Complete Guide to John Deere D140 Repair Manual

Proper upkeep of your lawn care equipment is crucial for ensuring optimal performance and longevity. This resource aims to provide essential insights into the complexities of maintaining a specific model of lawn tractor, focusing on key components and common issues faced by users. Understanding how to troubleshoot and address various problems can significantly enhance your mowing experience and save time and resources.

For enthusiasts and homeowners alike, a reliable source of information can make all the difference when tackling maintenance tasks. This guide breaks down intricate procedures into manageable steps, offering detailed instructions that cater to both novices and experienced individuals. By following these guidelines, you can empower yourself to effectively manage your equipment, ensuring it operates smoothly throughout the seasons.

Exploring the intricacies of your machine not only fosters a deeper appreciation for its mechanics but also encourages proactive care. Armed with the right knowledge, you can identify potential issues before they escalate, thus preserving the functionality and efficiency of your equipment. Let’s dive into the world of lawn tractor care, equipping you with the tools needed for successful maintenance.

Understanding the John Deere D140

This section aims to provide an in-depth look at a popular model of riding mower, emphasizing its features, performance, and overall utility. Designed for efficiency, this machine is tailored for those seeking to maintain their lawns with ease and precision. Understanding its components and functions will help users maximize its capabilities.

The engine, transmission, and deck design are crucial elements that contribute to the mower’s effectiveness. Each part works in harmony to deliver a smooth mowing experience, whether tackling flat terrains or slightly uneven surfaces. Below is a brief overview of the key specifications and features.

| Feature | Description |

|---|---|

| Engine Type | Powerful gasoline engine for reliable performance |

| Cutting Width | 42 inches for efficient mowing |

| Transmission | Automatic transmission for ease of use |

| Fuel Capacity | Large tank for extended operation |

| Deck Material | Durable steel for long-lasting performance |

By familiarizing oneself with these characteristics, users can ensure they make the most of their mowing experience, leading to well-maintained outdoor spaces.

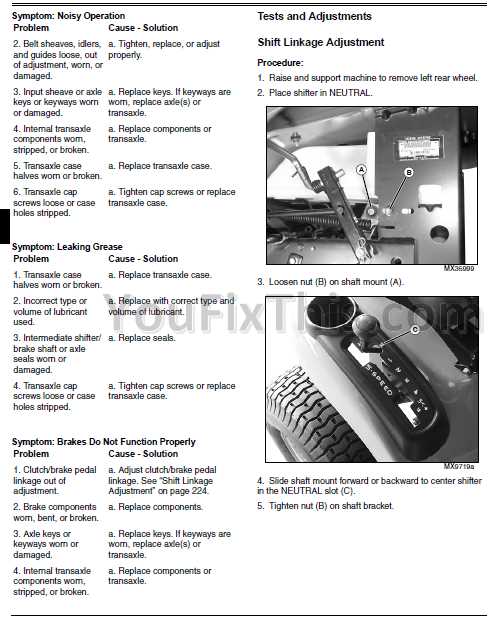

Common Issues with the D140 Model

Understanding the frequent problems associated with this lawn care equipment can enhance maintenance and prolong its lifespan. Many users encounter specific challenges that, when identified early, can be easily addressed.

- Starting Difficulties: Many operators report issues with the engine not starting or stalling unexpectedly. This may stem from fuel system complications or electrical failures.

- Mower Blade Problems: Dull or damaged blades can lead to uneven cutting performance. Regular inspection and sharpening are essential for optimal operation.

- Transmission Issues: Users may experience difficulty in shifting gears, which can be attributed to low fluid levels or worn components.

- Battery Malfunctions: A common complaint involves battery drainage or failure. Ensuring connections are secure and replacing old batteries can resolve this.

- Overheating: The engine may overheat due to clogged air filters or low coolant levels. Regular maintenance helps to prevent this problem.

Addressing these concerns proactively can lead to smoother operation and enhanced efficiency of the equipment.

Tools Required for D140 Maintenance

Proper upkeep of your lawn equipment is essential for ensuring optimal performance and longevity. A variety of implements are necessary to effectively service and maintain your machine. Familiarizing yourself with these tools will make the process more efficient and straightforward.

- Wrenches: A set of adjustable and socket wrenches is crucial for loosening and tightening various bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for adjusting and securing components.

- Oil Filter Wrench: This tool simplifies the removal and replacement of the oil filter, preventing spills and mess.

- Grease Gun: Essential for lubricating moving parts, ensuring smooth operation.

- Spark Plug Socket: Specifically designed to remove and install spark plugs easily, maintaining engine efficiency.

- Fuel Stabilizer: While not a tool, using this additive can help prolong fuel life, particularly during storage periods.

- Safety Gear: Gloves, goggles, and a mask are important for personal protection during maintenance tasks.

Having the right tools on hand not only streamlines maintenance but also enhances safety and effectiveness during the process. Regular attention with the appropriate equipment can lead to better performance and increased lifespan of your equipment.

Step-by-Step Repair Procedures

This section provides a comprehensive approach to addressing common issues encountered with the equipment. By following these detailed steps, users can ensure efficient troubleshooting and maintenance, ultimately enhancing the longevity and performance of the machine.

Initial Assessment

Before proceeding with any work, it is crucial to conduct a thorough evaluation of the situation. Inspect the machine for visible damage and listen for unusual sounds during operation. Document any irregularities, as this will assist in pinpointing the problem.

Disassembly and Troubleshooting

Once the assessment is complete, carefully disassemble the necessary components to access the internal mechanisms. Utilize the appropriate tools for each task, ensuring that parts are labeled for reassembly. Identify any worn or faulty elements, and replace them as needed, following the prescribed guidelines for installation.

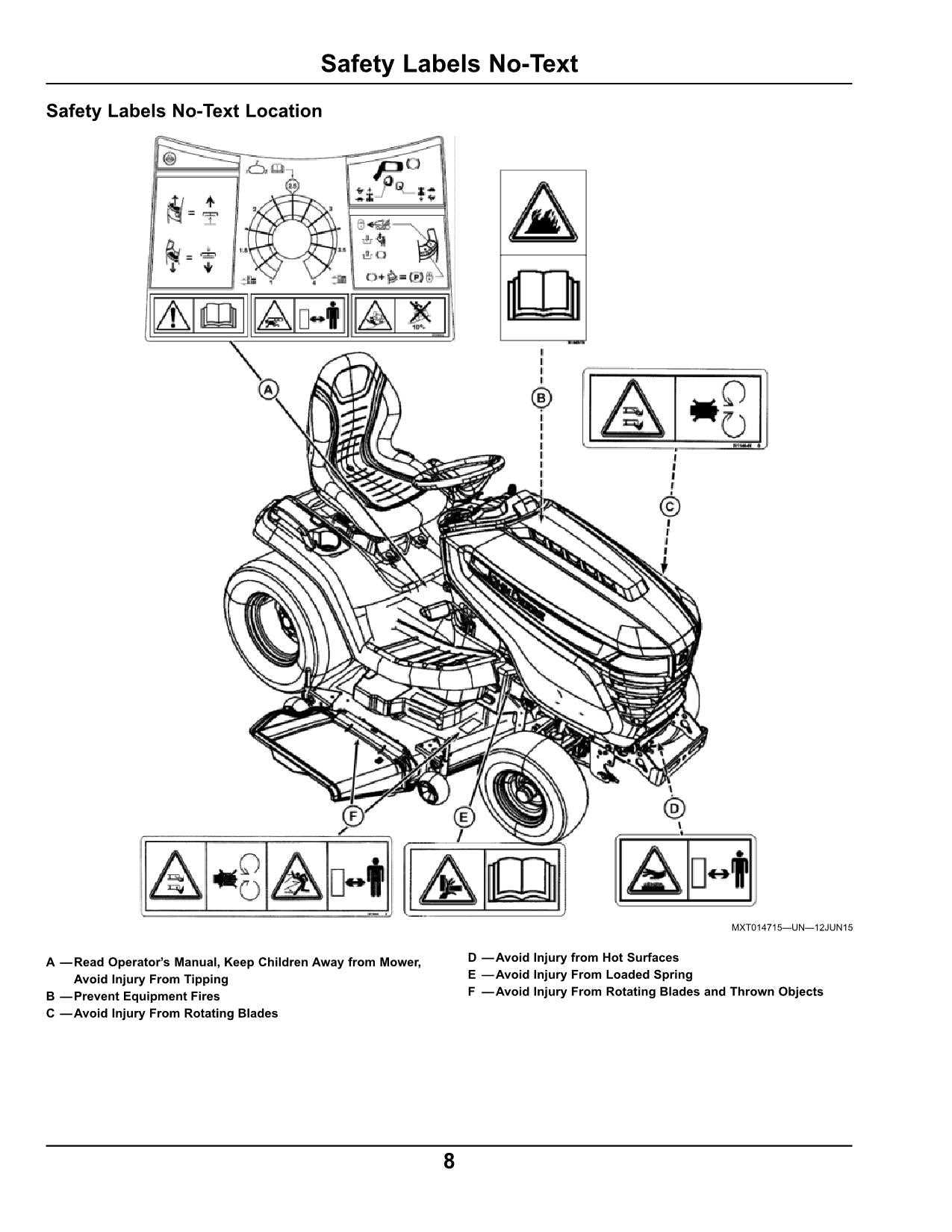

Safety Tips for Equipment Repair

When working with machinery, ensuring safety is paramount. Proper precautions help prevent accidents and promote a secure working environment. Following specific guidelines can significantly reduce risks associated with maintenance and troubleshooting tasks.

Essential Precautions

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-lit and free from clutter to avoid trips and falls.

- Disconnect power sources before beginning any service to prevent unintentional start-ups.

- Utilize proper lifting techniques or equipment when handling heavy components.

Tools and Equipment Safety

- Inspect tools regularly for wear and damage before use.

- Use the right tool for the job to avoid accidents and equipment damage.

- Keep tools organized and stored properly to prevent mishaps.

- Follow manufacturer guidelines for specific equipment to ensure safe handling and operation.

Preventative Maintenance Guidelines

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a structured maintenance routine, you can prevent unexpected breakdowns and extend the life of your machinery. This section outlines key practices that should be implemented to maintain peak operational efficiency.

Routine Checks

Implementing a schedule for frequent inspections can help identify potential issues before they escalate. These checks should encompass various components, including fluid levels, filters, and belts. Keeping a detailed log of these inspections will aid in tracking performance over time.

Seasonal Maintenance Tasks

Different seasons may pose unique challenges to machinery. Seasonal maintenance tasks should be tailored to address specific environmental factors that could affect operation. Ensuring that equipment is properly prepared for both harsh winters and hot summers is crucial for sustained performance.

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use recommended oil type. |

| Air Filter Check | Every 25 hours | Replace if dirty. |

| Battery Inspection | Monthly | Clean terminals and check charge. |

| Tire Pressure Check | Weekly | Adjust to manufacturer specifications. |

By adhering to these preventative maintenance guidelines, operators can enhance the reliability of their equipment, ensuring it remains in top condition throughout its lifespan.

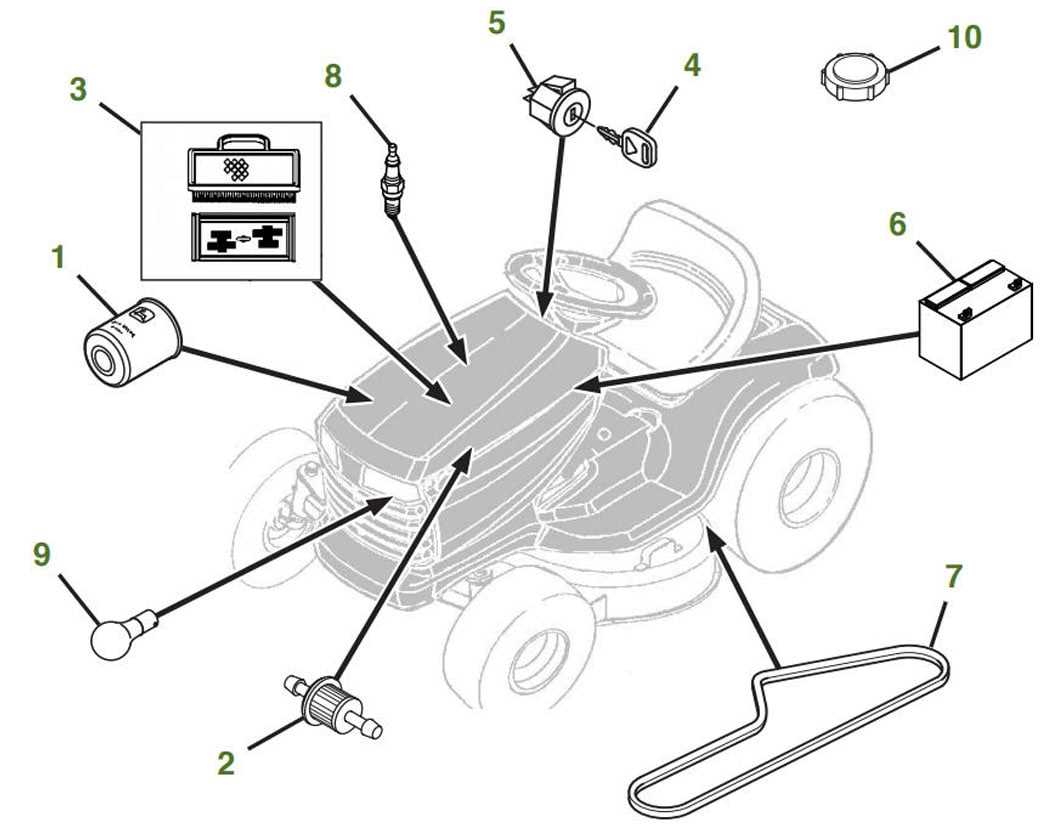

Replacing Key Components Easily

Maintaining machinery requires attention to vital parts that may need replacement over time. Understanding how to swap out these components can enhance performance and prolong the life of the equipment. This section provides straightforward guidance to help you navigate through the process efficiently.

Here are some common components that may require replacement:

- Blades

- Batteries

- Filters

- Belt

- Tires

To ensure a smooth replacement process, follow these steps:

- Identify the Component: Determine which part needs to be replaced by conducting a thorough inspection.

- Gather Tools: Collect necessary tools, such as wrenches, screwdrivers, and replacement parts.

- Safety First: Disconnect power sources and follow safety protocols before beginning any work.

- Remove the Old Part: Carefully detach the worn component, taking note of any specific connections or placements.

- Install the New Part: Position the new component and secure it in place, ensuring all connections are tight.

- Test the Equipment: Reconnect power and test functionality to ensure everything operates smoothly.

By following these steps, you can efficiently replace essential parts and maintain optimal performance.

Troubleshooting Electrical Problems

Electrical issues can often disrupt the performance of your equipment, leading to frustrating downtime. Identifying and resolving these problems requires a systematic approach to ensure reliable operation. This section aims to guide you through common electrical challenges, helping you pinpoint the source of malfunctions effectively.

Common Symptoms

When faced with electrical difficulties, certain signs may indicate underlying issues. Look for symptoms such as flickering lights, unresponsive controls, or unexpected shutdowns. These problems may stem from a range of causes, including faulty connections, damaged wiring, or depleted batteries. Observing these indicators closely will provide valuable insights into the necessary corrective measures.

Steps to Diagnose Issues

Begin your troubleshooting by checking the battery condition and ensuring connections are clean and secure. If the battery appears functional, inspect the wiring for any visible damage or wear. Testing fuses and relays can also reveal issues within the electrical circuit. Using a multimeter can further assist in identifying voltage inconsistencies. Documenting your findings can help create a clearer picture of the problem and facilitate an effective resolution.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance and longevity. Various sources offer high-quality alternatives, ensuring you can restore functionality without compromising on standards. Whether you seek OEM options or aftermarket parts, knowing where to look can simplify the process.

Online retailers provide a vast selection, often at competitive prices. Websites specializing in agricultural and lawn care supplies frequently stock the necessary items, making it easy to browse and compare options. Additionally, manufacturer websites can direct you to authorized dealers who maintain an inventory of genuine parts.

Local repair shops and authorized service centers are also excellent resources. These establishments often have access to a range of components and can assist in identifying the right part for your specific needs. Engaging with knowledgeable staff can lead to valuable insights and recommendations.

For those seeking community advice, forums and social media groups dedicated to equipment maintenance can be beneficial. Fellow enthusiasts and professionals often share their experiences and suggestions for sourcing parts, providing leads on reliable vendors.

Ultimately, taking the time to explore multiple avenues will ensure you find the right components efficiently, allowing you to keep your machinery in top condition.

Utilizing Online Repair Resources

In today’s digital age, the internet serves as an invaluable asset for individuals seeking guidance on maintenance and troubleshooting. Accessing a variety of platforms can provide essential information, instructional videos, and community support, making it easier to address issues independently.

Finding Reliable Sources

When searching for assistance, it’s crucial to identify trustworthy websites that offer accurate and detailed information. Look for official sites, reputable forums, and video channels that specialize in machinery and equipment. User reviews and ratings can also guide you to quality content, ensuring that you gather helpful tips and techniques.

Engaging with Online Communities

Participating in online forums and social media groups can enhance your knowledge and provide practical insights. Connecting with fellow enthusiasts allows for the exchange of experiences and solutions. Don’t hesitate to ask questions or share your findings, as collaboration often leads to effective problem-solving.