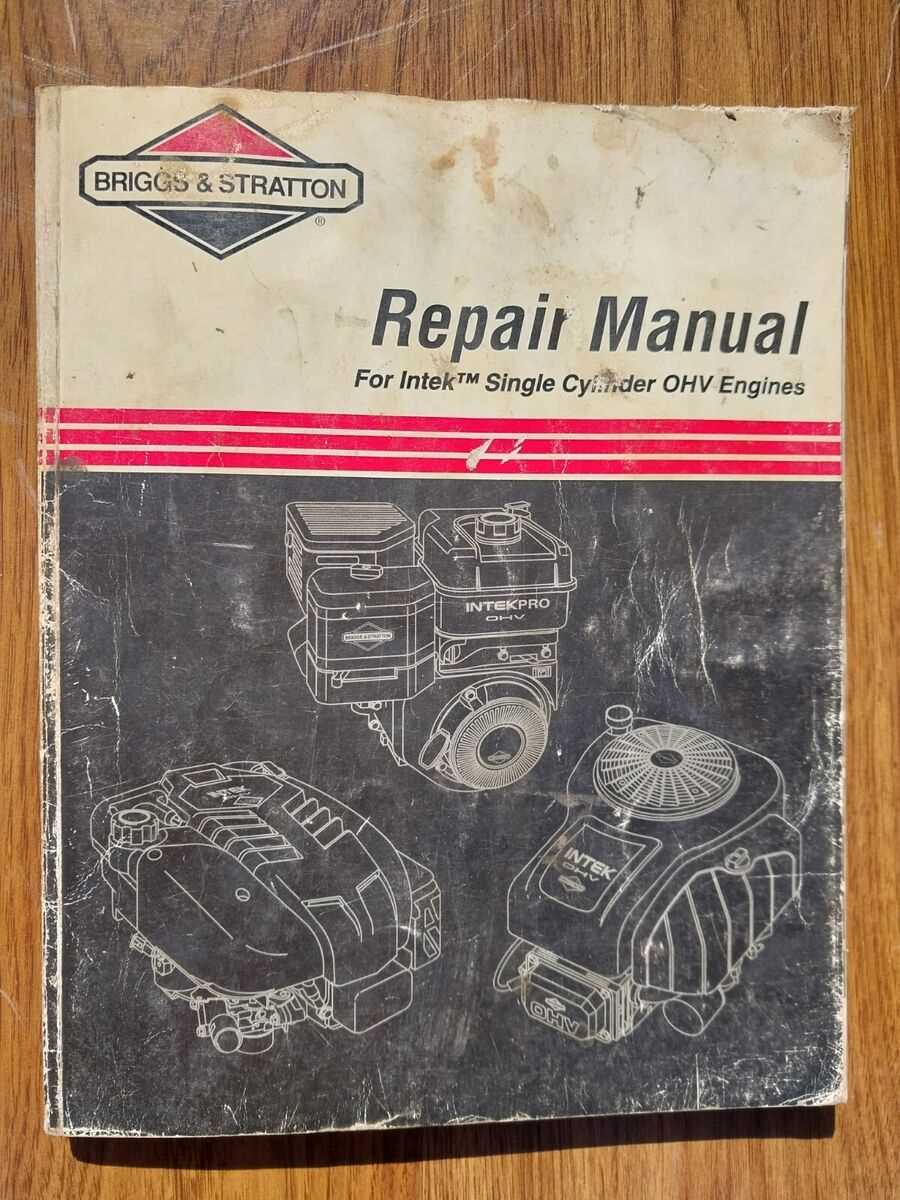

Repair Guide for 12.5 HP Engine

Ensuring the longevity and optimal performance of compact power units requires a comprehensive understanding of their components and functionalities. This section aims to provide valuable insights into the upkeep and troubleshooting of these machines, equipping users with the knowledge necessary for efficient operation.

From routine checks to complex adjustments, a systematic approach is essential for addressing common challenges that may arise during usage. By following practical guidelines, users can effectively maintain their equipment and enhance its reliability, ultimately leading to improved performance.

Whether you are a novice or an experienced user, the information presented here will empower you to tackle various tasks confidently. Familiarizing yourself with the intricacies of your unit will enable you to perform necessary actions with precision, ensuring a seamless experience.

Small power units are essential for various applications, but they often face several recurring problems. Understanding these common complications can help users maintain their equipment effectively and ensure optimal performance.

Frequent Problems

- Starting Difficulties: Many users report trouble initiating operation, which may stem from fuel issues, spark plug faults, or battery deficiencies.

- Fuel Leaks: Over time, seals and gaskets can wear out, leading to unwanted leaks that can affect performance and safety.

- Overheating: Insufficient cooling or clogged air filters can result in overheating, potentially causing significant damage.

Maintenance Tips

- Regularly check and replace the fuel filter to ensure clean fuel flow.

- Inspect spark plugs frequently and replace them as needed to maintain ignition efficiency.

- Keep air filters clean and free from debris to prevent overheating and maintain proper airflow.

Tools Needed for Repairs

When tackling maintenance tasks for small machinery, having the right instruments is essential. A well-equipped toolkit can make the process smoother and more efficient, ensuring that each component is addressed correctly. This section outlines the key implements required for effective upkeep.

Essential Hand Tools

Basic hand tools are indispensable for any maintenance job. Commonly needed items include wrenches, screwdrivers, pliers, and sockets. These tools allow for precise adjustments and enable the removal or installation of various parts.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be necessary. Torque wrenches, multimeters, and diagnostic tools can provide valuable assistance in troubleshooting and ensuring that components are functioning optimally.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your small motor. By following systematic procedures, you can effectively maintain key components and avoid potential issues.

Regular Checks and Cleaning

Routine inspections are essential for identifying wear and tear. Start by examining the air filter and spark plug, replacing them if they show signs of damage. Clean the cooling fins and exterior surfaces to prevent overheating.

Fluid Changes and Adjustments

Regularly changing the oil and checking the fuel system helps maintain efficiency. Use the recommended oil type and ensure the fuel is fresh. Adjust the throttle and governor settings as necessary for smooth operation.

How to Troubleshoot Engine Problems

Tackling issues with a small motor can seem daunting, but with a systematic approach, it becomes manageable. Understanding the common signs of malfunction allows for effective identification and resolution of problems. The key is to observe the symptoms carefully and follow a logical process to isolate the cause.

Begin by ensuring that the power source is functional. Check for a full tank of fuel and verify that the ignition system is operational. A faulty spark plug is often a primary culprit, so inspect it for wear and replace if necessary. Additionally, examine the air intake for blockages, as this can significantly affect performance.

If the motor is running but lacks power, consider the possibility of a clogged fuel filter or a dirty carburetor. Cleaning or replacing these components can restore functionality. Furthermore, listen for unusual noises that may indicate internal wear or damage, which may require more extensive intervention.

Remember: Regular maintenance is crucial for preventing issues before they arise. Keeping components clean and well-lubricated ensures longevity and efficiency.

Replacing Oil and Filters

Regular maintenance of lubrication fluids and filtration components is essential for the optimal performance and longevity of your power unit. Changing these fluids not only enhances efficiency but also prevents potential damage caused by contaminants and degraded substances.

Steps for Oil Replacement

Begin by warming up the unit slightly to thin the lubricant, which facilitates easier drainage. Ensure the power source is turned off, then place a container beneath the drain plug to catch the old oil. Remove the plug and allow the fluid to fully drain out. Once drained, replace the plug securely.

Filter Change Procedure

Locate the filter and use an appropriate tool to remove it. Apply a small amount of new lubricant to the gasket of the new filter to ensure a proper seal. Install the new filter and tighten it according to the manufacturer’s specifications. Finally, refill the system with fresh oil to the recommended level.

Tip: Always dispose of used oil and filters at designated recycling centers to protect the environment.

Fuel System Cleaning Techniques

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity. Over time, contaminants can accumulate, leading to inefficient operation and potential damage. Implementing effective cleaning methods can enhance fuel flow and ensure proper combustion.

Here are some techniques to consider for cleaning the fuel system:

- Fuel Filter Replacement: Regularly change the fuel filter to prevent debris from entering the system.

- Fuel Injector Cleaning: Use a specialized cleaner or professional service to remove deposits from injectors, ensuring a steady fuel spray.

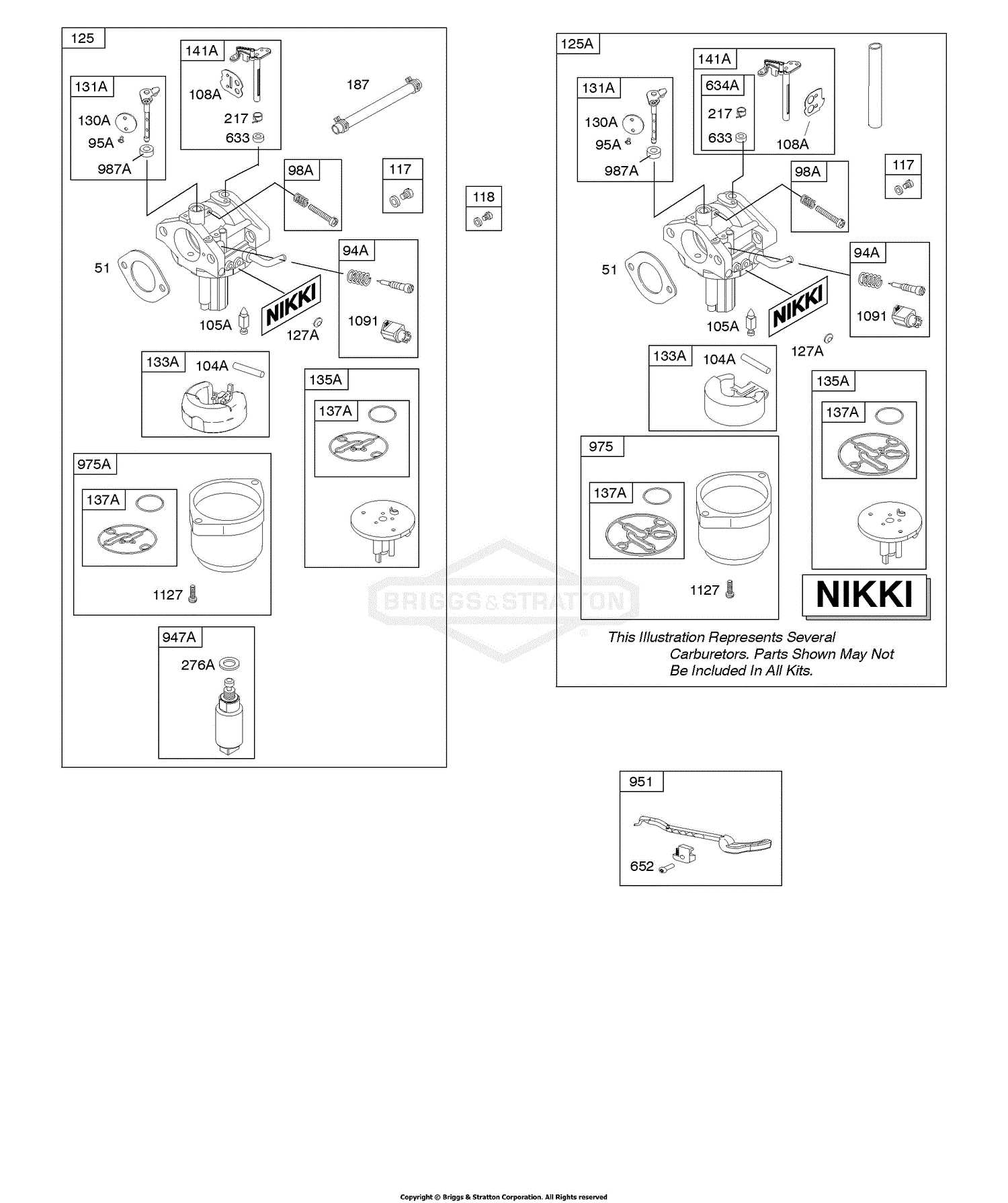

- Carburetor Cleaning: Disassemble the carburetor and clean all components with a suitable solvent to eliminate blockages and improve fuel delivery.

- Fuel Line Inspection: Examine fuel lines for cracks or clogs; replace as necessary to maintain unobstructed fuel flow.

By following these methods, you can keep the fuel system functioning effectively, reducing the likelihood of performance issues and extending the life of the machinery.

Electrical System Diagnosis

The electrical system is crucial for the proper functioning of small motors. Identifying and resolving issues within this system can enhance performance and reliability. This section provides guidance on diagnosing common electrical problems that may arise.

Understanding Components

Familiarize yourself with the primary components involved, such as the battery, ignition coil, and wiring harness. Each element plays a significant role in ensuring the system operates effectively.

Common Symptoms

Common indicators of electrical issues include difficulty starting, erratic operation, or complete failure to run. Noting these symptoms can assist in pinpointing the source of the problem.

Testing Procedures

Utilize a multimeter to check voltage and continuity in various parts of the electrical circuit. Start with the battery to ensure it holds a charge, then proceed to test the ignition components and switches for any faults.

Troubleshooting Steps

Follow a systematic approach: first, verify connections and inspect for any signs of wear or damage. Next, test individual components based on the symptoms observed. Replacing faulty parts promptly can restore functionality.

By maintaining a proactive stance toward electrical system diagnostics, users can prolong the life of their machinery and ensure optimal performance.

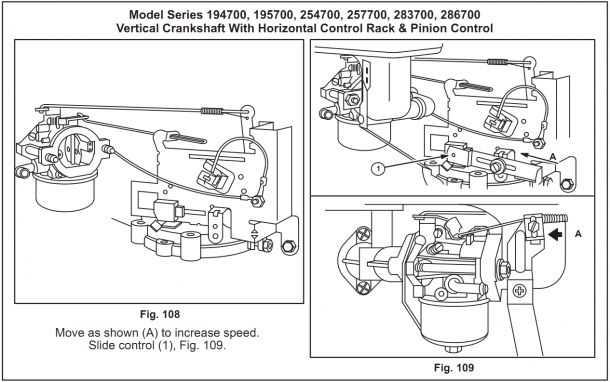

Adjusting Carburetor Settings

Properly configuring the fuel-air mixture is essential for optimal performance and efficiency of small power units. Adjustments to the carburetor settings can enhance the engine’s responsiveness and ensure smooth operation.

Start by locating the adjustment screws, usually found on the carburetor body. These screws regulate the idle speed and mixture richness. Using a screwdriver, carefully turn the screws to achieve the desired settings. It is advisable to make small incremental adjustments while monitoring the engine’s performance.

After making initial adjustments, run the unit to check for any irregularities in operation. Listen for smooth acceleration and a steady idle. If the engine stutters or stalls, further fine-tuning may be necessary. Repeat the adjustment process until the desired performance is achieved.

Importance of Regular Inspections

Conducting routine evaluations of machinery is crucial for maintaining optimal performance and extending lifespan. Regular checks help identify potential issues before they escalate, ensuring that the equipment operates smoothly and efficiently.

Timely detection of wear and tear can prevent unexpected breakdowns, which often lead to costly repairs and downtime. By monitoring the condition of vital components, operators can make informed decisions about necessary maintenance.

Additionally, consistent inspections contribute to safety. Ensuring that all parts are functioning correctly reduces the risk of accidents and enhances overall workplace safety. Implementing a schedule for these assessments fosters a proactive approach to care and can significantly enhance operational reliability.

Best Practices for Engine Storage

Proper maintenance and preparation are essential for ensuring the longevity and performance of your machinery during periods of inactivity. By following a few key guidelines, you can safeguard vital components and minimize the risk of deterioration.

Clean the Exterior: Before storing, thoroughly clean the outer surfaces to remove dirt and debris. This helps prevent rust and corrosion, ensuring that the unit remains in optimal condition.

Drain Fluids: It’s advisable to drain fuel and oil to prevent contamination and potential damage. Emptying these fluids reduces the risk of leaks and preserves the integrity of internal parts.

Protect Moving Parts: Apply a light coat of oil to exposed moving components. This lubrication creates a barrier against moisture, helping to prevent rust and maintaining smooth operation when you bring the unit back into service.

Store in a Dry Environment: Choose a cool, dry place for storage to avoid humidity and temperature fluctuations. A stable environment contributes to the overall health of the machinery and minimizes the chances of issues arising.

Cover the Unit: If possible, use a protective cover to shield the unit from dust and debris. This simple step adds an extra layer of protection, keeping it clean and ready for future use.

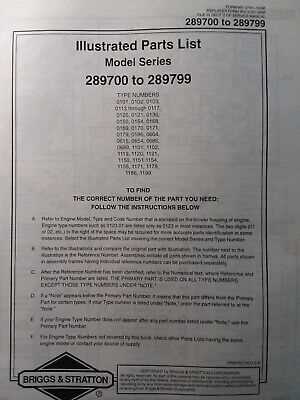

Finding Replacement Parts

When it comes to maintaining small power units, sourcing suitable components is essential for optimal performance. This section highlights effective strategies for locating the necessary parts to ensure your equipment operates efficiently.

Online Resources

The internet offers a wealth of information and shopping options. Consider the following sources:

- Official websites of manufacturers for authorized parts.

- Specialized online retailers focusing on outdoor equipment components.

- Marketplace platforms where users can find new and used parts.

Local Suppliers

Visiting local stores can also yield valuable resources. Keep an eye out for:

- Hardware stores that may carry compatible components.

- Specialty shops focused on garden and outdoor machinery.

- Auto parts retailers with sections for small engines.