Ensuring that your vehicle remains in optimal working condition requires an understanding of its essential components and maintenance needs. This guide provides valuable insights and step-by-step guidance to help owners confidently approach various upkeep tasks, from regular check-ups to addressing specific issues. Whether for experienced drivers or newcomers to vehicle care, these insights foster a deeper understanding of proper vehicle handling and functionality.

Covering key areas such as engine performance, transmission adjustments, and suspension health, this resource aims to empower users with practical knowledge for maintaining their vehicle’s reliability. Each section has been crafted to simplify the complex mechanics behind these systems, allowing readers to tackle upkeep with clarity and precision. Adopting a preventive approach can help avoid costly repairs and ensure long-lasting performance on the road.

Through this guide, owners will find helpful advice on common troubleshooting steps, safe practices, and optimal solutions for vehicle care. Emphasis is placed on accurate diagnosis and efficient problem-solving, offering a straightforward approach for addressing both minor and significant concerns. With the right tools and techniques at hand, vehicle owners can confidently navigate any maintenance task.

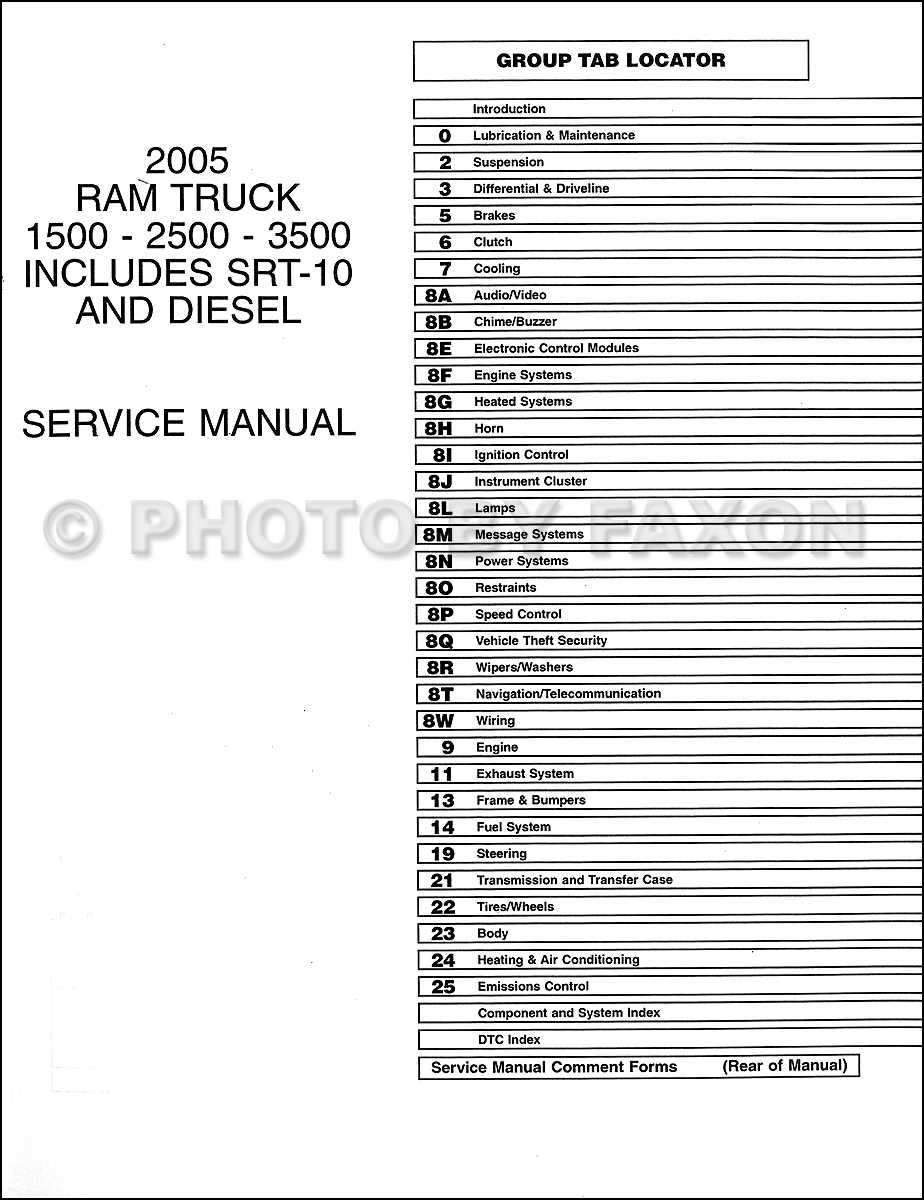

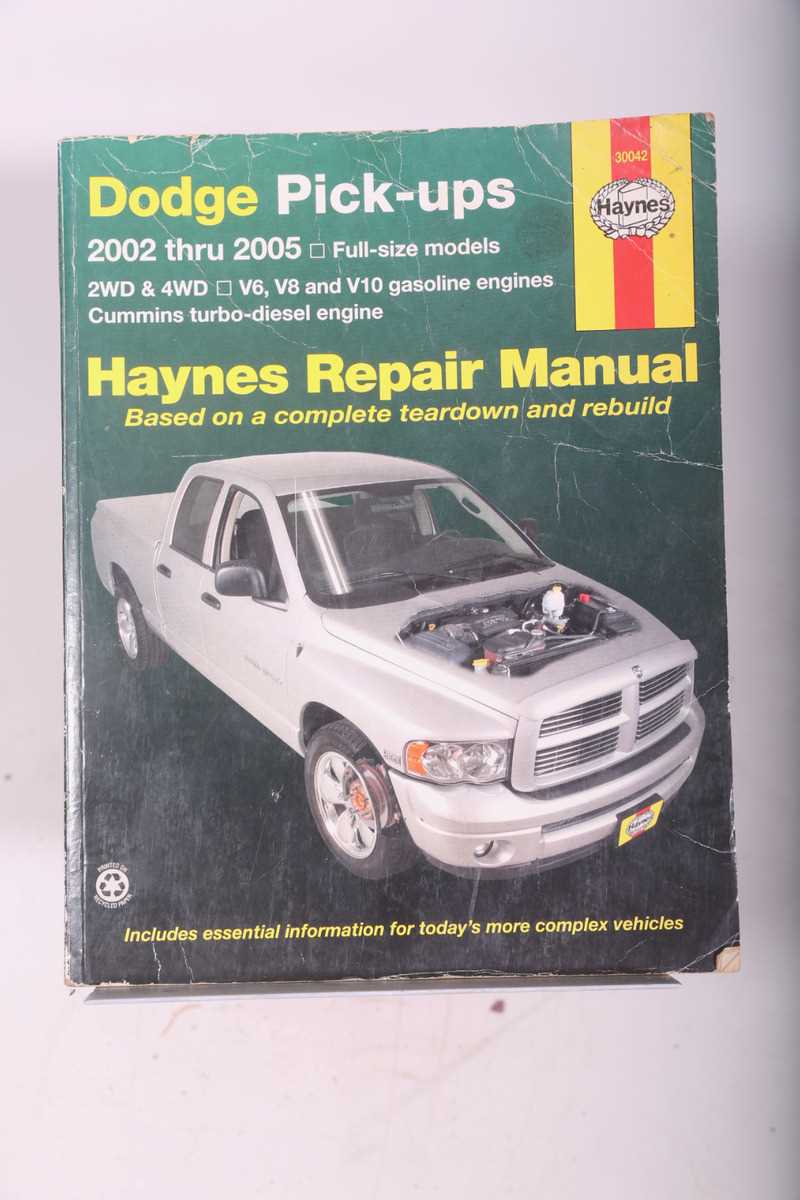

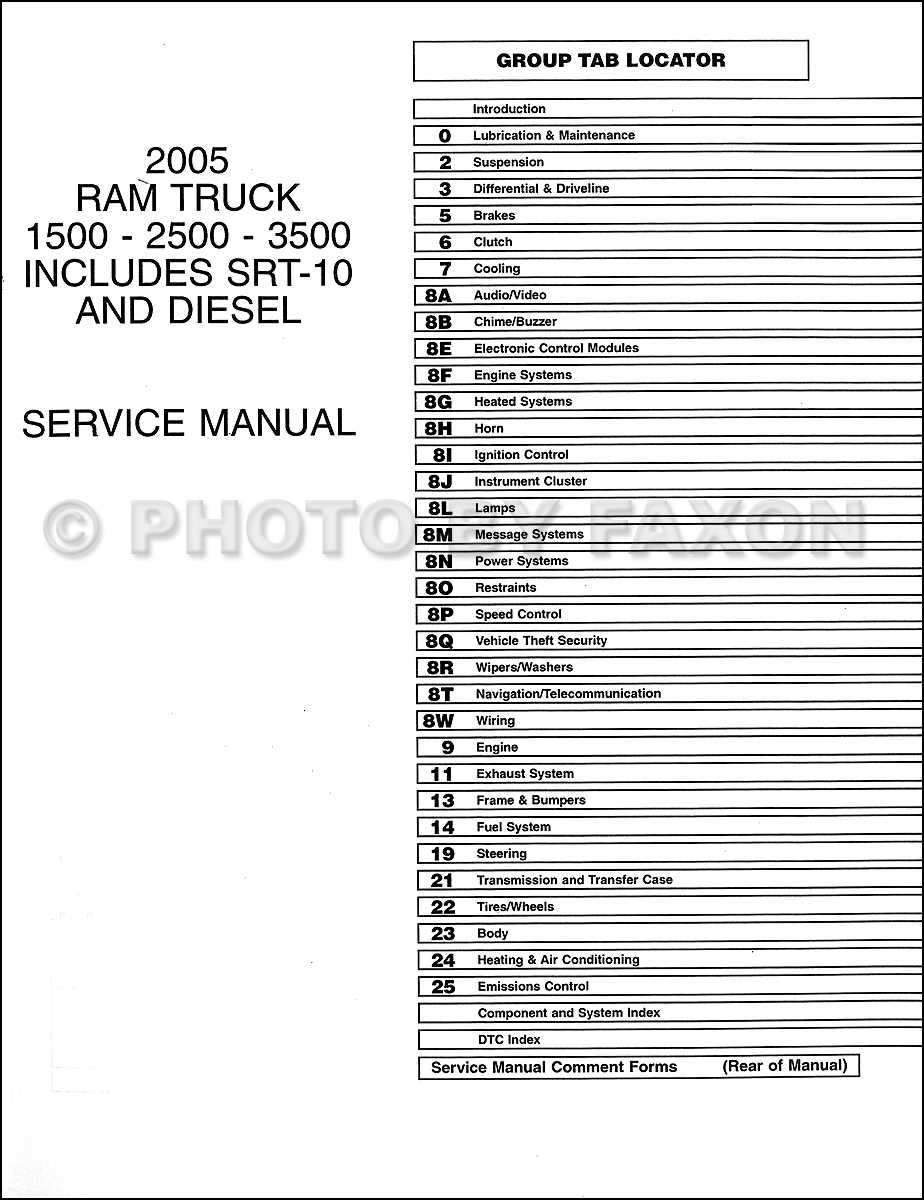

2005 Dodge Ram 2500 Repair Guide

This section provides an in-depth overview for vehicle enthusiasts looking to enhance their understanding of maintaining a robust, heavy-duty pickup model. We’ll delve into essential aspects of upkeep and address key areas to ensure optimal performance and longevity.

Key Maintenance Areas

Regular checks and timely interventions help prevent common issues and enhance the vehicle’s durability. Below is a summary of crucial areas that require attention:

- Engine Care: Ensuring the engine is consistently clean and well-lubricated can improve fuel efficiency and reduce long-term wear.

- Transmission Fluid: Routine checks of transmission fluid levels and quality help maintain smooth gear shifts and overall drivability.

- Cooling System: Inspecting the cooling system and hoses prevents overheating, a common issue in heavier models.

Additional Tips for Enhanced Performance

In addition to basic maintenance, these practical steps can contribute to better overall function:

- Perform regular oil changes and monitor the quality to avoid engine strain.

- Check tire pressure frequently to improve safety, handling, and fuel economy.

- Inspect brake pads and rotors periodically to ensure consistent braking performance.

Staying proactive about these practices will ensure the vehicle remains reliable and prepared for diverse driving conditions.

Common Engine Troubleshooting Steps

Identifying engine issues often requires a systematic approach to ensure accurate diagnosis and effective repairs. This section covers essential steps to help pinpoint and resolve common mechanical problems, guiding vehicle owners through initial checks and fundamental inspection techniques.

Step 1: Inspect Fuel and Air Supply

One of the primary areas to examine is the fuel and air supply systems. Begin by checking fuel levels and ensuring no restrictions are present in the fuel line. Air filters should also be clean and unobstructed, as clogged filters can disrupt the air intake, leading to poor engine performance. If the engine struggles to start or idles roughly, fuel and air flow checks are crucial for maintaining efficient operation.

Step 2: Assess Electrical Components

Another vital aspect to investigate involves the electrical system, particularly the battery and spark plugs. Verify that the battery is fully charged and terminals are free of corrosion. Examine spark plugs for signs of wear or deposits, as these can lead to misfires and impact overall functionality. Ensuring all electrical connections are secure can help avoid intermittent power issues.

Through a careful examination of these essential components, vehicle owners can address common engine troubles effectively, often enhancing performance and preventing further complications. For complex issues, however, consulting a professional technician is recommended to ensure thorough resolution.

Transmission Maintenance and Repairs

Ensuring the longevity and reliability of a vehicle’s transmission system requires a proactive approach to upkeep and occasional fixes. Regular inspections and timely adjustments help prevent common issues that may affect performance and lead to costly complications. This section provides essential insights into preserving and servicing this crucial part of the vehicle, outlining practical steps for routine care and recognizing signs of wear.

Signs of Transmission Wear

Identifying early indicators of wear can significantly extend the transmission’s operational life. Common signs may include unusual noises, difficulty shifting gears, or delayed engagement when accelerating. Recognizing these symptoms promptly allows for early intervention, potentially preventing major breakdowns. Regularly checking fluid levels, as well as inspecting for leaks, plays an important role in maintaining smooth and efficient function.

Routine Transmission Care

Regular maintenance is essential for preventing transmission malfunctions. Fluid replacement is one of the most crucial aspects, as it helps to keep internal components lubricated and reduces friction. It’s recommended to use manufacturer-approved fluids and follow appropriate intervals for replacement. Additionally, paying attention to transmission filters and keeping them clean aids in avoiding contaminant build-up, which can impede functionality over time.

Braking System Inspections and Fixes

Ensuring the proper function of a vehicle’s braking system is essential for safety and performance. Regular evaluations help to identify early signs of wear or potential issues, allowing for timely corrections before they develop into more significant problems. This section covers fundamental inspection steps and effective remedies to keep the braking components in optimal condition.

Visual Inspection: Start by examining the visible elements of the braking system, such as the brake pads, rotors, and calipers. Look for signs of wear, cracks, or discoloration. Excessive dust or an uneven pad surface can indicate abnormal wear, which may require replacement or adjustment.

Brake Fluid Check: Fluid levels and quality play a crucial role in maintaining brake responsiveness. Inspect the brake fluid reservoir and check for darkened or cloudy fluid, which could suggest contamination. Replacing old fluid as part of routine maintenance can help preserve the hydraulic components and ensure consistent performance.

Addressing Common Issues: Many braking issues stem from worn-out parts or improper alignment. If you notice grinding noises, diminished stopping power, or vibrations during braking, these can indicate worn rotors or pads. Replacing these parts promptly helps restore effective braking and minimizes further wear on the system.

Regularly assessing and addressing brake system components enhances both the safety and longevity of the vehicle. Following recommended maintenance intervals and staying alert to unusual sounds or sensations can prevent many common braking issues.

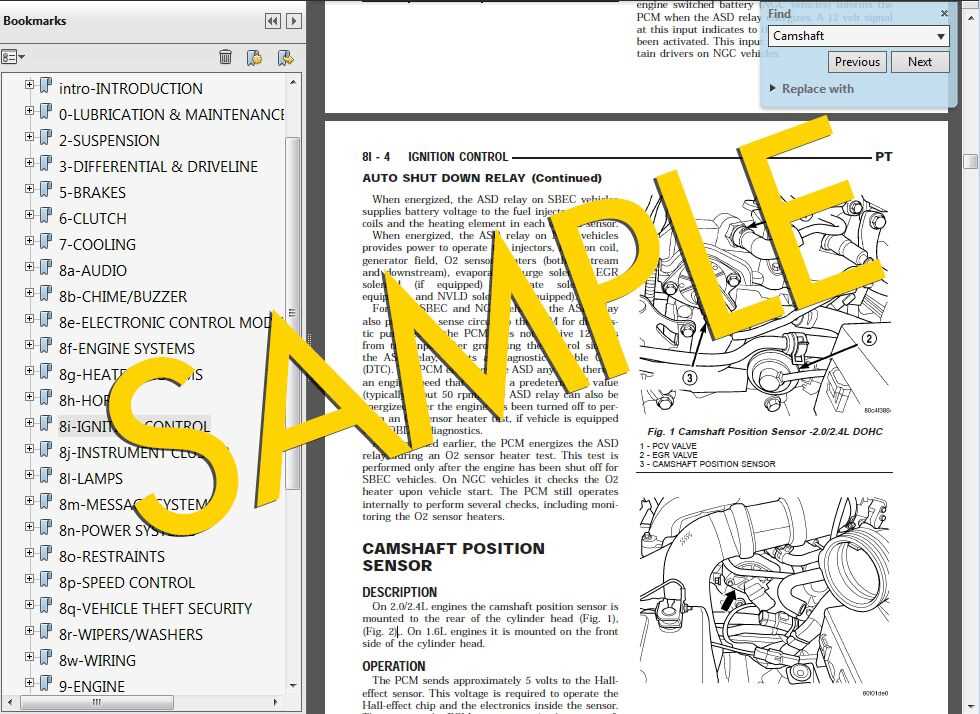

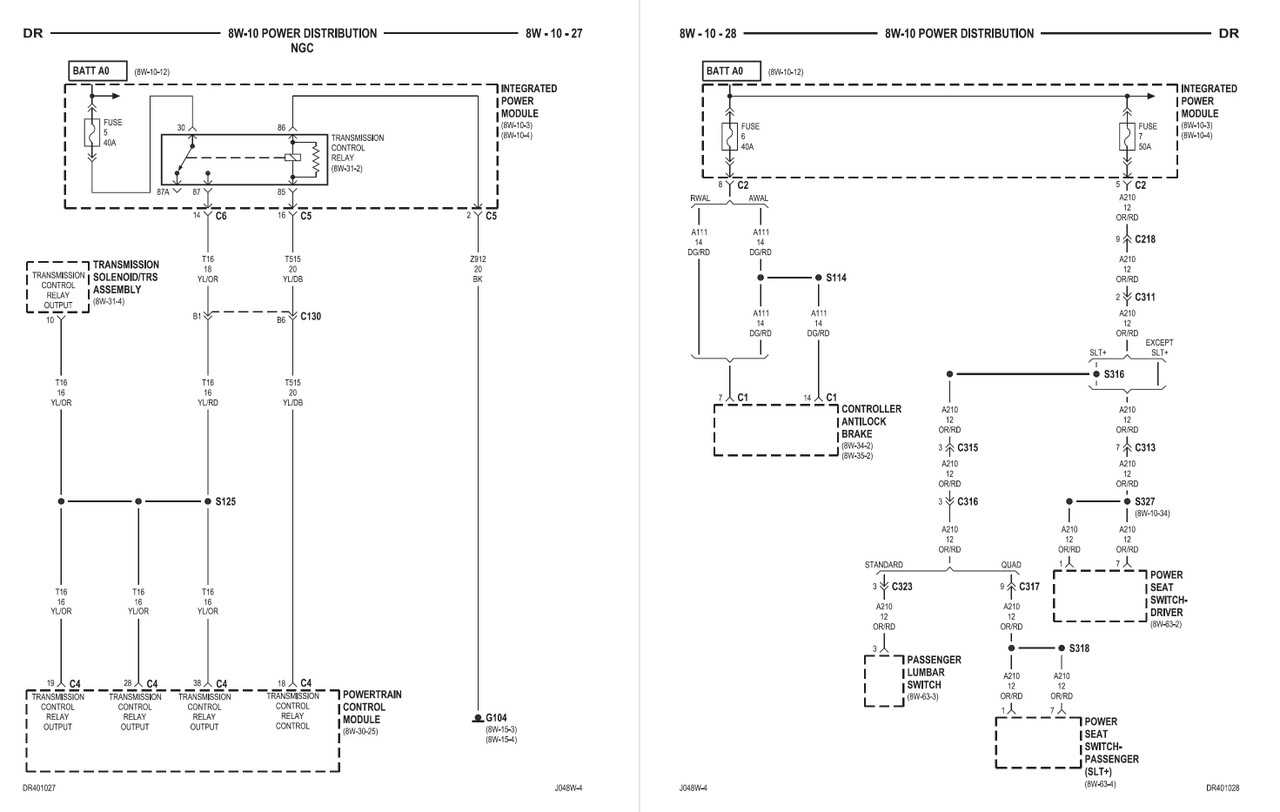

Electrical System Diagnostic Tips

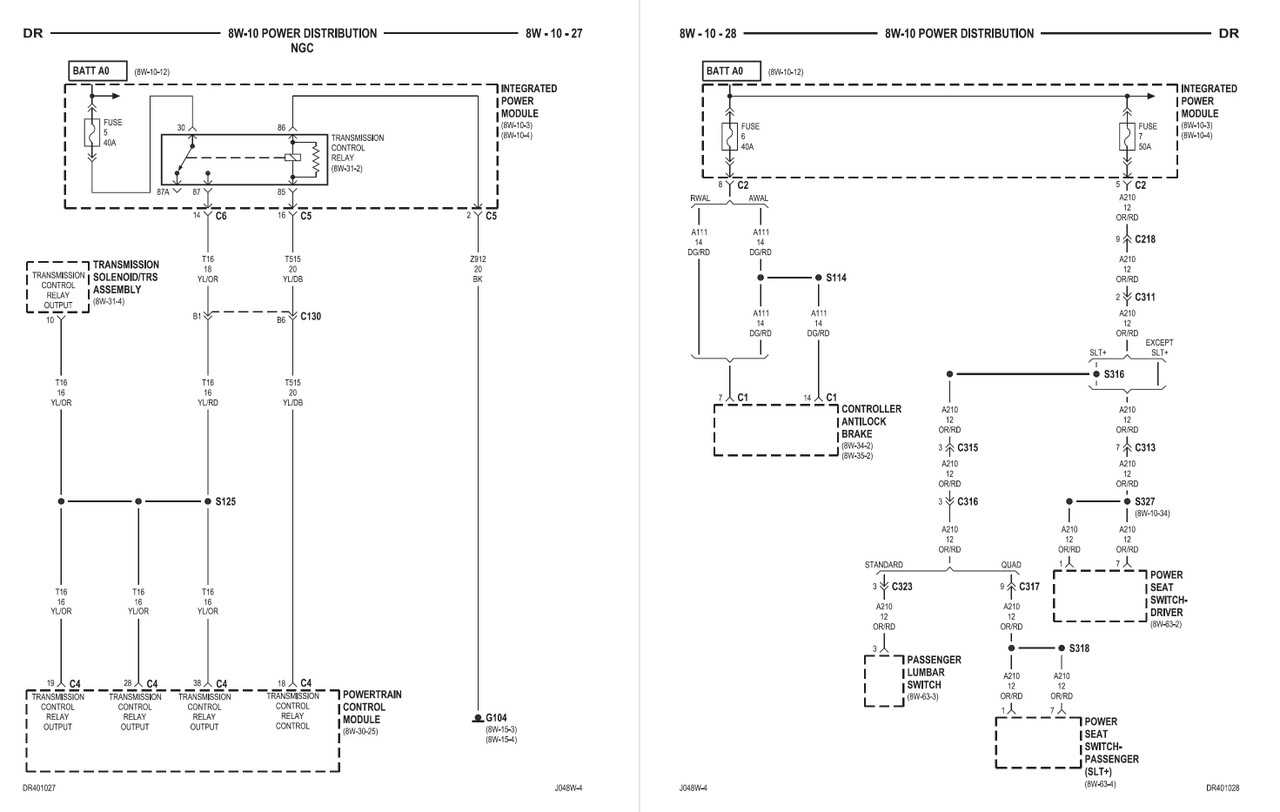

In order to maintain vehicle performance and ensure reliability, conducting a thorough inspection of the electrical system is essential. Proper diagnostic methods help identify potential issues early on, preventing costly repairs and ensuring all components function optimally. Below are effective strategies and methods for diagnosing common issues within a vehicle’s electrical system.

Step-by-Step Voltage Testing

One of the most efficient ways to detect faults within the electrical system is by testing voltage across key components. Using a multimeter, begin with the battery and move systematically through connections to verify consistent voltage levels. This helps pinpoint areas with possible voltage drops or unstable current, which can affect the operation of other systems.

Common Wiring and Fuse Troubleshooting

Another critical aspect of electrical diagnostics is inspecting the condition of wiring and fuses. Loose connections, corroded terminals, or blown fuses are common culprits behind intermittent or non-functional components. Regular examination and testing can ensure that the wiring remains secure and each fuse maintains proper continuity.

| Component |

Diagnostic Method |

Common Symptoms |

| Battery |

Voltage Check |

Dim lights, weak start |

| Alternator |

Output Measurement |

Battery drain, flickering lights |

| Starter |

Current Draw Test |

No start, slow crank |

| Fuses |

Continuity Test |

Non-functional circuits |

| Wiring |

Visual Inspection |

Intermittent connections, shorts |

Cooling System Repair Techniques

The effective maintenance of a vehicle’s cooling system is crucial for ensuring optimal performance and longevity. Understanding various methods to troubleshoot and address common issues can help keep the engine at the right temperature, preventing overheating and related damage.

Regular Inspections: Routine checks of the cooling components, including hoses, radiator, and thermostat, are essential. Look for signs of wear, leaks, or corrosion that could impede the system’s functionality. Early detection can save time and resources.

Flush and Refill: Over time, coolant can become contaminated or lose its effectiveness. Performing a thorough flush of the system removes old fluid and any deposits, allowing for a fresh refill of the appropriate coolant. This process helps maintain efficient heat transfer.

Thermostat Testing: A malfunctioning thermostat can lead to inconsistent engine temperatures. Testing this component involves checking its opening and closing temperatures to ensure it operates within specified ranges. Replacing a faulty thermostat is a straightforward process that can restore system efficiency.

Leak Repair: Addressing leaks promptly is vital to prevent coolant loss. Depending on the location and severity, leaks can often be fixed with sealants or by replacing affected hoses or fittings. In cases of severe damage, component replacement may be necessary.

Radiator Maintenance: Keeping the radiator clean and free from debris enhances airflow and cooling efficiency. Regularly inspect the fins and use a soft brush or compressed air to clear any buildup. This practice supports optimal performance during operation.

Pressure Testing: Conducting a pressure test helps identify hidden leaks within the cooling system. This method involves pressurizing the system and monitoring for drops, which can indicate the presence of a leak that needs attention.

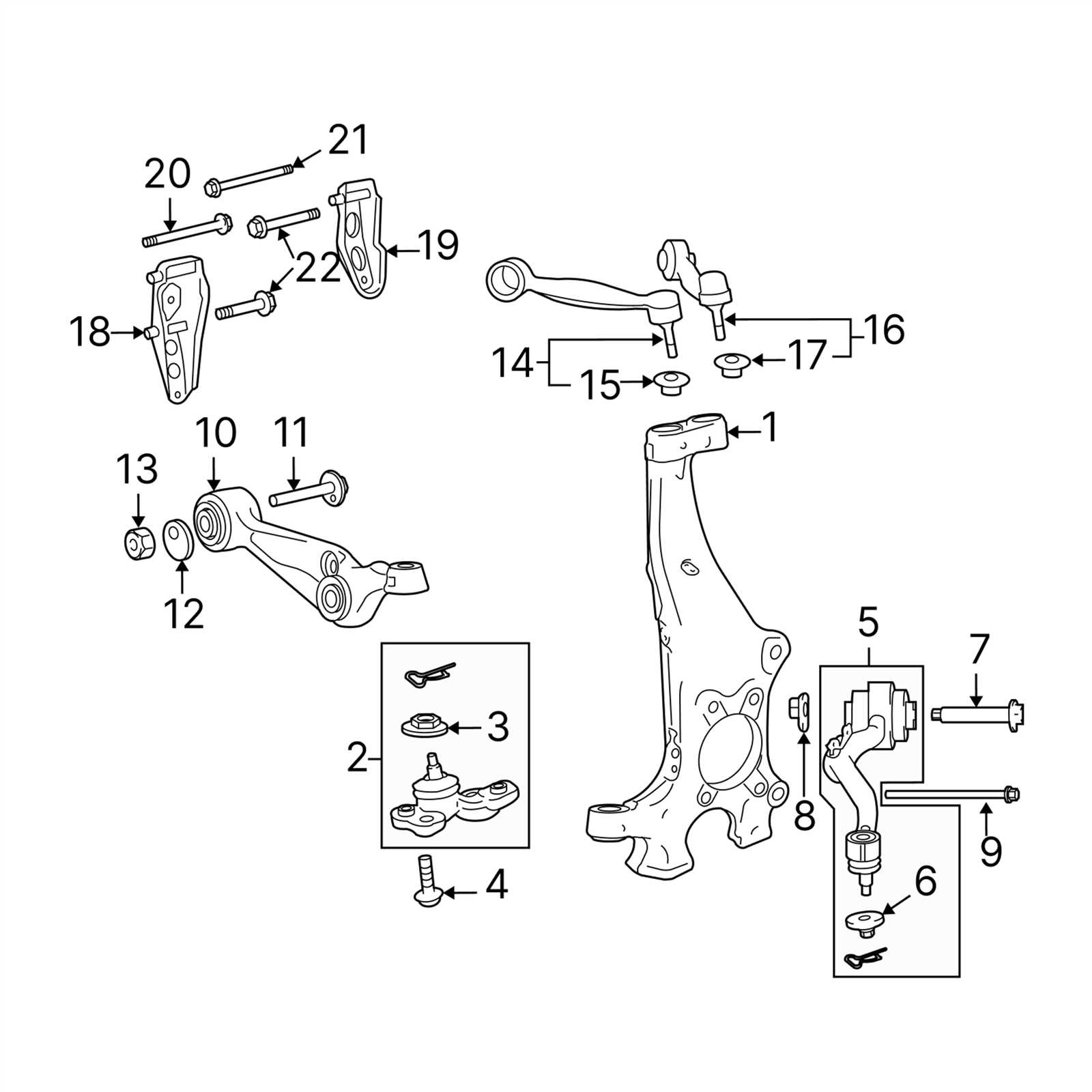

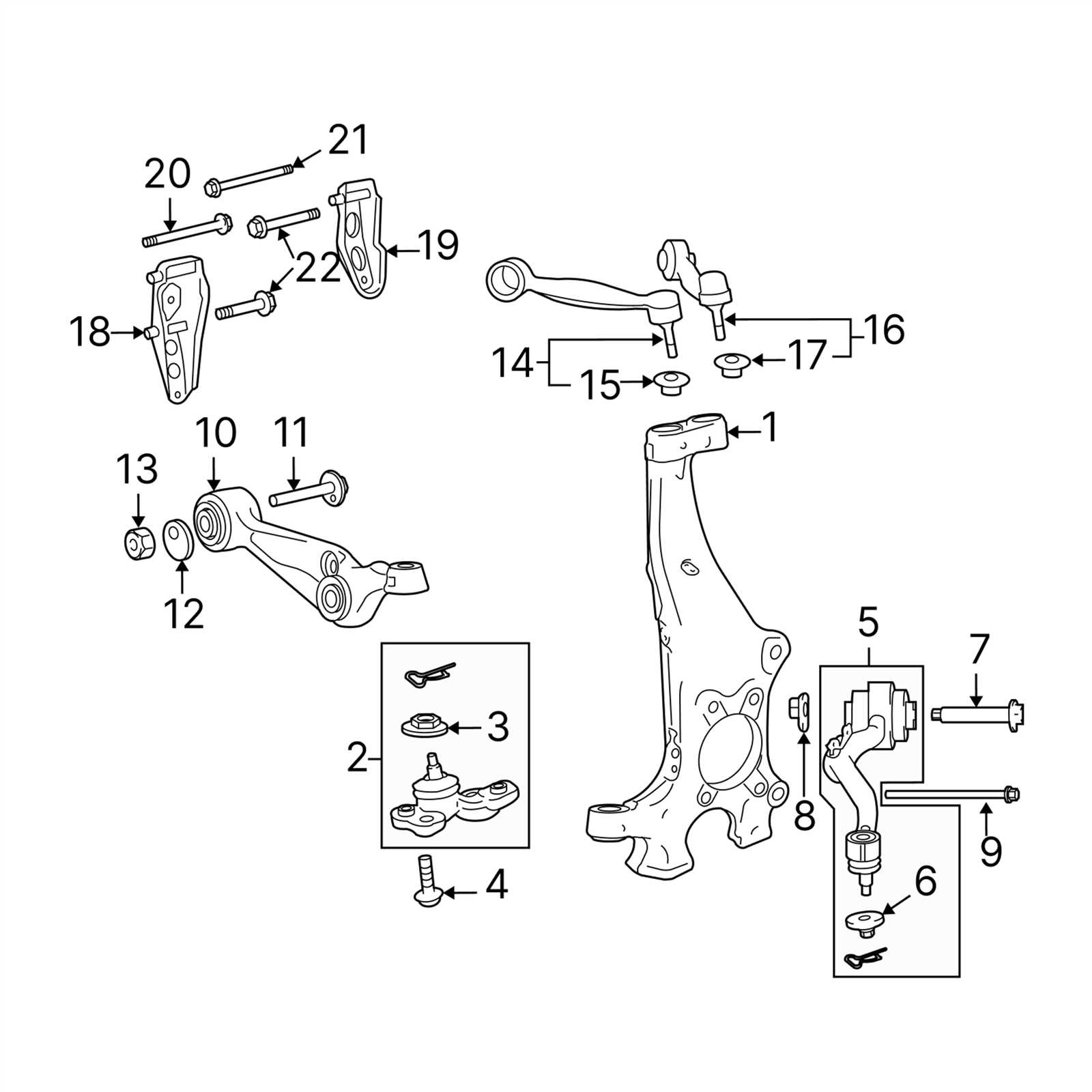

Suspension Adjustment and Upkeep

Proper maintenance and fine-tuning of the suspension system are crucial for ensuring optimal performance and ride comfort in heavy-duty vehicles. Regular checks and adjustments can prevent excessive wear and improve handling characteristics, contributing to overall safety and efficiency.

Inspecting Suspension Components: Begin by examining all suspension parts, including shocks, struts, and springs, for signs of damage or wear. Look for leaks, corrosion, or any physical deformation that might affect functionality.

Alignment and Adjustment: Maintaining proper alignment is essential for even tire wear and improved vehicle stability. Adjust the camber, toe, and caster angles as necessary, ensuring that they meet the manufacturer’s specifications. Utilize specialized equipment for precise measurements.

Lubrication: Regularly lubricate joints and bushings to reduce friction and prolong the lifespan of suspension components. Use high-quality lubricants that are compatible with the materials used in the suspension system.

Spring Preload Adjustment: Adjusting the preload on springs can enhance ride quality and handling. This adjustment should be based on load requirements and personal preference, keeping in mind the vehicle’s intended use.

Testing and Fine-Tuning: After making adjustments, test drive the vehicle to assess changes in handling and comfort. Pay attention to any unusual noises or vibrations, and be prepared to make further tweaks to achieve the desired performance.

Regular attention to these aspects will ensure a well-functioning suspension system, enhancing both safety and comfort during operation.

Fuel System Repair Essentials

Understanding the intricacies of the fuel delivery mechanism is crucial for maintaining optimal performance in your vehicle. This section focuses on the fundamental aspects of the fuel system, including diagnosis, maintenance, and troubleshooting techniques that ensure efficient operation. Proper attention to this system can lead to improved efficiency and longevity of your vehicle.

Key Components and Their Functions

The fuel system comprises several essential parts, each playing a vital role in delivering fuel from the tank to the engine. Components such as the fuel pump, injectors, and filters must work harmoniously to maintain an uninterrupted flow. Regular inspection of these elements can help prevent issues like clogging or pressure loss, which can significantly affect performance.

Maintenance Tips

Routine upkeep is essential to prolong the life of your fuel system. Ensure that filters are replaced periodically to avoid contamination and check for leaks in the fuel lines. Additionally, utilizing high-quality fuel can minimize deposits and enhance the overall efficiency of the system. Monitoring fuel pressure can also aid in identifying potential problems before they escalate.

Steering Components Maintenance

Maintaining the steering system is crucial for ensuring safe and responsive vehicle handling. Regular checks and servicing of these parts can prevent wear and tear, enhancing overall driving performance. This section provides guidelines for the upkeep of steering components, ensuring optimal functionality and longevity.

Key Maintenance Tasks

- Inspecting power steering fluid levels and quality

- Checking for leaks in the steering system

- Examining the condition of the steering rack and pinion

- Testing the steering response and ease of movement

Periodic Checks

- Every 5,000 miles, verify fluid levels and look for any signs of deterioration.

- Inspect tie rods and ball joints for any signs of wear or damage.

- At least once a year, consider having a professional evaluate the steering system.

By adhering to these maintenance practices, vehicle owners can ensure their steering system remains in top condition, contributing to a safer driving experience.

Interior and Exterior Care Tips

Maintaining both the inside and outside of your vehicle is essential for preserving its appearance and functionality. Regular attention to these areas not only enhances aesthetic appeal but also contributes to the longevity of various components. Below are some practical suggestions for keeping your automobile in top condition.

Exterior Care

- Regular Washing: Wash the exterior frequently to remove dirt, grime, and contaminants that can damage the paint.

- Waxing: Apply a high-quality wax every few months to protect the finish and provide a glossy shine.

- Paint Protection: Consider using a paint sealant or ceramic coating for added protection against environmental elements.

- Tire Maintenance: Check tire pressure regularly and clean the tires to prevent cracking and fading.

- Glass Care: Keep windows and mirrors clean for better visibility; consider applying a water-repellent treatment.

Interior Care

- Regular Vacuuming: Vacuum the seats and carpets often to eliminate dust and debris.

- Stain Removal: Address spills promptly to avoid permanent stains on upholstery.

- Conditioning: Use appropriate cleaners and conditioners for leather or fabric surfaces to maintain their quality.

- Dashboard Care: Wipe down the dashboard and controls with a soft cloth to prevent dust buildup.

- Air Quality: Replace cabin air filters as needed to ensure good air circulation inside the vehicle.

By following these guidelines, you can significantly enhance the appearance and functionality of your automobile, ensuring it remains a reliable and stylish companion on the road.

Routine Oil Change Instructions

Regularly replacing the engine lubricant is essential for maintaining optimal performance and extending the lifespan of your vehicle. This process helps ensure that the engine operates smoothly, reducing wear and tear on its components. Following proper procedures will not only enhance efficiency but also contribute to better fuel economy.

Begin by gathering the necessary tools and materials, including a suitable oil filter, the recommended type and amount of lubricant, an oil catch pan, and basic hand tools. It is advisable to park the vehicle on a level surface and allow the engine to cool down before starting the procedure.

Next, position the catch pan underneath the oil pan and remove the drain plug using the appropriate tool. Allow the used oil to fully drain into the pan. Afterward, replace the drain plug securely to prevent leaks. Proceed to remove the old oil filter using an oil filter wrench, ensuring that any residual oil is caught in the catch pan.

Install the new filter, applying a thin layer of fresh lubricant to the rubber gasket for a proper seal. Once the filter is in place, refill the engine with the new lubricant through the designated opening, using a funnel for accuracy. Ensure you pour in the correct amount as specified in the vehicle specifications.

Finally, start the engine and let it idle for a few minutes, checking for any leaks around the filter and drain plug. After this, turn off the engine and wait a moment before checking the oil level with the dipstick. Add more lubricant if necessary to achieve the optimal level. Regular oil changes contribute significantly to the longevity and reliability of your vehicle.

Battery Replacement and Care

Maintaining the power source of your vehicle is essential for optimal performance and reliability. Regularly checking and replacing the energy storage unit ensures that your vehicle operates smoothly and efficiently. Understanding the process of changing this component and proper maintenance techniques can extend its lifespan and enhance overall functionality.

Replacement Process: To initiate the swap, ensure the ignition is off and remove any necessary covers or panels. Disconnect the negative terminal first, followed by the positive terminal to prevent electrical shorts. Carefully remove the old unit and replace it with a new one, securing it properly. Reconnect the terminals, starting with the positive, then the negative, and ensure all connections are tight.

Maintenance Tips: Regular inspection is vital. Keep the terminals clean and free of corrosion; a mixture of baking soda and water can help remove any buildup. Check fluid levels if applicable, and ensure the unit is securely fastened to avoid vibrations that can lead to damage. Additionally, test the charging system periodically to confirm that it is functioning correctly.

By following these guidelines, you can ensure that your vehicle’s power unit remains in top condition, minimizing the risk of unexpected failures and enhancing overall performance.