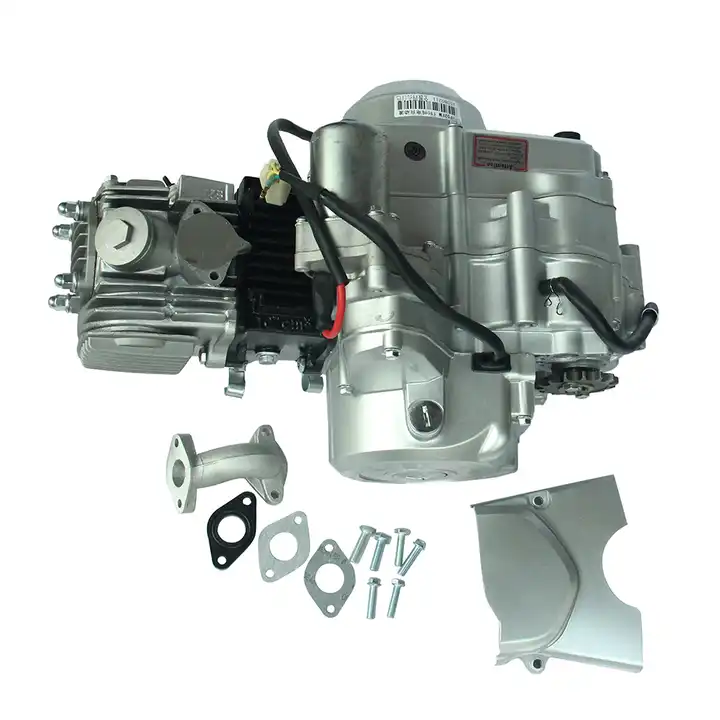

Comprehensive Guide to 152FMH Engine Repair

This section aims to provide a thorough understanding of the essential practices involved in maintaining complex machinery. By exploring various techniques and methodologies, users can enhance the longevity and efficiency of their equipment.

It covers critical aspects such as troubleshooting common issues, ensuring optimal functionality, and implementing preventive measures. Familiarity with these processes is vital for anyone seeking to ensure their machinery operates smoothly over time.

Emphasizing systematic approaches, the guide will equip readers with the knowledge necessary to tackle maintenance challenges effectively. With clear instructions and best practices, users can achieve remarkable results in upkeep and performance enhancement.

Common Issues in Engine Performance

When it comes to optimal operation of any power unit, certain challenges can arise that affect overall functionality. Identifying these common difficulties is essential for maintaining performance and efficiency. Recognizing the signs of these issues early can prevent further complications and enhance the longevity of the machinery.

One prevalent issue is inconsistent power delivery. This can manifest as irregular acceleration or difficulty maintaining speed. Such symptoms often indicate problems with fuel supply or ignition systems. Ensuring that these components are functioning properly is crucial for a smooth operation.

Another frequent concern is overheating. This situation can lead to severe damage if not addressed promptly. Overheating can result from inadequate cooling, low fluid levels, or even blockages in the cooling pathways. Regular monitoring of temperature levels is vital to avoid catastrophic failures.

Additionally, unusual noises can signal underlying issues. Rattles, knocks, or grinding sounds may point to wear and tear in moving parts or insufficient lubrication. It is important to investigate these sounds immediately to determine their source and prevent further damage.

Lastly, excessive emissions are not just an environmental concern; they often indicate inefficiencies within the system. Monitoring exhaust quality can help identify problems related to combustion processes or faulty sensors. Addressing these issues not only aids in compliance with regulations but also enhances operational efficiency.

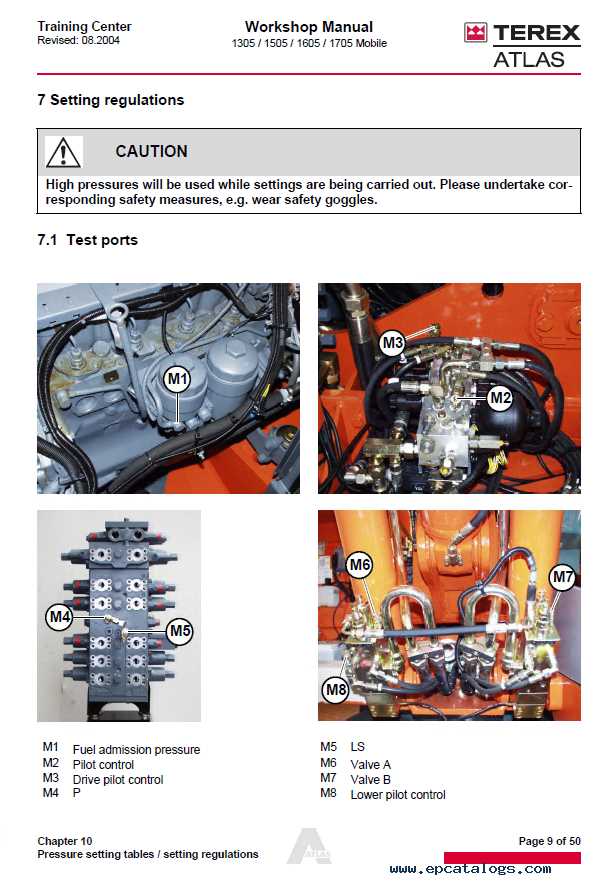

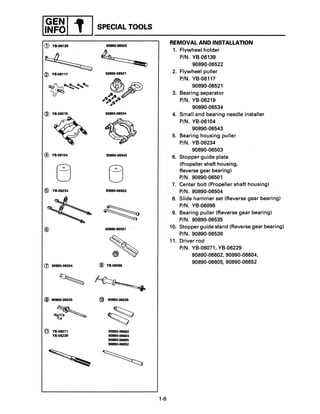

Essential Tools for Repairing

Having the right equipment is crucial for effectively maintaining and restoring machinery. A well-equipped workspace not only enhances efficiency but also ensures safety during the entire process. Various instruments serve specific purposes, making it easier to tackle different tasks systematically.

Basic Hand Tools

Every technician should possess a set of fundamental hand tools, including wrenches, screwdrivers, and pliers. These instruments are vital for loosening or tightening components, as well as for accessing hard-to-reach areas. Investing in high-quality hand tools can significantly improve the overall experience of working on machinery.

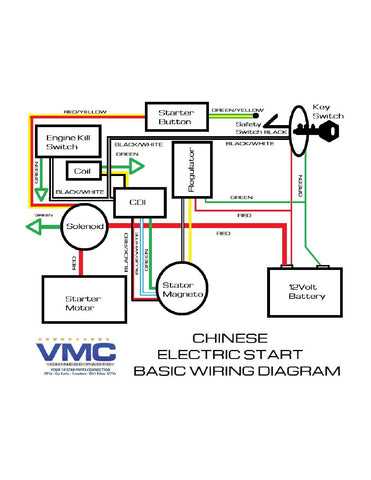

Diagnostic Equipment

Utilizing diagnostic devices is essential for identifying issues quickly. Tools such as multimeters and compression testers allow for accurate assessments of system functionality. These instruments help in pinpointing problems and determining the necessary actions for resolution, ultimately streamlining the maintenance process.

Step-by-Step Disassembly Process

Undertaking the process of disassembling a mechanical unit requires careful planning and precision. This section will guide you through a systematic approach to ensure each component is handled correctly, minimizing the risk of damage and facilitating efficient reassembly.

1. Preparation: Before starting, gather all necessary tools and safety equipment. Ensure you have a clean, organized workspace to keep track of all parts.

2. Initial Assessment: Begin by examining the unit to identify all components that need to be removed. Take note of any connections or attachments that may require special attention.

3. Systematic Removal: Start with the outermost parts, loosening screws and fasteners in a logical sequence. This will prevent unnecessary strain on the remaining elements.

4. Labeling Components: As you remove each part, label it clearly. This practice will simplify the reassembly process, ensuring that everything returns to its proper place.

5. Handling Sensitive Parts: Be cautious with delicate components. Use appropriate tools to avoid damaging any sensitive areas during disassembly.

6. Documenting the Process: Keep a record of the steps taken and any observations made during disassembly. This documentation will serve as a helpful reference during reassembly.

Following these steps will facilitate a smooth disassembly process, making it easier to understand and manage each element involved.

Inspecting Engine Components Effectively

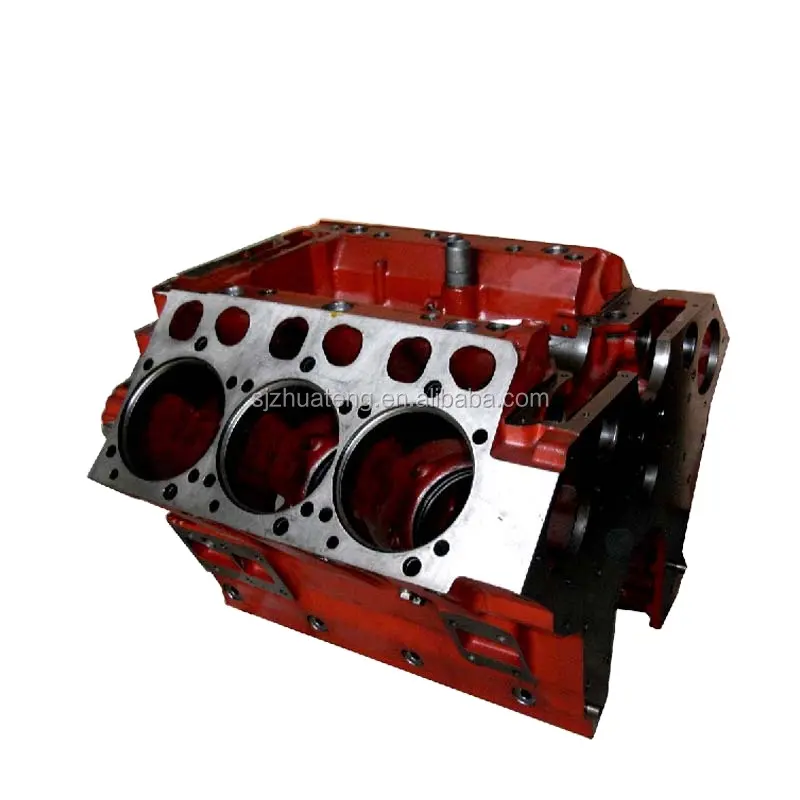

Thorough examination of various mechanical parts is crucial for maintaining optimal performance and longevity. This process involves a systematic approach to identify any signs of wear, damage, or misalignment that could affect functionality.

Identifying Signs of Wear

Regularly checking for indications of degradation, such as cracks, corrosion, or abnormal wear patterns, helps in preemptively addressing issues. Utilizing specialized tools can enhance the accuracy of these assessments, ensuring no detail is overlooked.

Ensuring Proper Alignment

Maintaining correct positioning of components is essential for efficient operation. Employing alignment tools allows for precise adjustments, reducing the risk of further complications. Regular inspections are key to ensuring all parts function harmoniously and effectively.

Replacing Worn-Out Parts

Over time, components within a machine may deteriorate due to regular usage, leading to decreased performance and efficiency. Identifying and substituting these aging elements is crucial for restoring optimal functionality and ensuring longevity.

Begin by assessing the various parts that show signs of wear, such as fraying, corrosion, or irregularities in operation. Prioritize replacements based on the extent of damage and their impact on overall performance. When selecting new components, ensure they meet the necessary specifications and quality standards to maintain compatibility.

Once you have gathered the replacement parts, proceed with the installation carefully. Follow the appropriate procedures for disassembly, taking care to document the arrangement of components for easier reassembly. After replacing the worn items, conduct thorough checks to confirm that everything operates smoothly before returning the unit to service.

Reassembling the Engine Correctly

Ensuring that components are rejoined accurately is crucial for optimal functionality and longevity. A systematic approach is essential to avoid issues during operation.

Start by organizing all parts and tools needed for the process. Cleanliness is paramount; dirt or debris can lead to significant problems later. Inspect each component for wear and damage, replacing any that show signs of fatigue.

When reassembling, follow a logical sequence. Begin with the largest parts, securing them firmly. Use appropriate fasteners and torque specifications to maintain structural integrity. Double-check alignment to ensure that everything fits perfectly without undue stress on any component.

After assembly, perform a thorough inspection to confirm that all parts are properly positioned and secured. This step can prevent potential failures in the future. Finally, conduct a test run to verify that the entire system operates smoothly.

Tips for Engine Maintenance

Proper upkeep of mechanical systems is essential for ensuring optimal performance and longevity. Regular attention can prevent minor issues from escalating into significant problems, thereby enhancing efficiency and reliability.

Routine Inspections: Conduct frequent evaluations of critical components to identify any wear or damage. This proactive approach allows for timely interventions.

Fluid Levels: Maintain adequate levels of essential fluids, such as oils and coolants. Regularly check and replace them as needed to ensure smooth operation.

Filter Replacements: Change filters periodically to prevent contaminants from affecting system performance. Clean filters promote better airflow and fluid circulation.

Cleanliness: Keep the surroundings clean and free from debris. A tidy environment reduces the risk of foreign objects causing damage during operation.

Follow Recommendations: Adhere to the guidelines provided by manufacturers regarding maintenance schedules and practices. These instructions are tailored to ensure optimal functionality.

Implementing these practices not only safeguards the system but also enhances its overall efficiency, ensuring reliable performance for years to come.

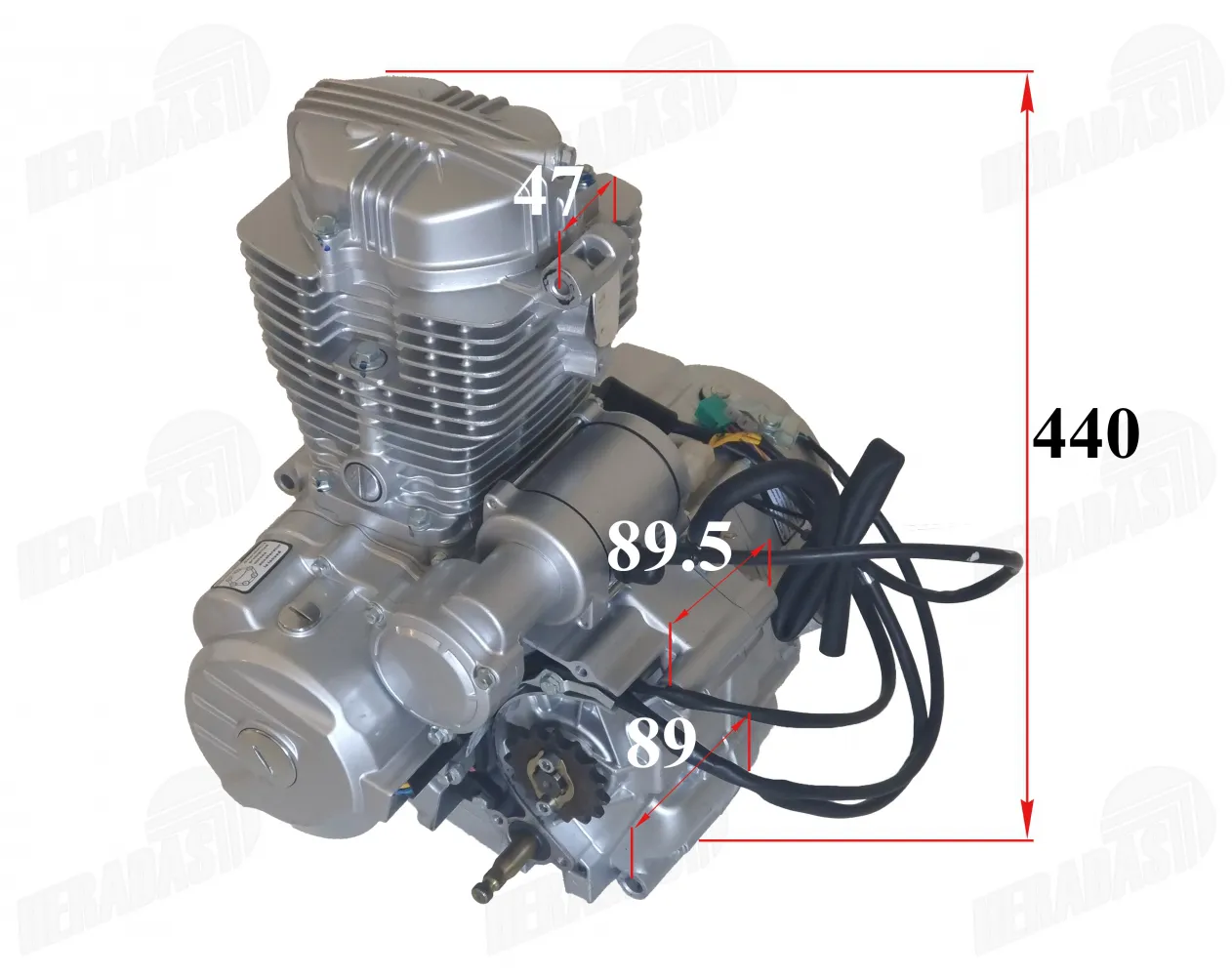

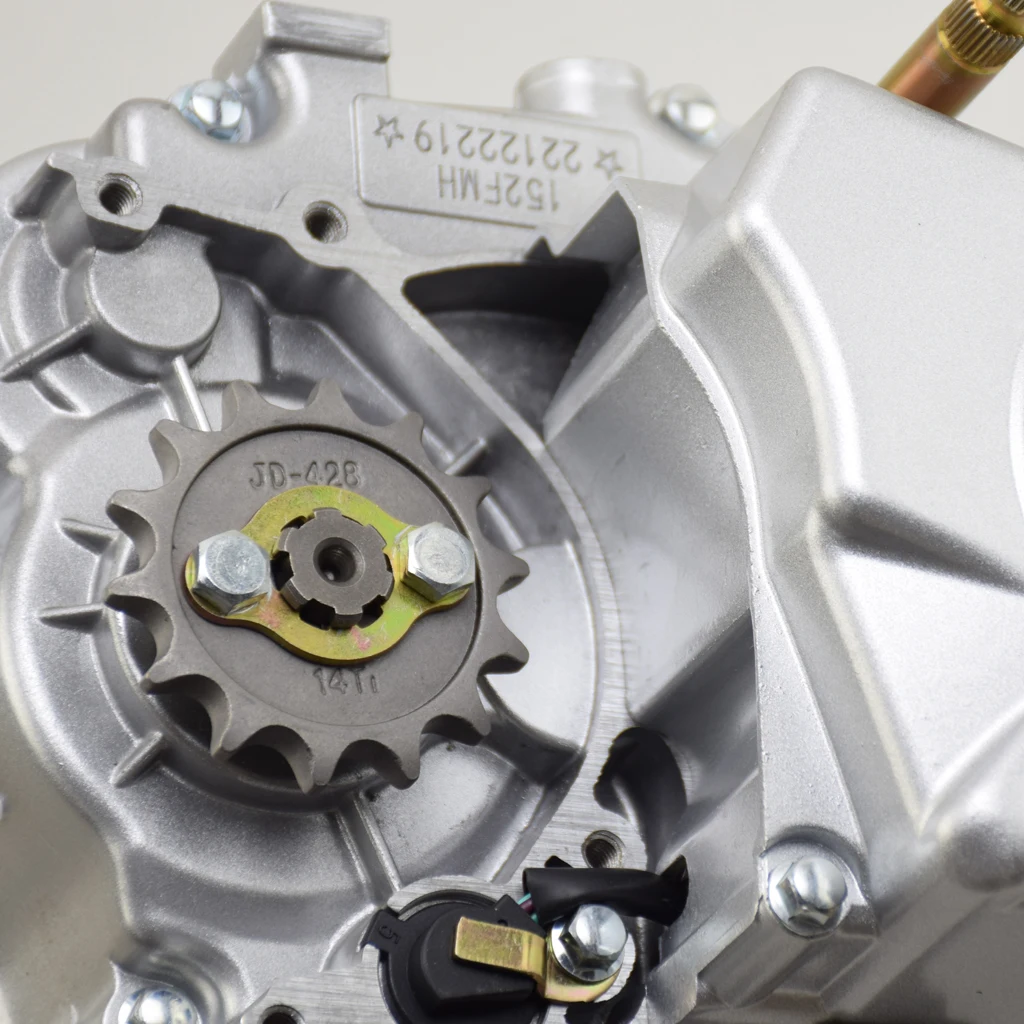

Understanding Engine Specifications

Grasping the technical details of a power unit is essential for anyone involved in its upkeep. Specifications provide crucial insights into performance capabilities, efficiency, and overall functionality. By familiarizing oneself with these parameters, one can ensure optimal operation and longevity of the machinery.

Key Parameters to Consider

When analyzing the features of a power unit, several aspects should be prioritized. These include displacement, compression ratio, and power output. Displacement refers to the total volume of the cylinders, while the compression ratio indicates the degree to which the air-fuel mixture is compressed within the combustion chamber. Power output reflects the maximum achievable horsepower, which directly influences the machinery’s performance.

Importance of Specifications

Understanding these details is not just for the sake of knowledge; it plays a pivotal role in maintenance and troubleshooting. Accurate comprehension aids in diagnosing issues, selecting suitable parts, and making informed decisions during service. Additionally, it enhances the ability to optimize performance through proper tuning and adjustments.

Diagnostic Techniques for Faults

Identifying issues within complex machinery requires systematic approaches that ensure accurate assessment and effective solutions. By employing a variety of diagnostic methods, technicians can isolate problems, understand their underlying causes, and implement appropriate corrective actions. This section outlines several key techniques that enhance troubleshooting efficiency.

Visual Inspection

Conducting a thorough visual examination is often the first step in identifying potential irregularities. Technicians should look for signs of wear, leaks, or any physical damage that may indicate underlying faults. This initial assessment can provide valuable insights and direct further investigation.

Performance Testing

Utilizing performance tests allows for the evaluation of the system’s operational parameters. By measuring factors such as pressure, temperature, and flow rates, technicians can compare the results against manufacturer specifications. Deviations from expected values often signal areas requiring attention and repair.

Safety Precautions During Repairs

When working on mechanical systems, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to proper protocols not only safeguards the individual performing the tasks but also ensures the longevity of the components involved.

Before commencing any maintenance, always wear appropriate protective gear such as gloves, goggles, and steel-toed boots. This equipment minimizes the risk of injury from sharp objects or hazardous materials.

It is essential to work in a well-ventilated area to avoid inhaling harmful fumes. Additionally, ensure that all tools are in good condition and suited for the task at hand. Using the correct instruments reduces the likelihood of mishaps.

Furthermore, familiarize yourself with the specific requirements of the task before beginning. Taking the time to understand the system’s layout and function can significantly enhance safety and efficiency during the process.

Lastly, always keep a first aid kit accessible and know how to use it in case of emergencies. Being prepared for unexpected situations is a fundamental aspect of any maintenance work.

Testing Engine After Repair

After completing maintenance work on the power unit, it is essential to ensure its functionality and performance. This phase involves a series of assessments to verify that everything operates as intended and meets operational standards.

First, conduct a thorough visual inspection to identify any signs of leaks or loose connections. Pay attention to fluid levels and ensure that all components are properly secured. Following this, start the unit to listen for any unusual sounds that may indicate underlying issues.

Once the unit is running, monitor its performance metrics such as temperature, pressure, and vibration levels. These parameters should fall within the specified range to confirm optimal operation. If any discrepancies are detected, further diagnostics may be necessary to address potential faults.

Finally, it is advisable to run the unit under load conditions to evaluate its performance in real-world scenarios. This final test helps to ensure that the system can handle operational demands without failure.

Resources for Further Learning

Exploring advanced topics in machinery maintenance can greatly enhance your understanding and skills. Various resources are available to assist enthusiasts and professionals alike in gaining deeper insights and practical knowledge.

Online Courses and Tutorials

Numerous platforms offer structured courses covering different aspects of mechanical upkeep. These resources often include video tutorials, interactive exercises, and community forums, allowing learners to engage with experts and peers.

Books and Technical Publications

In-depth literature on mechanical systems is invaluable for anyone seeking to broaden their expertise. Reference materials and textbooks provide detailed explanations, diagrams, and case studies, serving as excellent companions for hands-on practice.