and an awareness of potential challenges can significantly extend the functionality of your machinery. Emphasizing the importance of proper care can lead to sustained performance and reliability in the field.

Understanding the Repair Manual’s Purpose

A comprehensive guide serves as an essential resource for anyone involved in the maintenance and service of machinery. It provides valuable insights and instructions that help users navigate through various procedures, ensuring efficient operation and longevity of the equipment.

The significance of such a document can be outlined as follows:

- Facilitates Maintenance: Offers step-by-step guidance on regular upkeep tasks to prevent breakdowns.

- Enhances Troubleshooting: Equips users with methods to identify and resolve issues effectively.

- Promotes Safety: Emphasizes safe operating procedures and potential hazards, protecting both the user and the machine.

- Increases Efficiency: Streamlines processes by providing clear instructions, reducing downtime during repairs.

- Educates Users: Imparts knowledge about the machinery’s components and functionality, empowering users to make informed decisions.

In conclusion, such a guide is not merely a reference document; it is an invaluable tool that fosters a deeper understanding of machinery, enabling users to perform tasks confidently and competently.

Key Features of John Deere 6115D

This section highlights the essential characteristics and functionalities of a versatile agricultural machine, designed to enhance efficiency and performance in various farming tasks.

Power and Performance

The machine is equipped with a robust engine that provides significant horsepower, enabling it to tackle demanding jobs effectively. Its design ensures optimal fuel efficiency, reducing operational costs over time.

Advanced Technology

- Intuitive Controls: The user-friendly interface simplifies operation, making it accessible for both experienced operators and newcomers.

- Precision Farming: Features integrated technologies that support precision agriculture, allowing for more accurate planting and resource management.

- Safety Features: Designed with multiple safety measures, ensuring a secure working environment for operators.

Versatility and Adaptability

This agricultural machine can accommodate various attachments, making it suitable for a wide range of applications, from tillage to transportation. Its adaptability ensures it meets the diverse needs of modern farming.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of agricultural machinery. Proper tools not only facilitate the repair process but also enhance safety and efficiency, ensuring that tasks are completed swiftly and correctly.

Basic Hand Tools

- Wrenches: A variety of sizes is necessary to handle different nuts and bolts.

- Screwdrivers: Flat and Phillips head screwdrivers are essential for removing and securing screws.

- Pliers: These are useful for gripping, twisting, and cutting wires or small components.

- Hammer: A sturdy hammer is needed for various applications, including assembling parts.

Specialized Equipment

- Torque Wrench: This tool ensures that bolts are tightened to the specified torque for optimal performance.

- Diagnostic Tools: Equipment for troubleshooting electronic and mechanical issues can save time and effort.

- Jack Stands: Necessary for safely elevating machinery during inspections or repairs.

- Toolbox: A well-organized toolbox helps keep tools accessible and protected.

Common Issues with John Deere 6115D

The agricultural machine in question may encounter several frequent problems that can impact its performance and efficiency. Identifying these issues early can help prevent more severe complications and ensure smooth operation in various farming tasks.

Engine Performance: One of the most notable challenges involves engine efficiency. Symptoms such as stalling, reduced power output, or unusual noises may indicate underlying issues that require attention.

Transmission Difficulties: Operators often report complications with the transmission system. Slipping gears or unresponsive shifting can hinder productivity and may necessitate a thorough inspection.

Electrical Failures: Electrical components are also prone to malfunction. Problems like flickering lights, faulty gauges, or starting difficulties can stem from wiring issues or battery failures.

Hydraulic System Problems: The hydraulic system is crucial for various functions. Signs of leaks, reduced lifting capacity, or unresponsive controls should be addressed promptly to maintain operational efficiency.

Regular maintenance and timely intervention are key to addressing these challenges and prolonging the lifespan of the machinery.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing common issues encountered with agricultural machinery. By following structured methods, users can effectively troubleshoot and resolve mechanical problems, ensuring optimal performance and longevity of the equipment.

Initial Assessment

Begin by conducting a thorough examination of the machine. Look for visible signs of wear or damage, including leaks, unusual noises, or warning indicators on the dashboard. Document your findings, as this will guide subsequent steps in the process.

Disassembly and Inspection

Once the initial assessment is complete, carefully disassemble the relevant components. Utilize appropriate tools to avoid damage and ensure safety. Inspect each part for any signs of malfunction or excessive wear. Replace any faulty elements with compatible alternatives to maintain the functionality of the unit.

After reassembling, conduct a test run to confirm that the issues have been resolved and the machinery operates smoothly.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of machinery. Implementing a structured maintenance routine not only ensures optimal performance but also reduces the likelihood of unexpected breakdowns. By following some fundamental practices, operators can keep their equipment running smoothly for years to come.

Routine Inspections: Conducting frequent checks on key components is vital. Look for any signs of wear and tear, such as leaks, unusual noises, or loose parts. Early detection of issues allows for timely repairs, preventing more extensive damage.

Fluid Changes: Regularly changing oils and fluids is crucial for maintaining engine health. Clean fluids facilitate better lubrication, cooling, and overall efficiency. Adhere to the manufacturer’s recommendations regarding intervals for fluid changes to ensure peak performance.

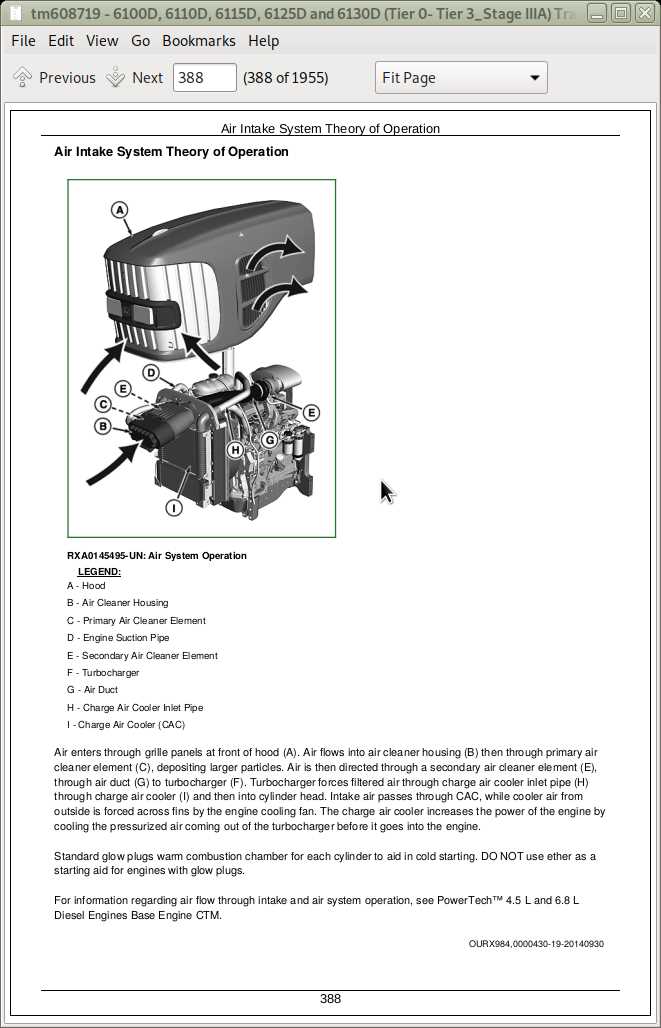

Air Filter Maintenance: Keeping air filters clean is imperative for optimal airflow and engine efficiency. Regularly inspect and replace filters as needed to prevent contaminants from entering the system, which can lead to reduced performance.

Tire Care: Maintaining proper tire pressure and tread is essential for stability and traction. Regularly check tire conditions and rotate them as per guidelines to ensure even wear and prolong their lifespan.

Storage Practices: When not in use, ensure that equipment is stored properly. Keeping it in a sheltered area protects it from environmental factors that could cause damage. Additionally, consider using covers to shield against dust and debris.

By adhering to these maintenance tips, operators can significantly extend the operational life of their machinery while ensuring reliability and performance.

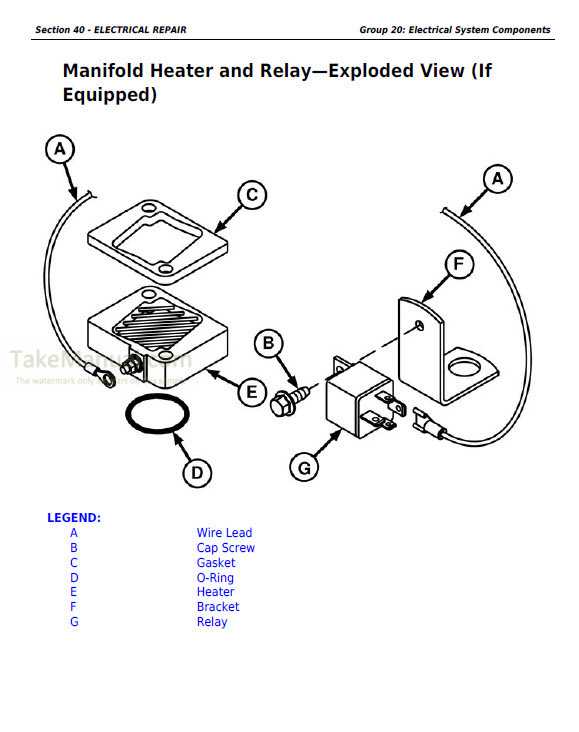

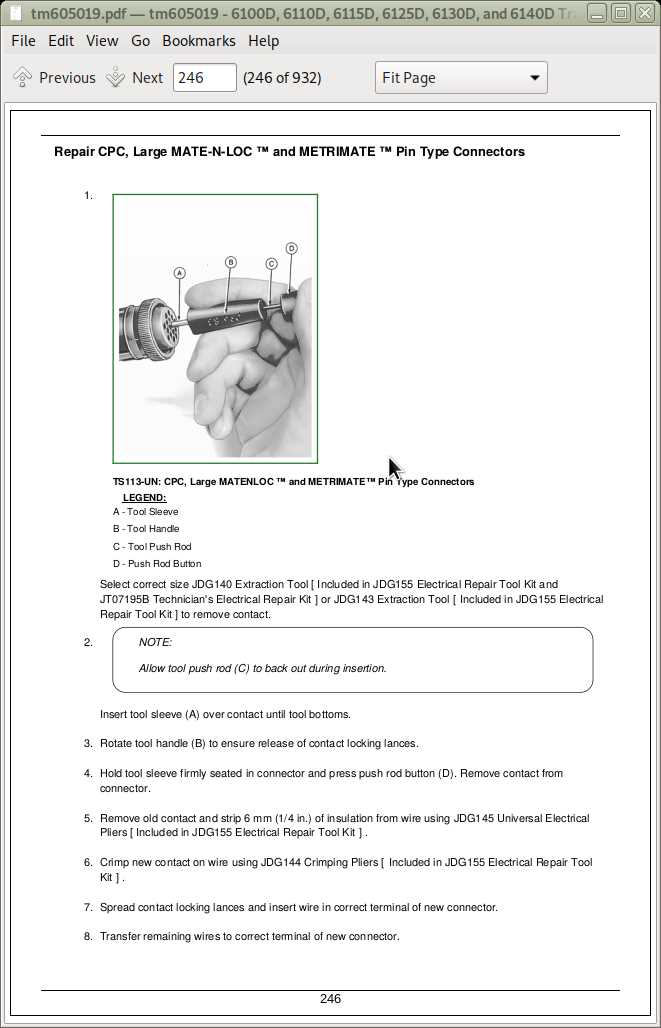

Electrical System Troubleshooting

Troubleshooting the electrical system of agricultural machinery is essential for maintaining optimal performance and preventing operational failures. Understanding the components and their functions allows for effective diagnostics and timely interventions.

Common Issues and Symptoms

Several symptoms may indicate electrical problems, such as inconsistent starting, flickering lights, or unresponsive controls. Identifying these issues early can prevent more extensive damage and reduce downtime.

Diagnostic Steps

Begin troubleshooting by inspecting the battery and connections for corrosion or loose terminals. Next, check fuses and relays to ensure they are functioning properly. Utilize a multimeter to test voltage at various points in the system. This systematic approach helps in isolating the fault.

Note: Always refer to specific technical guidelines for detailed procedures and safety precautions when working on electrical systems.

Engine Overhaul Guidelines

Performing an engine overhaul is a crucial task that ensures optimal performance and longevity of machinery. This process involves a thorough inspection and restoration of engine components to address wear and tear, improve efficiency, and extend operational life. Adhering to systematic procedures during an overhaul can significantly enhance the reliability of the equipment.

Preparation Steps

Before commencing the overhaul, it is essential to prepare adequately. This includes gathering necessary tools, securing replacement parts, and creating a clean workspace. Proper planning can prevent delays and facilitate a smoother process.

Key Components to Inspect

During the overhaul, various components must be meticulously examined. Below is a table outlining critical parts and their corresponding functions:

| Component | Function |

|---|---|

| Cylinder Head | Controls airflow and combustion within the cylinders. |

| Piston | Converts pressure from combustion into mechanical work. |

| Crankshaft | Transfers power from the piston to the transmission. |

| Valves | Regulate the intake of air and fuel, and the exhaust of gases. |

| Timing Belt | Synchronizes the movement of the crankshaft and camshaft. |

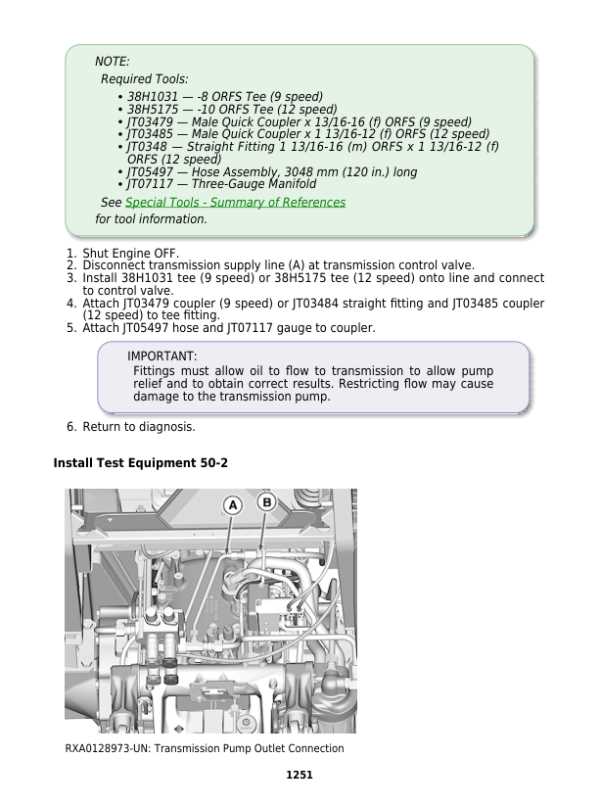

Hydraulic System Diagnostics

Effective assessment of hydraulic systems is crucial for ensuring optimal performance and longevity of machinery. Understanding the functionality and identifying potential issues within these systems can significantly reduce downtime and maintenance costs.

To carry out a thorough diagnostic evaluation, the following steps are essential:

- Visual Inspection: Begin with a comprehensive examination of the hydraulic components. Look for signs of leaks, corrosion, and wear.

- Check Fluid Levels: Ensure that the hydraulic fluid is at the recommended level, as low fluid can lead to performance issues.

- Evaluate Fluid Quality: Inspect the hydraulic fluid for contamination, discoloration, or odor. Poor fluid quality can affect system efficiency.

- Test Pressure: Utilize a pressure gauge to measure the system’s operational pressure. This helps identify any discrepancies from the manufacturer’s specifications.

- Inspect Filters: Regularly check and replace filters to prevent clogs that can impair system function.

- Listen for Abnormal Noises: Unusual sounds during operation may indicate mechanical issues or cavitation within the hydraulic system.

- Monitor System Performance: Observe the performance of hydraulic components during operation. Inconsistencies can signal underlying problems.

Implementing these diagnostic practices can help identify issues early, ensuring that the hydraulic system operates efficiently and reliably.

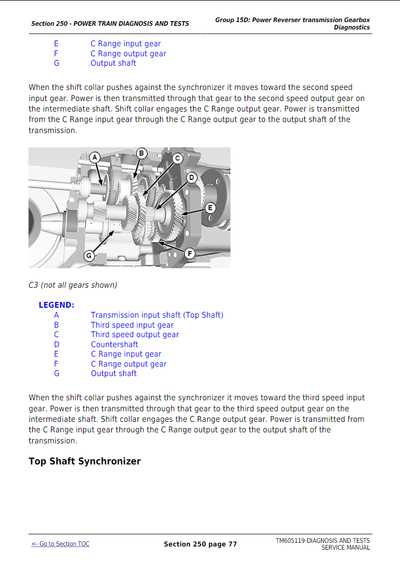

Transmission Repair Techniques

Effective techniques for addressing issues in transmission systems are essential for maintaining optimal performance and longevity. A thorough understanding of these methods can significantly enhance the troubleshooting process and streamline repairs. By employing best practices, mechanics can ensure that systems operate smoothly and efficiently.

Diagnosis and Analysis: The first step in any repair process involves a careful assessment of the transmission’s performance. Identifying symptoms such as unusual noises, slipping gears, or fluid leaks is crucial. Utilizing diagnostic tools can aid in pinpointing specific problems and determining the necessary interventions.

Disassembly and Inspection: Once issues are identified, the next phase involves the disassembly of the transmission unit. Each component should be meticulously examined for wear, damage, or misalignment. Special attention should be given to gears, seals, and bearings, as these parts are often critical to functionality.

Component Replacement: In cases where components are found to be defective, timely replacement is vital. Sourcing high-quality parts ensures compatibility and reliability. Following manufacturer specifications during this process helps maintain the integrity of the transmission system.

Reassembly and Testing: After repairs, the reassembly of the transmission must be conducted with precision. Proper alignment and torque settings are essential to prevent future failures. Following reassembly, rigorous testing under various conditions verifies the effectiveness of the repairs and ensures readiness for operation.

Safety Precautions During Repairs

Ensuring a secure working environment is crucial when performing maintenance tasks on heavy machinery. Adopting safety measures can significantly reduce the risk of accidents and injuries. It is essential to follow best practices to protect oneself and others while working with complex equipment.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is vital. This includes wearing safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges and chemicals, and steel-toed boots for foot protection. Additionally, using ear protection can help mitigate noise-related risks when working with loud machinery.

Workspace Organization

A well-organized workspace minimizes hazards. Ensure that tools and equipment are stored properly when not in use, and keep the area free of clutter. This practice not only enhances efficiency but also prevents tripping and other accidents. Always be aware of your surroundings and communicate with colleagues to maintain a safe environment.

Resources for Further Assistance

When dealing with complex machinery, having access to reliable resources can significantly enhance maintenance and troubleshooting efforts. This section outlines various avenues where users can seek additional guidance and support for their equipment.

Online Forums and Communities

Engaging with online communities can provide valuable insights and practical advice from experienced users. Consider the following platforms:

- Dedicated agricultural forums

- Social media groups focused on equipment enthusiasts

- Professional networks related to farming and machinery

Official Support Channels

Utilizing official channels ensures that you receive accurate and relevant information. Here are some recommended resources:

- Manufacturer’s website for product-specific details

- Customer service hotlines for direct assistance

- Local dealerships for in-person support and services