Essential Repair Manuals for John Deere Riding Lawn Mowers

Ensuring the longevity and efficiency of outdoor equipment is crucial for both enthusiasts and professionals alike. With proper knowledge and resources, anyone can tackle various issues that may arise during use. These valuable resources provide detailed instructions and insights to navigate common challenges effectively.

Whether you are looking to enhance performance or address specific malfunctions, having access to comprehensive documentation is invaluable. These guides cover everything from routine upkeep to troubleshooting techniques, empowering users to confidently manage their machines. With step-by-step processes and diagrams, even complex tasks become manageable.

Utilizing these informative references not only promotes skill development but also saves time and money. Understanding the intricacies of your equipment can lead to better decision-making when it comes to maintenance and repairs. Embrace the opportunity to enhance your expertise and keep your machinery in top-notch condition.

Understanding John Deere Lawn Mowers

Exploring the intricacies of outdoor equipment designed for efficient grass management reveals a blend of innovation and practicality. These machines are engineered to enhance the mowing experience, making it accessible for both professionals and homeowners alike.

Key features that define these machines include:

- Robust construction for durability and longevity

- User-friendly controls for ease of operation

- Advanced cutting technology for precise results

- Various models tailored to different yard sizes and terrains

Understanding the components is essential for optimal performance. Some important parts include:

- Engine: Powers the machine, ensuring efficient operation.

- Blade assembly: Critical for achieving clean cuts.

- Transmission: Affects speed and maneuverability.

- Chassis: Provides stability and support during use.

Regular maintenance is crucial to prolong the life of these machines. Key maintenance tasks include:

- Checking and changing the oil

- Sharpening or replacing blades

- Inspecting tires and ensuring proper inflation

- Cleaning the undercarriage to prevent grass buildup

By familiarizing oneself with these aspects, users can ensure their equipment remains in peak condition, leading to efficient and enjoyable grass management tasks.

Common Issues with Riding Mowers

Owning a garden machine can bring immense convenience, yet it’s not without its challenges. Users often encounter various problems that can hinder performance and efficiency. Understanding these common issues is crucial for maintaining the longevity and effectiveness of the equipment.

Engine Difficulties: One of the most prevalent concerns involves engine performance. Issues such as difficulty starting or stalling during operation can stem from factors like a drained battery, old fuel, or clogged air filters. Regular maintenance can prevent these setbacks.

Transmission Problems: The drive system is vital for movement, and complications here can lead to frustration. Symptoms like slipping gears or a lack of responsiveness may indicate low fluid levels or worn components. Prompt attention is necessary to avoid further damage.

Cutting Deck Issues: The cutting mechanism plays a crucial role in achieving a neat finish. Dull blades, uneven cutting, or clumping grass can signal the need for blade sharpening or deck adjustments. Proper care ensures a clean and efficient cutting experience.

Electrical Failures: Electrical components are essential for various functions. Faulty switches, blown fuses, or issues with wiring can lead to malfunctioning lights or starting problems. Regular inspections can help identify and rectify these issues early on.

Wheel and Tire Concerns: The condition of wheels and tires significantly impacts performance. Flat tires, uneven wear, or misalignment can hinder movement and stability. Maintaining proper air pressure and alignment is key to ensuring optimal operation.

By familiarizing oneself with these common challenges, operators can take proactive steps to address issues before they escalate, ensuring smooth and efficient operation of their garden machines.

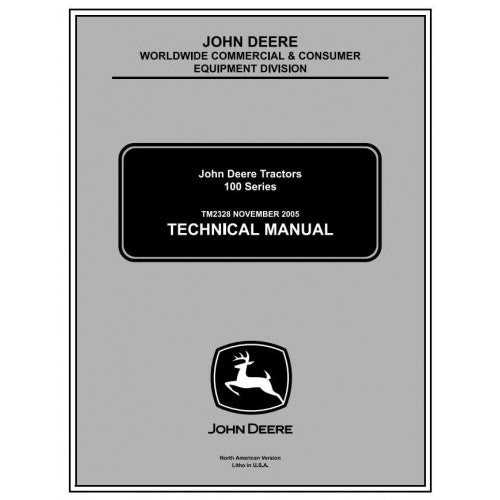

Finding the Right Repair Manual

Locating the appropriate guide for maintenance and troubleshooting can significantly enhance the performance of your equipment. A well-structured document not only offers detailed instructions but also provides insights into common issues and their solutions. It is crucial to ensure that the material you choose aligns perfectly with the specifications of your machinery.

Start by considering the model and year of your equipment. Different iterations may have distinct features and requirements, making it vital to find resources tailored to your specific version. Furthermore, official publications from the manufacturer often contain the most accurate and comprehensive information.

In addition to official resources, numerous third-party options exist. These can range from user-created content to professionally produced guides. While these alternatives can offer valuable tips and tricks, it is essential to verify their credibility and relevance to avoid potential pitfalls.

Utilizing online platforms can also prove beneficial. Many websites host digital copies of guides or forums where experienced users share advice. Engaging with a community can provide practical insights and support when navigating maintenance challenges.

Ultimately, investing time in finding the right documentation will lead to more efficient upkeep and greater longevity for your machinery. By choosing the correct source, you set the stage for successful maintenance and enhanced operational efficiency.

Step-by-Step Maintenance Procedures

Proper upkeep of your outdoor machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps in identifying potential issues before they escalate. This section outlines systematic procedures that will guide you through the essential tasks required for effective care.

1. Cleaning the Equipment: Begin by disconnecting the power source. Use a brush or compressed air to remove grass clippings and debris from the exterior and undercarriage. This step prevents rust and corrosion.

2. Checking and Replacing the Oil: Regularly inspect the oil level using the dipstick. If the oil appears dark or contaminated, change it. Use the recommended oil type and ensure the machine is level when adding new oil.

3. Inspecting the Blades: Examine the cutting blades for wear or damage. Sharpen them if dull and replace them if they are significantly worn. This ensures clean cuts and promotes healthy grass growth.

4. Air Filter Maintenance: Remove the air filter and check for dirt and debris. Clean it according to the manufacturer’s guidelines or replace it if necessary. A clean filter enhances engine performance.

5. Tire Pressure Check: Ensure that the tires are inflated to the recommended pressure. Properly inflated tires improve traction and handling, reducing wear on the machine.

6. Battery Care: Inspect the battery for corrosion and ensure that connections are tight. Clean terminals if needed, and keep the battery charged for optimal operation.

7. Seasonal Preparation: Before storing the equipment for the off-season, follow procedures such as draining fuel or adding stabilizer. This prevents fuel degradation and ensures reliable performance when it’s time to use the machinery again.

Following these steps will help maintain your equipment in excellent condition, extending its lifespan and enhancing its functionality.

Essential Tools for Lawn Mower Repair

Having the right set of tools is crucial for maintaining and fixing your outdoor equipment effectively. A well-equipped workshop not only saves time but also ensures that you can tackle any issue that arises. Below are some of the fundamental instruments that every enthusiast should consider having on hand.

Basic Hand Tools

At the core of any maintenance task are basic hand tools. A sturdy wrench set is indispensable for loosening or tightening various components. Pair it with a reliable screwdriver set, which should include both flathead and Phillips options for versatile usage. Additionally, having pliers can be invaluable for gripping and twisting wires or other materials.

Specialized Equipment

In addition to basic tools, certain specialized equipment can enhance your efficiency. A quality spark plug wrench is essential for changing ignition components, ensuring optimal performance. Furthermore, consider investing in a multimeter to diagnose electrical issues, as well as a tuning kit to keep engines running smoothly. These items can significantly reduce downtime and improve the longevity of your machinery.

Safety Tips for DIY Repairs

Engaging in maintenance tasks on outdoor machinery can be rewarding, but it is crucial to prioritize safety throughout the process. Whether you’re a seasoned enthusiast or a beginner, adhering to safety guidelines helps prevent accidents and ensures efficient work.

First, always wear appropriate personal protective equipment. This includes gloves to protect your hands, goggles to shield your eyes from debris, and sturdy footwear to prevent slips or injuries. Additionally, ensure your work area is clean and free from clutter to minimize tripping hazards.

Before starting any task, make sure to disconnect the power source to avoid accidental starts. This simple step can significantly reduce the risk of injury. Familiarize yourself with the specific equipment you are working on, including its components and potential hazards, to ensure a thorough understanding of the maintenance process.

Keep essential tools in good condition and use them for their intended purpose. Using the wrong tool can lead to mishaps or damage to the equipment. Always follow guidelines for handling chemicals or lubricants, and store them safely away from children and pets.

Finally, don’t hesitate to seek assistance or consult reliable resources if you encounter difficulties. Working together with knowledgeable individuals can enhance safety and improve the overall outcome of your projects.

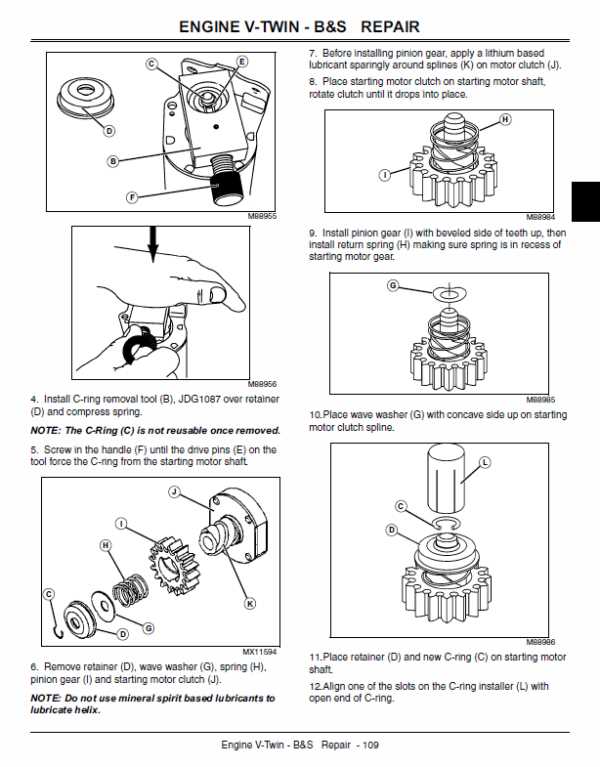

Troubleshooting Engine Problems

When your machine encounters difficulties with its power unit, identifying the root cause is essential for effective resolution. Various symptoms may indicate engine issues, from unusual noises to poor performance. Understanding these signs can help streamline the diagnostic process, ensuring you get back to work efficiently.

Common Symptoms and Possible Causes

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Faulty battery, fuel blockage, or spark plug issues |

| Excessive smoke | Overfilled oil, worn piston rings, or improper fuel mixture |

| Unusual noises | Lack of lubrication, damaged components, or loose parts |

| Poor acceleration | Clogged air filter, fuel line obstruction, or carburetor problems |

Steps to Diagnose Issues

Begin by performing a visual inspection to identify any obvious problems. Check the fuel level, battery condition, and for any leaks. Next, consult the documentation for specific troubleshooting guidelines. For persistent issues, consider engaging a professional for an in-depth assessment to ensure your power unit operates smoothly.

Replacing Mower Blades Effectively

Maintaining the sharpness and integrity of cutting implements is crucial for optimal performance. This section outlines essential steps for the efficient exchange of these components, ensuring a clean and precise cut. Understanding the process not only enhances equipment longevity but also promotes healthier turf management.

Step 1: Gather Necessary Tools

Step 2: Prepare the Equipment

Begin by turning off the engine and disconnecting the spark plug to prevent accidental starts. Ensure the device is on a stable surface and lifted safely. This precaution is vital for personal safety while working underneath or around the machinery.

Step 3: Remove the Old Blades

Locate the blade assembly and use a socket wrench to loosen the bolts securing the blades. Carefully detach them, taking note of their orientation. This information will be useful when installing the new components. Always dispose of worn blades properly to avoid any safety hazards.

Step 4: Install New Blades

Position the new cutting implements in the same orientation as the old ones. Secure them with the bolts, ensuring they are tightened adequately to prevent any movement during operation. Double-check the alignment to guarantee effective cutting.

Step 5: Final Checks

Once the installation is complete, reconnect the spark plug and lower the equipment. Conduct a brief inspection to ensure everything is secure. Performing a test run will confirm that the new blades function as expected, providing an efficient cutting performance.

Regularly replacing cutting components is a simple yet impactful way to enhance overall efficiency and ensure the best possible results in lawn maintenance.

Electrical System Diagnostics Explained

Understanding the intricacies of an electrical system is crucial for effective troubleshooting. This process involves identifying and analyzing various components that contribute to the overall functionality. By employing systematic techniques, one can pinpoint issues that may disrupt performance.

Initial assessment involves checking connections and verifying voltage levels. Tools such as multimeters play a vital role in this phase, allowing for accurate readings and evaluations. Identifying potential shorts or breaks in the wiring is essential to ensure the system operates smoothly.

Once basic checks are completed, component testing becomes necessary. Each element, from the battery to switches, must be evaluated individually to ascertain its condition. Conducting these tests helps uncover hidden problems that may not be immediately apparent.

Finally, documentation of findings is critical. Keeping a detailed record aids in tracking repairs and understanding recurring issues. This methodical approach not only enhances diagnostic accuracy but also contributes to the longevity of the electrical system.

Seasonal Maintenance Checklist

Regular upkeep of your outdoor equipment ensures optimal performance and longevity. This checklist provides essential tasks to complete at the start and end of each season, helping you maintain your machinery in peak condition.

Spring Preparation

- Inspect and clean the air filter for optimal airflow.

- Change the oil and replace the oil filter to keep the engine running smoothly.

- Sharpen or replace blades to ensure clean cutting.

- Check tire pressure and tread for safe operation.

- Inspect belts and cables for wear and tear.

- Clean the exterior to remove debris and dirt.

Fall Shutdown

- Drain fuel or add a fuel stabilizer to prevent contamination.

- Clean the undercarriage to prevent rust and buildup.

- Inspect battery condition and clean terminals.

- Store in a dry, sheltered area to protect from the elements.

- Check for any needed repairs before the next season starts.

Where to Buy Replacement Parts

Finding the right components for your equipment is crucial for maintaining its performance and longevity. Whether you are looking to replace a worn-out item or upgrade a specific feature, there are several reliable sources to consider. Below are some of the best options for acquiring quality spare parts.

Online Retailers

Many online platforms offer a vast selection of components for various types of machinery. Some advantages include convenience, competitive pricing, and user reviews. Here are a few popular options:

- Manufacturer’s Website: Directly purchasing from the manufacturer often ensures authenticity.

- Specialty Parts Websites: Websites dedicated to specific brands can offer an extensive inventory.

- General E-commerce Platforms: Sites like Amazon and eBay provide a wide range of choices from multiple sellers.

Local Dealers and Stores

For those who prefer to see parts in person before buying, local dealerships and hardware stores can be excellent resources. Here’s what to look for:

- Authorized Dealers: They usually carry original parts and can offer expert advice.

- Local Hardware Stores: Smaller stores may stock common components or be able to order them for you.

- Salvage Yards: These can be a treasure trove for used parts at a fraction of the cost.

By exploring these options, you can easily find the right parts to keep your equipment running smoothly.