Comprehensive Guide to John Deere LT133 Repair Manual

For those seeking to extend the longevity and efficiency of their essential machinery, understanding key aspects of upkeep is crucial. This guide provides valuable insights into the foundational principles of care and upkeep, focusing on helping users achieve optimal performance from their equipment. By following structured advice, users can ensure smoother operation and address potential issues effectively.

Each piece of equipment requires specific attention to keep it running smoothly. This guide emphasizes practical methods for routine checks, adjustments, and component assessments. With detailed steps to address a range of scenarios, users will gain the confidence to tackle common issues and perform essential adjustments, thus reducing downtime and enhancing overall productivity.

Whether you’re a novice or experienced with equipment management, this resource offers an easy-to-follow approach to common maintenance tasks and troubleshooting methods. By understanding the unique requirements of your machinery, you can ensure it remains dependable over time. Follow this guide to learn effective strategies for diagnosing issues, making adjustments, and executing minor repairs.

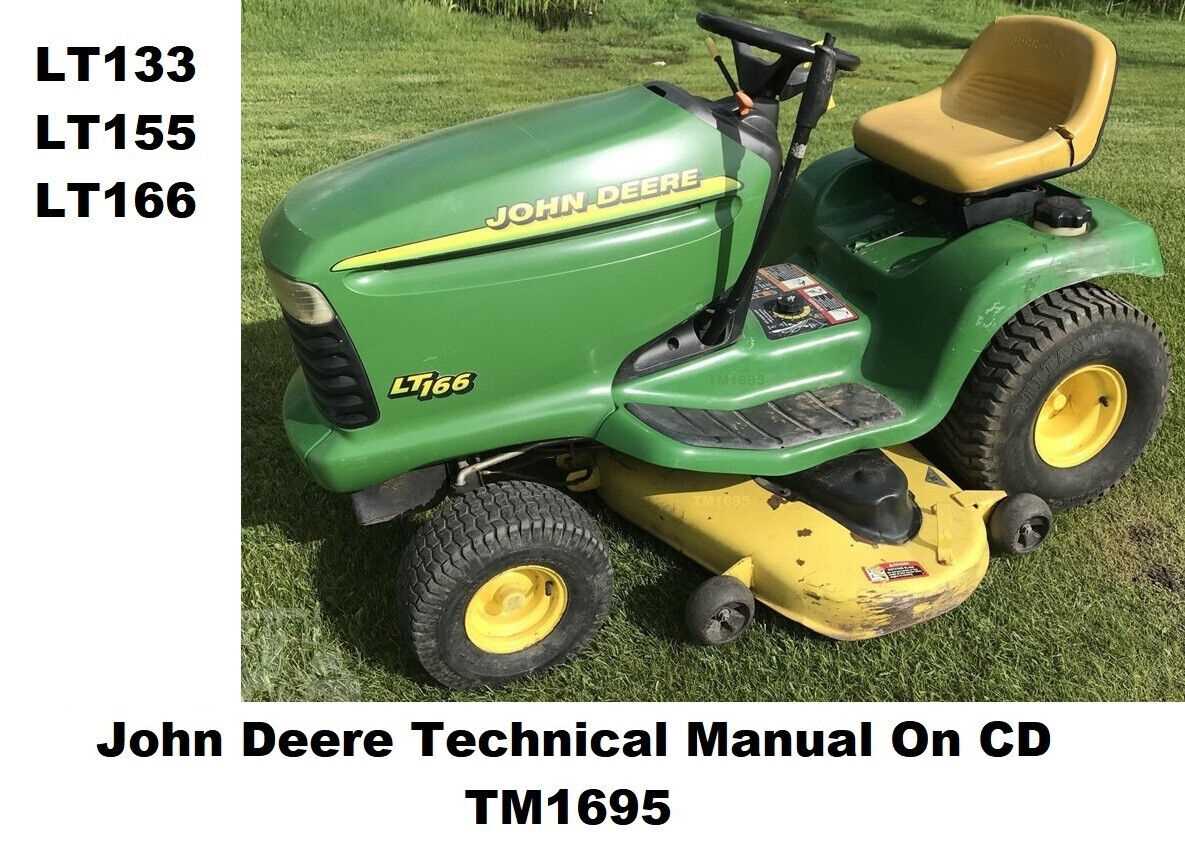

Overview of This Riding Mower Model

This versatile riding mower offers a blend of durability and efficiency, designed for residential landscaping tasks and medium-sized areas. Known for its compact frame and ease of use, it provides an accessible solution for those looking to maintain their outdoor spaces with a reliable machine. Users value its straightforward functionality, built to simplify lawn care routines without compromising on power.

Equipped with a robust engine and thoughtful design, this mower handles diverse lawn conditions, from flat surfaces to slightly uneven terrain. Its efficient fuel usage and dependable cutting capabilities make it a popular choice among homeowners seeking an affordable yet effective lawn care tool. With user-friendly features and a manageable build, this model caters to both novice users and those with moderate experience in lawn maintenance.

Common Issues and Solutions

Maintaining equipment in optimal condition requires awareness of potential malfunctions and effective ways to address them. Understanding common challenges can help operators prevent interruptions and ensure smooth performance over time. This section offers practical solutions for frequent issues to promote reliability and longevity.

| Issue | Possible Cause | Solution | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Fails to Start | Battery may be drained or connections could be loose. | Check battery connections and charge if necessary. Replace battery if it no longer holds charge. | |||||||||||

| Poor Engine Performance | Air filter might be clogged, or fuel system could have contaminants. | Clean or replace the air filter. Drain and refill with fresh fuel if contamination is suspected. | |||||||||||

| Uneven Cutting | Blade may be dull, or mower deck is not level. | Sharpen or replace the blade. Adjust the deck to ensure an even cut. | |||||||||||

| Excessive Vibration | L

Essential Tools for RepairsEffective maintenance relies on having the right set of instruments. Proper tools can simplify the process, ensuring accuracy and safety during adjustments and part replacements. Here, we outline some essential items to have on hand for efficient troubleshooting and regular upkeep. Primary Hand ToolsBasic hand tools form the foundation of any maintenance toolkit. These include wrenches, screwdrivers, pliers, and adjustable spanners, which assist in loosening or securing fasteners of various sizes. Having both metric and imperial sets can ensure compatibility with diverse components. Torque wrenches are also valuable, allowing precise control over tightening force, which can prevent damage to bolts and other parts. Power Tools and Diagnostic Equipment

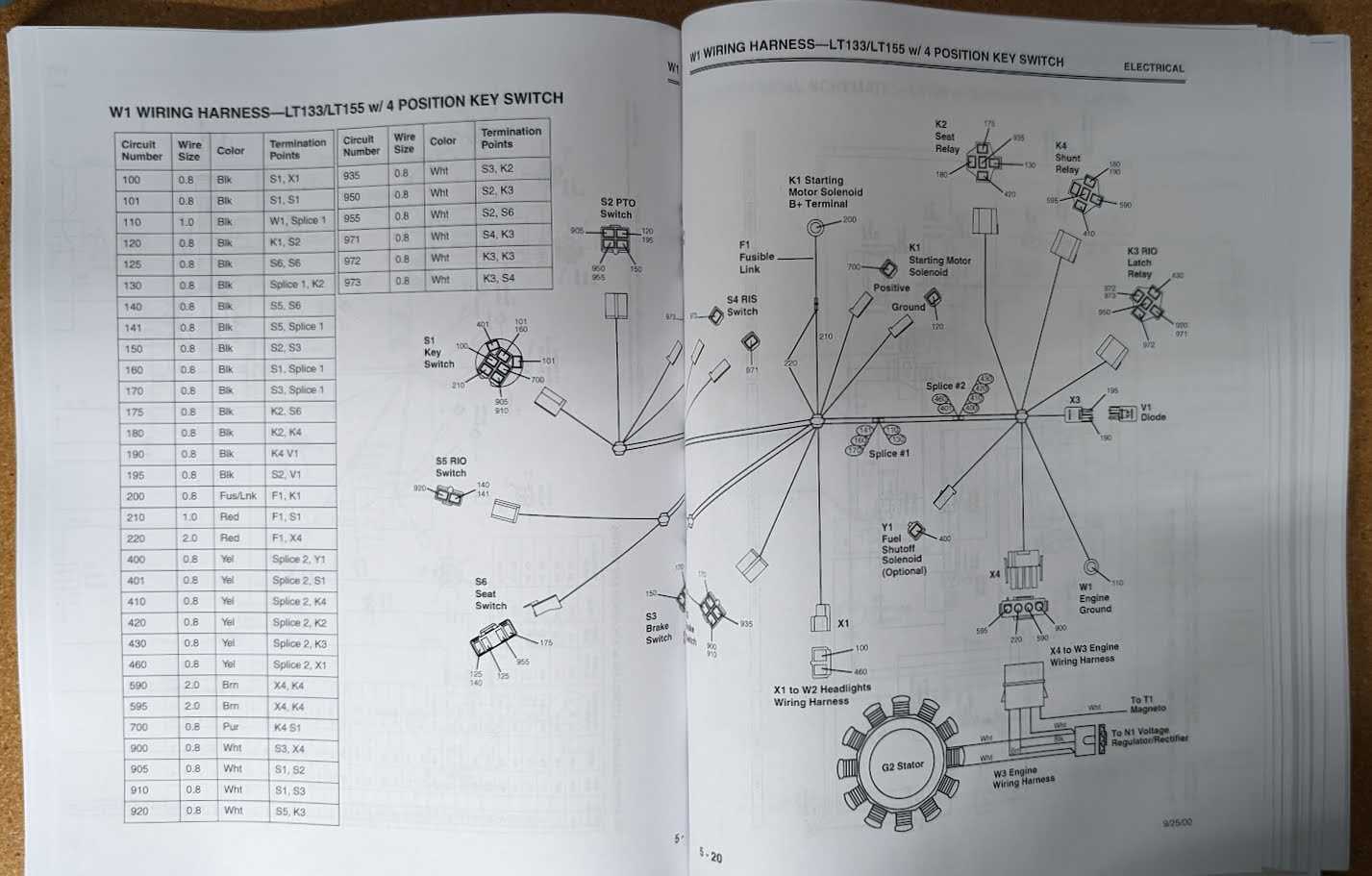

For more intricate tasks, power tools like impact drivers, drills, and grinders can increase efficiency. These tools not only expedite the work but also make it easier to handle resistant parts. Diagnostic tools, such as multimeters and testing lights, allow you to examine electrical connections and troubleshoot wiring issues, helping to prevent malfunctions and improve overall functionality.

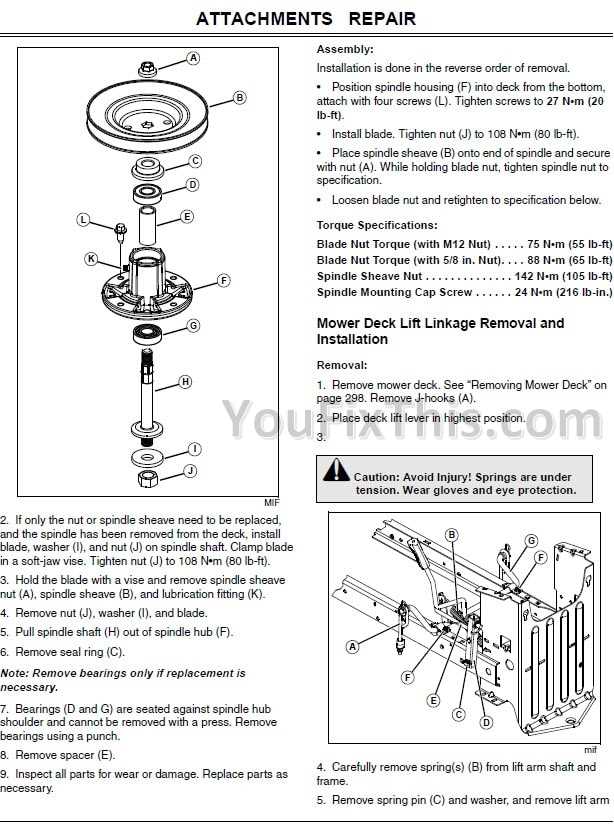

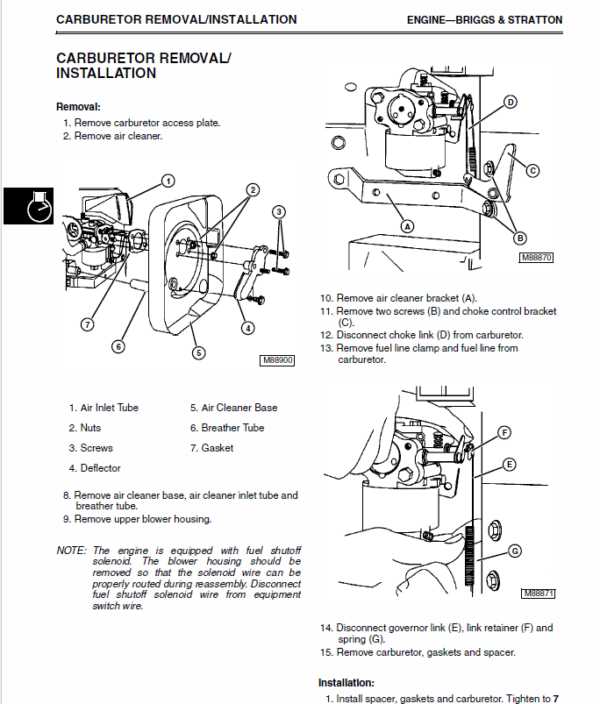

Step-by-Step Maintenance Procedures

Regular upkeep is essential to ensure that your equipment operates smoothly and remains reliable over time. Following a structured approach helps prevent wear and keeps all components in optimal condition. Below are detailed steps to guide you through essential maintenance tasks that enhance both performance and longevity. 1. Inspecting and Cleaning Key ComponentsBegin by visually inspecting crucial parts such as the engine, filters, and belts. Clean these components carefully to remove dust, debris, and any accumulated dirt. Filters should be examined regularly and replaced if they show signs of clogging or excess wear. Cleaning air filters especially improves airflow and ensures the engine runs efficiently. 2. Lubricating Moving PartsLubrication reduces friction in areas with moving parts, which helps prevent overheating and premature wear. Apply a quality lubricant to the wheel bearings, spindles, and any other critical joints. This task minimizes resistance and extends the lifespan of these components, ensuring smoother operation and reducing maintenance frequency. Maintaining a regular schedule for these procedures can significantly improve the equipment’s efficiency. Each step plays a key role in protecting against potential issues, ensuring your machine is always ready for optimal performance. Electrical System Troubleshooting GuideIdentifying and resolving issues within the electrical system can prevent operational interruptions and ensure that all components function optimally. This section provides a comprehensive overview of common electrical challenges and step-by-step strategies to address them effectively. Initial Checks and Safety MeasuresBefore examining specific components, start by conducting a basic inspection of the wiring and connections. Look for loose or corroded connectors, damaged wires, or blown fuses that may disrupt the current flow. Always disconnect the battery to prevent electrical hazards, ensuring a safe troubleshooting process. Common Electrical Issues and Solutions

Frequent issues include starting difficulties, inconsistent power supply, or sudden electrical failures. To diagnose, use a multimeter to test voltage levels and identify weak connections or malfunctioning switches. If the problem persists, assess the battery’s charge capacity and consider replacing it if it fails to retain power consistently. For troubleshooting further, examine components like the ignition switch and starter solenoid, as these are often linked to starting issues. Following systematic testing and replacing faulty parts will ensure the electrical system operates reliably under various conditions. Engine Specifications and CareThe engine in this model is designed to deliver reliable power and smooth performance under various conditions. To maintain optimal functionality, it is essential to understand its key specifications and follow consistent care routines. Regular attention to engine details can prolong its lifespan and ensure efficient operation.

Consistent maintenance is essential for engine health. The following are essential steps for routine care:

By following these care steps, the engine will remain in optimal condition, delivering reliable powe Transmission Repair TechniquesAddressing transmission challenges involves a systematic approach to diagnose and improve the overall functionality of the vehicle’s drive system. Understanding the core principles and utilizing reliable methods can significantly enhance durability and ensure optimal performance during operation. This section offers insights into fundamental techniques to maintain and restore the transmission to its best condition. Key Diagnostic StepsEffective analysis of the transmission is essential for identifying any underlying issues. Several common indicators signal when inspection and potential servicing are required:

Addressing these signals early can prevent more complex issues from developing, saving time and resources in the long run. Techniques for Servicing and Maintenance

Consistent maintenance and proactive servicing are the best approaches for ensuring a robust and responsive transmission system, keeping it in top shape for continuous and reliable use. Deck Maintenance and AdjustmentsRegular maintenance of the cutting deck is essential to ensure smooth operation and effective grass cutting. By keeping the deck in optimal condition, one can achieve a cleaner, more uniform cut and reduce strain on the machinery. This section provides guidance on essential care and minor adjustments for the deck to prolong its lifespan and performance. Cleaning and Inspecting the DeckAfter each use, it is important to clear any accumulated debris, grass clippings, and dirt from the deck. These residues can affect airflow and lead to uneven cutting. Use a brush or gentle spray to remove build-up, paying special attention to the area around the blades and belt. Regular inspections allow you to spot potential wear or damage early, preventing costly repairs in the future. Leveling the Deck

An even deck is crucial for maintaining a consistent cutting height. Begin by positioning the equipment on a level surface. Check both sides of the deck to ensure they are evenly spaced from the ground. Adjustments can typically be made by modifying the deck height levers on either side. Once adjusted, re-check the level to confirm accuracy, as an uneven deck can lead to scalping and uneven patches in the grass. Replacement Parts Overview

In this section, we explore essential replacement components, ensuring reliable function and extended longevity of outdoor equipment. Selecting compatible parts helps maintain optimal performance, whether replacing frequently used items or addressing specific issues. Common Replacement Components

Essential Tips for Choosing Replacement Parts

Using quality replacement parts can greatly extend the machine’s life, ensuring it performs well over time. Following a regular maintenance schedule with timely part replacements supports efficient, trouble-free operation. Seasonal Maintenance TipsProper upkeep of outdoor equipment throughout the year is essential for ensuring optimal performance and longevity. Regular seasonal maintenance can prevent costly repairs and enhance efficiency, allowing users to enjoy their machinery without interruptions. Here are some essential tips to keep in mind as the seasons change. Spring Preparation

Autumn Checklist

Safety Precautions During RepairsEnsuring safety is paramount when conducting maintenance or troubleshooting on machinery. Adopting proper safety measures protects not only the individual performing the work but also the equipment involved. Recognizing potential hazards and taking proactive steps can significantly reduce the risk of accidents. Personal Protective Equipment (PPE)Wearing appropriate personal protective gear is essential. The following items should always be considered:

Work Area ConsiderationsMaintaining a clean and organized workspace is vital for safety. Here are some tips:

Frequently Asked QuestionsThis section addresses common inquiries and concerns that users may encounter when dealing with their outdoor machinery. It aims to provide clarity on various topics, ensuring that operators can make informed decisions and maintain optimal performance. What should I do if my equipment won’t start? If the machinery fails to initiate, check the fuel level, battery condition, and ensure that all safety switches are engaged properly. A thorough inspection of the ignition system may also be necessary. How often should I perform maintenance on my machine? Regular upkeep is essential for longevity. It is advisable to follow a scheduled maintenance routine, typically every 25 hours of operation, including oil changes and filter replacements. What are the signs that my unit needs professional servicing? Indications such as unusual noises, decreased performance, or visible leaks should prompt users to seek assistance from a qualified technician. Early detection can prevent more significant issues down the line. Can I perform repairs on my own? Basic troubleshooting and minor repairs can often be handled by the owner, especially with the right guidance. However, more complex issues should be left to trained professionals to ensure safety and proper functioning. Where can I find parts for my equipment? Parts can typically be sourced through authorized dealers or reputable online retailers. Always verify that the components are compatible with your specific model to avoid complications. |