Comprehensive Guide to John Deere X500 Repair Manual

In the realm of outdoor equipment, understanding the intricacies of machinery can significantly enhance both performance and longevity. This section is dedicated to providing essential insights into the upkeep of a popular model in the landscaping and gardening sector. By familiarizing oneself with common issues and their solutions, users can ensure their equipment remains in optimal condition.

The information presented herein focuses on various operational aspects, offering practical advice and step-by-step instructions. Whether dealing with minor adjustments or more complex concerns, a systematic approach can make a substantial difference. Proper knowledge empowers owners to tackle challenges effectively, thereby avoiding unnecessary downtime.

Additionally, this guide emphasizes the importance of regular checks and preventive measures. By integrating these practices into routine maintenance, users can mitigate potential problems before they escalate. Understanding the machinery’s mechanics not only aids in immediate fixes but also fosters a deeper connection with the tools that facilitate outdoor endeavors.

Understanding the John Deere X500

This section delves into the essential features and capabilities of a popular lawn care machine, designed for efficiency and versatility. With robust engineering and a focus on user experience, this model has become a favorite among homeowners and professionals alike. Here, we explore the various components and advantages that contribute to its appeal.

Key Features

- Powerful engine for enhanced performance

- Intuitive controls for ease of operation

- Wide range of attachments for multifunctionality

- Durable construction for longevity

Benefits of Ownership

- Improved efficiency in lawn maintenance tasks

- Time-saving capabilities with advanced technology

- Increased property value through well-maintained landscapes

- Enhanced user comfort with ergonomic design

Understanding these aspects can help users maximize their experience, ensuring that they fully leverage the capabilities of this exceptional machine.

Common Issues with the X500

Owners of this series often encounter a range of typical problems that can affect performance and usability. Understanding these common challenges can help in diagnosing issues early and ensuring proper maintenance.

- Engine Troubles: Difficulties with starting or stalling can arise, often linked to fuel system issues or electrical components.

- Cutting Deck Problems: Uneven cutting or grass buildup may occur, necessitating adjustments or cleaning.

- Transmission Failures: Users may experience slipping or reduced responsiveness, usually indicating the need for fluid checks or component replacements.

- Electrical Malfunctions: Battery issues or faulty wiring can lead to problems with lights and other electronic features.

- Tire Wear: Uneven or excessive wear can result from improper inflation or alignment issues.

By being aware of these common issues, owners can take proactive steps to maintain their equipment and ensure it operates efficiently.

Tools Needed for Repairing X500

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial for efficient and effective work. The appropriate tools not only simplify the process but also ensure that tasks are completed safely and accurately. In this section, we will explore essential items that facilitate the upkeep of this particular model.

Essential Hand Tools

First and foremost, a set of basic hand tools is indispensable. Wrenches and screwdrivers of various sizes are vital for loosening and tightening bolts and screws. Additionally, a good socket set is necessary for reaching tight spaces. A pair of pliers can also be handy for gripping and twisting components during maintenance tasks.

Specialized Equipment

In addition to standard tools, certain specialized items may be required for more complex procedures. A multimeter is essential for electrical diagnostics, allowing for the detection of faults in the system. Furthermore, an oil filter wrench will prove invaluable when changing fluids, ensuring a clean and efficient operation. Lastly, having a set of jacks and stands is crucial for safely elevating the unit during inspection or repairs.

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is essential for optimal performance and longevity. This section offers a comprehensive approach to ensure your machinery runs smoothly and efficiently. Following these guidelines will help you identify potential issues early and maintain the best condition possible.

1. Regular Inspection: Start by conducting a thorough visual check of all components. Look for signs of wear, loose connections, or any abnormalities that could indicate a problem. Pay special attention to the belts, hoses, and electrical connections.

2. Cleaning: Keep the machine clean to prevent debris buildup, which can hinder performance. Use a soft brush and a cloth to remove dirt and grime from critical areas. For tougher spots, a gentle cleaning solution can be used, but ensure it’s safe for your equipment’s materials.

3. Fluid Checks: Regularly check and change the fluids. This includes engine oil, coolant, and fuel. Low or contaminated fluids can lead to severe engine damage. Always refer to your specifications for the correct types and levels.

4. Filter Replacement: Filters play a crucial role in maintaining clean fluids and air intake. Replace oil, air, and fuel filters as recommended in your guidelines. This simple task can greatly enhance the efficiency and lifespan of your machine.

5. Tire Maintenance: Inspect tires for proper inflation and tread wear. Under-inflated or worn-out tires can affect performance and safety. Adjust tire pressure as needed and replace any tires showing significant wear.

6. Seasonal Preparations: Before seasonal changes, perform a complete check. This includes battery maintenance, checking for corrosion, and ensuring all systems are operational. Prepare your machinery for extreme weather conditions to avoid potential issues.

7. Document Everything: Keep a detailed log of all maintenance activities. Record dates, tasks performed, and any parts replaced. This information is invaluable for tracking the health of your equipment over time.

By adhering to this maintenance schedule, you can ensure the longevity and reliability of your equipment, ultimately saving time and resources in the long run.

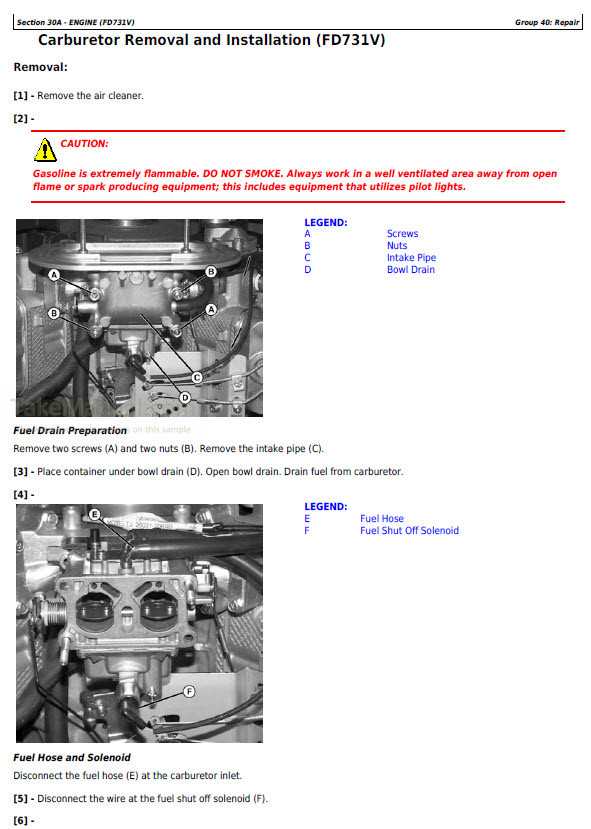

Engine Troubleshooting Techniques

When facing issues with engine performance, employing systematic troubleshooting methods can help identify and resolve problems efficiently. By understanding common symptoms and applying targeted techniques, one can ensure optimal functionality and longevity of the machine.

Identifying Symptoms

Start by observing the engine’s behavior. Listen for unusual noises, watch for abnormal vibrations, and pay attention to changes in power output. Fluid leaks and excessive smoke can also be significant indicators of underlying issues. Documenting these symptoms will assist in narrowing down potential causes.

Diagnostic Procedures

Once symptoms are identified, begin with a visual inspection of the engine components. Check for loose connections, worn parts, and signs of wear and tear. Utilizing diagnostic tools, such as multimeters or pressure gauges, can provide precise readings that reveal performance discrepancies. Regular maintenance practices, including changing filters and fluids, should also be incorporated to prevent future complications.

Replacing the Mower Deck

When it comes to maintaining your outdoor equipment, ensuring the proper functionality of the cutting apparatus is crucial. Over time, wear and tear can lead to performance issues, necessitating a replacement of the mowing component. This guide will walk you through the essential steps to effectively swap out the deck, restoring efficiency to your machine.

Preparation Steps

Before starting the replacement process, gather the necessary tools, including wrenches, screwdrivers, and safety gloves. It’s important to disconnect the power source to prevent any accidental activation. Ensure you have a suitable replacement deck that matches your equipment specifications. Familiarize yourself with the assembly layout to streamline the installation process.

Removal and Installation

Begin by lifting the unit to access the underside where the deck is attached. Carefully detach the belt and any bolts securing the deck in place. Once removed, align the new deck with the mounting points and secure it using the appropriate fasteners. Reattach the belt, ensuring it is properly tensioned. Finally, double-check all connections and test the equipment to confirm that the new deck is functioning as intended.

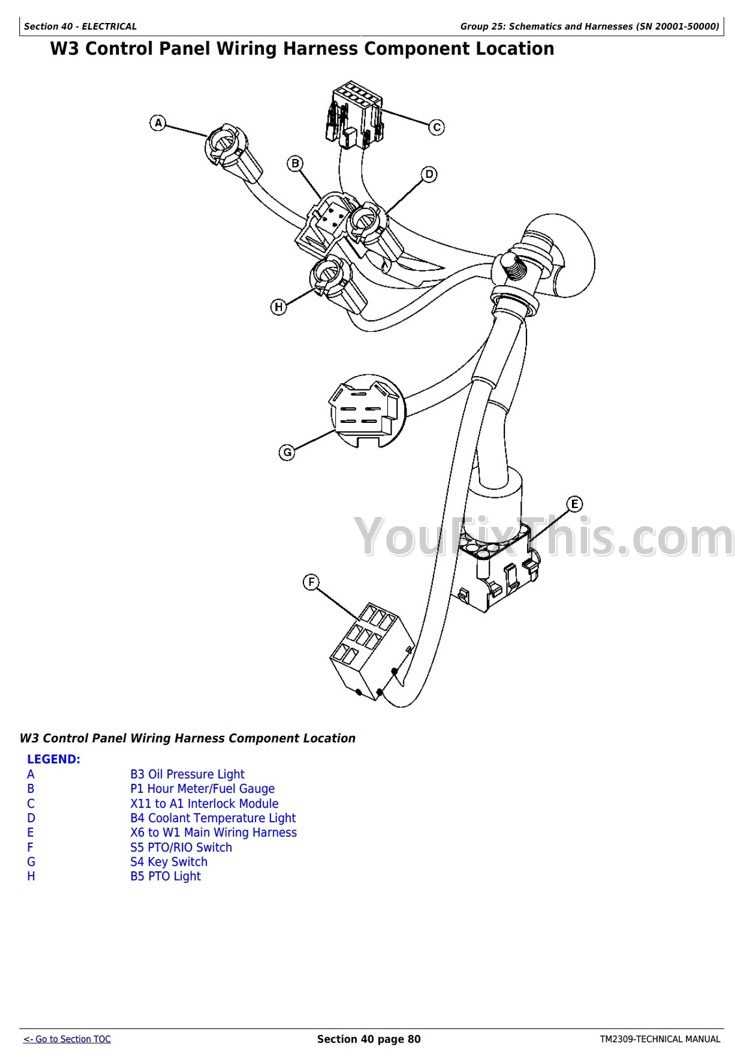

Electrical System Diagnostics

Diagnosing the electrical framework of machinery is crucial for optimal performance and longevity. A thorough understanding of the components and their interconnections enables efficient troubleshooting. This section outlines key procedures for identifying and resolving electrical issues, ensuring that the system operates reliably.

Common Electrical Issues

Several common problems can affect the electrical system, including battery failures, faulty connections, and issues with the ignition system. Recognizing these issues early can prevent more significant damage and ensure smooth operation.

Diagnostic Procedures

To effectively diagnose electrical problems, follow these systematic steps:

| Step | Description |

|---|---|

| 1 | Inspect the battery for corrosion or damage. |

| 2 | Check all wiring connections for tightness and wear. |

| 3 | Test fuses and relays to ensure they are functioning properly. |

| 4 | Use a multimeter to check voltage levels at various points. |

| 5 | Assess the ignition system components for proper operation. |

By systematically following these steps, one can identify electrical faults and implement the necessary repairs to maintain functionality and efficiency.

Checking and Changing Oil

Regular maintenance of the lubrication system is essential for optimal performance and longevity of your equipment. Ensuring that the oil is at the correct level and in good condition can prevent serious mechanical issues and enhance efficiency. This section provides guidance on how to properly assess and replace the oil, ensuring your machinery runs smoothly.

Inspecting Oil Levels

Begin by locating the dipstick or oil level indicator. With the machine on a level surface, remove the dipstick and wipe it clean before reinserting it fully. Remove it again to check the oil level; it should fall within the marked range. If the level is low, top it off with the recommended type of lubricant. Regular checks help identify leaks and maintain proper lubrication.

Changing the Oil

To perform an oil change, start by warming up the engine slightly to thin the oil, making it easier to drain. Turn off the machine and allow it to cool for a few minutes. Place a suitable container beneath the drain plug, remove the plug, and allow the used oil to flow out completely. Once drained, replace the plug securely. Fill the engine with fresh oil using a funnel, ensuring it meets the specifications outlined in the guidelines. Always dispose of the old oil responsibly.

Adjusting the Tire Pressure

Proper tire inflation is crucial for optimal performance and safety. Ensuring that tires are adequately inflated helps maintain traction, fuel efficiency, and overall handling of the vehicle. Regular checks and adjustments can prevent uneven wear and extend the lifespan of the tires.

To achieve the best results, it’s essential to follow a few simple steps to adjust tire pressure correctly. Begin by gathering the necessary tools and information, such as the recommended pressure levels for your specific vehicle. This information is usually found in the owner’s guidelines or on a label located on the frame.

| Step | Action |

|---|---|

| 1 | Check the current tire pressure using a reliable gauge. |

| 2 | Compare the reading with the manufacturer’s recommended pressure. |

| 3 | If adjustment is needed, inflate the tire using an air compressor or let out air if it is overinflated. |

| 4 | Recheck the pressure to ensure it is within the recommended range. |

Maintaining the correct pressure is not only beneficial for performance but also enhances safety and comfort during operation. Regular inspections should be part of your maintenance routine to ensure long-lasting and efficient use of your vehicle.

Blade Sharpening Methods

Maintaining the sharpness of cutting blades is essential for optimal performance and longevity. Properly sharpened blades ensure efficient operation, reduce strain on equipment, and provide cleaner cuts. This section explores various techniques for honing blades, highlighting the benefits and considerations for each method.

Manual Sharpening Techniques

One of the most traditional approaches involves using a hand file or sharpening stone. This method allows for precise control over the blade’s edge. To begin, securely clamp the blade in place, ensuring safety during the sharpening process. Using consistent, even strokes, work along the edge at the manufacturer’s recommended angle. Regular maintenance with this method can lead to enhanced cutting efficiency and prolong the lifespan of the blades.

Power Sharpening Options

For those seeking a quicker alternative, powered sharpeners are widely available. These tools can effectively restore sharpness with minimal effort. It’s important to adjust the settings according to the blade type and material. While power sharpening can save time, it’s crucial to monitor the heat generated during the process to avoid damaging the blade. Investing in a high-quality sharpener can lead to consistent results and a reduction in manual labor.

Battery Care and Maintenance

Proper upkeep of the energy source is essential for optimal performance and longevity of your equipment. By following a few straightforward guidelines, you can ensure that the battery remains in excellent condition, thereby enhancing its efficiency and lifespan.

Routine Checks

Regular inspections can help identify potential issues before they escalate. Consider the following:

- Examine the terminals for corrosion or buildup.

- Ensure connections are secure and free from rust.

- Inspect for any signs of leaks or damage.

Charging Guidelines

Maintaining the correct charge level is crucial. Follow these recommendations:

- Avoid deep discharges; recharge promptly when levels are low.

- Use a compatible charger to prevent overcharging.

- Store the battery in a cool, dry place when not in use.

Winterizing Your John Deere

Preparing your equipment for the colder months is essential to ensure its longevity and optimal performance. This process involves several key steps that protect vital components from harsh weather conditions and minimize potential damage. By taking the time to properly prepare your machinery, you can save on costly repairs and maintain its efficiency throughout the year.

First, start with a thorough cleaning of the exterior. Remove any dirt, debris, or grass clippings that may have accumulated during use. This will prevent rust and corrosion from developing over the winter. Pay special attention to the undercarriage and other hard-to-reach areas.

Next, it’s crucial to check and change the oil if necessary. Old oil can contain contaminants that may cause engine wear. Using fresh oil will help keep the engine lubricated and running smoothly when spring arrives.

Additionally, inspect the fuel system. Consider adding a fuel stabilizer to prevent the gasoline from degrading over time. This will ensure that your engine starts easily when you’re ready to use it again. Make sure to fill the tank to minimize moisture buildup inside.

Lastly, don’t forget about the battery. Remove it and store it in a cool, dry place. Regularly check the charge level and clean the terminals to prevent corrosion. A well-maintained battery will help ensure reliable starts when warmer weather returns.

By following these steps, you can effectively protect your machinery during the winter months, ensuring it remains in excellent condition for the seasons to come.

Finding Genuine Replacement Parts

When it comes to maintaining machinery, sourcing authentic components is crucial for ensuring longevity and optimal performance. Utilizing original parts can help prevent future issues and maintain the integrity of the equipment.

Here are some steps to consider when searching for reliable replacements:

- Research Authorized Dealers: Look for certified retailers that specialize in the brand’s products. They typically offer a range of genuine parts and provide assurance of quality.

- Verify Part Numbers: Always check the specific part number associated with your equipment. This will help you find the exact match and avoid compatibility issues.

- Consult Online Resources: Many manufacturers provide online catalogs or databases. Use these tools to cross-reference parts and access user guides for additional information.

- Join Community Forums: Engaging with fellow enthusiasts or professionals can provide insights into where to find authentic parts and share personal experiences.

- Inspect the Packaging: Genuine parts usually come in branded packaging. Ensure the seals and labels are intact to avoid counterfeit items.

By following these steps, you can ensure that your equipment remains in peak condition with the right components, ultimately leading to better performance and reliability.