Comprehensive Guide to John Deere 6430 Repair Manual

Understanding the intricacies of machinery used in agriculture is essential for optimal performance and longevity. This section offers insights into the essential upkeep practices that every operator should consider. Proper maintenance not only enhances functionality but also minimizes unexpected breakdowns, ultimately ensuring a smoother workflow.

Farm equipment is a significant investment, and knowing how to care for it can save time and resources. This guide provides detailed instructions and valuable tips for troubleshooting common issues, thereby empowering users to address concerns proactively. Whether you are a seasoned professional or a novice, the information contained herein is designed to enhance your knowledge and skills.

By familiarizing yourself with the specifics of machinery care, you can significantly improve productivity on the field. Each chapter focuses on different aspects of maintenance, from basic checks to more advanced procedures, ensuring that all users can find relevant guidance tailored to their needs.

Understanding John Deere 6430 Specifications

Familiarizing oneself with the technical details of agricultural machinery is crucial for optimal performance and maintenance. Each model presents a unique set of features and capabilities that influence its effectiveness in various farming tasks. This section delves into the essential specifications that define a particular tractor, emphasizing the significance of these elements in enhancing productivity.

Engine Power is a vital specification, often determining the machine’s capacity to handle different implements and terrains. Knowing the horsepower allows operators to match the tractor with suitable attachments, ensuring efficiency and reducing strain.

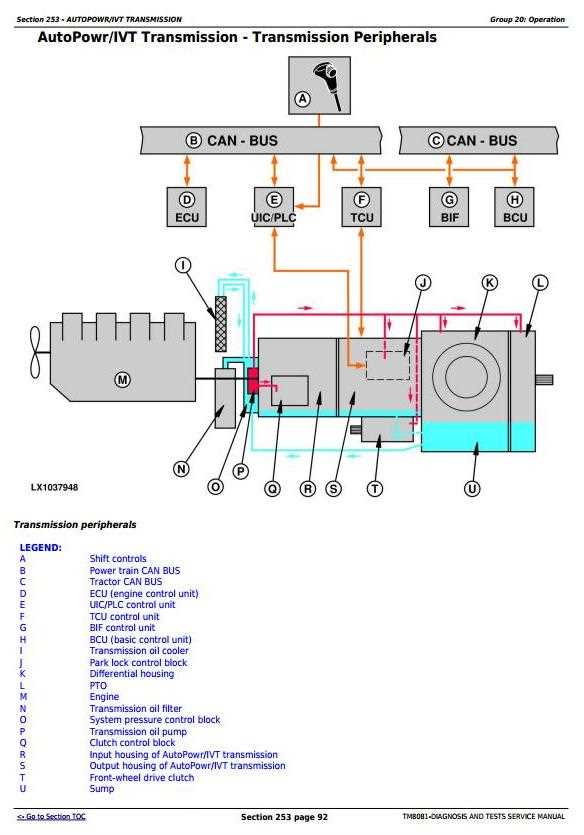

Transmission Type plays a significant role in maneuverability and control. Whether it features a manual or hydrostatic system, understanding how it affects driving experience and responsiveness is key for operators looking to maximize performance.

Hydraulic System specifications, including flow rate and pressure, are critical for implementing various attachments. A robust hydraulic system ensures smooth operation and effective power transfer, making it essential for tasks such as lifting and towing.

Dimensions and Weight also influence stability and traction. Recognizing the overall size helps in planning for transport and storage, while weight distribution affects handling and ground engagement, especially in diverse field conditions.

Lastly, fuel efficiency and maintenance intervals contribute to the overall operational costs. Understanding these aspects allows owners to plan budgets and schedules effectively, ensuring that the machinery remains in optimal working condition for years to come.

Common Issues with John Deere 6430

When operating agricultural machinery, certain challenges may arise that can affect performance and efficiency. Understanding these frequent problems can help users troubleshoot effectively and maintain optimal functionality. Below are some common concerns that operators might encounter.

Mechanical and Electrical Problems

Mechanical and electrical components are vital for the smooth operation of farming equipment. Issues in these areas can lead to significant downtime and costly repairs.

| Issue | Description | Potential Solution |

|---|---|---|

| Hydraulic Leaks | Fluid loss can occur due to worn seals or damaged hoses. | Inspect and replace damaged components; check connections regularly. |

| Electrical Failures | Malfunctions in wiring can lead to starting issues or loss of power. | Examine wiring for wear and corrosion; ensure connections are secure. |

Performance Issues

Performance-related challenges can impact productivity and efficiency. Recognizing these issues early can mitigate long-term effects.

| Issue | Description | Potential Solution |

|---|---|---|

| Poor Fuel Efficiency | Increased fuel consumption can be indicative of underlying problems. | Check for clogged filters and ensure proper maintenance is followed. |

| Overheating | Excessive heat can signal cooling system failures or blockages. | Inspect the cooling system and clean any debris from the radiator. |

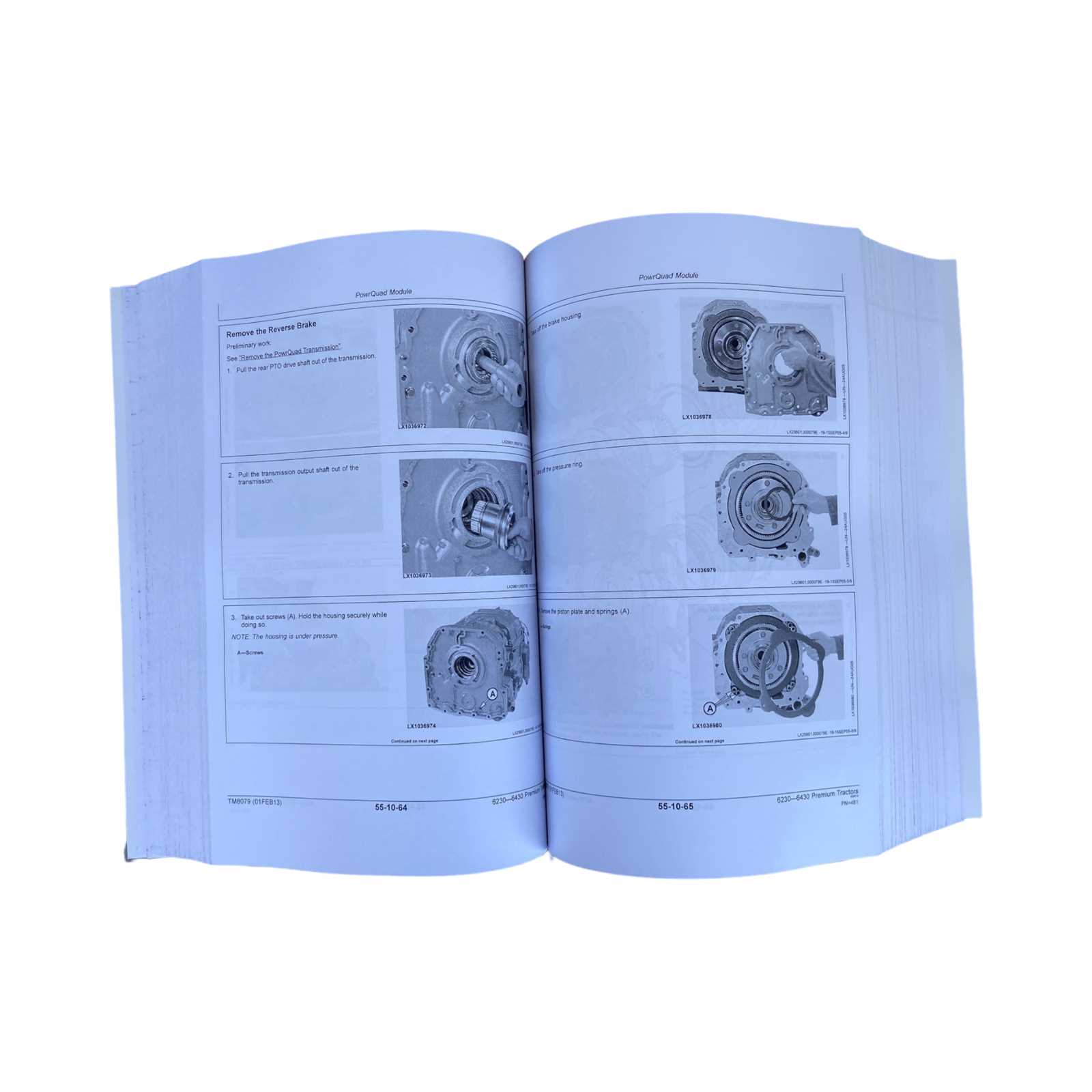

Importance of Repair Manuals

Having access to comprehensive guides is crucial for anyone involved in the maintenance and restoration of machinery. These documents provide essential information, enabling users to troubleshoot issues effectively and perform necessary adjustments with confidence. Understanding the intricacies of equipment operation can significantly enhance efficiency and longevity.

In the realm of equipment upkeep, detailed guides serve as invaluable resources. They contain specific instructions and diagrams that clarify complex processes, ensuring that individuals can carry out tasks accurately. This level of guidance minimizes the risk of errors that could lead to costly damage or unsafe operating conditions.

Furthermore, thorough documentation fosters a sense of self-sufficiency among users. By empowering individuals with the knowledge needed to address problems independently, these resources reduce dependence on external technicians, ultimately saving time and money. Access to well-structured information not only aids in immediate repairs but also enhances overall understanding of the machinery.

Ultimately, these essential documents play a pivotal role in preserving the functionality and reliability of equipment. By investing time in learning from these guides, users can ensure that their machinery remains in optimal condition for years to come.

Tools Needed for Repairs

When undertaking maintenance tasks on agricultural machinery, having the right equipment is essential for effective and efficient work. A well-equipped toolkit not only facilitates the process but also ensures safety and precision during operations. Understanding the various implements required can significantly enhance your ability to address issues that may arise.

Essential Hand Tools

Basic hand tools form the backbone of any maintenance activity. Wrenches, screwdrivers, and pliers are indispensable for loosening or tightening components. Ratchet sets and sockets provide versatility for accessing tight spaces, while a torque wrench ensures that fasteners are secured to the correct specifications. Additionally, having a reliable set of hammers and chisels can assist in more intensive tasks.

Power Tools and Diagnostic Equipment

Power tools can dramatically reduce the time required for repairs. Drills, impact wrenches, and angle grinders are commonly used for more demanding applications. Moreover, diagnostic equipment such as multimeters and pressure gauges can help identify issues more accurately, enabling targeted solutions rather than guesswork. Investing in high-quality tools not only improves outcomes but also prolongs the lifespan of your machinery.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues in agricultural machinery. Following a structured method ensures that tasks are completed efficiently and effectively, minimizing downtime and maximizing productivity.

Assessing the Problem

Begin by identifying the specific issue affecting the equipment. Conduct a thorough visual inspection and listen for any unusual sounds. Documenting symptoms will assist in pinpointing the source of the malfunction, leading to a more focused repair strategy.

Gathering Tools and Parts

Once the problem is identified, compile a list of necessary tools and components required for the task. Ensure that all items are on hand before starting the work to avoid interruptions. Having everything ready enhances workflow and contributes to a smoother repair experience.

Maintenance Tips for Longevity

Ensuring the durability of your agricultural machinery requires consistent care and attention. By implementing regular maintenance practices, you can enhance performance, prevent breakdowns, and extend the lifespan of your equipment.

1. Routine Inspections: Regularly check all major components, including the engine, transmission, and hydraulic systems. Look for signs of wear, leaks, or unusual noises that could indicate potential issues.

2. Fluid Changes: Regularly replace engine oil, hydraulic fluid, and coolant as recommended by the manufacturer. Clean fluids are essential for optimal performance and can significantly reduce wear and tear.

3. Filter Maintenance: Replace air, fuel, and oil filters at specified intervals to ensure that contaminants do not affect the machinery’s efficiency. Clogged filters can lead to reduced performance and increased fuel consumption.

4. Tire Care: Maintain proper tire pressure and inspect for any damage or uneven wear. Well-maintained tires improve traction and handling, reducing the risk of accidents and increasing efficiency.

5. Cleaning: Keep the exterior and undercarriage free from dirt and debris. A clean machine not only looks better but also prevents rust and corrosion, which can compromise structural integrity.

6. Follow Guidelines: Always adhere to the manufacturer’s recommendations regarding maintenance schedules and procedures. Staying informed about the specific needs of your equipment ensures that it remains in peak condition.

7. Professional Servicing: Consider having periodic inspections conducted by qualified technicians. Their expertise can help identify issues that may go unnoticed and ensure that repairs are performed correctly.

By following these maintenance tips, you can promote the longevity of your agricultural equipment, ensuring it remains reliable and efficient for years to come.

Electrical System Troubleshooting Guide

This section provides essential guidance for diagnosing and resolving issues related to the electrical system of agricultural machinery. A systematic approach can help identify the root causes of malfunctions, ensuring efficient operation and longevity of the equipment.

Common Symptoms of Electrical Problems

- Inconsistent power supply to components

- Unresponsive controls or dashboard indicators

- Frequent blown fuses

- Battery not charging or rapid discharge

- Overheating of wiring or components

Troubleshooting Steps

- Start by checking the battery connections for corrosion and tightness.

- Inspect all fuses and replace any that are blown.

- Use a multimeter to measure voltage at various points in the system.

- Examine wiring for signs of wear, damage, or loose connections.

- Test switches and relays for functionality.

- Ensure proper grounding throughout the electrical system.

By following these steps, operators can effectively address and resolve electrical issues, maintaining optimal performance and reliability.

Engine Performance and Repairs

Optimizing engine functionality is crucial for ensuring the longevity and efficiency of any agricultural machine. Understanding common issues and their solutions can significantly enhance operational effectiveness. This section delves into various aspects of engine performance, highlighting potential problems and the corresponding corrective measures.

Key factors affecting engine performance include:

- Fuel quality and delivery

- Air intake and filtration

- Lubrication systems

- Cooling mechanisms

- Electrical components

Regular maintenance is essential to prevent issues. Here are some recommended practices:

- Check and replace fuel filters regularly.

- Inspect air filters for blockages and replace as needed.

- Ensure proper oil levels and change oil as per manufacturer guidelines.

- Monitor coolant levels and inspect for leaks.

- Test electrical connections for corrosion or wear.

In case of performance decline, consider the following troubleshooting steps:

- Evaluate fuel system for leaks or contamination.

- Examine ignition components for wear.

- Assess exhaust system for obstructions.

- Monitor engine temperature to identify cooling issues.

Addressing these factors promptly can restore optimal performance and reduce the risk of costly breakdowns. By implementing a proactive maintenance strategy, operators can ensure that their machinery remains reliable and efficient throughout its service life.

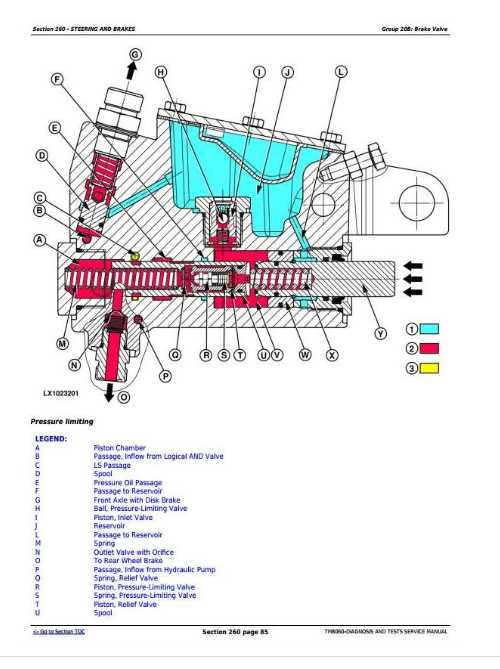

Hydraulic System Maintenance Essentials

The hydraulic system is a vital component that requires regular attention to ensure optimal performance and longevity. Proper maintenance practices not only enhance efficiency but also prevent potential failures that could lead to costly repairs. Understanding the key elements of hydraulic care is essential for any operator.

Fluid Quality and Levels: Regularly check the hydraulic fluid levels and quality. Contaminated or low fluid can lead to inefficient operation and increased wear on components. Always use the recommended type of fluid and replace it as necessary to maintain system health.

Filter Inspection: The filters play a crucial role in protecting the hydraulic system from debris and contaminants. Inspect and replace filters at recommended intervals to prevent blockages and ensure a smooth flow of fluid. Clean filters can significantly extend the lifespan of the hydraulic components.

Seal Integrity: Examine seals and hoses for any signs of wear, cracks, or leaks. A compromised seal can result in fluid loss and reduced system pressure, leading to suboptimal performance. Timely replacement of damaged seals is essential for maintaining system integrity.

Connection Tightness: Regularly inspect all connections for tightness. Loose fittings can lead to leaks, which not only waste fluid but can also create hazardous working conditions. Ensuring all connections are secure will promote system efficiency and safety.

System Operation Checks: Conduct periodic operational checks to ensure the hydraulic system responds appropriately to control inputs. Listen for unusual sounds or changes in responsiveness, as these can indicate underlying issues that need addressing.

Implementing these essential maintenance practices will help maintain the hydraulic system in peak condition, ultimately enhancing performance and reliability.

Finding Replacement Parts Efficiently

Locating suitable components for agricultural machinery can be a daunting task. With numerous options available, it is essential to streamline the process to ensure minimal downtime and maintain optimal performance. By leveraging various resources and strategies, operators can efficiently source the necessary items to keep their equipment running smoothly.

Utilizing Online Platforms

One of the most effective ways to find parts is through online marketplaces and specialized websites. These platforms often feature extensive catalogs, allowing users to search by model, part number, or description. Additionally, many sites provide customer reviews and ratings, which can guide purchasing decisions. It is advisable to compare prices across different vendors to secure the best deal.

Connecting with Local Dealers

Engaging with nearby suppliers can also yield positive results. Local dealers not only carry a range of inventory but can offer valuable insights based on their experience. Building a relationship with these providers can lead to faster service and potential discounts. Furthermore, they may assist in identifying compatible components that are not immediately obvious.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is paramount. Proper precautions can prevent accidents and injuries, creating a secure environment for both the technician and the equipment. Awareness of potential hazards and adherence to guidelines significantly contribute to a successful repair experience.

Before commencing any work, it is essential to wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and sturdy footwear to shield against debris and hazardous materials. Additionally, securing the workspace by removing any unnecessary items can minimize distractions and risks.

Always disconnect the power source before engaging in any disassembly or maintenance. This simple step can prevent unexpected starts or electrical shocks. Furthermore, utilizing the correct tools for the job ensures efficient and safe handling, reducing the chance of injuries related to tool misuse.

It is also advisable to work in well-ventilated areas, especially when dealing with fuel or chemical substances. Keeping a fire extinguisher nearby and knowing its location can provide an extra layer of safety in case of emergencies. Regularly reviewing safety protocols helps to maintain a culture of caution and awareness.