Comprehensive Guide to John Deere Gator Repair Manual

For enthusiasts and professionals alike, understanding the intricacies of utility vehicle upkeep is crucial. This comprehensive resource aims to provide valuable insights into the essential practices for maintaining these versatile machines, ensuring they operate at peak performance.

Detailed guidance on troubleshooting common issues is key for owners who want to extend the lifespan of their vehicles. By exploring various components and their functions, one can effectively tackle repairs and enhance overall efficiency.

Furthermore, this guide emphasizes the importance of regular inspections and preventive measures. Investing time in proper care not only saves money in the long run but also ensures reliable performance in the field.

Understanding John Deere Gator Models

Recognizing the various models within this popular utility vehicle lineup is essential for users to select the best option for their needs. Each version offers distinct features and specifications tailored to different tasks, environments, and preferences.

Key Variations

These vehicles come in a range of variations, each designed to excel in specific applications. Here are some key categories:

- Standard models: Ideal for general use and light-duty tasks.

- Utility versions: Designed for heavy lifting and towing capabilities.

- Sport models: Tailored for performance and recreational activities.

- Specialty variants: Focused on niche applications such as agricultural work or landscaping.

Factors to Consider

When evaluating different models, consider the following aspects:

- Payload capacity: Determine how much weight the vehicle can carry for your specific needs.

- Engine power: Assess the horsepower and torque required for your intended applications.

- Terrain suitability: Identify the type of surfaces the vehicle will primarily operate on.

- Comfort and features: Explore options for seating, storage, and technological enhancements.

Understanding these models allows users to make informed decisions and optimize their experience with these versatile vehicles.

Common Issues with John Deere Gators

Many utility vehicles encounter a range of challenges that can affect their performance and longevity. Understanding these frequent problems can help owners maintain their equipment more effectively. This section explores typical complications that operators might face.

Engine Troubles: One prevalent issue involves the engine, which may exhibit difficulties starting or running smoothly. This can often be attributed to fuel delivery problems, such as clogged filters or faulty pumps. Regular checks can prevent these disruptions.

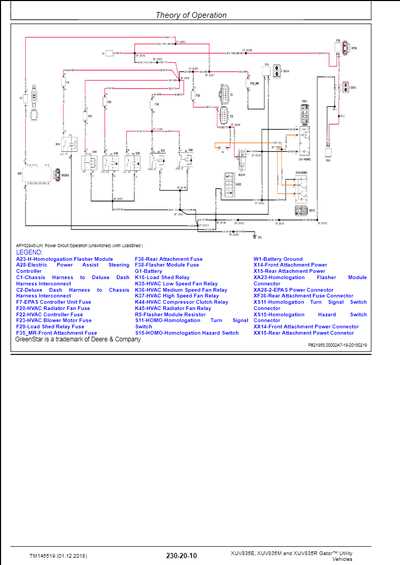

Electrical Failures: Another common complication relates to the electrical system. Issues such as dead batteries, malfunctioning switches, or damaged wiring can hinder operation. Ensuring all connections are secure and batteries are charged is crucial for reliability.

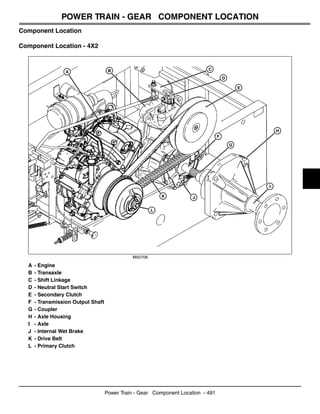

Transmission Concerns: Shifting difficulties or strange noises during operation may indicate problems within the transmission. Low fluid levels or worn-out components can lead to these issues, necessitating prompt attention to maintain functionality.

Brake Malfunctions: Brake systems may also present challenges, with signs of wear or improper adjustment. Regular inspections and timely replacements of pads and fluids can enhance safety and performance.

Tire Wear: Uneven tire wear can significantly impact handling and efficiency. Proper inflation and regular rotation can mitigate this problem, ensuring a smoother ride and prolonging tire life.

By being aware of these common complications, operators can take proactive steps to address issues early, ultimately extending the life and performance of their vehicles.

Essential Tools for Gator Repairs

When it comes to maintaining and servicing your utility vehicle, having the right equipment is crucial for ensuring efficiency and effectiveness. Proper tools not only facilitate the work but also help in achieving high-quality results. Below is a list of must-have instruments for any enthusiast or professional looking to tackle tasks related to these vehicles.

- Wrenches: A variety of wrenches, including socket and adjustable types, are essential for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for handling screws in various components.

- Plier Set: A good set of pliers, including needle-nose and slip-joint types, can assist in gripping, twisting, and cutting tasks.

- Torque Wrench: This tool is critical for applying the correct amount of force to bolts, ensuring proper assembly and safety.

- Jack and Stands: A reliable jack paired with sturdy stands is indispensable for lifting the vehicle safely while performing undercarriage work.

In addition to these basic tools, consider having specialized instruments that can further enhance your maintenance capabilities:

- Multimeter: Useful for diagnosing electrical issues and ensuring proper functionality of various systems.

- Oil Filter Wrench: A specific tool designed for removing and installing oil filters with ease.

- Diagnostic Scanner: An electronic device that reads error codes and provides insights into the vehicle’s performance.

- First Aid Kit: While not a tool for mechanical tasks, a first aid kit is vital for safety during any maintenance job.

Equipping yourself with these essential instruments will make tackling maintenance tasks more manageable and effective. Investing in quality tools pays off in the long run, ensuring that your utility vehicle remains in optimal condition.

Step-by-Step Repair Techniques

This section provides a comprehensive guide to addressing common mechanical issues through systematic procedures. Following a structured approach ensures that each task is handled efficiently, minimizing the risk of further complications.

1. Diagnosis: Begin by identifying the specific problem. Observe the machinery closely and listen for unusual sounds. Take note of any warning lights or error codes, as they can provide valuable insights into the underlying issue.

2. Gather Tools: Assemble all necessary tools and replacement parts before starting the work. Having everything at hand will streamline the process and reduce downtime.

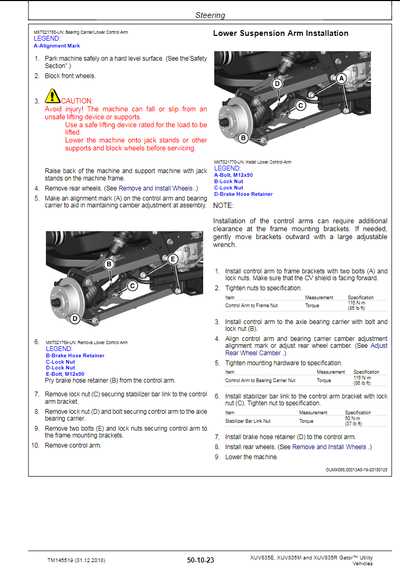

3. Safety First: Ensure that the equipment is powered off and properly secured. Use appropriate safety gear to protect yourself from potential hazards during the maintenance process.

4. Disassembly: Carefully remove any components that obstruct access to the area needing attention. Document each step, taking photos if necessary, to facilitate reassembly later.

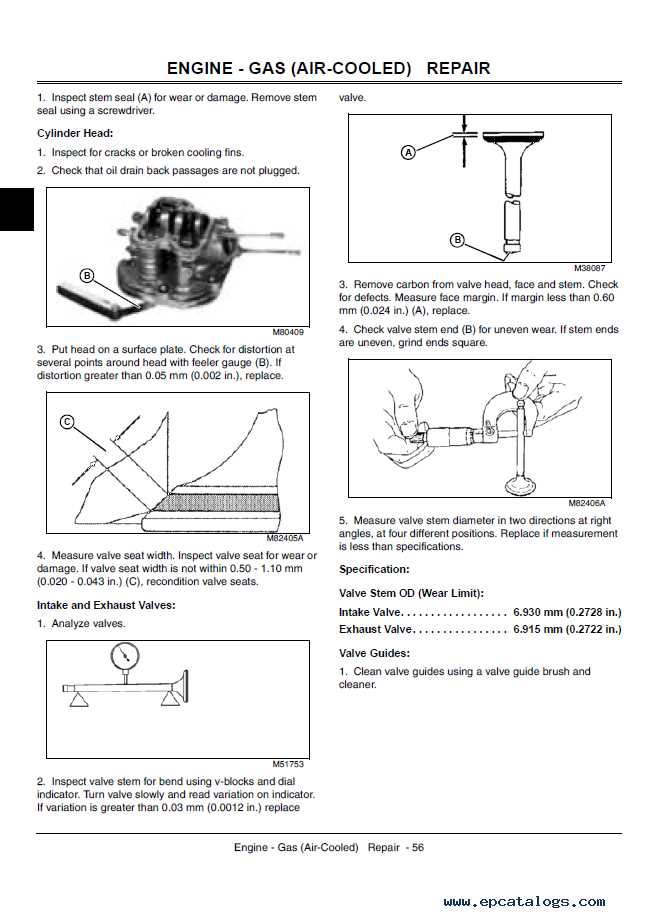

5. Inspection: Examine all parts for wear or damage. Pay special attention to seals, belts, and connections. Replace any components that show signs of deterioration to prevent future failures.

6. Repair or Replace: Depending on the findings during the inspection, either repair the damaged parts or replace them with new ones. Follow manufacturer guidelines to ensure proper installation.

7. Reassembly: Once repairs are complete, reassemble the equipment in the reverse order of disassembly. Ensure all fasteners are tightened to the recommended specifications.

8. Testing: After reassembly, perform a thorough test to confirm that the issue has been resolved. Monitor the equipment under normal operating conditions to ensure optimal performance.

9. Documentation: Keep detailed records of the work completed, including parts replaced and any observations made during the process. This information can be invaluable for future maintenance.

By adhering to these step-by-step techniques, you can effectively address a variety of mechanical challenges, ensuring your equipment remains in peak condition.

Maintenance Tips for Longevity

Proper care is essential for ensuring the extended lifespan and optimal performance of your utility vehicle. Regular attention to maintenance tasks not only prevents issues but also enhances efficiency and reliability. Below are key practices to keep your vehicle in top shape.

- Regular Inspections: Check components such as brakes, tires, and lights frequently to identify wear or damage early.

- Fluid Levels: Maintain adequate levels of oil, coolant, and other essential fluids to support smooth operation.

- Air Filter Cleaning: Clean or replace the air filter periodically to ensure proper airflow and engine performance.

In addition to these basics, consider the following recommendations:

- Tire Maintenance: Inspect tire pressure and tread regularly; inflate as necessary and rotate to promote even wear.

- Battery Care: Clean terminals and check connections to prevent corrosion and ensure reliable starting.

- Belts and Hoses: Examine for cracks or fraying; replace as needed to avoid breakdowns.

Implementing these practices will significantly contribute to the durability and efficiency of your utility vehicle, allowing you to enjoy its capabilities for years to come.

When to Seek Professional Help

Understanding the limits of your own mechanical skills is crucial when dealing with complex machinery. While many issues can be tackled with a basic toolkit and some know-how, there are situations where calling in an expert is the most prudent choice. Recognizing these moments can save time, resources, and prevent potential damage.

First and foremost, if you encounter problems that involve intricate systems or components, such as the electrical or hydraulic systems, it’s advisable to consult a professional. These areas often require specialized knowledge and tools that the average user may not possess.

Additionally, if your attempts at troubleshooting have not yielded results, and the machinery remains inoperable, it may be time to seek assistance. Persistent issues can indicate underlying problems that are not easily identifiable without the right experience.

Finally, safety should always be a priority. If you feel uncertain or uncomfortable with any task, especially those involving heavy components or potential hazards, don’t hesitate to reach out for professional help. It’s better to be safe than to risk injury or further damage.

Finding Genuine Replacement Parts

When it comes to maintaining your utility vehicle, sourcing authentic components is crucial for optimal performance and longevity. Using original parts ensures compatibility, reliability, and the best possible fit, preventing issues that can arise from substandard alternatives. In this section, we will explore effective strategies for locating and acquiring these essential items.

Why Authentic Components Matter

Investing in genuine parts significantly impacts the efficiency and durability of your machine. These components are specifically designed to meet the manufacturer’s specifications, which means they are rigorously tested for quality and performance. By opting for original replacements, you can avoid the risks associated with counterfeit or generic options, such as premature wear or mechanical failure.

Where to Find Authentic Parts

Several avenues exist for obtaining reliable components. Authorized dealers and service centers are often the best places to start, as they typically stock a wide range of original parts and provide expert advice. Additionally, reputable online retailers can offer convenience and competitive pricing. Always verify the source to ensure you are receiving authentic merchandise. Utilizing online forums and communities can also connect you with fellow enthusiasts who may have recommendations or insights into trusted suppliers.

Safety Precautions During Repairs

When engaging in maintenance tasks on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to proper guidelines ensures a secure environment for both the individual performing the work and anyone nearby.

Here are essential safety measures to consider:

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the machine is turned off and disconnected from any power sources before beginning work.

- Use tools that are in good condition and suitable for the task at hand.

- Keep the workspace clean and organized to minimize hazards.

- Be aware of your surroundings and ensure that no one is in the immediate vicinity when performing tasks.

- Read and understand all safety guidelines provided by the manufacturer.

Implementing these precautions not only safeguards the individual but also enhances the efficiency of the maintenance process, contributing to a longer lifespan for the equipment.

Upgrading Your Gator’s Performance

Enhancing the capabilities of your utility vehicle can significantly improve its efficiency and overall experience. By implementing various modifications and adjustments, you can optimize performance for different tasks, whether it’s for work or recreation. This section will explore several methods to elevate your vehicle’s functionality.

Engine Enhancements

One of the most effective ways to boost performance is by upgrading the engine components. Consider installing a high-performance air intake system, which can increase airflow and improve combustion efficiency. Additionally, tuning the engine with a programmable ECU can allow for more precise fuel delivery and timing adjustments, resulting in enhanced power and torque.

Suspension and Tires

Upgrading the suspension system can significantly affect handling and comfort. A better shock absorber setup will provide improved stability on rough terrain, while also increasing load capacity. Choosing the right tires is equally crucial; opting for all-terrain or specialized tires can enhance traction and control, making your vehicle more versatile in various environments.

Investing in these enhancements will not only optimize performance but also extend the lifespan of your utility vehicle, ensuring it remains reliable for years to come.

Resourceful Online Repair Communities

In today’s digital age, enthusiasts and owners of various machinery often turn to virtual platforms for assistance and knowledge sharing. These communities provide a wealth of information, fostering connections among individuals who face similar challenges. By leveraging collective experiences, members can troubleshoot issues, exchange tips, and discover innovative solutions to enhance the performance of their vehicles.

Benefits of Joining Online Communities

Participating in these groups offers numerous advantages. Members gain access to a plethora of shared resources, including step-by-step guides, videos, and user-generated content that simplifies complex tasks. Additionally, the support from fellow enthusiasts creates a sense of camaraderie, making problem-solving a collaborative effort rather than a solitary task.

Finding the Right Community

Identifying the most suitable online platform is crucial for effective engagement. Many forums and social media groups cater to specific machinery types or brands, ensuring that discussions are relevant and focused. By joining these networks, users can tap into a vibrant pool of knowledge and expertise, empowering them to tackle any maintenance or upgrade projects with confidence.