Comprehensive Guide to John Deere 6420 Repair Manual

In the realm of agricultural machinery, ensuring optimal performance and longevity is crucial. Understanding the intricacies of your equipment can make a significant difference in both efficiency and productivity. This section aims to provide essential insights and resources for those seeking to enhance their knowledge and skills in handling a specific model of tractor.

Thorough documentation plays a vital role in the upkeep of complex machinery. By familiarizing yourself with operational guidelines and technical specifications, you empower yourself to tackle various challenges effectively. Whether addressing minor adjustments or more significant issues, having access to detailed information is invaluable.

Additionally, proactive maintenance can prevent unexpected breakdowns and extend the lifespan of your equipment. This guide offers a wealth of information that will help users understand the fundamental aspects of their machinery, enabling them to carry out necessary tasks with confidence and precision.

Overview of John Deere 6420

This section provides a comprehensive look at a popular agricultural machine known for its efficiency and reliability in various farming tasks. With its robust design and advanced features, this model has gained recognition among operators seeking both performance and comfort.

Key Features

- Powerful engine options that enhance productivity.

- Advanced hydraulic systems for improved implement control.

- Ergonomic cab design for operator comfort during long hours of work.

- Versatile attachments that expand functionality across different applications.

Applications

- Tillage and soil preparation.

- Crop planting and maintenance.

- Hay and forage harvesting.

- Transporting materials across the farm.

This machine is an ideal choice for farmers looking to enhance their operational efficiency and achieve better yields while ensuring ease of use and maintenance.

Common Issues and Solutions

In the realm of agricultural machinery, various challenges can arise, affecting performance and efficiency. Identifying these problems early on is crucial for maintaining optimal operation. This section highlights frequent difficulties encountered by users and provides practical solutions to address them.

1. Engine Starting Difficulties: A common issue is the failure to start the engine, often caused by battery problems or fuel supply issues. Ensure that the battery is charged and connections are secure. Additionally, check for fuel blockages or contaminated fuel, and replace filters if necessary.

2. Overheating: Overheating can lead to severe damage. This is frequently due to low coolant levels or a malfunctioning radiator. Regularly inspect coolant levels and ensure the radiator is clean and unobstructed. If problems persist, consider checking the thermostat or water pump.

3. Hydraulic System Failures: Hydraulic issues can manifest as unresponsive controls or leaks. Start by inspecting hoses and connections for signs of wear. Regularly replacing hydraulic fluid and filters can prevent many issues, ensuring smooth operation.

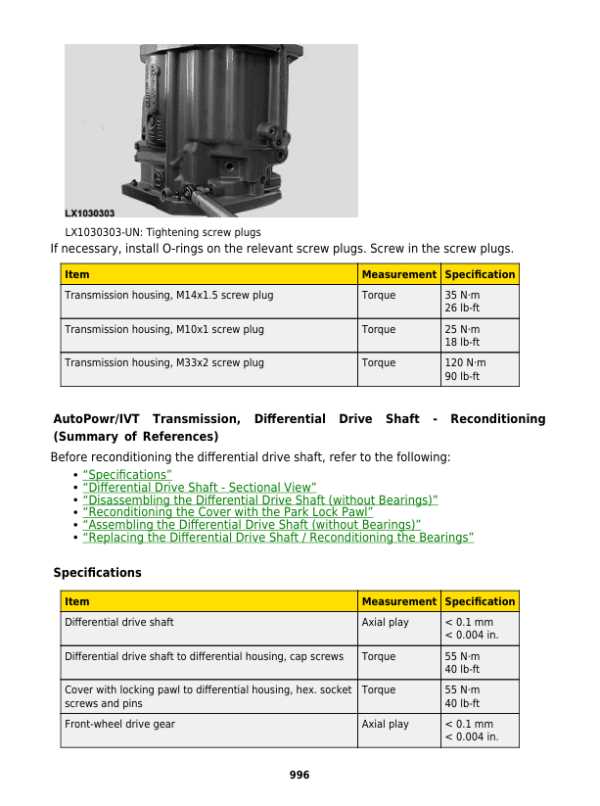

4. Transmission Problems: Users may experience difficulties with gear shifting. This can often be traced to low transmission fluid or worn components. Regularly check fluid levels and replace as needed. If issues continue, inspect for any damaged gears or linkage problems.

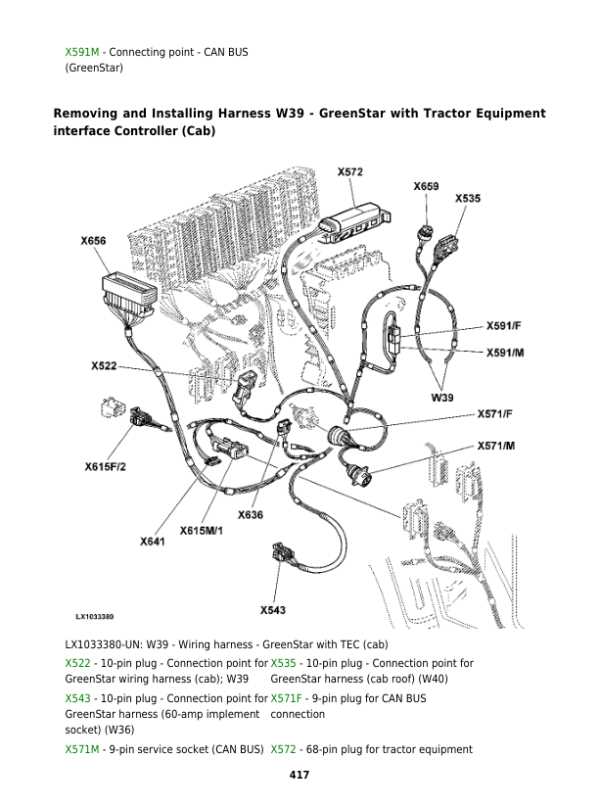

5. Electrical System Malfunctions: Electrical failures can result in various operational problems. Inspect wiring for corrosion or loose connections. Fuses should be checked and replaced as needed. A thorough electrical system inspection can help identify underlying issues.

By understanding these common challenges and their solutions, operators can enhance the longevity and reliability of their equipment, minimizing downtime and ensuring efficient performance in the field.

Maintenance Tips for Longevity

Ensuring the extended life of your agricultural machinery requires consistent attention and care. By following a structured maintenance routine, you can enhance performance and minimize the likelihood of unexpected breakdowns. This section outlines essential practices that contribute to the durability of your equipment.

Regular Inspections: Conducting frequent checks on various components is crucial. Look for signs of wear and tear, such as cracks or leaks, and address them promptly to prevent larger issues.

Fluid Levels: Keeping an eye on fluid levels, including oil and coolant, is vital. Regularly changing these fluids based on manufacturer recommendations can significantly improve operational efficiency.

Cleanliness: Maintaining a clean machine is essential. Dirt and debris can cause components to wear out faster. Regularly clean filters and ensure that all areas are free of buildup.

Tire Care: Proper tire maintenance enhances both performance and safety. Check tire pressure frequently and ensure that they are properly aligned to avoid uneven wear.

Lubrication: Regular lubrication of moving parts reduces friction and extends the lifespan of mechanical components. Follow the guidelines for lubrication intervals to ensure optimal function.

Storage Practices: When not in use, store your machinery in a dry, sheltered environment. This helps prevent rust and deterioration caused by exposure to the elements.

By adhering to these maintenance tips, you can significantly enhance the reliability and lifespan of your equipment, ensuring that it remains a valuable asset for years to come.

Understanding the Repair Manual

Grasping the intricacies of maintenance documentation is essential for effective machinery upkeep. Such guides serve as comprehensive resources, offering vital information about troubleshooting, servicing, and optimizing equipment performance. Familiarity with these documents ensures that operators can address issues efficiently, prolonging the lifespan of their machines.

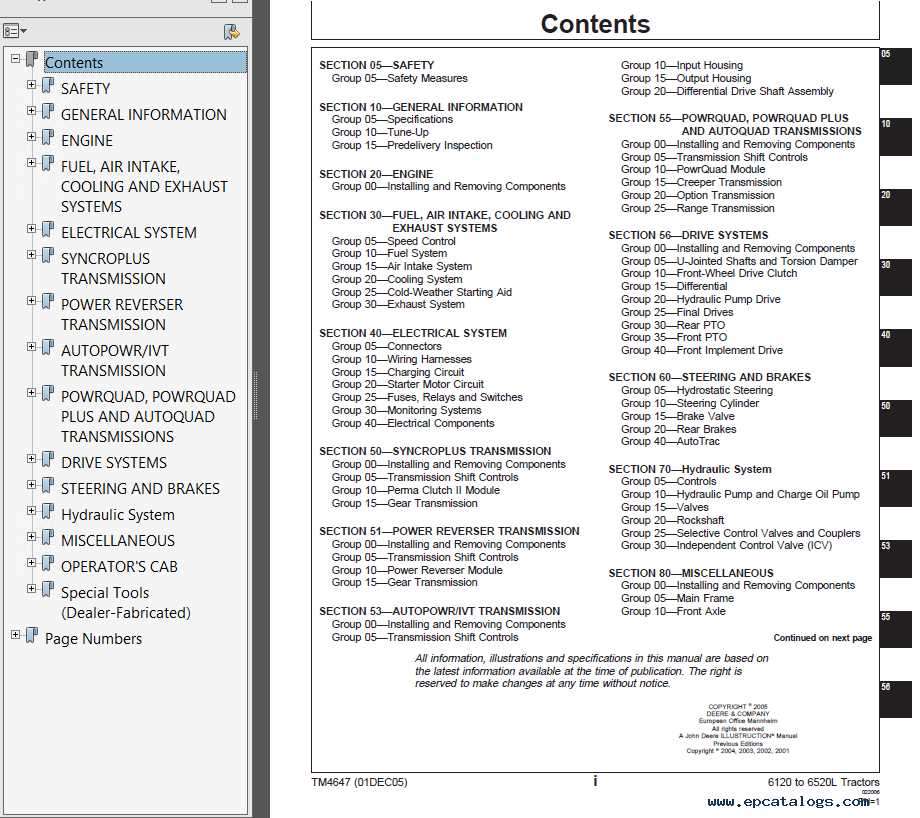

Key Components of the Documentation

The essential sections of maintenance documentation typically include systematic troubleshooting steps, detailed specifications, and clear illustrations. Understanding these components allows users to navigate the content with ease and apply the necessary procedures correctly.

Utilizing the Guide Effectively

To maximize the utility of the documentation, users should familiarize themselves with the layout and organization. Prioritizing sections relevant to specific issues can lead to quicker resolutions and minimize downtime.

| Section | Description |

|---|---|

| Troubleshooting | Step-by-step guidance for diagnosing common issues. |

| Specifications | Detailed information on machine parts and performance metrics. |

| Diagrams | Visual aids that assist in understanding component layouts. |

| Maintenance Tips | Best practices for regular upkeep to enhance longevity. |

Key Components to Inspect Regularly

Routine examination of critical elements is essential for maintaining optimal performance and extending the lifespan of your equipment. By focusing on specific areas, operators can identify potential issues before they escalate, ensuring smoother operation and reducing costly downtime.

- Fluid Levels: Regularly check oil, coolant, and hydraulic fluid levels. Maintaining appropriate levels is vital for efficient operation and preventing overheating or mechanical failure.

- Filters: Inspect air, oil, and fuel filters frequently. Clogged filters can hinder performance and lead to increased wear on the engine and other components.

- Tires: Monitor tire pressure and tread wear. Proper inflation ensures better traction and fuel efficiency while reducing the risk of blowouts.

- Batteries: Examine battery terminals and connections for corrosion. A well-maintained battery is crucial for reliable starting and electrical system performance.

- Belts and Hoses: Look for signs of wear, cracking, or fraying. Regular checks can prevent unexpected breakdowns and maintain efficiency.

By making these inspections a regular part of your maintenance routine, you can ensure the reliability and performance of your machinery, ultimately saving time and resources in the long run.

Tools Needed for Effective Repairs

When tackling machinery maintenance and enhancement tasks, having the right instruments is crucial for achieving optimal outcomes. The effectiveness of your work largely hinges on the selection and quality of the tools at your disposal. This section highlights essential implements that will streamline your efforts and ensure durability and precision in your tasks.

Basic Hand Tools: A solid collection of hand tools is foundational for any repair activity. Items such as wrenches, pliers, and screwdrivers should be readily available. These tools are versatile and can address a wide range of issues, making them indispensable in any toolkit.

Diagnostic Equipment: To accurately identify problems, employing diagnostic devices is essential. Tools such as multimeters and pressure gauges provide valuable insights into the functionality of various components, enabling you to pinpoint issues effectively.

Power Tools: For larger-scale projects, power tools can significantly enhance efficiency. Drills, impact wrenches, and grinders can save time and effort, especially when dealing with stubborn or heavy-duty components. However, it is vital to choose tools that are appropriate for the task to avoid damage.

Safety Gear: Prioritizing safety is non-negotiable. Equip yourself with protective eyewear, gloves, and ear protection to safeguard against potential hazards during your work. Proper gear not only protects you but also enhances focus and productivity.

Specialized Tools: Depending on the specific tasks at hand, specialized instruments may be required. Items like torque wrenches or hydraulic jacks can make certain jobs more manageable and ensure that all aspects of the machinery are properly addressed.

By ensuring that you are equipped with these essential tools, you will be well-prepared to handle a variety of maintenance tasks efficiently and effectively. A well-stocked toolbox not only facilitates repairs but also enhances your confidence and ability to manage challenges as they arise.

Step-by-Step Repair Procedures

This section provides detailed guidance for performing maintenance and troubleshooting on agricultural machinery. By following systematic steps, operators can efficiently address common issues, ensuring optimal performance and longevity of the equipment.

| Step | Description |

|---|---|

| 1 | Begin by assessing the machine’s overall condition, checking for visible wear or damage. |

| 2 | Consult the relevant specifications to understand the required tools and parts for the task. |

| 3 | Gather all necessary equipment and ensure a clean workspace to prevent contamination. |

| 4 | Follow the outlined steps to disassemble the components, taking care to note their arrangement. |

| 5 | Inspect each part for signs of wear or malfunction and replace any faulty components. |

| 6 | Reassemble the machine carefully, ensuring that all parts are fitted securely and correctly. |

| 7 | Perform a thorough test to confirm that the repairs have been successful and the machinery operates smoothly. |

Troubleshooting Electrical Problems

When dealing with machinery, identifying and resolving electrical issues is crucial for maintaining optimal performance. Various components can malfunction, leading to operational disruptions. This section provides a systematic approach to diagnosing and fixing these electrical challenges effectively.

Common Symptoms of Electrical Failures

Recognizing the signs of electrical faults is the first step in troubleshooting. Here are some typical indicators:

- Inconsistent or no power to certain systems

- Flickering or dimming lights

- Unresponsive controls or switches

- Strange noises or smells emanating from electrical components

Step-by-Step Diagnostic Process

Follow these steps to systematically identify and resolve electrical issues:

- Inspect Fuses and Breakers: Check for blown fuses or tripped circuit breakers, which can interrupt power flow.

- Examine Wiring Connections: Look for loose, corroded, or damaged wires that may hinder electrical conductivity.

- Test Voltage Levels: Use a multimeter to measure voltage at various points, ensuring components receive the necessary power.

- Check Components: Assess switches, relays, and sensors for proper functionality, replacing any faulty parts as needed.

- Review Ground Connections: Ensure that all ground connections are secure, as poor grounding can lead to erratic behavior.

By following this structured approach, you can efficiently address and resolve electrical problems, ensuring your equipment runs smoothly and reliably.

Importance of Regular Oil Changes

Maintaining optimal performance in machinery hinges significantly on routine maintenance practices, particularly the frequency of oil changes. Regularly refreshing the lubricant not only ensures smooth operation but also extends the lifespan of critical components.

Enhancing Engine Efficiency

Regular oil changes play a pivotal role in enhancing the efficiency of the engine. Clean oil reduces friction and wear on moving parts, leading to improved fuel economy. Neglecting this vital task can result in increased operational costs and diminished performance over time.

Preventing Damage and Wear

Frequent replacement of oil prevents the accumulation of contaminants and sludge, which can lead to severe damage. By prioritizing this essential maintenance step, operators can avert costly repairs and ensure their machinery runs smoothly for years to come.

When to Seek Professional Help

Understanding when to consult an expert can be crucial for effective machinery maintenance. While many issues can be addressed through basic knowledge and skills, certain situations may require specialized expertise to ensure safety and proper functionality.

If you encounter persistent problems despite following troubleshooting steps, or if the equipment exhibits unusual behavior, it may be time to seek assistance. Additionally, complex repairs involving intricate systems or components often necessitate professional intervention to avoid further damage.

Furthermore, when faced with unfamiliar tasks or when the necessary tools and resources are unavailable, relying on trained technicians can save time and prevent potential hazards. In these cases, investing in professional support can lead to better long-term outcomes and ensure your machinery operates at peak efficiency.