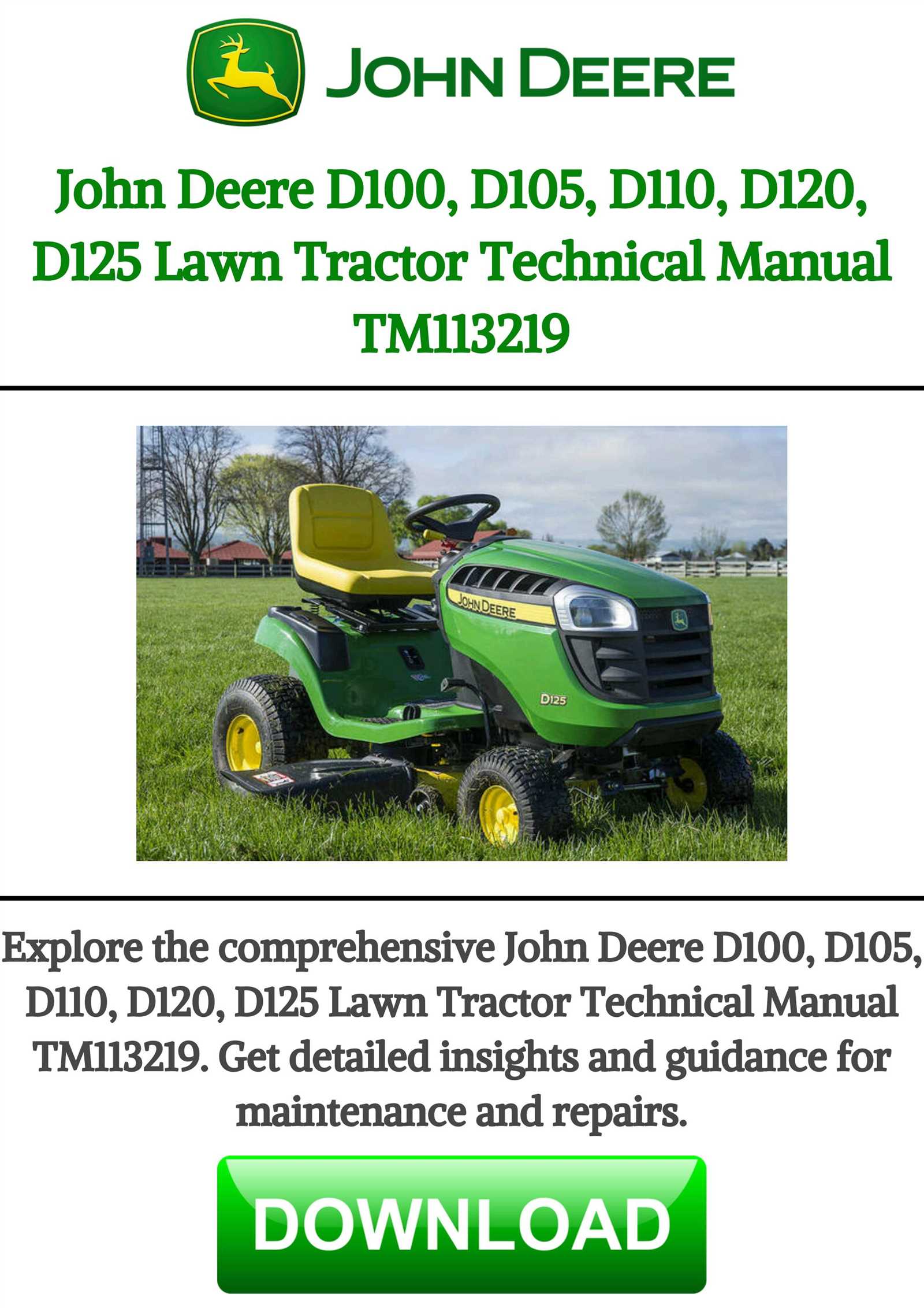

Comprehensive Guide to John Deere D100 Repair Manual

When it comes to ensuring the longevity and efficiency of your outdoor machinery, having access to reliable resources is crucial. This section serves as a vital tool for owners seeking to optimize the performance of their equipment. Whether you’re facing minor issues or planning routine upkeep, understanding the intricacies of your machine can make all the difference.

In this guide, you will find detailed instructions and practical tips designed to assist you in navigating common challenges. From identifying symptoms of malfunction to executing essential tasks, each aspect is covered thoroughly. Empowering yourself with knowledge not only enhances your confidence but also contributes to the overall health of your machinery.

Utilizing a structured approach to maintenance can lead to significant improvements in functionality and durability. With this resource at your disposal, you can tackle repairs systematically and avoid unnecessary complications. Let’s delve into the essential aspects that will help you keep your equipment in top shape for years to come.

Overview of John Deere D100 Series

This section provides a comprehensive look at a popular line of lawn care equipment designed for residential use. These machines are engineered to meet the needs of homeowners seeking efficiency and reliability for their landscaping tasks.

The series features a range of models, each with distinct specifications and capabilities, making them suitable for various yard sizes and terrains. Here are some key characteristics:

- Engine Performance: Equipped with robust engines that ensure smooth operation and adequate power for cutting grass and handling other tasks.

- Cutting Width: Available in multiple cutting widths, allowing users to choose the best fit for their lawn size.

- Transmission Options: Models come with different transmission systems, providing options for ease of use and maneuverability.

- Comfort Features: Designed with ergonomic seating and user-friendly controls, enhancing the overall mowing experience.

Additionally, these machines are known for their durability and low maintenance requirements, making them a favorite among homeowners. The series combines innovation with practical design, catering to the diverse needs of lawn enthusiasts.

Common Issues with D100 Models

Many users encounter a range of challenges when operating this series of lawn maintenance equipment. Understanding these frequent problems can aid in effective troubleshooting and ensure optimal performance throughout the mowing season.

Engine Difficulties: One of the most prevalent issues involves starting difficulties. Owners often report that the engine fails to turn over, which can be attributed to battery problems, fuel supply issues, or faulty ignition components. Regularly checking the battery connections and fuel lines can prevent these interruptions.

Cutting Performance: Inconsistent cutting is another common concern. This can result from dull blades, improper deck height adjustments, or clogged discharge areas. Ensuring blades are sharpened and the deck is clean will improve the overall cutting efficiency.

Transmission Problems: Users may also face challenges with the transmission. Symptoms include slipping gears or unresponsive controls. This could stem from low fluid levels or worn components. Regular maintenance and timely inspections are crucial for prolonging the lifespan of the transmission.

Electrical Issues: Electrical malfunctions, such as lights not functioning or fuses blowing, frequently occur. These can often be traced back to wiring issues or corroded connectors. Routine checks of the electrical system can help catch these problems early.

Being aware of these common challenges allows operators to address issues promptly, ensuring a smoother and more efficient mowing experience.

Essential Tools for D100 Repair

Maintaining and fixing lawn equipment requires a specific set of instruments to ensure effective performance. Utilizing the right tools can significantly simplify the process and enhance the longevity of your machinery. This section highlights the essential gear needed for comprehensive maintenance tasks.

First and foremost, a sturdy set of hand tools is crucial. Wrenches, pliers, and screwdrivers of various sizes will enable you to tackle most mechanical issues. Socket sets are particularly useful for dealing with nuts and bolts in tight spaces.

Next, consider investing in a reliable multimeter for electrical diagnostics. This device will help you troubleshoot any wiring issues and ensure that all electrical components are functioning properly.

A jack and jack stands are also important for safely lifting equipment during maintenance. They provide access to the underside, making it easier to inspect and service critical areas.

Finally, keep a supply of cleaning materials and lubricants on hand. Regular cleaning and proper lubrication are vital for preventing wear and tear, ensuring your equipment operates smoothly for years to come.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for optimal performance and longevity of your equipment. Following a systematic approach to maintenance ensures that all components function efficiently and helps prevent unexpected breakdowns.

Below are the essential steps to maintain your machinery effectively:

-

Inspection:

- Check for any visible wear or damage.

- Inspect belts and hoses for cracks or fraying.

- Examine tires for proper inflation and tread depth.

-

Cleaning:

- Remove debris from the chassis and engine compartment.

- Clean air filters to ensure proper airflow.

- Wash the exterior to prevent rust and corrosion.

-

Fluid Checks:

- Verify oil levels and change if necessary.

- Inspect coolant levels and top off if needed.

- Check hydraulic fluid levels for proper operation.

-

Sharpening and Adjustments:

- Sharpen blades to enhance cutting efficiency.

- Adjust tire pressures to recommended specifications.

- Calibrate controls for optimal responsiveness.

-

Testing:

- Run the equipment to ensure all systems are functioning correctly.

- Listen for unusual noises that may indicate issues.

- Perform a test cut or task to assess performance.

By adhering to these procedures, you can maintain the reliability and efficiency of your machinery, ultimately extending its lifespan and enhancing performance.

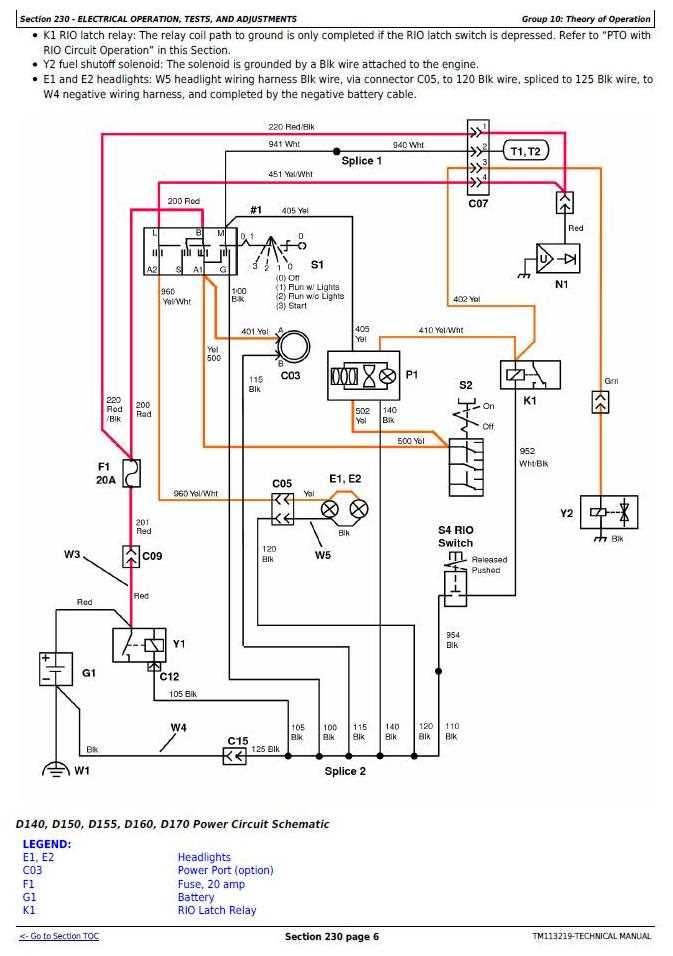

Understanding the D100 Electrical System

The electrical framework of this lawn equipment plays a crucial role in its overall performance and functionality. A solid grasp of its components and operations can significantly enhance maintenance and troubleshooting efforts. This system comprises various elements that work in tandem to ensure optimal performance, from the battery to the ignition and wiring harness.

At the core of the electrical architecture lies the battery, which supplies power to the entire unit. Understanding its condition and proper maintenance is essential for reliable starts and efficient operation. Additionally, the ignition system is responsible for firing the engine, making its integrity vital for smooth functioning.

Wiring connections throughout the equipment must be inspected regularly to prevent failures. A clear comprehension of how these wires interact and transmit power can aid in identifying issues early. Furthermore, knowing how to interpret electrical diagrams can provide valuable insights when diagnosing problems.

Finally, understanding the role of fuses and relays in the electrical network is essential. These components protect the system from overloads and shorts, ensuring longevity and reliability. Overall, familiarity with the electrical system enhances the user’s ability to maintain and troubleshoot effectively, leading to a more efficient and dependable experience.

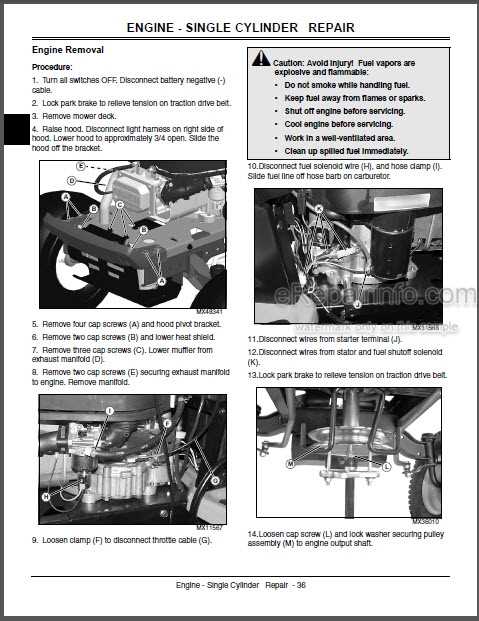

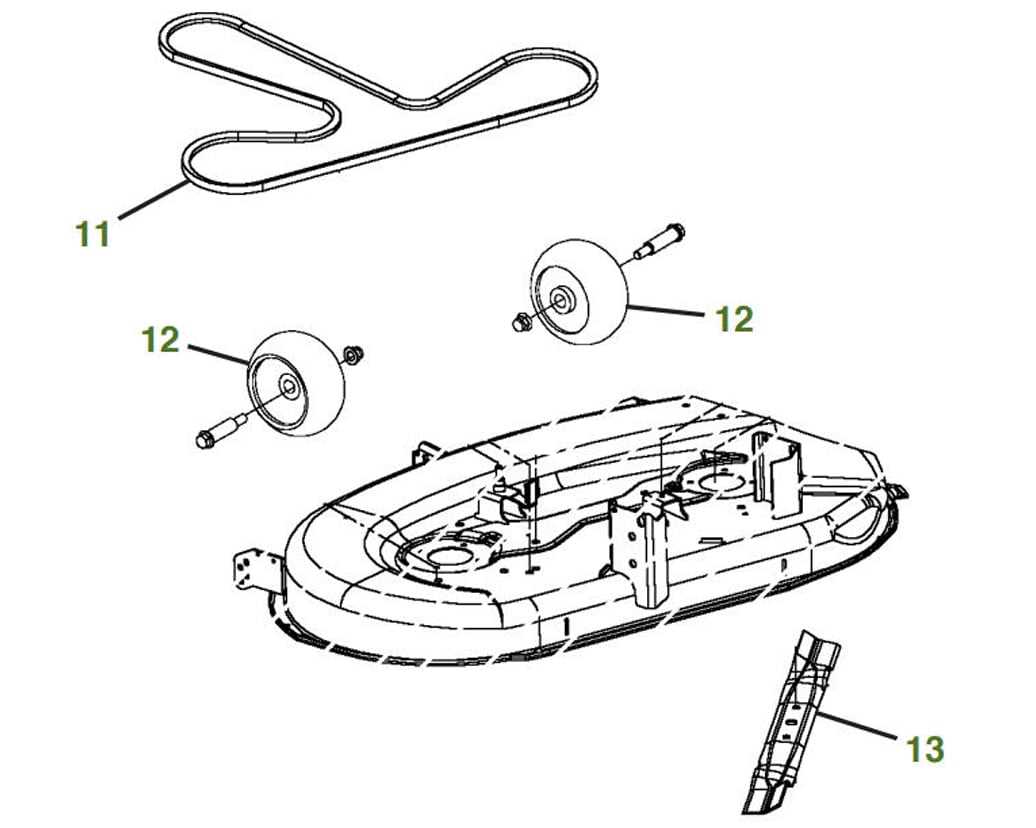

Replacing D100 Blades and Belts

Maintaining optimal performance in your lawn care equipment is essential for achieving a pristine yard. One of the key aspects of upkeep involves the timely replacement of cutting components and drive belts. This process ensures that the machine operates efficiently and provides a clean cut while minimizing wear and tear.

Before starting the replacement, gather all necessary tools, including wrenches, a socket set, and safety gloves. Ensure the equipment is turned off and the engine is cool. For blade replacement, lift the deck and securely support it. Remove the old blades by loosening the bolts that hold them in place, taking care to note their orientation for proper installation of the new ones.

When installing new blades, align them correctly and tighten the bolts securely to avoid any hazards during operation. For belt replacement, first identify the worn or damaged belt and carefully remove it from the pulleys. Consult the specifications for the correct belt size, and install the new one by threading it through the appropriate pulleys, ensuring it sits firmly in place.

After completing both replacements, lower the deck and test the equipment to verify that everything functions smoothly. Regularly checking and replacing these components not only enhances performance but also extends the lifespan of your lawn maintenance tool.

Engine Troubleshooting Tips

When dealing with engine issues, identifying the root cause can often feel overwhelming. However, a systematic approach to diagnosing problems can lead to effective solutions. By focusing on common symptoms and their potential origins, you can efficiently resolve mechanical difficulties and ensure optimal performance.

Common Symptoms and Causes

Many issues arise from a few key symptoms. If the engine fails to start, it may be due to a drained battery, faulty ignition system, or fuel delivery problems. Unusual noises, such as knocking or grinding, often indicate internal wear or damage. Pay attention to warning lights on the dashboard; they provide critical information regarding potential malfunctions.

Diagnostic Steps

Begin troubleshooting by checking the battery connections and ensuring the battery is charged. Next, inspect the fuel system for clogs or leaks. If the ignition system is suspected, test the spark plugs and wires for any signs of wear. Regular maintenance can prevent many issues; keep filters clean and fluids topped up. By following these steps, you can systematically address engine troubles and maintain its efficiency.

How to Adjust the Deck Height

Maintaining the correct cutting height of your lawn equipment is essential for achieving a neat and healthy lawn. Proper adjustment ensures that the blades cut grass evenly, promoting optimal growth and a well-kept appearance. Follow these steps to set the desired deck height effectively.

- Gather Necessary Tools: Before starting, make sure you have the required tools on hand, such as a ruler or tape measure, and a wrench set.

- Park on Level Ground: Position the equipment on a flat, even surface. This helps to ensure accurate height measurements.

- Check Current Height: Measure the current deck height using your ruler. This provides a baseline for adjustments.

- Locate Adjustment Mechanism: Identify the height adjustment lever or knob, usually located near the deck or operator’s seat.

- Adjust the Height:

- If your equipment has a lever, pull it to the desired height setting.

- If using a knob, turn it clockwise or counterclockwise as required to reach the preferred level.

- Recheck Measurements: After making adjustments, use your ruler to confirm that the deck height aligns with your preferences.

- Test the Equipment: Start the machine and conduct a test run over the grass. Observe the cutting performance and make further adjustments if necessary.

By following these straightforward steps, you can ensure your lawn equipment is set to the optimal height, leading to a beautiful and healthy lawn.

Fuel System Maintenance Guidelines

Maintaining the fuel system is essential for ensuring optimal performance and longevity of your equipment. Regular attention to this critical component helps prevent issues such as fuel contamination and inefficient combustion. Following a systematic approach to upkeep will enhance reliability and reduce the likelihood of costly repairs.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fuel Filter Inspection | Every 50 hours | Check for dirt and debris; replace if necessary to ensure clean fuel flow. |

| Fuel Line Check | Monthly | Inspect for cracks or leaks; ensure connections are secure. |

| Fuel Tank Cleaning | Annually | Remove sediment and contaminants to prevent clogs and ensure fuel quality. |

| Use of Fresh Fuel | Every fill-up | Always use clean, high-quality fuel to minimize the risk of deposits. |

| Fuel Additive Application | As needed | Consider using additives to enhance performance and prevent gumming. |

By adhering to these guidelines, operators can enhance the efficiency and reliability of their equipment, ensuring it operates smoothly and effectively throughout its service life.

Resources for Finding Replacement Parts

Locating suitable components for machinery maintenance can be a straightforward task with the right resources. Whether you are repairing a lawn mower, tractor, or other equipment, having access to quality parts is essential for optimal performance. Here are some reliable avenues to explore when searching for replacement items.

Online Retailers

- Manufacturer Websites: Many brands offer direct sales through their official websites, ensuring authenticity.

- Specialized Parts Stores: Numerous online stores focus exclusively on agricultural and landscaping equipment.

- Marketplace Platforms: Websites like eBay or Amazon often have both new and used options available.

Local Suppliers and Salvage Yards

- Authorized Dealers: Local dealerships can provide genuine components and expert advice.

- Salvage Yards: These locations can be treasure troves for hard-to-find parts at a fraction of the cost.

- Community Workshops: Local repair shops may have connections to parts distributors or offer parts themselves.

Utilizing these resources can significantly enhance your ability to find the necessary components for your equipment, ensuring it remains in top condition.