Comprehensive Repair Guide for John Deere D110

Maintaining your garden equipment is essential for ensuring its longevity and optimal performance. This section provides a thorough overview of essential practices and troubleshooting steps for your lawn tractor. With regular care, you can prevent costly breakdowns and keep your machine running smoothly throughout the seasons.

In this detailed resource, you will discover various techniques for upkeep, including detailed insights into parts identification and replacement procedures. Each segment is designed to enhance your understanding of the machinery, empowering you to take charge of your maintenance tasks with confidence.

From basic cleaning routines to more intricate adjustments, the information presented here is aimed at both novices and seasoned users. Whether you’re dealing with minor issues or preparing for seasonal tasks, this guide serves as a valuable tool in your maintenance arsenal.

Overview of John Deere D110

This section provides a comprehensive examination of a popular lawn care machine designed for efficiency and durability. It highlights key features, specifications, and performance aspects that make it a preferred choice among users seeking reliable outdoor equipment.

Equipped with a powerful engine and user-friendly controls, this model offers excellent maneuverability and cutting precision. Its robust construction ensures longevity, making it suitable for various lawn maintenance tasks.

| Feature | Description |

|---|---|

| Engine Type | V-twin, air-cooled |

| Cutting Width | 42 inches |

| Transmission | Automatic, continuously variable |

| Fuel Capacity | 1.3 gallons |

| Weight | Approx. 350 lbs |

This machinery’s design not only enhances functionality but also prioritizes user comfort and ease of operation, making it an invaluable asset for lawn care enthusiasts.

Common Issues Faced by Users

Owners of small garden equipment often encounter a variety of challenges that can hinder optimal performance. These issues can range from mechanical failures to electrical problems, leading to frustration and downtime. Understanding these common difficulties is crucial for effective troubleshooting and maintenance.

One prevalent concern is difficulty starting the engine, which can stem from fuel system problems, battery issues, or ignition system malfunctions. Users may also face issues with the cutting mechanism, such as dull blades or improper height adjustment, impacting the quality of the cut.

Another frequent problem is the overheating of the engine, often caused by inadequate lubrication, dirty air filters, or blocked cooling fins. Regular maintenance and inspections can help identify these issues early, preventing more significant damage and ensuring longevity.

Lastly, transmission difficulties, such as slipping gears or unresponsive controls, can disrupt operation. These issues may require careful examination of the belts, cables, and overall drive system to ensure smooth functionality.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment involves a combination of regular upkeep and mindful usage practices. By following specific guidelines, you can significantly enhance performance and prevent premature wear and tear.

Routine Inspections

Conducting regular checks on essential components is crucial. Look for signs of wear, such as fraying belts or corrosion on metal parts. Timely identification of potential issues can help avoid costly repairs down the line.

Proper Cleaning

Keeping your machinery clean not only improves its appearance but also promotes efficiency. Remove debris from cooling systems and engine areas, as buildup can lead to overheating and reduced functionality. Regular washing of external surfaces helps prevent rust and maintains optimal performance.

Tools Required for Repairs

When it comes to maintaining and fixing machinery, having the right equipment is essential for achieving optimal results. This section outlines the necessary instruments and supplies that will aid in the effective servicing of your equipment.

Basic Hand Tools: A comprehensive set of hand tools is fundamental. This includes wrenches, pliers, and screwdrivers of various sizes to accommodate different fasteners.

Power Tools: For more extensive tasks, power tools such as drills and impact wrenches can significantly enhance efficiency. These tools are invaluable for tackling stubborn bolts and for making precise adjustments.

Diagnostic Equipment: Utilizing diagnostic tools can help identify issues more quickly. Multimeters and compression testers are examples of instruments that can aid in troubleshooting electrical and mechanical problems.

Safety Gear: Always prioritize safety. Ensure you have gloves, goggles, and other protective equipment to shield yourself from potential hazards while working.

Having a well-equipped toolkit will streamline the maintenance process and ensure that tasks are completed safely and effectively.

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing common issues encountered with lawn maintenance machinery. Each procedure is designed to guide users through the necessary steps to ensure optimal performance and longevity of their equipment.

1. Initial Inspection

Begin with a thorough examination of the unit. Check for visible signs of wear, leaks, or damage. Verify that all components are securely attached and free of debris.

2. Diagnostic Testing

Utilize diagnostic tools to assess functionality. Monitor performance metrics and identify any abnormal readings that may indicate underlying problems.

3. Component Replacement

If issues are detected, locate the faulty parts and replace them with compatible components. Ensure proper alignment and secure connections to prevent future malfunctions.

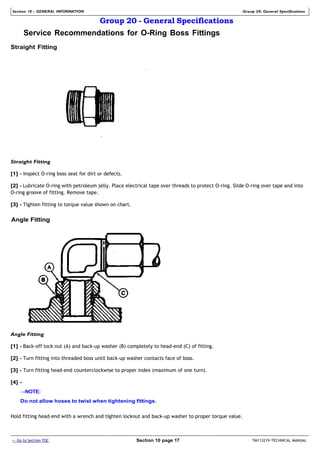

4. Lubrication and Maintenance

Apply appropriate lubricants to moving parts as specified in the guidelines. Regular maintenance helps in minimizing friction and wear, promoting smooth operation.

5. Final Testing

After completing the repairs, conduct a final test run. Observe the machinery for any unusual noises or performance issues. Confirm that all functions are operating as expected before returning the equipment to service.

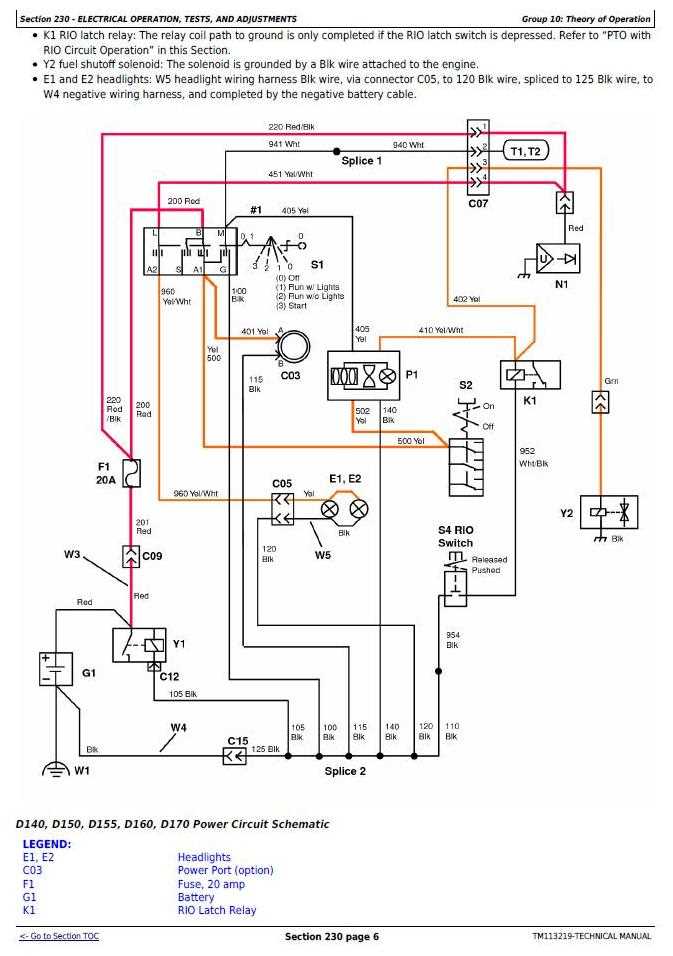

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of machinery is crucial for maintaining optimal performance. Understanding the common problems and effective strategies for resolution can significantly reduce downtime and enhance reliability.

Common Electrical Issues

Several typical malfunctions may occur within the electrical system. These can include problems such as blown fuses, faulty wiring connections, and malfunctioning components. Regular inspections and prompt attention to any irregularities are essential to prevent escalation.

Troubleshooting Steps

To effectively troubleshoot electrical concerns, follow a systematic approach. Begin by checking the battery voltage and connections, as weak power sources can lead to various complications. Next, examine the wiring harness for signs of wear or damage. Utilize a multimeter to test continuity and identify any short circuits. Properly documenting findings can help in recognizing patterns for future reference.

Always prioritize safety when working with electrical systems. Ensure that the power is disconnected before performing any inspections or repairs. This practice not only protects the technician but also prevents potential damage to the equipment.

Engine Maintenance Guidelines

Regular upkeep of your engine is crucial for optimal performance and longevity. Implementing a consistent maintenance routine helps prevent potential issues and ensures that your machine operates efficiently. By adhering to specific practices, you can enhance the reliability and durability of your equipment.

Routine Inspections: Conduct frequent examinations of key components, including belts, hoses, and filters. Look for signs of wear or damage that may require immediate attention.

Oil Changes: Regularly changing the oil is vital for engine health. Use high-quality oil and replace it according to the manufacturer’s recommendations to maintain proper lubrication and reduce friction.

Air Filter Maintenance: A clean air filter is essential for optimal airflow and performance. Check the filter regularly and replace it if it appears dirty or clogged.

Coolant Levels: Ensure that the coolant is at the appropriate level to prevent overheating. Regularly inspect the cooling system for leaks or corrosion that could affect performance.

Fuel System Care: Use clean, high-quality fuel to prevent sediment buildup and fuel line clogs. Consider using fuel additives to enhance performance and reduce deposits.

By following these guidelines, you can maintain your engine’s efficiency and prolong its lifespan, ensuring reliable operation for years to come.

Understanding the Transmission System

The transmission system plays a crucial role in the functionality of any lawn care vehicle, facilitating the transfer of power from the engine to the wheels. This intricate mechanism is responsible for ensuring that the equipment operates efficiently under various conditions, adapting to the demands of the terrain and load.

Key Components of the Transmission

- Gearbox: Houses the gears that regulate speed and torque.

- Drive Belts: Transfers power from the engine to the gearbox.

- Shifter: Allows the operator to select different speed settings.

- Hydraulic System: Provides smooth operation and transitions between gears.

Common Issues and Maintenance Tips

- Regularly check and replace worn drive belts to prevent slippage.

- Inspect fluid levels and quality to ensure optimal performance.

- Monitor shifting responsiveness; adjust linkage as necessary.

- Clean the gearbox to remove debris that could hinder operation.

Safety Precautions During Repairs

Ensuring safety is crucial when performing maintenance or servicing on machinery. Adhering to proper protocols not only protects the individual but also extends the longevity of the equipment.

Before commencing any work, it is essential to equip oneself with the right personal protective gear. This includes items such as gloves, goggles, and sturdy footwear, which serve as a barrier against potential hazards.

| Protective Gear | Purpose |

|---|---|

| Gloves | To prevent cuts and abrasions |

| Goggles | To shield eyes from debris |

| Safety Boots | To protect feet from heavy objects |

| Ear Protection | To reduce noise exposure |

Additionally, it is vital to ensure the work area is clean and organized. A cluttered environment can lead to accidents and hinder efficient work. Always disconnect power sources before beginning any task to avoid unintended starts.

By implementing these fundamental safety measures, individuals can work more effectively and minimize the risk of injury.

Parts Replacement and Upgrades

Maintaining optimal performance and longevity of machinery involves timely component replacements and enhancements. Upgrading specific parts not only ensures efficient operation but also can improve functionality and user experience. This section delves into essential considerations for replacements and potential upgrades that can elevate performance standards.

Common Parts for Replacement

Identifying components that frequently require attention is crucial for effective maintenance. Below is a list of common parts that may need replacement over time:

| Part Name | Symptoms of Wear | Recommended Action |

|---|---|---|

| Battery | Slow starts or dim lights | Replace with a compatible model |

| Belts | Creaking noises or visible cracks | Inspect and replace as necessary |

| Filters | Reduced performance or increased fuel consumption | Replace regularly as part of maintenance |

Upgrading Components

In addition to replacements, certain components can be upgraded for enhanced performance. Here are a few recommendations:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine Oil | Synthetic oil | Improved lubrication and efficiency |

| Blades | High-performance steel | Sharper cuts and durability |

| Tires | All-terrain options | Better traction and stability |

Where to Find Replacement Parts

Locating suitable components for maintenance and upgrades is essential for optimal performance and longevity of your machinery. Various sources offer reliable options for sourcing these necessary items, ensuring that your equipment remains functional and efficient.

Online Retailers

Numerous e-commerce platforms provide an extensive selection of parts. When searching for specific items, consider the following:

- Well-known online marketplaces, where users can compare prices and read reviews.

- Specialized websites dedicated to outdoor equipment and machinery parts.

- Manufacturer’s official websites, which often feature parts catalogs and ordering systems.

Local Dealers and Stores

In addition to online options, local suppliers can be invaluable resources. Here are some benefits of purchasing from them:

- Immediate access to parts without the wait for shipping.

- Expert advice from staff who are knowledgeable about the equipment.

- Possibility of finding used or refurbished components at a lower cost.

By exploring both online and local avenues, you can effectively find the necessary components to keep your machinery operating smoothly.