John Deere F510 Maintenance Guide

This section provides essential insights into maintaining and troubleshooting various machinery. Understanding the intricacies of equipment operation is crucial for ensuring longevity and efficiency.

Users can explore detailed instructions that address common issues, preventive measures, and the overall upkeep necessary to keep their devices in optimal condition. By following these guidelines, operators can enhance performance and reduce the risk of malfunction.

Emphasizing practical knowledge, this resource aims to empower individuals with the skills required for effective management and care of their equipment. Engaging with these insights will facilitate a smoother operational experience.

Common Issues and Solutions

This section addresses frequent challenges encountered by users of this specific model, providing effective remedies and tips for maintenance. Understanding these common problems can enhance the overall performance and longevity of the equipment.

Engine Troubles

- Hard Starting: Ensure that the fuel system is clean and that the battery is fully charged.

- Overheating: Check the coolant levels and inspect for any blockages in the cooling system.

Electrical Failures

- Faulty Lights: Inspect the wiring for loose connections or damaged bulbs.

- Battery Issues: Regularly test the battery condition and clean the terminals to prevent corrosion.

Routine Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By following a consistent maintenance schedule, you can prevent potential issues and enhance performance over time.

Check Fluid Levels: Regularly inspect all fluid levels, including oil, coolant, and hydraulic fluids. Keeping these at optimal levels helps prevent overheating and ensures smooth operation.

Inspect Belts and Hoses: Examine belts and hoses for signs of wear or damage. Replacing worn components promptly can prevent more serious mechanical failures.

Clean Air Filters: A clean air filter is crucial for maintaining engine efficiency. Check and replace air filters as needed to ensure proper airflow and reduce strain on the engine.

Sharpen Blades: For equipment with cutting mechanisms, regularly sharpening blades ensures efficient performance and a clean cut. Dull blades can lead to increased fuel consumption and poor results.

Check Tires: Monitor tire pressure and tread wear. Properly inflated and maintained tires enhance stability and traction, contributing to overall safety and efficiency.

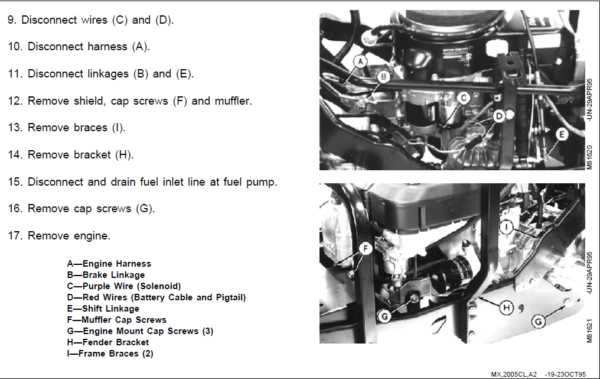

Engine Specifications and Troubleshooting

This section provides essential information regarding the performance parameters and common issues associated with the engine. Understanding these aspects is crucial for effective maintenance and efficient operation.

Engine Specifications

- Type: Four-stroke, air-cooled

- Displacement: 20.5 cubic inches (335 cc)

- Power Output: 10.5 horsepower at 3600 RPM

- Fuel Type: Regular unleaded gasoline

- Oil Capacity: 1.5 quarts (1.4 liters)

Troubleshooting Common Issues

- Engine Won’t Start:

- Check fuel level and quality.

- Inspect spark plug for wear and proper gap.

- Ensure battery is charged and connections are clean.

- Overheating:

- Check for proper airflow around the engine.

- Ensure coolant levels are adequate.

- Inspect for blockages in the cooling fins.

- Strange Noises:

- Identify the source of the sound; it may indicate loose components.

- Inspect for signs of wear on belts and pulleys.

- Examine oil levels and quality to prevent excessive friction.

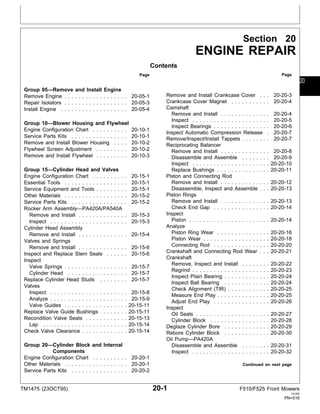

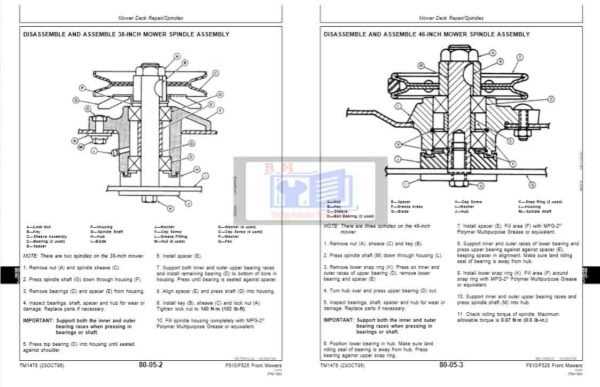

Transmission Repair Techniques

This section explores various methods for addressing issues within transmission systems. Understanding these techniques is essential for ensuring smooth operation and longevity of machinery.

Diagnostics and Assessment

Before initiating any repairs, a thorough diagnostic process is crucial. Identifying the symptoms accurately allows for targeted interventions. Utilize specialized tools to assess fluid quality, pressure levels, and component functionality.

Component Replacement and Adjustment

Once the problem has been diagnosed, specific components may require replacement or adjustment. This may involve swapping out worn parts or fine-tuning existing mechanisms to restore optimal performance. Always ensure that replacements meet the required specifications to avoid further complications.

Electrical System Diagnostics

Understanding the intricacies of a vehicle’s electrical framework is essential for effective troubleshooting. This section delves into the methods and tools required to evaluate and rectify issues within the electrical components, ensuring optimal performance and reliability.

Begin by inspecting the battery for signs of wear, corrosion, or insufficient charge. A multimeter can be used to measure voltage and ensure the battery is functioning correctly. Next, check the fuses and relays, as these are critical in maintaining circuit integrity. Replacing any faulty fuses can resolve many common electrical issues.

Wiring should also be examined for any signs of damage or loose connections. Utilize a wiring diagram to trace circuits and identify any problematic areas. Continuity tests can help pinpoint breaks or shorts in the wiring. Additionally, connectors must be clean and secure to prevent any intermittent failures.

For more complex issues, diagnostic scanners can provide valuable insights into the system’s performance. These tools can read error codes and help identify malfunctioning sensors or components. Once identified, repairs can be made, ensuring the system operates smoothly and efficiently.

Hydraulic System Maintenance

Regular upkeep of the hydraulic system is essential for ensuring optimal performance and longevity of the machinery. Proper maintenance not only enhances functionality but also helps prevent costly breakdowns and repairs. A thorough understanding of the components and their care is vital for achieving efficient operation.

Routine Checks

Conducting periodic inspections is crucial. Check for fluid levels, leaks, and signs of wear on hoses and connections. Ensure that all components are securely fastened and free from dirt or debris that could impede function.

Fluid Replacement

Changing the hydraulic fluid at recommended intervals is necessary for system health. Old fluid can accumulate contaminants, which may lead to reduced efficiency. Always use the specified type of fluid to maintain the integrity of the system.

Replacing Tires and Wheels

Changing out the rolling components of a vehicle is crucial for maintaining optimal performance and safety. This process involves selecting the appropriate replacements and ensuring proper installation. Regular checks can prevent potential issues and enhance the longevity of the equipment.

Steps for Replacement

To successfully swap the tires and wheels, follow these key steps:

- Gather the necessary tools and replacement parts.

- Lift the vehicle using a suitable jack.

- Remove the existing wheels and tires carefully.

- Install the new tires onto the wheels, ensuring they are properly seated.

- Attach the wheels back to the vehicle securely.

Tools Required

| Tool | Purpose |

|---|---|

| Jack | To lift the vehicle for tire removal |

| Lug Wrench | To remove and tighten lug nuts |

| Tire Pressure Gauge | To check air pressure in new tires |

| Torque Wrench | To ensure proper tightness of lug nuts |

Understanding the Fuel System

The fuel system is a crucial component in any machinery, ensuring the efficient delivery of energy needed for operation. Its design encompasses various elements that work in harmony to provide the right mixture of fuel and air to the engine, facilitating optimal performance and reliability.

Key elements of this system include the fuel tank, lines, pump, and injectors, each playing a significant role in maintaining a steady flow of fuel. The tank stores the fuel, while the pump transports it through the lines to the injectors, where it is atomized and mixed with air for combustion. Regular maintenance of these components is essential to prevent issues such as clogging or leaks, which can disrupt functionality.

Understanding the operation and potential challenges of the fuel system allows for timely interventions and repairs, enhancing the longevity of the equipment. Proper troubleshooting techniques can help identify problems early, ensuring that the machinery operates smoothly and efficiently over time.

Blade Replacement and Adjustment

Replacing and adjusting the cutting element is essential for maintaining optimal performance and efficiency. Proper upkeep ensures a clean cut and extends the lifespan of the machinery. This section provides guidelines for the safe and effective process of replacing and adjusting the blade.

Steps for Blade Replacement

To successfully replace the cutting element, follow these steps:

- Ensure the equipment is turned off and disconnected from any power source.

- Lift the mower deck to gain access to the cutting element.

- Remove the securing bolts that hold the blade in place.

- Carefully detach the old blade and replace it with the new one.

- Secure the new blade with the bolts, ensuring it is tightened appropriately.

Adjustment Techniques

After replacing the blade, it is crucial to adjust it for optimal performance. Follow these adjustment techniques:

- Check the level of the blade in relation to the mower deck.

- Adjust the height settings according to the desired cutting length.

- Test the cutting performance and make further adjustments if necessary.

| Component | Adjustment Type | Notes |

|---|---|---|

| Blade Height | Increase/Decrease | Ensure even cutting across the surface. |

| Blade Tightness | Tighten/Loosen | Avoid excessive vibrations during operation. |

Seasonal Storage Best Practices

Proper seasonal storage is essential for maintaining equipment and ensuring optimal performance when it’s needed again. Following best practices helps prevent damage and prolongs the lifespan of your machinery.

Here are key tips to consider for effective seasonal storage:

- Clean Thoroughly: Remove dirt, debris, and residue from surfaces to prevent corrosion and buildup.

- Inspect Components: Check for any signs of wear or damage. Replace or repair parts as necessary.

- Drain Fluids: Empty fuel tanks and fluid reservoirs to avoid deterioration and contamination.

- Store in a Dry Location: Keep equipment in a covered, dry area to protect it from moisture and the elements.

- Use Protective Covers: Cover machinery with appropriate tarps or covers to shield it from dust and pests.

- Check Battery Condition: Remove and store batteries in a cool, dry place, and consider using a trickle charger.

Implementing these practices will help ensure that your equipment remains in top condition throughout the off-season, ready for use when needed.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for efficient maintenance and troubleshooting tasks. A well-equipped toolkit not only enhances the quality of your work but also ensures safety and precision during the process.

Here are some fundamental items to consider:

- Wrenches: Adjustable and fixed types are essential for loosening and tightening various fittings.

- Screwdrivers: A set including both flathead and Phillips is necessary for handling screws of different types.

- Pliers: Needle-nose and regular pliers assist in gripping and manipulating small components.

- Socket Set: A comprehensive socket set provides versatility for various sizes of bolts and nuts.

- Torque Wrench: This tool ensures that fasteners are tightened to the correct specifications, preventing damage.

Equipping yourself with these tools will enable you to tackle a variety of maintenance challenges effectively.

Finding Replacement Parts Easily

Locating suitable components for your equipment can streamline maintenance and ensure optimal performance. Understanding where to search and how to identify the right parts can save time and enhance efficiency.

Several resources are available to assist you in this process:

| Resource Type | Description |

|---|---|

| Online Retailers | Websites specializing in machinery parts often have extensive catalogs and easy search features. |

| Manufacturer’s Website | Official sites usually provide part numbers and compatibility information directly from the source. |

| Local Dealerships | Authorized dealers can offer personalized assistance and access to genuine parts. |

| Online Forums | Community platforms allow users to share experiences and recommendations regarding parts sourcing. |

Utilizing these resources effectively can make the process of finding and acquiring replacement components much more manageable.