Comprehensive Guide to John Deere JX75 Repair Manual

Effective upkeep of garden machinery is essential for ensuring longevity and optimal performance. This guide serves as a valuable resource for those seeking to understand the intricacies of caring for their outdoor equipment. By following systematic procedures and informed practices, users can enhance the functionality and reliability of their machines.

Understanding common issues is the first step toward effective management. Familiarity with the typical challenges that arise can empower users to address problems swiftly and efficiently. This knowledge not only saves time but also reduces the likelihood of costly repairs down the line.

Additionally, implementing regular maintenance routines is crucial. Establishing a consistent schedule for inspections and minor adjustments can prevent major breakdowns. Through this proactive approach, operators can enjoy uninterrupted service and maximize the utility of their equipment.

Overview of John Deere JX75

This section provides an insight into a popular lawn care machine known for its efficiency and reliability. Designed for both residential and professional use, it offers features that enhance performance and ease of maintenance. Understanding its components and functions can help users make the most of their investment.

Key Features

This model is equipped with several noteworthy attributes that contribute to its effectiveness in lawn management. Below is a summary of its essential features:

| Feature | Description |

|---|---|

| Engine Power | Robust engine providing ample power for cutting various grass types. |

| Cutting Width | Generous cutting width allowing for quicker mowing sessions. |

| Adjustable Heights | Multiple height settings for tailored lawn care. |

| Durability | Built with high-quality materials for long-lasting use. |

Benefits of Usage

Utilizing this equipment provides numerous advantages. Its design ensures ease of handling, reducing fatigue during operation. Additionally, efficient fuel consumption makes it an economical choice for regular lawn maintenance.

Common Issues with JX75 Lawnmower

The lawn maintenance machine in question often faces several challenges that can affect its performance. Understanding these common problems is essential for ensuring efficient operation and prolonging its lifespan.

1. Starting Difficulties: One of the most frequently encountered issues is trouble starting the engine. This can be attributed to a variety of factors, including a faulty spark plug, stale fuel, or issues with the battery.

2. Uneven Cutting: Many users report uneven grass cutting. This issue can stem from a dull blade, improper cutting height, or a buildup of debris under the mower deck.

3. Overheating: Overheating can occur when the engine is working harder than usual. This may be due to inadequate oil levels or airflow obstruction caused by grass clippings.

4. Excessive Vibration: Unusual vibrations during operation can indicate loose parts or imbalanced blades. Regular maintenance checks can help identify and rectify these problems early.

5. Fuel Leaks: Fuel leakage is a serious concern that can lead to performance issues and safety hazards. It’s crucial to inspect fuel lines and connections regularly to prevent spills.

Addressing these common concerns promptly can enhance the reliability and effectiveness of the lawn maintenance device, ensuring a well-kept lawn with minimal hassle.

Essential Tools for JX75 Repairs

When maintaining and servicing outdoor power equipment, having the right instruments is crucial for effective and efficient work. The proper tools not only enhance the quality of the task but also ensure safety and longevity of the machinery. This section will highlight the fundamental instruments necessary for tackling various maintenance and troubleshooting activities.

First and foremost, a comprehensive set of wrenches is indispensable. This includes both standard and metric sizes, allowing for the loosening and tightening of various fasteners. Additionally, screwdrivers of different types–flathead and Phillips–are essential for accessing multiple components. For more intricate work, a socket set will prove invaluable, enabling users to reach tight spaces with ease.

Moreover, pliers are versatile tools that come in handy for gripping, bending, and cutting wires or small parts. It’s also beneficial to have a torque wrench to ensure that fasteners are secured to the manufacturer’s specifications, preventing any potential damage from over-tightening.

Finally, safety equipment should never be overlooked. Gloves protect hands from sharp edges, while safety goggles shield eyes from debris. By equipping oneself with these essential instruments, one can confidently approach any task related to the upkeep of their outdoor machinery.

Step-by-Step Maintenance Procedures

Regular upkeep of your equipment is essential for ensuring optimal performance and longevity. Following systematic procedures not only enhances functionality but also prevents potential issues that may arise from neglect. This section outlines comprehensive steps to effectively maintain your machinery, ensuring it operates smoothly and efficiently.

1. Cleaning the Equipment

Begin by disconnecting the power source. Use a soft brush or cloth to remove dirt and debris from the exterior. Pay special attention to air vents and cooling fins, as blockages can lead to overheating. For tougher grime, a mild detergent mixed with water can be applied. Rinse thoroughly and allow the equipment to dry completely before reconnecting.

2. Checking and Replacing Fluids

Next, inspect the fluid levels, including oil, fuel, and any hydraulic fluids. Use the dipstick to gauge oil levels and replace it if necessary. Ensure all fluids are clean and free of contaminants. If any fluid appears dark or has particles, drain and replace it with fresh, manufacturer-recommended fluids. This step is crucial for maintaining smooth operation and preventing wear and tear.

Replacing Blades on the JX75

Maintaining the cutting performance of your lawn equipment is essential for achieving a pristine lawn. One of the most important tasks is the replacement of the cutting blades. Dull or damaged blades can lead to uneven cuts and unhealthy grass. This section will guide you through the process of changing the blades efficiently and safely.

Before starting, ensure you have the necessary tools at hand, including a wrench, safety gloves, and a flat surface for stability. Begin by disconnecting the spark plug to prevent accidental starts. Once secured, tilt the machine for better access to the underside, where the blades are located.

Using the appropriate wrench, remove the bolts securing the blades. Take care to note their orientation for proper reinstallation. Carefully detach the old blades and inspect the spindle for any signs of wear. If necessary, clean the area to prevent debris from affecting the new blades.

Next, position the new blades, aligning them according to the original orientation. Secure them with the bolts, ensuring they are tightened adequately. Once everything is in place, return the machine to its upright position and reconnect the spark plug. Your equipment is now ready for use, equipped with sharp blades for optimal cutting performance.

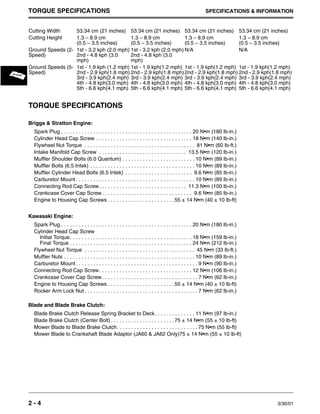

Understanding the Engine Specifications

Gaining insight into the engine specifications of your equipment is crucial for optimal performance and maintenance. These details provide a foundation for understanding how to care for your machine and enhance its longevity. Key specifications often include power output, displacement, and operational features that define the engine’s capabilities.

- Power Output: This metric indicates the maximum horsepower or kilowatts produced by the engine. It’s essential for assessing the machine’s performance during various tasks.

- Displacement: Referring to the total volume of all the cylinders, this specification influences the power and efficiency of the engine.

- Type of Engine: Understanding whether the engine is a two-stroke or four-stroke can affect fuel efficiency and maintenance requirements.

- Fuel Type: Knowing the recommended fuel type ensures that the engine operates smoothly and prevents potential damage.

Familiarizing yourself with these specifications allows you to make informed decisions regarding maintenance and upgrades, ultimately leading to improved functionality and performance of your machinery.

How to Troubleshoot Electrical Problems

Tackling issues related to electrical systems can be challenging yet essential for maintaining optimal performance. A systematic approach is crucial for identifying and resolving faults effectively. By understanding the core components and employing basic diagnostic techniques, you can enhance your troubleshooting skills.

1. Visual Inspection: Start with a thorough visual examination of the wiring and connections. Look for any signs of wear, corrosion, or loose connections. Pay special attention to the battery terminals, as poor contact can lead to significant issues.

2. Check the Battery: Ensure that the battery is fully charged and functioning properly. A weak or dead battery can cause various electrical failures. Use a multimeter to measure the voltage; it should typically read around 12.6 volts when fully charged.

3. Fuses and Relays: Inspect fuses and relays for any signs of damage. A blown fuse can interrupt power flow to critical components. Replace any faulty fuses and check the relays to ensure they are operating correctly.

4. Wiring Continuity: Utilize a multimeter to test for continuity in the wiring. Breaks or shorts in the wires can lead to malfunctions. If you detect any interruptions, consider replacing the affected sections of wiring.

5. Component Testing: Test individual electrical components, such as switches and sensors, to ensure they are functioning as intended. Consult the specifications for each part to determine proper operational parameters.

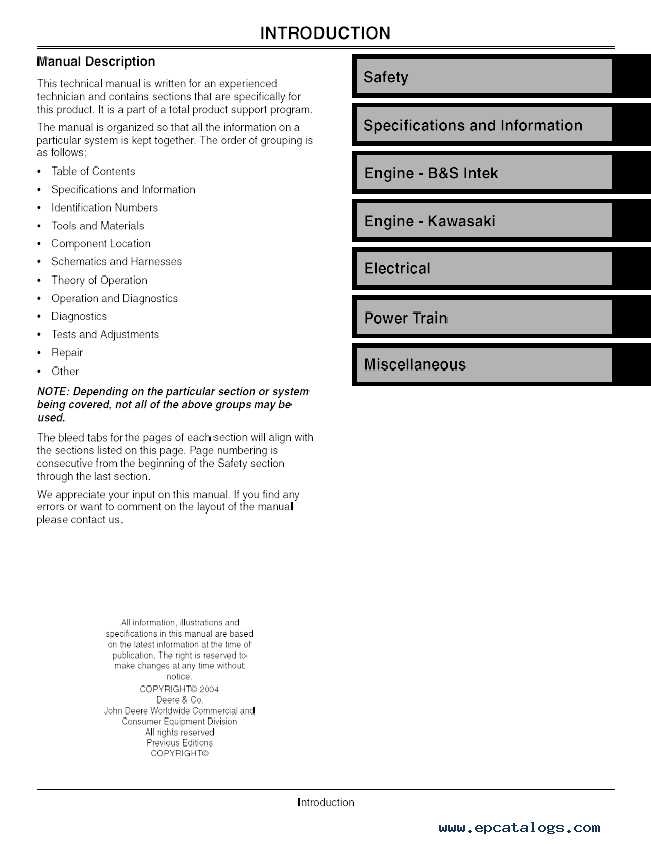

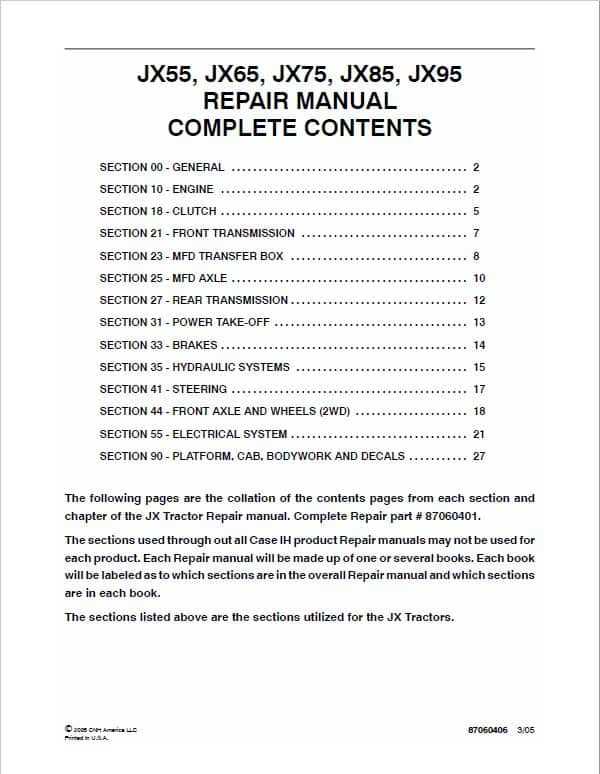

6. Consult Documentation: Refer to technical resources and diagrams to better understand the electrical system layout. These documents can provide valuable insights into common issues and troubleshooting steps.

By following these guidelines, you can systematically address electrical challenges and restore functionality efficiently. Remember to prioritize safety during all troubleshooting activities to prevent accidents or further damage.

Best Practices for Seasonal Storage

Preparing equipment for seasonal storage is essential to ensure longevity and optimal performance. Proper maintenance before storage can prevent issues that may arise during downtime, helping to maintain the integrity of your machinery and reducing future repair costs.

1. Clean Thoroughly: Before storing, make sure to clean all surfaces, removing dirt, debris, and any organic matter. This prevents rust and corrosion, which can damage parts over time.

2. Perform Maintenance Checks: Conduct a thorough inspection of all components. Check for wear and tear, replace any damaged parts, and lubricate moving parts to prevent seizing.

3. Drain Fluids: Empty fuel tanks and oil reservoirs to avoid degradation and contamination. If applicable, run the engine until it runs out of fuel to ensure the system is cleared.

4. Store in a Controlled Environment: Choose a cool, dry location for storage. Protecting your equipment from extreme temperatures and humidity can significantly extend its lifespan.

5. Use Protective Covers: Invest in high-quality covers to shield machinery from dust and moisture. This will help maintain the equipment’s condition and appearance.

6. Periodic Checks: Even during storage, periodically check the equipment for signs of wear or damage. This proactive approach can save you from larger issues when it’s time to use the machinery again.

Implementing these best practices will not only enhance the durability of your equipment but also ensure it’s ready for use when the season changes.

Safety Tips for Operating JX75

Ensuring safety during operation is crucial for both the operator and the equipment. By following a few essential guidelines, you can minimize risks and enhance your overall experience while using the machine. This section outlines important safety practices to keep in mind.

Pre-Operation Checks

- Inspect the equipment for any visible damage or wear before starting.

- Ensure that all safety guards are in place and functioning correctly.

- Check fluid levels, including oil and fuel, to avoid malfunctions.

- Examine the blades for sharpness and signs of damage.

During Operation

- Always wear appropriate personal protective equipment, such as gloves and safety glasses.

- Maintain a clear area around the machine to prevent accidents.

- Do not operate the equipment in wet or slippery conditions.

- Stay alert and avoid distractions while using the machinery.

- Follow the manufacturer’s guidelines for safe operation and maintenance.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward task if you know where to look. Understanding the different avenues available for sourcing parts can save both time and effort. This guide will help you navigate the options and streamline the process of obtaining what you need.

Online Resources

The internet offers a wealth of information and options for finding the right components. Many websites specialize in outdoor equipment parts, providing detailed catalogs and search functions. You can often find reviews and ratings for various sellers, which can help you make informed choices.

Local Dealers and Shops

In addition to online options, local dealerships and repair shops can be valuable resources. These establishments often carry a selection of parts and can order specific items if they are not in stock. Building a relationship with your local dealer can also lead to expert advice and personalized service.

| Source | Advantages | Disadvantages |

|---|---|---|

| Online Retailers | Convenience, Wide Selection | Shipping Time, Return Policies |

| Local Dealers | Immediate Availability, Expert Advice | Higher Prices, Limited Stock |

| Salvage Yards | Cost-Effective, Unique Finds | Condition Variability, Time-Consuming |

By exploring these different avenues, you can efficiently find the parts necessary to keep your machinery in optimal condition, ensuring it runs smoothly for years to come.

User Experiences and Reviews

This section aims to share insights and opinions from individuals who have utilized this specific model of lawn care equipment. Their feedback provides a valuable perspective on performance, ease of use, and maintenance challenges encountered during ownership.

Overall Satisfaction

- Many users report high satisfaction due to its efficiency and reliability in maintaining lawns.

- Several owners appreciate the comfortable handling and maneuverability in tight spaces.

- Common praise includes the smooth operation and minimal noise levels during use.

Common Issues and Solutions

- Some users experienced difficulties with starting the engine, particularly after prolonged periods of inactivity.

- A few individuals noted that routine maintenance can be more demanding than expected, especially with blade sharpening.

- There were occasional complaints regarding the availability of replacement parts, which some found challenging to source.

Overall, feedback indicates that while there are challenges, the advantages of owning this equipment often outweigh the drawbacks, making it a preferred choice for many lawn enthusiasts.