Comprehensive Guide to John Deere GT235 Repair Manual

In the realm of outdoor machinery, understanding the intricacies of your equipment can significantly enhance its longevity and performance. Whether you are a seasoned operator or a novice, having access to detailed information about upkeep procedures and common issues can make all the difference. This section serves as a valuable resource, empowering users to effectively address mechanical challenges and optimize their machine’s functionality.

Equipped with insights into systematic diagnostics and practical solutions, you will be better prepared to tackle any situation that arises. From routine care to resolving specific malfunctions, this guide aims to equip you with the knowledge necessary to keep your equipment running smoothly. Emphasizing clarity and precision, it breaks down complex processes into manageable steps, ensuring that even the less experienced can confidently engage in the maintenance of their machinery.

Moreover, a well-informed operator not only enhances their own skills but also contributes to the overall efficiency and productivity of their operations. By familiarizing yourself with essential techniques and strategies, you are taking a proactive approach to machinery stewardship. This guide is designed to be your companion in navigating the often-challenging landscape of mechanical maintenance, ensuring that you have the tools and information needed for success.

Overview of John Deere GT235

This section provides a comprehensive look at a popular lawn care machine known for its reliability and efficiency. Designed for homeowners, it excels in maintaining gardens and yards, combining advanced engineering with user-friendly features.

Key Features

The model is equipped with a powerful engine, ensuring optimal performance for various mowing tasks. With an ergonomic design, it allows for comfortable operation, making it suitable for extended use.

Maintenance Insights

Regular upkeep is essential to ensure longevity and peak performance. Understanding the basic components and their functions can help owners effectively manage their equipment and tackle any issues that may arise.

Common Issues Faced by Owners

Many individuals encounter various challenges when maintaining their lawn equipment. Understanding these frequent problems can help owners take proactive steps to ensure optimal performance and longevity of their machines.

| Issue | Description | Potential Solutions |

|---|---|---|

| Starting Problems | Difficulty in starting the engine can arise due to fuel issues or battery failure. | Check fuel levels, replace old fuel, or test the battery condition. |

| Cutting Quality | Uneven cutting or grass clumping can result from dull blades or incorrect height settings. | Sharpen blades regularly and adjust cutting height as needed. |

| Overheating | Engines may overheat due to clogged air filters or low oil levels. | Clean or replace air filters and regularly check oil levels. |

| Transmission Issues | Problems with gear shifting can occur from worn belts or insufficient fluid. | Inspect belts for wear and check transmission fluid levels. |

| Electrical Failures | Malfunctions in electrical components can lead to lighting or starting issues. | Inspect wiring and connections, and replace faulty components. |

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right instruments is crucial. The effectiveness and efficiency of any task often depend on the availability of specific tools designed for various functions. This section highlights the necessary equipment that can help ensure smooth operations and prolong the lifespan of your machinery.

Basic Hand Tools

Starting with the fundamentals, a good set of hand tools is indispensable. Wrenches, screwdrivers, and pliers are essential for loosening and tightening components. Investing in high-quality options ensures durability and reliability, making your tasks easier and more efficient. A comprehensive toolbox should also include a hammer and a utility knife, which can be handy in a variety of situations.

Power Tools and Safety Gear

For more demanding jobs, power tools can significantly reduce the time and effort required. Drills, saws, and grinders are often necessary for more complex repairs. Additionally, safety gear such as gloves, goggles, and ear protection is vital to ensure personal safety while working. Prioritizing both efficiency and safety will contribute to successful maintenance practices.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your equipment in optimal condition. Regular upkeep not only extends the lifespan of your machinery but also ensures it operates efficiently. Follow these steps to maintain peak performance.

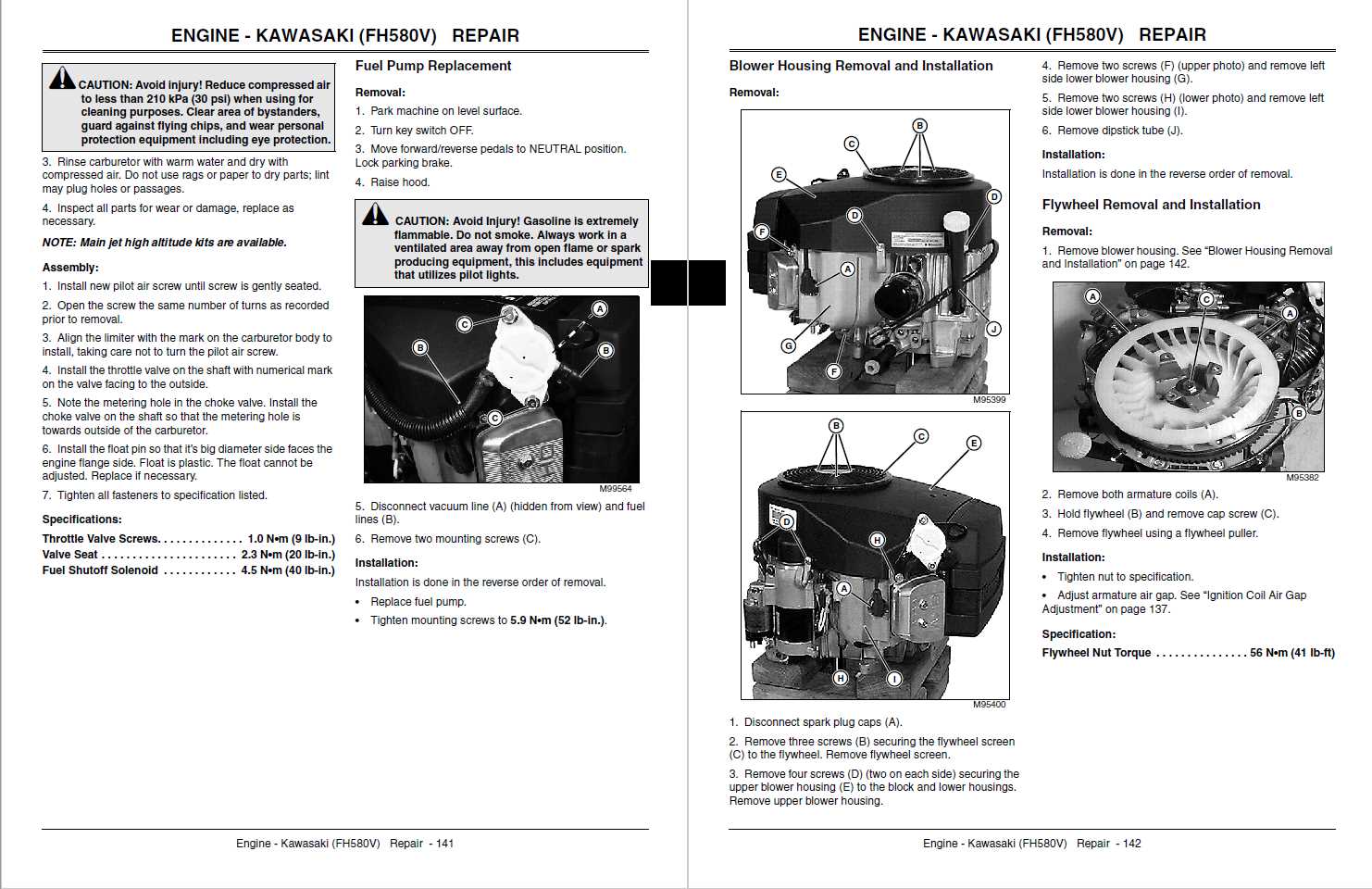

- Inspect the Engine:

- Check oil levels and change if necessary.

- Examine air filters for dirt and replace as needed.

- Look for any leaks around the engine components.

- Examine the Fuel System:

- Ensure fuel is clean and fresh.

- Inspect fuel lines for cracks or wear.

- Replace fuel filters according to schedule.

- Maintain the Deck:

- Clear any debris and grass buildup.

- Check for rust and treat as necessary.

- Inspect blade sharpness and sharpen or replace as needed.

- Check the Tires:

- Ensure proper inflation for optimal performance.

- Inspect for signs of wear and replace if needed.

- Rotate tires regularly to promote even wear.

- Inspect Belts and Cables:

- Look for fraying or cracks in belts.

- Check tension and adjust if necessary.

- Ensure cables are free from corrosion and functioning properly.

Following these steps regularly will help you avoid unexpected issues and enhance the performance of your machinery. Always consult your specific guidelines for more detailed instructions.

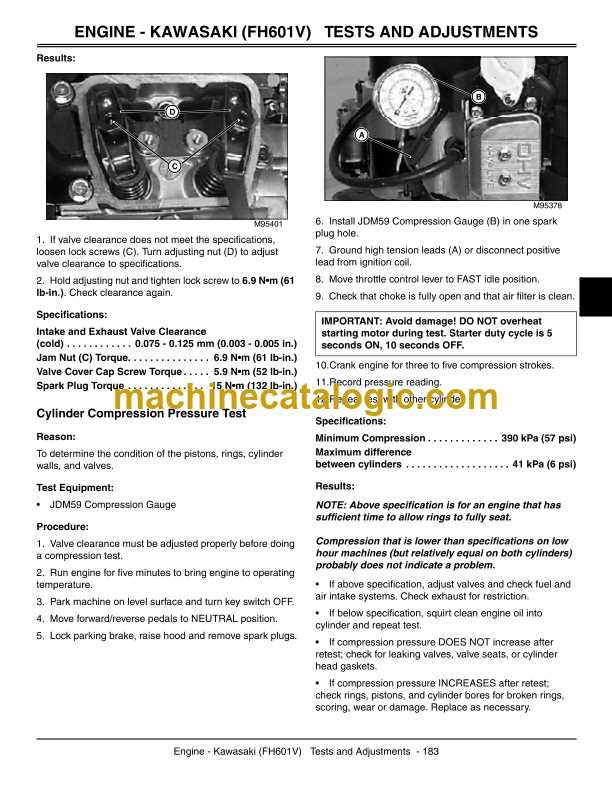

Engine Troubleshooting Techniques

Effective diagnosis of engine issues is essential for maintaining optimal performance and longevity. This section outlines various strategies and methods for identifying common problems that may arise during operation. By understanding the underlying mechanics, one can swiftly pinpoint malfunctions and implement appropriate solutions.

When faced with engine troubles, the following steps are crucial for a systematic approach:

| Step | Description |

|---|---|

| 1 | Visual Inspection: Begin with a thorough examination of the engine components for visible signs of wear, leaks, or damage. |

| 2 | Check Fluid Levels: Ensure that all necessary fluids, including oil and coolant, are at appropriate levels to prevent overheating and lubrication issues. |

| 3 | Listen for Unusual Noises: Pay attention to any irregular sounds that could indicate mechanical problems, such as knocking or grinding. |

| 4 | Conduct Performance Tests: Evaluate engine performance through various tests to determine if it meets standard operational parameters. |

| 5 | Use Diagnostic Tools: Employ specialized equipment to read error codes and assess the engine’s electronic systems for faults. |

By following these techniques, one can effectively identify and address engine issues, ensuring that the machinery operates smoothly and efficiently.

Transmission Repair Tips

Maintaining the efficiency of your machine’s transmission is essential for optimal performance. Understanding common issues and solutions can help ensure smooth operation and prolong the lifespan of the equipment. Here are some valuable insights to assist you in addressing potential challenges.

1. Regular Inspection: Frequently check for leaks, unusual noises, or performance changes. Early detection of problems can prevent more significant damage and costly interventions.

2. Fluid Maintenance: Ensure that the transmission fluid is at the correct level and in good condition. Old or contaminated fluid can lead to overheating and wear. Consider changing the fluid according to the manufacturer’s recommendations.

3. Component Cleaning: Dirt and debris can accumulate over time, affecting the functionality of various parts. Regularly clean filters and housing to maintain optimal conditions.

4. Gear Adjustment: If you experience shifting issues, check the alignment and adjustment of the gears. Proper calibration can enhance shifting performance and reduce stress on the system.

5. Seek Professional Guidance: If you encounter persistent issues that you cannot resolve, don’t hesitate to consult a professional. Experienced technicians can provide insights and solutions that may not be immediately apparent.

By following these guidelines, you can enhance the reliability and efficiency of your machine’s transmission, ensuring it operates effectively for years to come.

Electrical System Diagnostics

Understanding the intricacies of an electrical system is crucial for efficient troubleshooting and maintenance. This section focuses on identifying and resolving issues related to electrical components and circuits, ensuring optimal performance and longevity of the equipment.

To begin the diagnostic process, it is essential to gather the necessary tools, including a multimeter and wiring diagrams. These instruments help in measuring voltage, resistance, and continuity, allowing for a comprehensive assessment of the electrical pathways.

Common symptoms of electrical malfunctions may include dim lights, inconsistent starting, or erratic behavior of electrical accessories. By systematically isolating each component and testing its functionality, one can pinpoint the source of the problem. This methodical approach reduces the risk of overlooking critical issues that could lead to further complications.

In addition to component testing, inspecting wiring for damage or corrosion is vital. Frayed wires or poor connections can disrupt the flow of electricity, resulting in operational failures. Regular visual checks and cleaning can prevent these issues from escalating.

Ultimately, mastering electrical diagnostics involves a combination of knowledge, experience, and the right tools. By diligently following diagnostic procedures, users can maintain a reliable electrical system, ensuring their equipment remains in peak condition.

Seasonal Maintenance Checklist

Regular upkeep of your equipment is essential for optimal performance throughout the year. This checklist serves as a guide to ensure all critical areas are addressed during seasonal transitions, enhancing longevity and functionality.

Spring Preparation

As the season changes, it’s important to prepare your machinery for increased usage. Focus on:

- Fluid Levels: Check and top off oil, coolant, and fuel.

- Filters: Replace air and fuel filters to ensure efficient operation.

- Blades: Sharpen or replace cutting blades for effective performance.

Autumn Wrap-Up

As activities wind down, it’s crucial to prepare your equipment for winter storage. Key tasks include:

- Cleaning: Thoroughly wash and dry to prevent rust and corrosion.

- Storage Preparation: Add stabilizer to fuel and run the engine briefly.

- Batteries: Disconnect and store in a cool, dry place to extend life.

Following this checklist will help ensure your machinery remains in peak condition, ready for action when the next season arrives.

Finding Replacement Parts

Locating suitable components for your machinery is crucial to ensure optimal performance and longevity. Whether you are dealing with maintenance or upgrades, understanding where to source these items can save time and effort. This section will guide you through effective strategies to find the right parts for your equipment.

Online Retailers offer a vast selection of components, often at competitive prices. Websites dedicated to machinery parts frequently provide detailed specifications and customer reviews, which can aid in making informed decisions. Searching by model number can yield precise results, helping you find exactly what you need.

Local Dealers can also be a valuable resource. Building a relationship with a nearby distributor can facilitate access to genuine parts and expert advice. They often have inventory readily available, allowing for quick replacements and minimizing downtime.

Salvage Yards are another option worth considering. These facilities often have a range of used components at a fraction of the cost of new ones. While there may be some risk involved regarding the condition of these parts, diligent inspection can lead to significant savings.

Networking with fellow enthusiasts or professionals in the field can provide additional insights. Online forums and local clubs often have members willing to share their experiences and recommend reliable sources for parts. Engaging with a community can open doors to unique finds and opportunities for assistance.

DIY vs. Professional Repairs

When it comes to maintaining equipment, enthusiasts often face the decision of whether to tackle tasks themselves or enlist the help of trained experts. Both approaches have their advantages and drawbacks, making it essential to evaluate personal skills, available resources, and the complexity of the job at hand.

Do-It-Yourself efforts can foster a sense of accomplishment and save money on labor costs. For those who enjoy hands-on projects, taking the initiative can lead to a deeper understanding of how machinery operates. However, this route may require a considerable investment of time and sometimes comes with the risk of errors that could lead to more significant issues down the line.

On the other hand, opting for professional assistance ensures that tasks are completed efficiently and effectively by individuals with specialized knowledge. This approach can be particularly beneficial for intricate problems or when time is of the essence. While it may incur higher expenses, the peace of mind that comes with expert service often outweighs the cost, especially in critical situations.

Ultimately, the choice between self-service and seeking professional help hinges on one’s confidence in their abilities and the specific demands of the maintenance task. Balancing both options can lead to optimal outcomes, enhancing both personal skills and the longevity of the equipment.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance work is paramount for both personal well-being and equipment integrity. Adhering to specific guidelines can significantly reduce the risk of accidents and enhance the effectiveness of the tasks at hand. Understanding these essential practices is crucial for anyone involved in mechanical servicing.

Before beginning any service, it’s vital to prepare the workspace and equipment. Here are key considerations:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, such as gloves, goggles, and sturdy footwear to protect against potential hazards. |

| Ventilation | Ensure adequate airflow in the workspace, especially when working with chemicals or fuels to prevent inhalation of harmful fumes. |

| Tool Inspection | Examine tools for any damage or wear before use. Faulty tools can lead to serious accidents. |

| Stability | Make sure that the machinery is stable and properly secured before starting any work to avoid unexpected movements. |

| Emergency Procedures | Be familiar with emergency protocols and have a first-aid kit readily available to address any unforeseen incidents. |

By following these precautions, individuals can create a safer environment, ultimately leading to more efficient and effective maintenance work.