Comprehensive Guide to John Deere LT166 Repair Manual

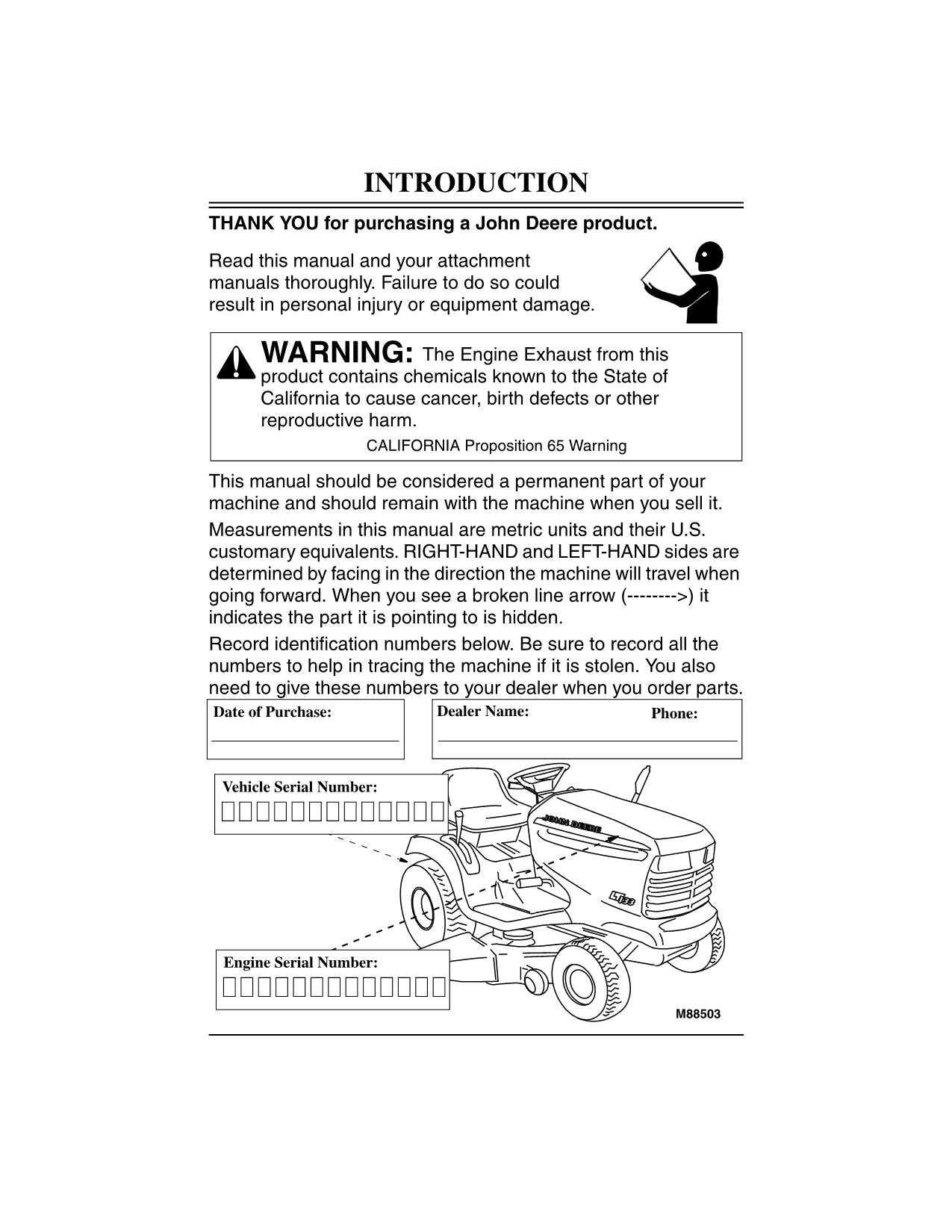

Maintaining your machinery is crucial for optimal performance and longevity. Understanding the intricacies of upkeep not only enhances efficiency but also minimizes unexpected breakdowns. Proper care ensures that your investment continues to serve you well for years to come.

In this section, we will explore comprehensive resources designed to assist you in troubleshooting and enhancing your equipment’s functionality. From routine checks to more complex adjustments, having access to reliable information can make all the difference in your maintenance efforts.

Whether you are a seasoned professional or a beginner, the right guidance empowers you to take charge of your machinery’s health. Dive into the details, and you’ll discover the ultimate path to ensuring that your equipment operates at its best.

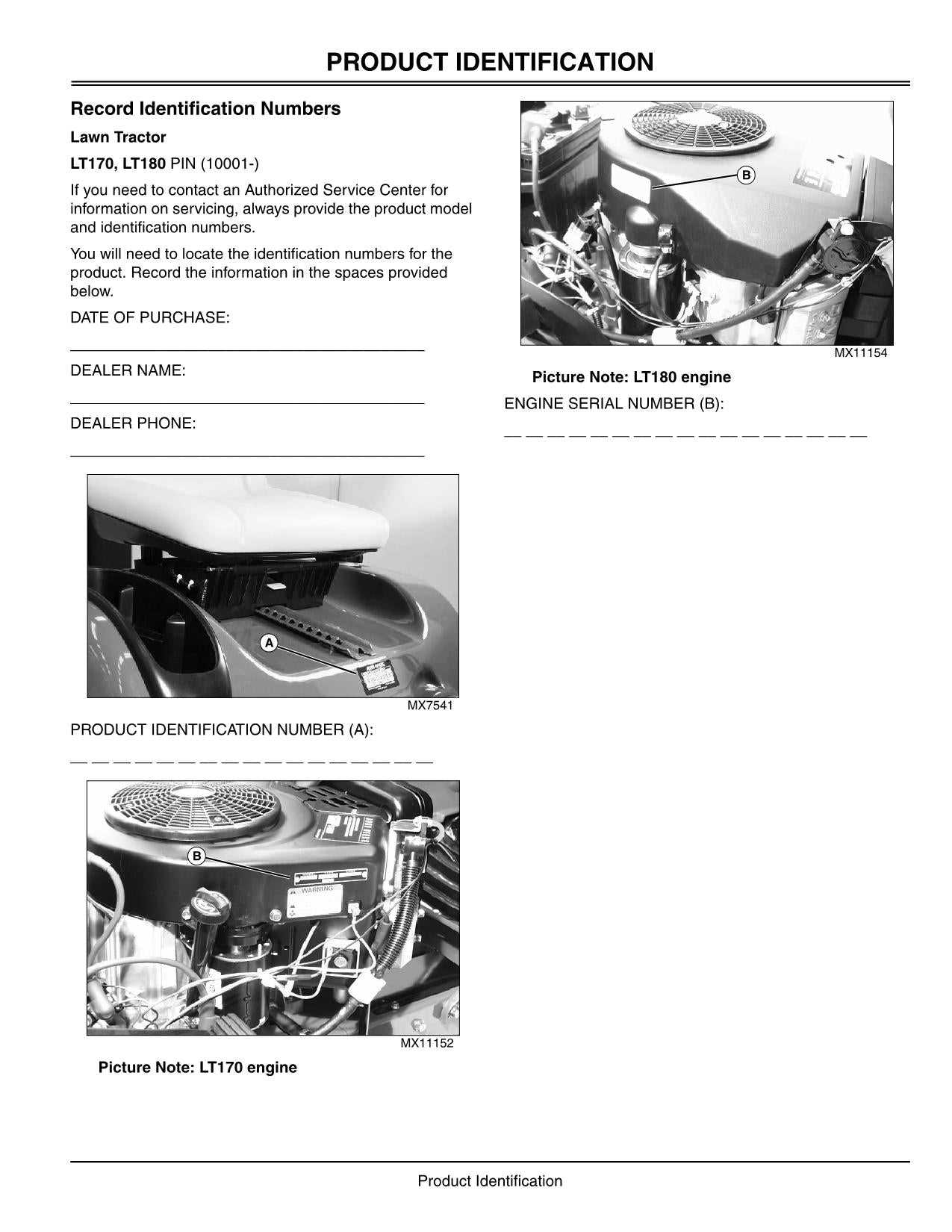

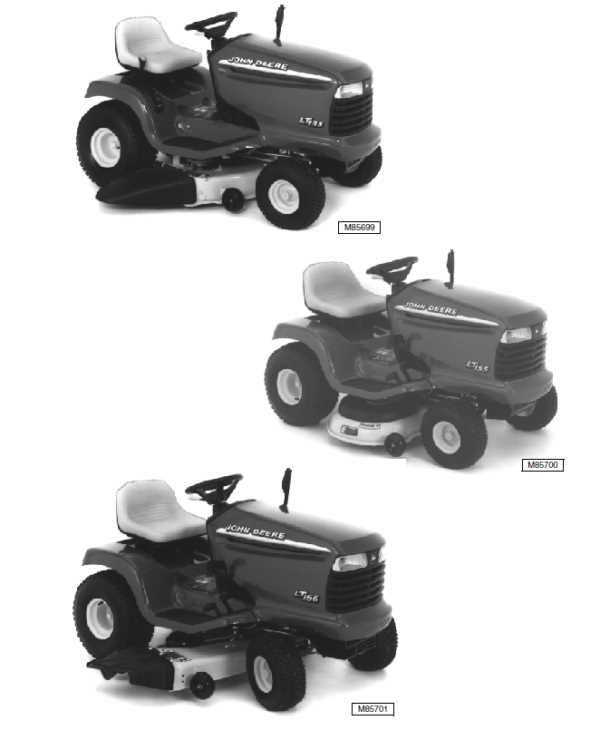

Understanding the John Deere LT166

This section aims to provide insights into a popular lawn care machine known for its efficiency and versatility. Designed for maintaining lawns and gardens, this model has become a reliable choice among homeowners and landscapers alike. Its robust features and ease of use make it a valuable asset in outdoor maintenance tasks.

Engine Performance: The heart of this machine lies in its powerful engine, which delivers impressive torque and speed. This capability allows for smooth operation across various terrains, ensuring that mowing or trimming tasks are completed quickly and effectively.

Cutting System: Equipped with a precision cutting system, this model ensures a clean and even cut, contributing to the overall aesthetics of the lawn. The adjustable cutting height allows users to customize their mowing experience, catering to different grass types and conditions.

User-Friendly Design: The layout of controls is intuitive, making it accessible even for those who may be new to operating such machinery. Features like comfortable seating and easy maneuverability enhance the overall experience, reducing fatigue during extended use.

Maintenance Considerations: Regular upkeep is essential for optimal performance. Understanding key components and their functions can help users identify potential issues early on, ensuring longevity and reliability of the equipment.

In summary, grasping the fundamentals of this particular lawn care machine can empower users to maximize its capabilities while maintaining their outdoor spaces with ease and efficiency.

Common Issues with LT166 Lawn Tractors

Lawn tractors are essential for maintaining a well-groomed yard, but like any machinery, they can encounter various challenges over time. Understanding these common problems can help users diagnose issues quickly and maintain their equipment efficiently.

- Starting Problems:

- Battery issues, such as low charge or faulty connections.

- Faulty ignition switch preventing the engine from turning over.

- Clogged fuel lines affecting fuel delivery.

- Cutting Performance:

- Uneven cutting due to dull blades.

- Deck height adjustment problems leading to improper cutting heights.

- Grass buildup under the mower deck, causing blockages.

- Transmission Issues:

- Slipping or jerking while changing gears.

- Fluid leaks affecting overall performance.

- Clutch problems leading to difficulty in engaging or disengaging.

- Electrical Concerns:

- Faulty wiring resulting in intermittent power loss.

- Blown fuses causing various electrical components to fail.

- Defective safety switches preventing operation.

Being aware of these issues allows users to take proactive steps in maintenance and troubleshooting, ensuring their lawn tractor operates smoothly for years to come.

Essential Tools for Repairing LT166

Having the right instruments is crucial for effective maintenance and troubleshooting of your equipment. This section outlines the necessary items that will streamline the process, ensuring you are well-prepared for various tasks.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Wrench Set | For adjusting and securing fittings. |

| Multi-Tool | Versatile for various tasks, including cutting and screwing. |

| Screwdriver Set | Essential for different types of screws. |

| Jack Stands | For safely elevating the machinery. |

| Lubrication Tools | To maintain moving parts and reduce wear. |

Step-by-Step Maintenance Guide

This guide provides a comprehensive approach to ensuring the longevity and optimal performance of your equipment. By following a systematic routine of care and attention, you can prevent issues and enhance efficiency over time. Regular upkeep not only safeguards your investment but also promotes safe and reliable operation.

Begin by gathering all necessary tools and supplies. A clean workspace is essential for effective maintenance. Familiarize yourself with the owner’s documentation to understand specific requirements and schedules.

Start with a thorough inspection of the machine. Check for any visible wear, loose components, or leaks. Addressing minor issues early can prevent more significant problems later. Pay special attention to fluid levels and replace any filters as recommended.

Next, clean all exterior surfaces to remove debris and dirt. This not only improves aesthetics but also allows for better functionality. Make sure to access hard-to-reach areas to ensure a complete cleaning process.

After cleaning, proceed to lubricate moving parts according to the specifications provided in your reference guide. Proper lubrication reduces friction and wear, extending the life of mechanical components.

Finally, conduct a functional test to verify that everything operates as intended. Regularly repeating these steps will contribute to the overall health and efficiency of your machinery, ensuring it remains in peak condition for years to come.

Diagnosing Engine Problems Effectively

Identifying issues within an engine requires a systematic approach to pinpoint the underlying causes. By understanding the symptoms and utilizing appropriate diagnostic techniques, one can effectively address malfunctions and restore optimal performance.

Begin by observing the behavior of the engine. Unusual sounds, vibrations, or performance drops can provide crucial clues. Listening carefully to these indicators allows for a more targeted investigation.

Next, check for visible signs of trouble. Look for leaks, worn components, or any irregularities in the engine bay. Physical inspections often reveal issues that may not be immediately evident through testing alone.

Utilize diagnostic tools such as code readers or multimeters to gather data on engine performance. These instruments can help identify error codes and provide insights into electrical systems and sensor functionality.

Consider environmental factors that might affect performance, such as fuel quality or operating conditions. External influences can sometimes be the source of problems, making it essential to evaluate all aspects surrounding the engine.

By following these steps and maintaining a methodical approach, one can enhance the accuracy of diagnostics and ensure effective resolutions to engine issues.

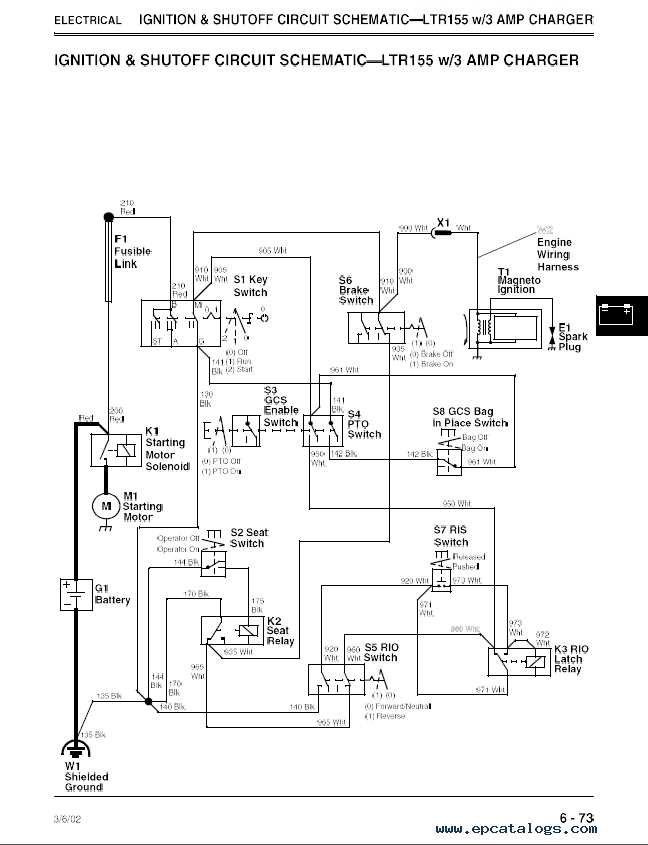

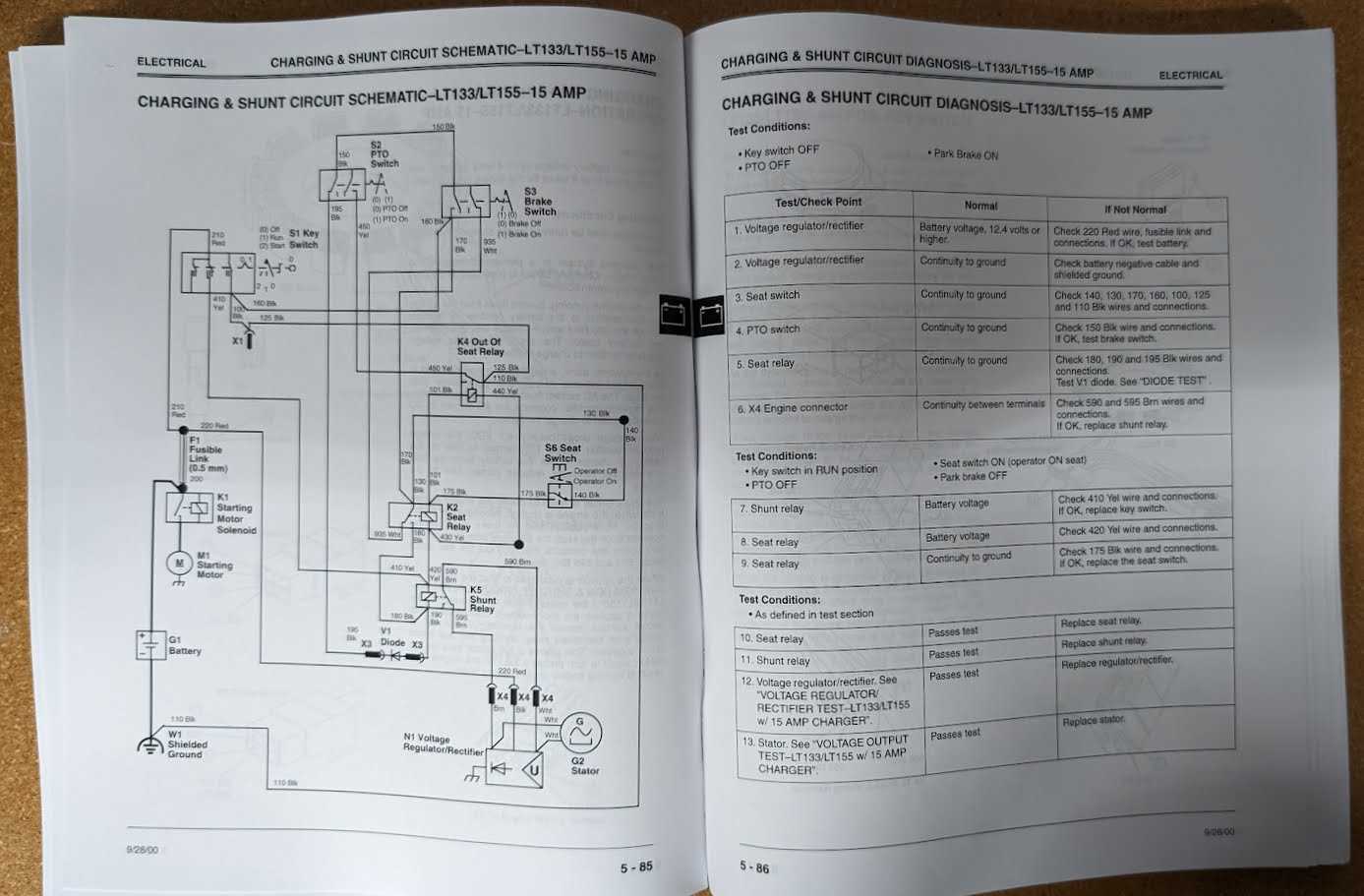

Electrical System Troubleshooting Tips

Troubleshooting electrical systems can be a daunting task, but with the right approach and knowledge, you can efficiently identify and resolve issues. Understanding the components and their functions is essential for effective diagnostics.

Common Symptoms and Their Causes

- Battery Not Charging: Check connections and inspect the alternator for faults.

- Lights Flickering: Look for loose wiring or failing switches.

- Starter Not Engaging: Examine the ignition switch and battery condition.

- Electrical Shorts: Inspect for damaged insulation or frayed wires.

Step-by-Step Diagnostic Process

- Verify the battery voltage using a multimeter.

- Inspect fuses and relays for any signs of damage.

- Test individual components, such as switches and sensors, for proper function.

- Use wiring diagrams to trace circuits and identify potential issues.

- Document findings to keep track of any patterns or recurring problems.

By following these guidelines, you can streamline the troubleshooting process and ensure your electrical system operates smoothly.

How to Change LT166 Oil

Regular maintenance of your lawn equipment is crucial for its longevity and performance. One of the essential tasks in upkeep is the replacement of engine lubricant. This process ensures that your machine runs smoothly and efficiently, preventing wear and tear. Follow these steps to successfully change the oil in your equipment.

| Step | Action |

|---|---|

| 1 | Gather necessary tools and materials: new oil, an oil filter, a wrench, a drain pan, and a funnel. |

| 2 | Start the engine for a few minutes to warm up the oil, which helps it drain more easily. |

| 3 | Turn off the engine and allow it to cool slightly, then position the drain pan underneath the oil drain plug. |

| 4 | Remove the oil drain plug and let the old lubricant fully drain into the pan. |

| 5 | Replace the drain plug securely after the oil has drained. |

| 6 | If applicable, remove the old oil filter and replace it with a new one, ensuring a tight fit. |

| 7 | Using the funnel, pour the new lubricant into the fill port, checking the level with the dipstick as you go. |

| 8 | Start the engine and let it run for a few minutes, then check for leaks and ensure the new oil circulates properly. |

| 9 | Dispose of the old oil and filter according to local regulations. |

By following these straightforward steps, you can ensure that your equipment operates at peak performance while extending its lifespan. Regular oil changes are a vital part of preventive maintenance.

Replacing Blades: A Quick Guide

Maintaining sharp and effective cutting tools is essential for achieving optimal performance in your lawn care equipment. This guide outlines the steps needed to efficiently replace blades, ensuring a smooth operation and a healthy lawn.

Tools and Materials Needed

- New blades

- Wrench or socket set

- Safety gloves

- Sturdy work surface

- Oil or lubricant (optional)

Step-by-Step Instructions

- Ensure the equipment is turned off and cooled down.

- Disconnect the spark plug to prevent accidental starting.

- Lift the deck for easy access to the blades.

- Use the wrench to loosen and remove the bolts securing the blades.

- Carefully detach the old blades and set them aside.

- Align the new blades with the mounting holes and secure them with bolts.

- Reattach the deck and reconnect the spark plug.

- Check the blade alignment and ensure everything is secure before use.

Following these steps will help maintain your cutting equipment in peak condition, allowing for efficient and effective lawn care. Regular blade replacements will promote healthy grass growth and enhance the overall appearance of your yard.

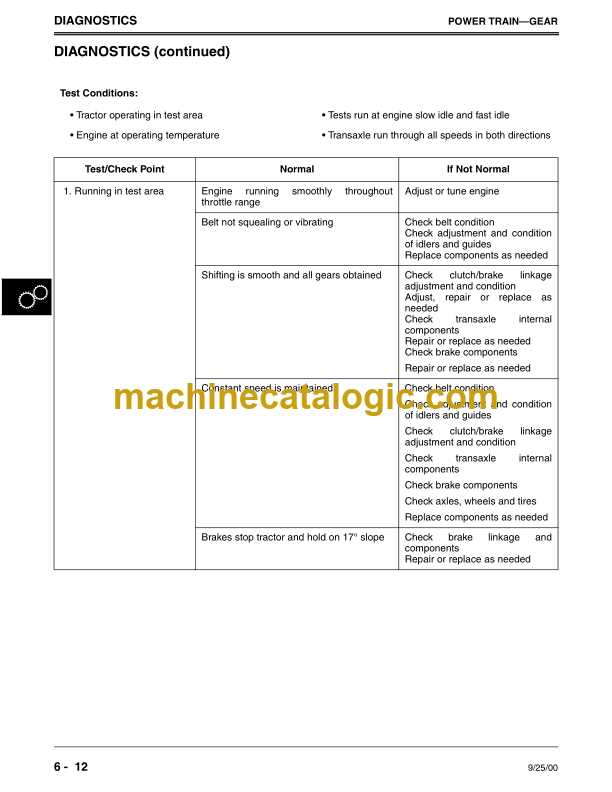

Transmission Repair Techniques Explained

This section explores essential methods for addressing issues within the gearbox system, emphasizing the importance of thorough diagnostics and precise adjustments. Understanding the mechanics behind transmission functions is crucial for effective maintenance and restoration.

Common approaches include fluid analysis to detect contamination, which can indicate underlying problems. Disassembly and inspection of internal components allow for identifying wear or damage that may compromise performance.

Additionally, employing proper sealing techniques during reassembly ensures the longevity of repairs. Implementing torque specifications is vital for maintaining structural integrity, preventing future malfunctions.

Ultimately, a combination of meticulous troubleshooting and skilled hands-on techniques can significantly enhance the durability and efficiency of the transmission system.

Finding Genuine John Deere Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Genuine parts are designed specifically for your machine, providing a perfect fit and superior reliability. In this section, we will explore effective ways to locate these essential components.

Why Choose Authentic Components?

- Quality Assurance: Genuine parts meet strict manufacturing standards.

- Performance: They are engineered to work seamlessly with your machinery.

- Warranty Protection: Using authentic components often helps maintain your warranty.

- Longevity: They typically last longer than generic alternatives, reducing long-term costs.

Where to Find Authentic Parts

- Authorized Dealers: Visiting an authorized dealer guarantees access to genuine products.

- Official Websites: Many manufacturers offer online catalogs for direct purchases.

- Service Centers: Local service centers often have a supply of authentic parts.

- Online Marketplaces: Ensure the seller is reputable and specializes in original components.

By focusing on these reliable sources, you can ensure that your equipment remains in top condition for years to come.

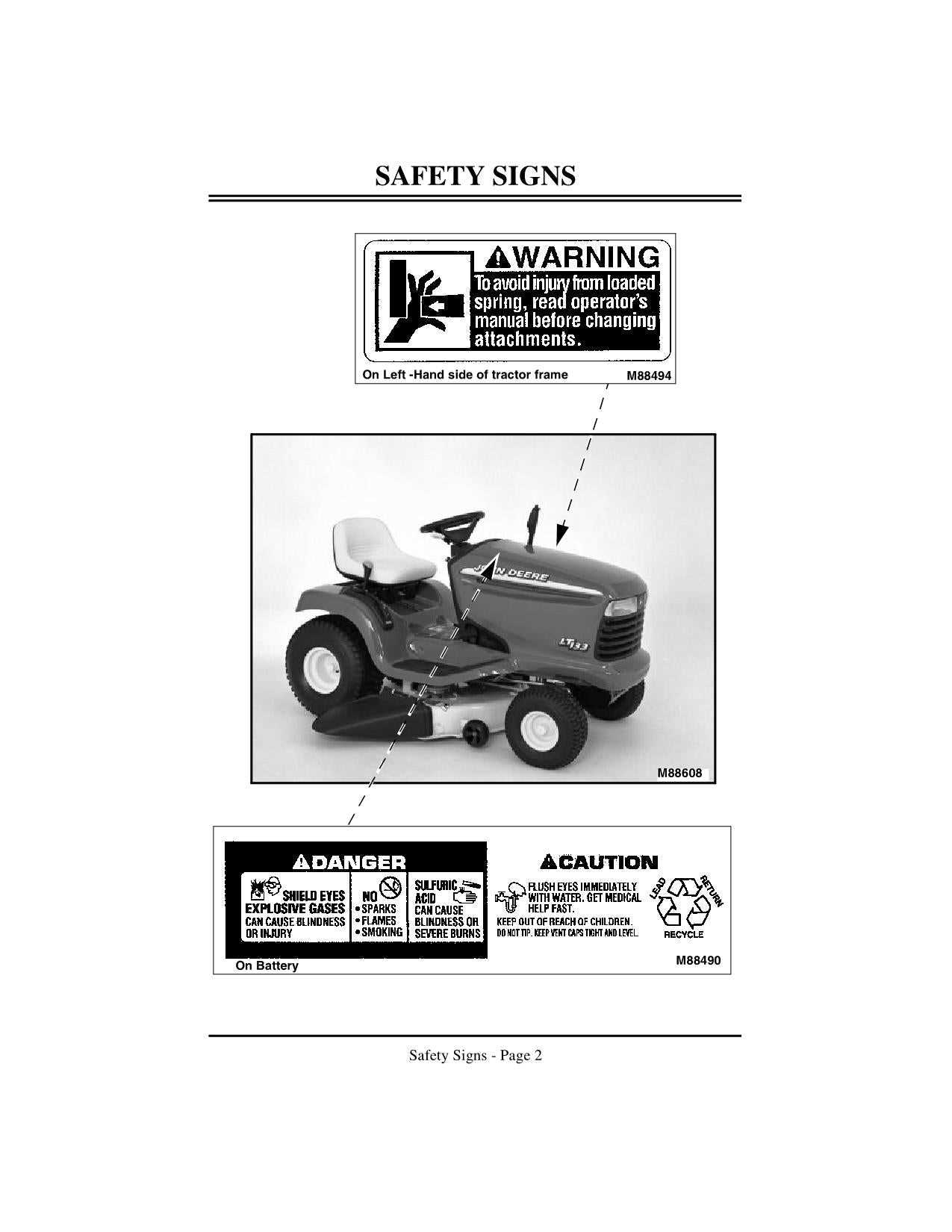

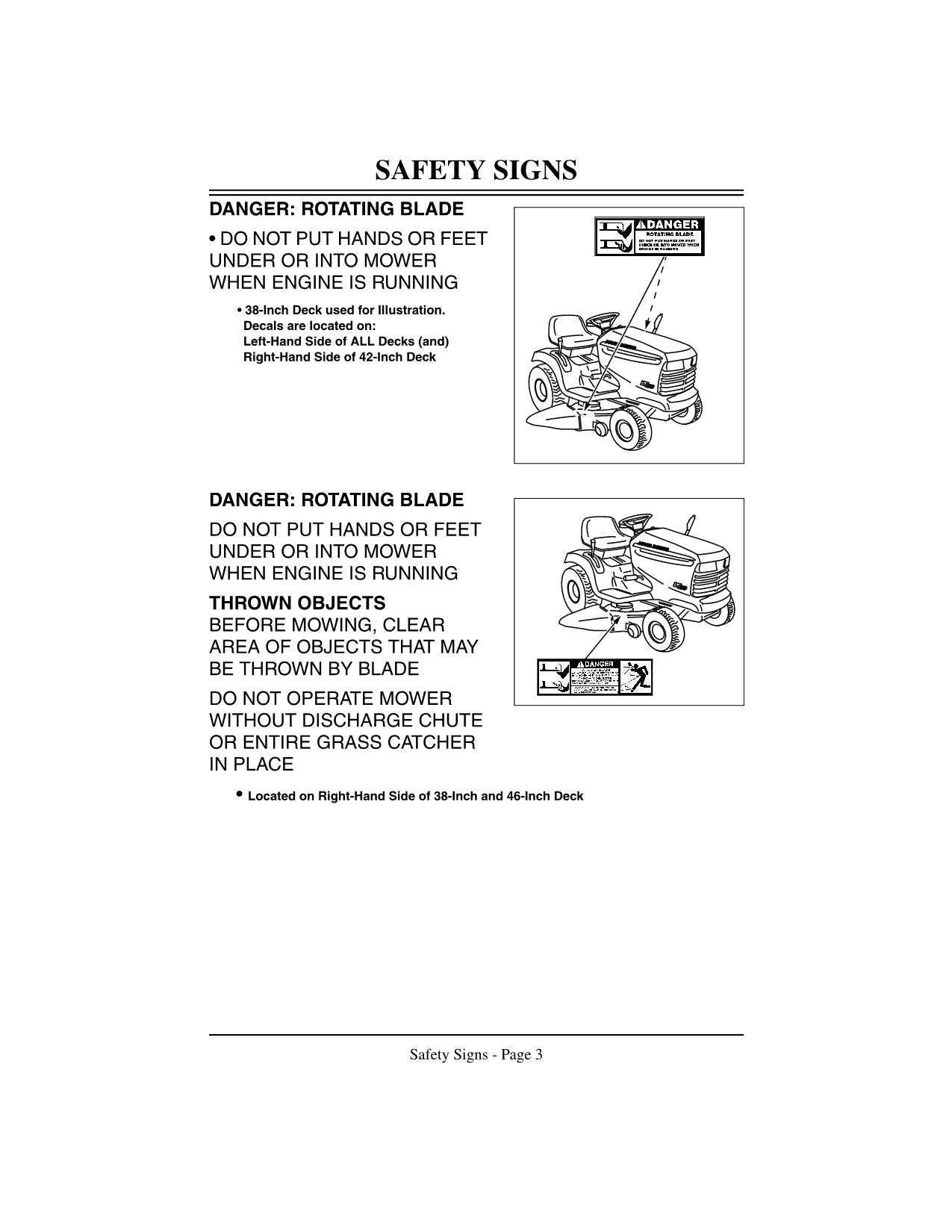

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe environment is paramount. Proper precautions not only protect the individual performing the work but also preserve the integrity of the equipment. Adhering to safety guidelines minimizes the risk of accidents and enhances overall efficiency during the process.

Essential Safety Gear

Wearing the appropriate safety equipment is crucial. This includes protective eyewear, gloves, and sturdy footwear. Ensuring that the workspace is clear of hazards is equally important to prevent injuries.

Workplace Organization

A well-organized workspace promotes safety and efficiency. Keeping tools neatly stored and materials properly labeled can significantly reduce the chance of accidents. Regularly checking equipment for any potential issues before beginning tasks is also advised.

| Safety Item | Description |

|---|---|

| Protective Eyewear | Prevents eye injuries from debris. |

| Gloves | Protects hands from sharp objects and chemicals. |

| Sturdy Footwear | Offers protection against heavy items and slips. |