Comprehensive Guide to John Deere Z425 Repair Manual

In the realm of outdoor machinery, understanding the intricacies of upkeep is crucial for optimal performance and longevity. This section delves into the essential techniques and knowledge required for maintaining specific models of lawn equipment, ensuring they operate efficiently throughout their lifespan. Whether you’re a seasoned user or a newcomer, having access to detailed instructions and insights can significantly enhance your experience.

Regular maintenance plays a vital role in preventing issues that can arise from neglect. From routine checks to more in-depth servicing, knowing how to address common problems is invaluable. This guide aims to equip users with the information necessary to tackle various challenges and keep their equipment running smoothly.

Moreover, having a reliable source of information fosters confidence and encourages proactive care. By familiarizing yourself with the recommended practices, you can save time and resources while enhancing the performance of your machinery. Embrace the journey of equipment maintenance with a wealth of knowledge at your fingertips.

Understanding the John Deere Z425

This section delves into the essential features and components of a popular riding mower, designed for efficiency and ease of use. With a blend of performance and comfort, this machine caters to both residential and commercial landscaping needs, making it a preferred choice among users.

At the heart of this mower’s design is a robust engine, delivering reliable power and ensuring smooth operation across various terrains. Its innovative cutting system enhances the mowing experience, providing a clean and precise finish. The ergonomic layout prioritizes user comfort, allowing for extended periods of operation without fatigue.

| Feature | Description |

|---|---|

| Engine Type | Powerful gasoline engine optimized for performance |

| Cutting Width | Generous cutting deck for efficient grass management |

| Drive System | Hydrostatic transmission for smooth speed control |

| Comfort Features | Adjustable seat and intuitive controls for user convenience |

| Maintenance | Designed for easy access to components for routine servicing |

Understanding the specifications and functionalities of this mower can significantly enhance the user experience, leading to better maintenance practices and overall performance. By familiarizing oneself with these attributes, operators can ensure optimal usage and longevity of the equipment.

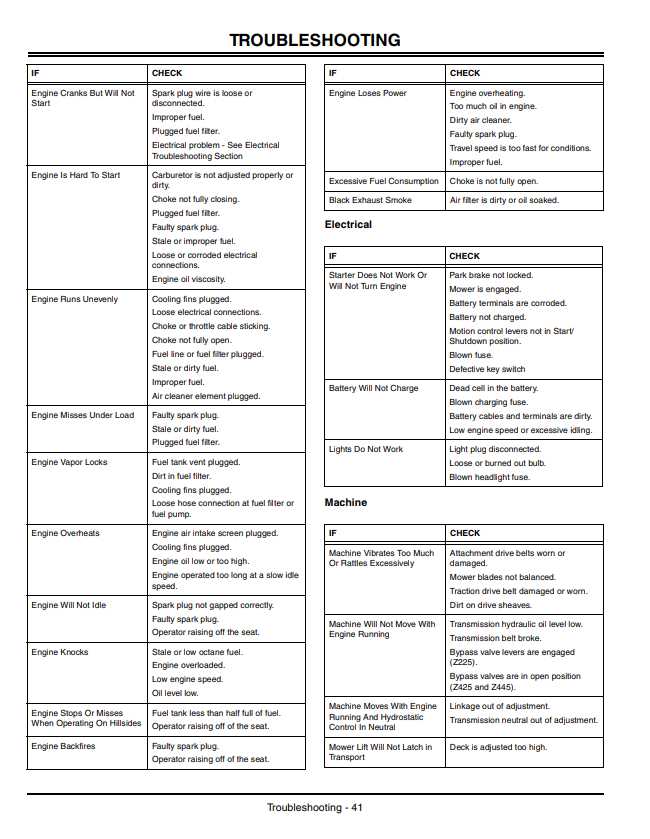

Common Issues with Z425 Mowers

When maintaining a lawn care machine, operators often encounter various challenges that can affect performance and efficiency. Understanding these typical problems can aid in troubleshooting and ensuring optimal operation. Below are some frequently observed concerns and their potential causes.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Won’t Start | Failure to initiate can be due to battery issues, fuel supply problems, or ignition system faults. | Check battery connections, ensure fuel is available and clean, and inspect spark plugs. |

| Uneven Cutting | Inconsistent lawn trimming may result from dull blades, improper deck height, or uneven tire pressure. | Sharpen or replace blades, adjust the deck height, and check tire inflation levels. |

| Overheating | Excessive heat can arise from clogged cooling fins, low oil levels, or a malfunctioning cooling system. | Clean cooling fins, check oil levels, and ensure the cooling system is functioning properly. |

| Vibration During Operation | Unusual shaking may indicate misaligned parts, worn bearings, or loose bolts. | Inspect and realign components, replace worn bearings, and tighten loose fasteners. |

| Fuel Leaks | Leaks can occur due to damaged fuel lines, loose connections, or a faulty carburetor. | Inspect fuel lines for wear, tighten connections, and service the carburetor as needed. |

Essential Tools for Repairing Z425

When it comes to maintaining your machinery, having the right instruments is crucial for effective servicing and troubleshooting. Proper equipment not only ensures efficiency but also enhances the longevity of your equipment. Below are the key items you should consider having on hand.

Wrenches and Sockets: A variety of wrenches and socket sets are essential for loosening and tightening bolts and nuts. It’s advisable to have both metric and standard sizes to accommodate different fasteners.

Screwdrivers: A set of flathead and Phillips screwdrivers will be necessary for accessing various components. Opt for those with magnetic tips to easily handle screws in tight spaces.

Pliers: Needle-nose and slip-joint pliers are useful for gripping and twisting wires or other small parts, making them indispensable for intricate tasks.

Jack Stands: Stability during work is paramount. Using jack stands ensures safety when lifting the equipment for maintenance tasks underneath.

Multimeter: This tool is vital for diagnosing electrical issues. It allows you to measure voltage, current, and resistance, helping you troubleshoot effectively.

Oil Filter Wrench: When changing fluids, this specialized tool aids in the removal of filters without damaging them, ensuring a smooth transition during maintenance.

Having these essential instruments on hand will empower you to tackle a variety of maintenance tasks with confidence and skill.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for optimal performance and longevity of your equipment. By following systematic processes, you can ensure that every component functions efficiently and any potential issues are addressed promptly. Here are detailed procedures to help you maintain your machine effectively.

Daily Maintenance Tasks

- Check fuel levels and top off as necessary.

- Inspect oil levels and add oil if required.

- Examine the air filter for debris and clean or replace as needed.

- Inspect tires for proper inflation and wear.

- Ensure all safety features are operational.

Weekly Maintenance Tasks

- Clean the exterior to remove dirt and debris.

- Check and tighten all bolts and fasteners.

- Inspect belts for signs of wear or damage.

- Lubricate all moving parts according to the specifications.

- Test the battery and clean the terminals if necessary.

Adhering to these guidelines will help maintain efficiency and extend the lifespan of your equipment. Always consult specific guidelines for further detailed instructions.

Diagnosing Engine Problems Effectively

Identifying issues within a motor requires a systematic approach to ensure accurate assessment and resolution. By following a structured process, one can isolate the root causes of malfunctions and implement appropriate solutions.

Begin with these fundamental steps:

- Visual Inspection: Examine the exterior for signs of wear or damage.

- Listen for Unusual Noises: Pay attention to sounds that deviate from normal operation.

- Check Fluid Levels: Ensure oil, coolant, and fuel are at recommended levels.

- Monitor Engine Performance: Observe acceleration, power loss, and stalling issues.

Utilizing diagnostic tools can also enhance the process:

- Multimeter for electrical issues

- Compression gauge to assess cylinder pressure

- OBD-II scanner for error codes

By systematically evaluating these aspects, one can delve deeper into potential complications, leading to effective solutions and improved performance.

Replacing the Blades Safely

Changing the cutting elements of your lawn equipment is an essential task for maintaining optimal performance and ensuring a healthy lawn. However, it is crucial to follow proper safety protocols during this process to prevent accidents and injuries. This section will guide you through the steps necessary to safely remove and replace the blades.

Before you begin, ensure that the machine is turned off and has cooled down. Disconnect the spark plug wire to eliminate any risk of accidental startup. Wearing protective gloves and eyewear is also recommended to safeguard against sharp edges and debris.

Next, use a suitable lifting device or ramp to elevate the equipment securely, ensuring stability during the blade replacement. Position a container underneath to catch any residual oil or debris that may fall during the process.

When removing the old blades, carefully unscrew the fasteners holding them in place, using the appropriate tools. Be mindful of the blade’s sharp edges and handle them with care. Once removed, inspect the area for any signs of wear or damage before installing the new blades.

Finally, attach the new blades securely, ensuring that they are oriented correctly for optimal cutting performance. Reconnect the spark plug wire and lower the equipment safely before testing its functionality. Following these precautions will help you complete the task efficiently and safely.

Fuel System Troubleshooting Tips

Effective management of the fuel system is crucial for optimal performance and longevity of your equipment. Issues in this area can lead to poor engine operation, decreased efficiency, and increased emissions. Understanding common symptoms and their causes can help in swiftly identifying and resolving problems.

Common Symptoms and Causes

Below is a table that outlines frequent issues encountered within the fuel system, along with their potential causes:

| Symptom | Possible Causes |

|---|---|

| Engine Won’t Start | Empty fuel tank, clogged fuel filter, faulty fuel pump |

| Rough Idling | Contaminated fuel, air leaks, improper fuel mixture |

| Reduced Power | Blocked fuel lines, failing injectors, low fuel pressure |

| Excessive Smoke | Over-fueling, poor combustion, malfunctioning sensors |

Troubleshooting Steps

To effectively address issues within the fuel system, follow these steps:

- Check the fuel level to ensure it is adequate.

- Inspect fuel lines for any signs of wear or blockages.

- Replace the fuel filter if it appears clogged or dirty.

- Test the fuel pump operation to confirm it is functioning properly.

- Examine the injectors for clogs or leaks.

By systematically analyzing these areas, you can pinpoint and rectify fuel system issues, ensuring reliable operation of your equipment.

Electrical Components Overview

This section provides a comprehensive examination of the various electrical elements present in the equipment, emphasizing their roles, interconnections, and maintenance considerations. Understanding these components is essential for optimal performance and troubleshooting procedures.

Key Electrical Parts

Each electrical component serves a specific function, contributing to the overall efficiency of the machinery. Here is a breakdown of some critical parts:

| Component | Function | Common Issues |

|---|---|---|

| Batteries | Store and supply electrical energy. | Corrosion, discharge, failure to start. |

| Alternator | Generates electrical power while the engine is running. | Overheating, poor output, noise. |

| Starter Motor | Initiates engine operation. | Clicking sound, failure to engage. |

| Fuse Box | Protects circuits from overload. | Blown fuses, poor connectivity. |

Maintenance Tips

Regular checks and maintenance of electrical components can prevent unexpected failures and extend the lifespan of the equipment. Ensure connections are tight, inspect for wear and corrosion, and replace faulty parts promptly to maintain operational efficiency.

Hydraulic System Maintenance Guidelines

Proper upkeep of the hydraulic system is crucial for ensuring optimal performance and longevity of your equipment. Regular attention to this system can prevent costly repairs and enhance efficiency. This section outlines essential practices to maintain the hydraulic components effectively.

Routine Inspection

Conducting frequent assessments of the hydraulic system can identify potential issues before they escalate. Focus on checking fluid levels, inspecting hoses for wear, and ensuring all connections are secure.

| Inspection Area | Frequency | Notes |

|---|---|---|

| Fluid Levels | Weekly | Ensure fluid is at recommended levels to avoid overheating. |

| Hoses and Fittings | Monthly | Look for signs of cracks or leaks. |

| Filters | Every 50 hours | Replace if dirty or clogged to maintain flow. |

Fluid Quality Management

Maintaining the integrity of the hydraulic fluid is essential for smooth operation. Contaminated fluid can lead to system failures. Regularly replace the fluid according to the manufacturer’s specifications and monitor its condition to ensure optimal performance.

Seasonal Care for Longevity

Maintaining outdoor equipment throughout the year is essential for ensuring its optimal performance and extending its lifespan. By implementing a seasonal care routine, you can prevent common issues and enhance the efficiency of your machinery. Proper upkeep not only protects your investment but also promotes safety and reliability during operation.

Spring Preparation

As the weather warms, it’s crucial to prepare your equipment for the busy months ahead. Begin by thoroughly cleaning the machine to remove dirt and debris that accumulated during the winter. Check all fluids, including oil and fuel, and replace them if necessary. Inspect the blades and belts for wear, and sharpen or replace them as needed. This proactive approach will ensure that your equipment is ready for optimal performance when it’s time to tackle your outdoor tasks.

Fall Maintenance

As the season transitions, it’s important to conduct a comprehensive inspection and maintenance check. Drain fuel or add a stabilizer to prevent degradation during the colder months. Clean the equipment meticulously, paying special attention to the air filters and cooling systems. Store the machinery in a dry, sheltered location to protect it from harsh weather conditions. This careful preparation will help safeguard against damage and ensure a smooth start when spring arrives.

Upgrading Parts for Improved Performance

Enhancing the capabilities of your equipment can significantly impact its overall efficiency and longevity. By selecting higher-quality components and making thoughtful upgrades, users can experience improved functionality, reduced downtime, and a more enjoyable operating experience. This section focuses on key areas where modifications can yield noticeable benefits.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | High-performance air filter | Increased airflow and better combustion efficiency |

| Blades | Premium cutting blades | Sharper edges for cleaner cuts and improved durability |

| Transmission | Heavy-duty belt | Enhanced power transfer and reduced wear |

| Wheels | All-terrain tires | Better traction and stability on various surfaces |

| Battery | High-capacity battery | Longer run times and improved reliability |

By investing in these upgrades, users can achieve superior performance and extend the lifespan of their machinery. Evaluating each component and considering potential enhancements will lead to a more efficient and effective operation, making maintenance and use more rewarding.

Resources for Further Assistance

When facing challenges with your outdoor equipment, having access to reliable resources is essential. Various platforms and tools can provide valuable insights, detailed guidance, and community support to ensure optimal performance and longevity of your machinery.

| Resource Type | Description | Website/Contact |

|---|---|---|

| Manufacturer’s Website | Official site offers technical documents, FAQs, and customer support. | example.com |

| Online Forums | Community-driven platforms where users share experiences and solutions. | forumexample.com |

| Repair Blogs | Expert articles and step-by-step guides on common issues and fixes. | blogexample.com |

| Local Repair Shops | Professional services offering repairs and maintenance advice. | Contact via local listings |

| YouTube Channels | Video tutorials demonstrating repair processes and maintenance tips. | youtube.com |