Comprehensive Guide to John Deere D170 Repair Manual

Maintaining complex machinery is crucial for ensuring optimal performance and longevity. This comprehensive guide aims to provide users with vital information and practical insights to address common challenges that arise during operation. By understanding the intricacies of your equipment, you can enhance its efficiency and extend its lifespan.

In this resource, you’ll find detailed instructions, helpful tips, and troubleshooting techniques tailored to specific issues. Whether you’re looking to enhance your knowledge or seeking immediate solutions, the information presented here serves as a valuable tool for operators and enthusiasts alike.

Equipped with the right knowledge, users can confidently approach maintenance tasks and prevent potential problems before they escalate. Emphasizing preventative care and regular checks will ultimately lead to a smoother experience and a more reliable machine.

Understanding the John Deere D170

This section delves into a popular model known for its efficiency and durability in the realm of outdoor maintenance equipment. Designed for various landscaping tasks, it combines power with user-friendly features, making it a favored choice among homeowners and professionals alike.

Featuring a robust engine, this machine offers exceptional performance for tasks such as mowing and yard care. Its design emphasizes ease of operation, with intuitive controls and comfortable seating that enhance the user experience. Moreover, the construction quality ensures longevity, allowing users to rely on it for many seasons.

Regular maintenance is crucial for optimal functioning. Understanding key components and their roles can significantly improve performance and extend the lifespan of the equipment. Familiarity with essential parts and systems equips users to address minor issues before they escalate, ensuring that the equipment remains in peak condition.

Overall, this model exemplifies reliability and effectiveness in outdoor tasks, making it a valuable asset for anyone involved in lawn care or gardening. Comprehensive knowledge of its features and upkeep will maximize its potential, contributing to successful landscaping endeavors.

Common Issues with D170 Models

When operating these specific lawn care machines, users may encounter various challenges that can hinder performance and efficiency. Understanding the common problems can help owners anticipate and address issues before they escalate, ensuring the longevity of their equipment.

Engine Performance Problems

One frequent concern is related to engine functionality. Users often report difficulties starting the machine, which can stem from fuel system issues, such as clogged filters or improper fuel types. Additionally, irregular engine speeds may occur due to problems with the ignition system or carburetor malfunctions. Regular maintenance and timely checks can mitigate these issues.

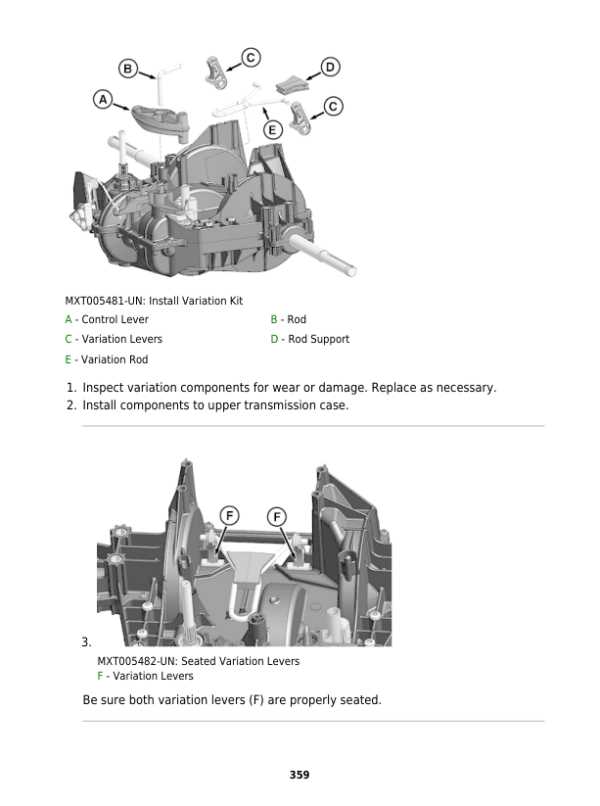

Transmission and Drive Train Complications

Another area where owners may face difficulties is the transmission and drive system. Symptoms can include slipping gears or unresponsive controls, often caused by low fluid levels or worn-out components. Routine inspections and ensuring that all parts are in good condition can help maintain optimal functionality and prevent more severe breakdowns.

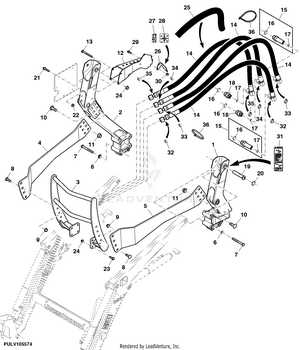

Essential Tools for D170 Repairs

To effectively maintain and restore your equipment, having the right set of instruments is crucial. This section will highlight the indispensable items you should have on hand to tackle various maintenance tasks and ensure smooth operation.

Basic Hand Tools

- Wrenches: A variety of sizes will help you handle different fasteners.

- Screwdrivers: Both flathead and Phillips types are necessary for various screws.

- Pliers: Needle-nose and adjustable pliers are useful for gripping and manipulating components.

- Socket Set: A comprehensive socket set allows for efficient tightening and loosening of bolts.

Specialized Instruments

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Multimeter: Essential for diagnosing electrical issues within the system.

- Oil Filter Wrench: Facilitates easy removal of the oil filter during maintenance.

- Grease Gun: Helps keep moving parts lubricated for optimal performance.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your equipment. Regular upkeep is essential to prevent issues and enhance functionality. Follow these guidelines to maintain your machine effectively and efficiently.

Routine Inspections

Conducting regular checks is crucial for identifying potential problems early. Focus on the following areas:

- Fluid Levels: Regularly check oil, coolant, and fuel levels to ensure everything is within the recommended range.

- Belts and Hoses: Inspect for wear and tear, replacing any that show signs of damage.

- Battery Condition: Keep terminals clean and ensure a secure connection.

Cleaning and Lubrication

Proper cleaning and lubrication will help maintain the equipment’s efficiency:

- Cleaning: Remove debris from filters and screens to avoid clogs and overheating.

- Lubrication: Apply grease to moving parts as specified in the guidelines to reduce friction and wear.

By following this systematic approach, you can ensure your equipment remains in peak condition, ultimately leading to improved performance and reduced repair costs.

Engine Troubleshooting Tips

Maintaining optimal performance in machinery requires a keen eye for potential issues that may arise within the engine. Understanding the signs of trouble can help diagnose problems early, preventing costly repairs and ensuring smooth operation. This section provides essential tips for identifying and addressing common engine-related concerns.

Common Symptoms to Watch For

Listening for unusual noises, observing abnormal vibrations, and checking for warning lights on the dashboard are crucial first steps. These indicators often signal underlying issues that may need immediate attention. Additionally, pay close attention to changes in power output and fuel consumption, as these can provide further clues about engine health.

Basic Diagnostic Steps

Start troubleshooting by inspecting the engine oil level and condition, as low or contaminated oil can lead to serious damage. Next, examine fuel lines for leaks or blockages and ensure that the air filter is clean to allow for proper airflow. Lastly, utilizing diagnostic tools can provide valuable insights into the engine’s performance, helping to pinpoint specific problems effectively.

Replacing the Mower Blades

Maintaining optimal cutting performance is essential for achieving a well-manicured lawn. One critical aspect of this maintenance is the timely replacement of the blades, which can become dull or damaged over time. This process not only enhances the efficiency of the mowing equipment but also contributes to healthier grass growth.

Follow these steps to successfully replace the blades:

- Safety First: Before beginning, ensure the mower is turned off and disconnected from any power source to prevent accidental starts.

- Gather Tools: Prepare the necessary tools, including a socket wrench, a blade removal tool, and a pair of gloves for safety.

- Lift the Mower Deck: Use a jack or mower lift to elevate the deck for easier access to the blades.

- Remove the Old Blades: Locate the blade bolts and use the socket wrench to remove them. Keep the bolts in a safe place for future use.

- Inspect Components: Check the blade spindle and other surrounding parts for wear and tear. Clean any debris before installing new blades.

- Install New Blades: Position the new blades and secure them with the bolts. Ensure they are tightened according to the manufacturer’s specifications.

- Lower the Mower Deck: Carefully lower the deck back to its normal position.

- Test the Equipment: Reconnect the power source and conduct a test run to ensure everything operates smoothly.

Regularly replacing the cutting implements will not only improve the quality of your mowing but also prolong the lifespan of your equipment. Adhering to these guidelines will help maintain a beautiful and healthy lawn throughout the seasons.

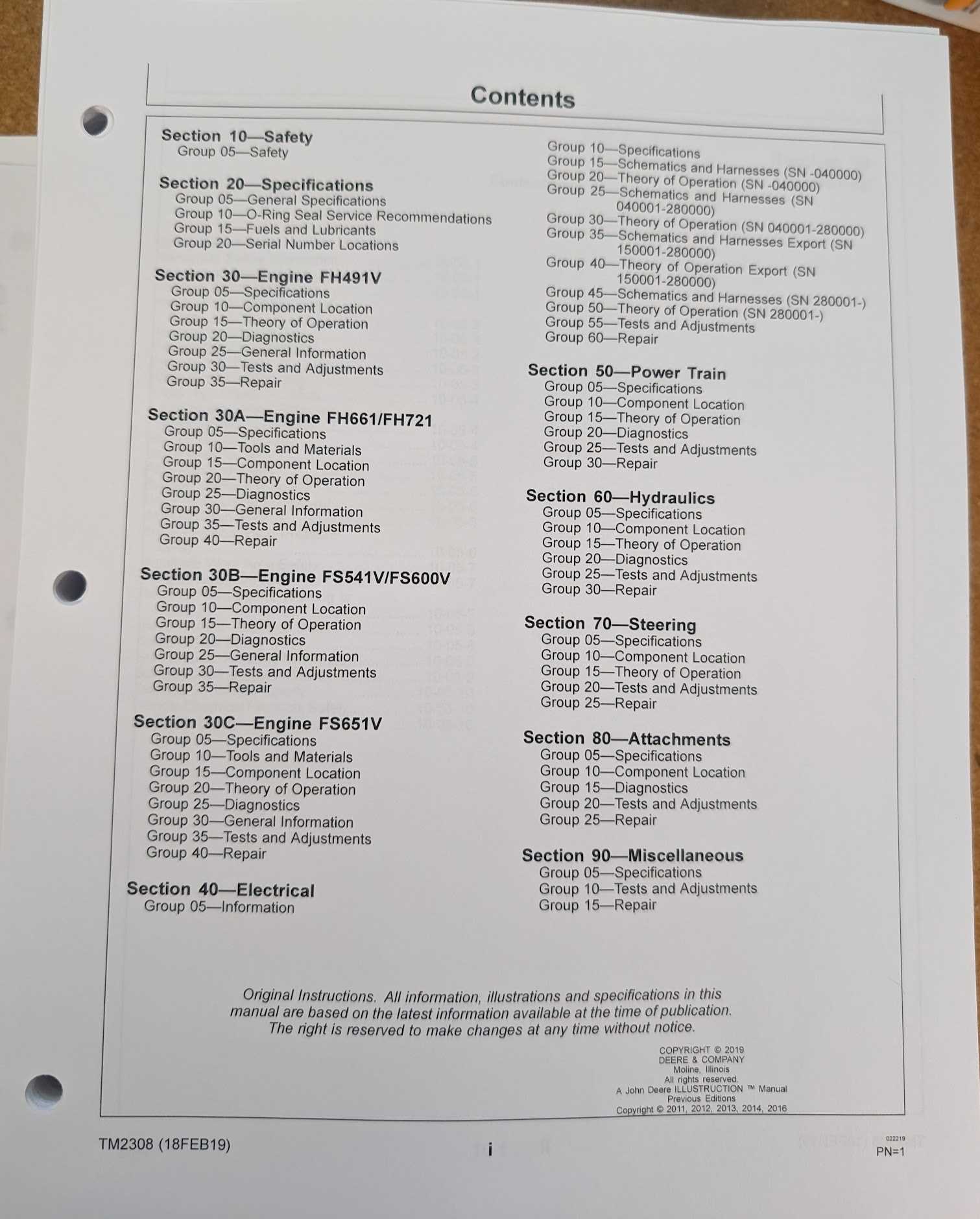

Electrical System Diagnostics

This section focuses on evaluating the electrical framework of your equipment to ensure optimal functionality. By systematically checking the various components, you can identify issues that may hinder performance or cause failures. A thorough understanding of the electrical system is crucial for effective troubleshooting.

Key aspects to consider include voltage levels, wiring integrity, and the operation of critical components such as batteries and starters. Regular diagnostics can prevent unexpected breakdowns and extend the lifespan of the machinery.

| Component | Symptoms of Failure | Testing Method |

|---|---|---|

| Battery | Difficulty starting, dim lights | Voltage measurement with a multimeter |

| Wiring | Corrosion, visible damage | Visual inspection and continuity test |

| Starter Motor | Clicking sound, no engine turnover | Bench test or direct power application |

| Alternator | Battery not charging, flickering lights | Output voltage test under load |

By systematically addressing these components, you can diagnose electrical issues effectively, ensuring your machinery operates reliably and efficiently.

Hydraulic System Maintenance Procedures

Proper upkeep of the hydraulic system is essential for optimal performance and longevity of equipment. Regular maintenance ensures that hydraulic components operate efficiently, reducing the risk of failures and costly repairs. Implementing a systematic approach to care for this system can enhance overall functionality and reliability.

Fluid Inspection and Replacement

Regularly checking the hydraulic fluid is critical. Start by inspecting the fluid level and its condition. If the fluid appears dirty or has a burnt smell, it should be replaced. Flushing the system may also be necessary to remove any contaminants that could impede performance. Ensure to use the recommended type of hydraulic fluid to maintain compatibility with system components.

Filter Maintenance

Hydraulic filters play a vital role in keeping the system clean. It is important to inspect and replace filters according to the manufacturer’s guidelines. Clogged filters can lead to decreased performance and potential damage. Additionally, regularly monitoring filter indicators can help prevent unexpected issues.

Seasonal Preparation for Your D170

Ensuring optimal performance of your lawn equipment throughout the year requires careful attention during seasonal transitions. As the weather changes, it’s crucial to prepare your machine to handle various conditions effectively. This involves routine checks and maintenance that enhance longevity and efficiency.

Spring and Summer Readiness

As warmer months approach, start by thoroughly cleaning your machine. Remove any debris and dirt accumulated during the winter. Check the blades for sharpness; dull blades can lead to uneven cutting. Additionally, inspect the tires for proper inflation and wear. It’s also essential to change the oil and replace the air filter to ensure smooth operation during the busy mowing season.

Fall and Winter Maintenance

As the growing season ends, take proactive steps to prepare for colder months. Winterize your equipment by draining fuel or adding a fuel stabilizer to prevent gumming. Check the battery condition and clean any corrosion. Cover the machine with a protective tarp to shield it from harsh weather. Taking these steps will ensure your equipment is ready to tackle the next season effectively.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration is crucial for maintaining the longevity and efficiency of your equipment. Regular inspections can help you spot potential issues before they escalate into significant problems, ensuring optimal performance and reducing costly repairs. This section will guide you through common signs that may suggest your machinery is experiencing wear and tear.

Visual Inspection

Begin with a thorough visual examination of the equipment. Look for cracks, rust, or any signs of corrosion on the exterior surfaces. Pay attention to the condition of belts and hoses; fraying or cracking can indicate that they need replacement. Additionally, check for fluid leaks, as these can be early signs of component failure.

Performance Changes

Monitor the performance of your machinery during operation. If you notice unusual vibrations, strange noises, or a decline in efficiency, these may be red flags. An engine that struggles to start or a reduction in power output can signify deeper issues requiring immediate attention. Keeping track of these changes can help you address problems proactively.

Recommended Replacement Parts and Suppliers

When maintaining or restoring machinery, selecting the right components is crucial for optimal performance and longevity. This section highlights essential replacement items and reliable sources for procurement, ensuring that your equipment operates smoothly and efficiently.

| Part Type | Description | Recommended Supplier |

|---|---|---|

| Air Filter | Ensures clean air intake for better engine performance. | QualityParts Co. |

| Oil Filter | Helps maintain engine oil cleanliness and efficiency. | BestOil Filters Inc. |

| Spark Plug | Crucial for ignition and optimal engine operation. | Ignition Solutions Ltd. |

| Belt | Transmits power between engine and various components. | PowerDrive Parts |

| Battery | Provides the necessary power for starting the engine. | EnergySource Batteries |

Helpful Resources and Community Support

Accessing the right resources and connecting with fellow enthusiasts can significantly enhance your experience with machinery. Whether you’re seeking troubleshooting tips or maintenance advice, a wealth of information is available through various platforms and communities. Engaging with others who share similar interests can provide invaluable insights and foster a supportive environment.

Online Resources

- Forums: Participate in specialized online discussion boards where users share their experiences and solutions.

- Video Tutorials: Explore platforms like YouTube for step-by-step guides that demonstrate maintenance techniques and common fixes.

- Official Websites: Check the manufacturer’s site for downloadable documents and product specifications.

- Blogs: Read expert blogs that cover a wide range of topics, from basic care to advanced modifications.

Community Engagement

- Local Clubs: Join regional groups to meet enthusiasts and attend workshops or social gatherings.

- Social Media Groups: Follow relevant pages and join groups on platforms like Facebook to stay updated on tips and community events.

- Workshops: Participate in hands-on training sessions that provide practical knowledge and skills.

- Newsletters: Subscribe to newsletters from local dealers or clubs for the latest news and resources.