Comprehensive Guide to John Deere 6415 Repair Manual

In the realm of agricultural machinery, understanding the intricacies of equipment upkeep is essential for ensuring optimal performance and longevity. This section aims to provide invaluable insights into the processes involved in maintaining a specific model, focusing on the various techniques and approaches necessary for effective operation.

Whether you are a seasoned operator or new to the world of heavy machinery, having access to comprehensive guidelines can significantly enhance your ability to address common issues. By following systematic procedures and utilizing the right tools, you can ensure that your equipment remains in excellent condition, ready to tackle any challenges that arise in the field.

Furthermore, this guide will explore troubleshooting methods that can help identify and resolve potential problems swiftly. Armed with the right knowledge, users can approach maintenance with confidence, ultimately leading to improved efficiency and productivity in their agricultural endeavors.

Comprehensive Overview of John Deere 6415

This section provides a thorough examination of a popular agricultural machine, emphasizing its essential features, capabilities, and overall performance. The focus is on understanding the design principles and operational efficiencies that make this piece of equipment valuable in various farming applications.

Known for its robust construction and reliability, this model is engineered to meet the demands of modern agriculture. It offers a balance of power and efficiency, making it suitable for both heavy-duty tasks and lighter operations. With advanced technology integrated into its systems, it ensures optimal performance in various terrains and conditions.

The machine’s user-friendly interface enhances the operator’s experience, allowing for easy navigation through its functionalities. Maintenance and serviceability are designed to be straightforward, ensuring minimal downtime during critical operational periods. This aspect is crucial for those relying on consistent productivity in their farming activities.

In summary, this model stands out in the agricultural sector due to its exceptional durability, versatility, and ease of use. It represents a significant investment for farmers seeking to enhance their productivity and efficiency in field operations.

Understanding the Engine Specifications

This section delves into the crucial aspects of engine characteristics, which play a vital role in the overall performance of agricultural machinery. A thorough understanding of these specifications can significantly enhance operational efficiency and maintenance practices.

Key Specifications to Consider

- Engine Type: Knowing the type of engine helps in understanding its functionality and compatibility with various attachments.

- Horsepower Rating: This indicates the engine’s power output, essential for determining its capability in handling specific tasks.

- Torque Output: Torque is critical for performance, especially in applications requiring heavy lifting or towing.

- Cylinder Configuration: The arrangement of cylinders affects the engine’s balance and efficiency.

- Fuel Type: Identifying the appropriate fuel ensures optimal performance and longevity of the engine.

Importance of Regular Monitoring

Regular assessment of engine specifications is vital for maintaining optimal functionality. Keeping track of performance metrics can help identify potential issues before they escalate, ensuring longevity and reliability.

- Monitor oil levels and quality.

- Check coolant levels to prevent overheating.

- Inspect air filters for cleanliness.

- Regularly review performance reports.

Common Issues and Solutions

This section highlights frequent challenges encountered by users of agricultural machinery and provides effective strategies to address them. Understanding these common problems can lead to better maintenance and enhanced performance.

Below are some typical issues and their corresponding solutions:

- Engine Overheating

- Check coolant levels and top up if necessary.

- Inspect the radiator for blockages or damage.

- Ensure the fan and belt are functioning properly.

- Difficulty Starting

- Examine the battery for charge and connection issues.

- Check the fuel lines for clogs or leaks.

- Inspect the ignition system for faults.

- Poor Performance

- Clean or replace the air filter.

- Ensure proper fuel quality is being used.

- Examine the throttle and governor settings.

- Hydraulic Issues

- Check fluid levels and top up if low.

- Inspect hoses for leaks or wear.

- Ensure filters are clean and replace if necessary.

By recognizing these issues and applying the suggested solutions, users can maintain their equipment in optimal condition, ensuring reliability and efficiency in the field.

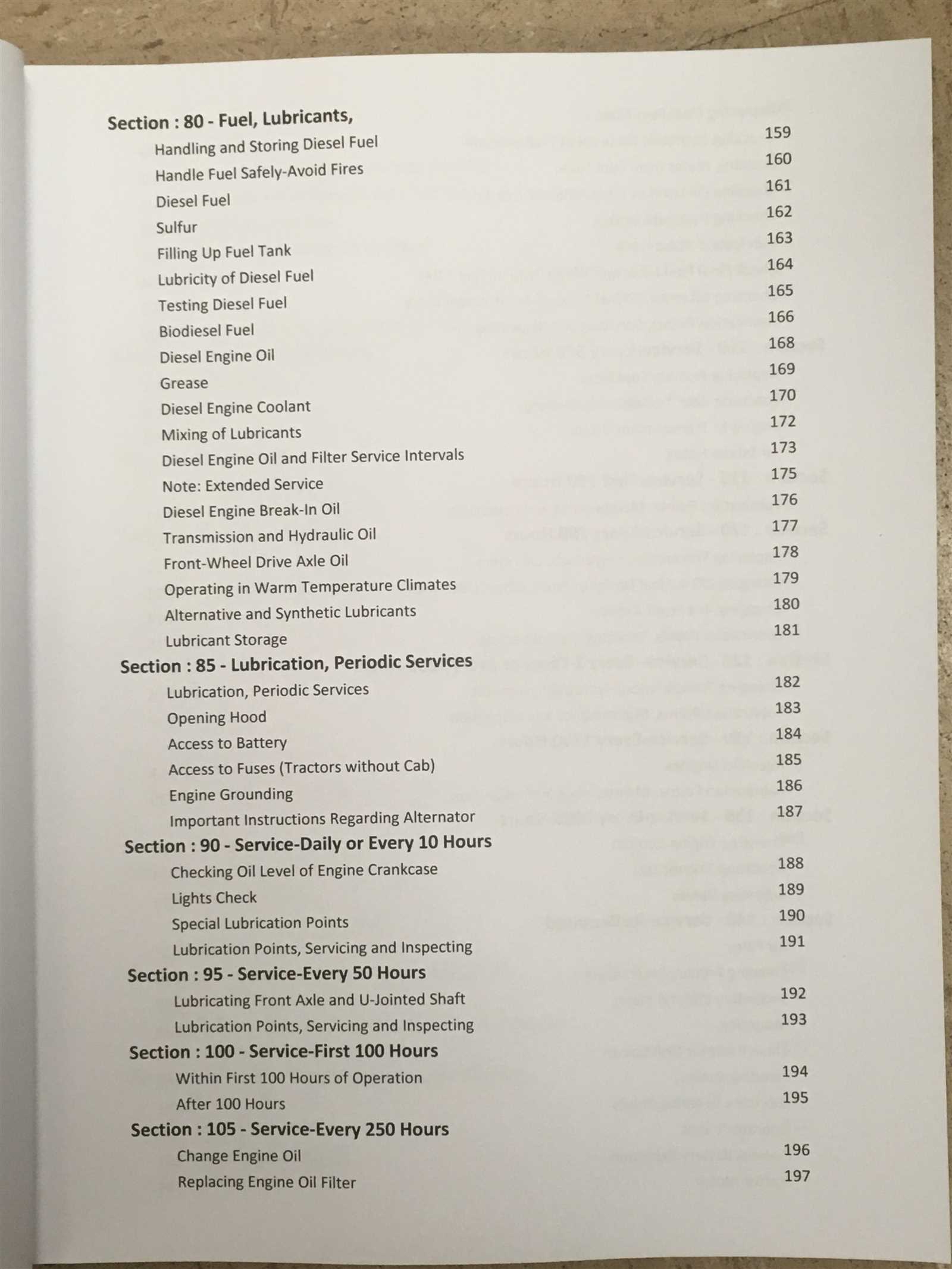

Essential Maintenance Practices

Regular upkeep is crucial for ensuring optimal performance and longevity of machinery. Implementing a consistent maintenance routine not only enhances efficiency but also prevents unexpected breakdowns. This section highlights key practices that should be adopted to maintain equipment effectively.

Routine Inspections

Conducting frequent assessments of the machinery helps identify potential issues before they escalate. Check fluid levels, belts, and filters regularly to ensure everything is functioning properly. Early detection of wear and tear can save time and resources in the long run.

Lubrication and Cleaning

Proper lubrication is essential for reducing friction and wear on moving parts. Make it a habit to apply suitable lubricants as recommended in the manufacturer’s guidelines. Additionally, keeping the equipment clean prevents dirt accumulation, which can hinder performance. Regularly clean surfaces and components to maintain optimal operation.

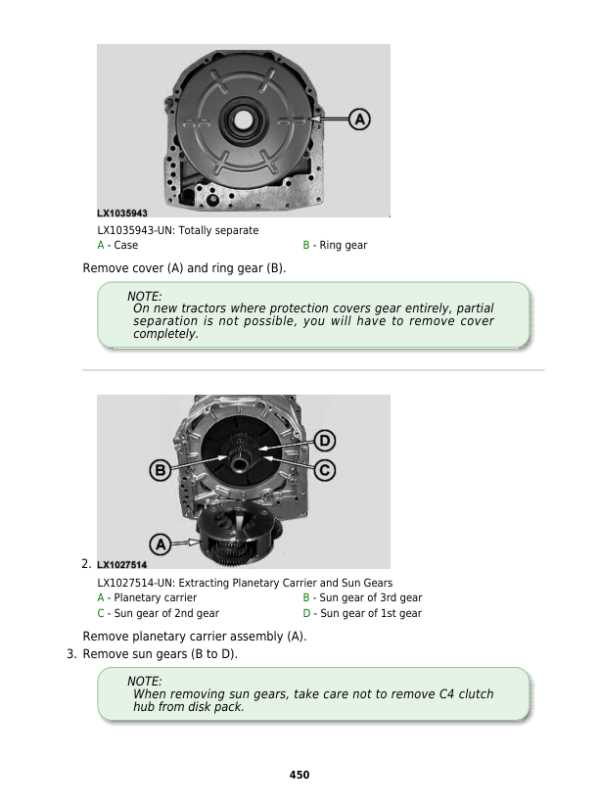

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues in agricultural machinery. By following a structured methodology, users can effectively diagnose and resolve various problems, ensuring optimal performance and longevity of their equipment.

1. Initial Assessment: Begin by inspecting the machinery thoroughly. Look for visible signs of wear or damage, and listen for any unusual sounds during operation. Document these observations to aid in the troubleshooting process.

2. Gather Necessary Tools: Before proceeding, ensure that all required tools and replacement parts are on hand. This will facilitate a smoother repair process and minimize downtime.

3. Disconnect Power Source: Safety is paramount. Always disconnect the power source before beginning any maintenance work. This step is crucial to prevent accidental injuries or equipment damage.

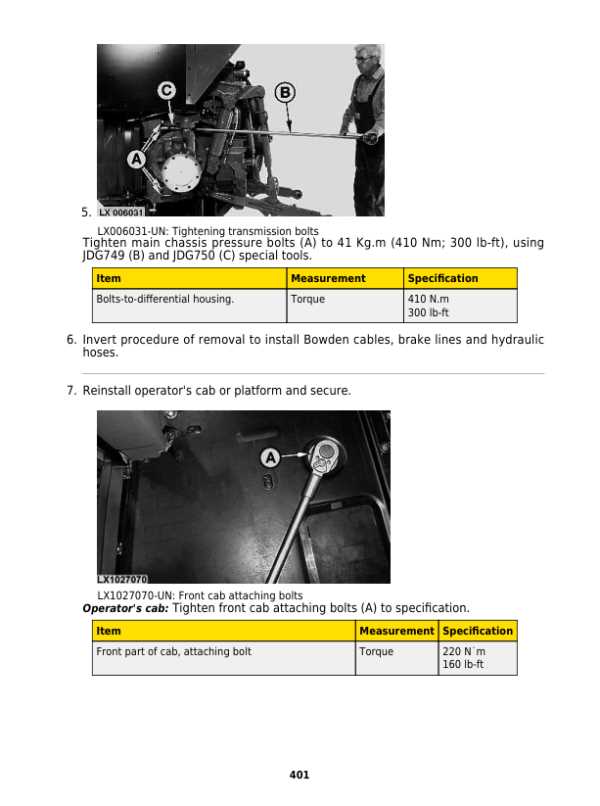

4. Follow Technical Specifications: Refer to the relevant technical specifications for guidance on disassembly and reassembly. Adhering to these guidelines will ensure that components are handled properly and maintain their integrity.

5. Replace or Repair Components: Identify defective parts and either replace them with new ones or perform necessary repairs. Ensure that all components are compatible and meet the required standards.

6. Reassemble and Test: Once repairs are complete, carefully reassemble the machinery. Conduct tests to verify that the equipment operates correctly and that the issues have been resolved.

7. Document the Process: Keep a detailed record of the steps taken, parts replaced, and any observations made during the repair. This documentation can be invaluable for future maintenance and troubleshooting efforts.

Tools Required for Effective Repairs

To ensure successful maintenance and troubleshooting, having the right equipment is crucial. The following section outlines essential implements that enhance efficiency and accuracy during the repair process.

Essential Tools

- Wrenches: Adjustable and fixed wrenches are necessary for loosening and tightening bolts and nuts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers should be on hand to accommodate different fasteners.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating small components.

- Socket Set: A comprehensive socket set facilitates the quick removal and installation of nuts and bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

Additional Equipment

- Multimeter: Useful for diagnosing electrical issues and measuring voltage, current, and resistance.

- Diagnostic Tools: Advanced devices can help identify specific problems and provide troubleshooting guidance.

- Lift Equipment: Jacks and hoists are vital for accessing lower parts safely.

- Cleaning Supplies: Brushes and degreasers help maintain a clean working environment, which is essential for effective repairs.

Safety Precautions During Repairs

When undertaking maintenance tasks on agricultural machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions should be observed to ensure a secure working environment and to protect both the individual and the equipment.

First and foremost, always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and steel-toed boots. This gear minimizes the risk of injuries from sharp objects, falling debris, and hazardous materials.

Additionally, ensure that the machinery is turned off and properly secured before beginning any work. Engaging safety locks and disconnecting the power source can significantly reduce the chance of accidental start-up.

Furthermore, maintain a clean and organized workspace. Clutter can lead to slips, trips, and falls, which are common hazards in maintenance environments. Keeping tools and parts neatly arranged will enhance safety and efficiency.

Finally, be aware of your surroundings and any potential hazards, such as moving equipment or other personnel. Communicating clearly with coworkers and using appropriate signals can help avoid misunderstandings and ensure a safer work atmosphere.

Replacement Parts and Their Sources

Finding suitable components for agricultural machinery is essential for maintaining optimal performance and longevity. Various sources provide a range of options for obtaining these parts, ensuring that equipment can be kept in peak condition. Understanding where to look for quality replacements can significantly impact efficiency and productivity.

Authorized dealers often carry original equipment manufacturer (OEM) parts, which guarantee compatibility and reliability. These suppliers typically offer a wide selection of components designed specifically for the machinery in question, ensuring that users receive high-quality replacements. Additionally, many dealers provide support and advice regarding installation and maintenance.

Aftermarket parts are another viable option, often available at a lower cost than OEM components. These alternatives can vary in quality, so it is crucial to research reputable manufacturers to ensure that the parts meet required standards. Online marketplaces and specialty retailers can be excellent sources for these alternatives, providing access to user reviews and ratings to aid in making informed choices.

For those seeking budget-friendly options, salvaged parts from reputable sources can also be considered. Disassembling machinery that is no longer in use can yield valuable components that are still functional. It is advisable to inspect these parts thoroughly to ensure they are in good condition before use.

In summary, whether opting for OEM, aftermarket, or salvaged components, understanding the available sources is key to maintaining agricultural machinery effectively. Ensuring that the right parts are chosen will contribute to the overall efficiency and reliability of the equipment.

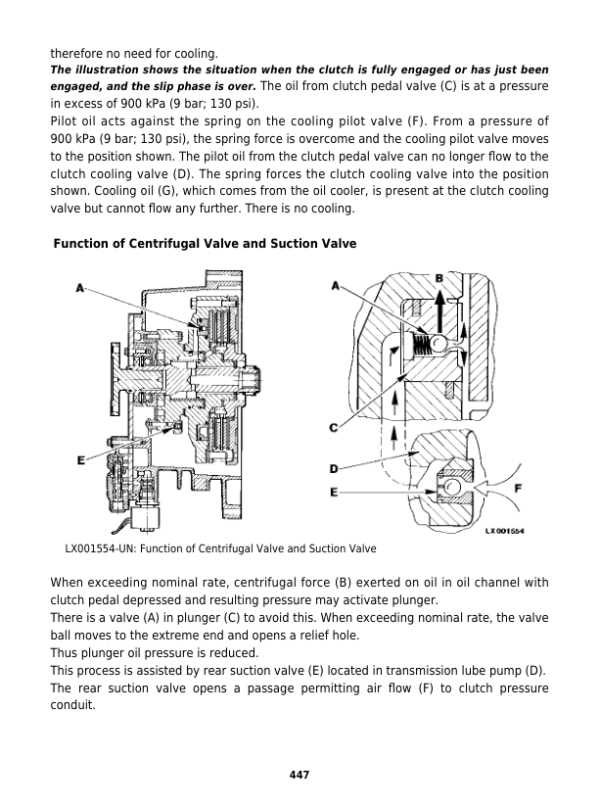

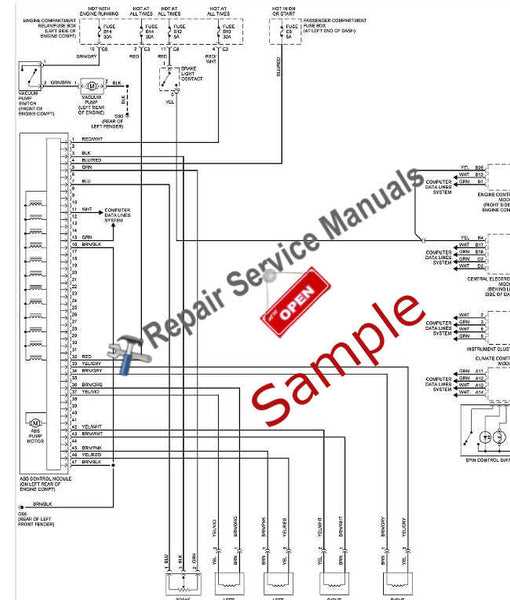

How to Troubleshoot Electrical Problems

Electrical issues can be frustrating and challenging to diagnose, often leading to unexpected equipment downtime. Identifying the root cause of these problems requires a systematic approach to isolate and address potential faults. By following a few essential steps, one can efficiently troubleshoot and resolve electrical malfunctions.

Start by inspecting all visible wiring for signs of damage or wear. Look for frayed insulation, loose connections, or corrosion, as these can significantly affect performance. Ensuring that all components are securely fastened and free from dirt or debris is crucial.

Next, utilize a multimeter to check voltage levels at various points in the circuit. This tool can help determine whether power is reaching specific components. If voltage readings are inconsistent, tracing the circuit to find interruptions or shorts is necessary.

Pay attention to any fuses or circuit breakers, as these safety devices often provide clues about underlying issues. If a fuse is blown or a breaker trips frequently, it indicates an overload or a short circuit that needs immediate attention.

Finally, consult any available diagrams or schematics for the equipment to understand the electrical layout better. This information can assist in pinpointing the exact location of the fault and guide repairs effectively.

Hydraulic System Maintenance Tips

Maintaining the hydraulic system is crucial for ensuring optimal performance and longevity of the machinery. Regular attention to this system can prevent costly repairs and enhance efficiency. This section provides essential tips to keep the hydraulic components in excellent condition.

Regular Fluid Checks

Consistently monitoring the hydraulic fluid levels is vital. Low fluid levels can lead to inadequate lubrication and increased wear on components. Ensure that the fluid is clean and at the recommended level. Replace the fluid as necessary to maintain proper system function.

Inspecting Hoses and Connections

Frequent inspection of hoses and connections is essential for identifying potential leaks or wear. Look for any signs of damage, such as cracks or bulges. Tighten any loose fittings to prevent fluid loss. Addressing these issues promptly can help avoid more significant problems down the line.

Adjustments for Optimal Performance

Achieving peak functionality in agricultural machinery requires meticulous tuning and regular adjustments. These modifications ensure that the equipment operates efficiently, thereby enhancing productivity and longevity. Careful attention to various components can lead to improved performance, reducing wear and tear while maximizing output.

Engine Tuning

Proper calibration of the engine is essential for optimal operation. This involves adjusting fuel injection settings and ensuring the air intake system functions correctly. Regular monitoring of these parameters can prevent power loss and enhance fuel efficiency, leading to smoother operation.

Hydraulic System Optimization

The hydraulic system plays a crucial role in the overall performance of the machinery. Ensuring that hydraulic fluid levels are adequate and that filters are clean can greatly impact responsiveness. Regular checks on pressure settings and hose integrity contribute to effective power transmission, allowing for precise control during operations.

Recommended Operating Techniques

Employing effective operational methods is essential for maximizing the performance and longevity of agricultural machinery. Understanding and implementing best practices can lead to enhanced efficiency, reduced wear, and a more enjoyable working experience.

One fundamental technique involves familiarizing oneself with the equipment’s features and controls before commencing any tasks. This ensures that operators can make informed decisions while utilizing the machinery, minimizing the risk of errors.

| Technique | Description |

|---|---|

| Regular Maintenance | Conduct routine inspections and servicing to keep machinery in optimal condition. |

| Proper Load Management | Distribute loads evenly to prevent undue stress on the equipment and enhance stability. |

| Speed Control | Adjust speeds according to terrain and task requirements to ensure safe and effective operation. |

| Training and Education | Ensure all operators are trained and understand the equipment thoroughly to avoid misuse. |

By adopting these recommended techniques, operators can significantly enhance the reliability and efficiency of their machinery, ensuring successful agricultural operations for years to come.

FAQs About John Deere 6415

This section addresses common inquiries regarding a popular agricultural machine known for its reliability and performance. Here, we provide concise answers to frequently asked questions, ensuring users have the necessary information for optimal operation and maintenance.

What are the key specifications of this model?

The machine features a robust engine, efficient fuel consumption, and various attachment options, making it suitable for diverse agricultural tasks.

How can I improve the lifespan of this equipment?

Regular maintenance, including timely oil changes and routine inspections, significantly enhances durability and ensures consistent performance.

What should I do if I encounter issues while operating?

If problems arise, consult the troubleshooting section of the documentation or seek professional assistance to diagnose and resolve any complications efficiently.

Are there any common issues reported by users?

While generally reliable, some users have noted minor electrical faults and hydraulic system concerns. Keeping the machine serviced regularly can mitigate these problems.

Where can I find parts for this model?

Replacement parts are available through authorized dealers or reputable online retailers, ensuring quality and compatibility with the machine.