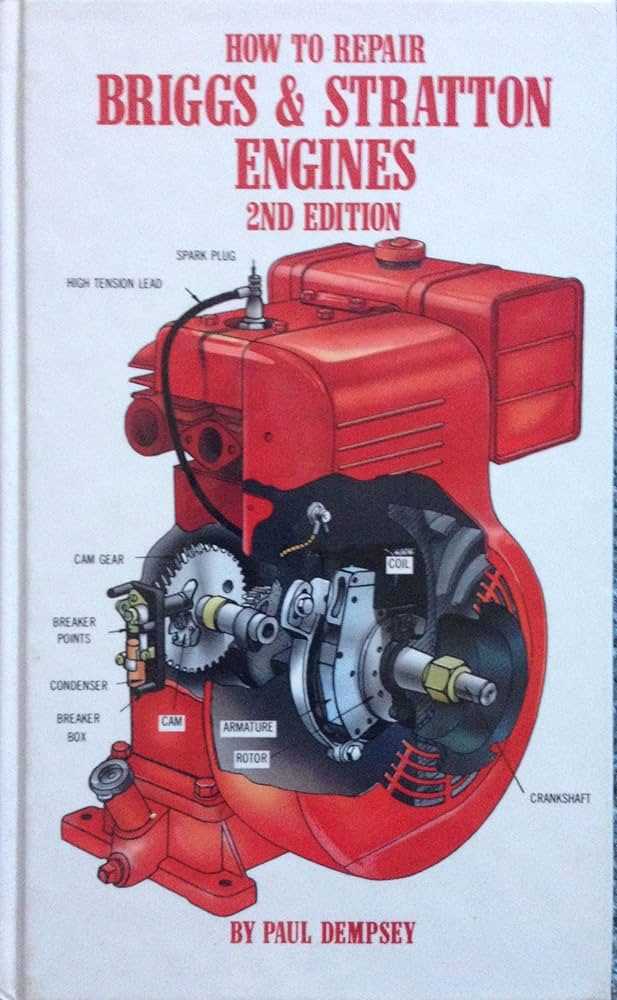

Comprehensive Guide to Repairing Briggs and Stratton Small Engines

In the realm of outdoor machinery, ensuring optimal performance is essential for longevity and efficiency. This section delves into the intricacies of maintaining various types of power units, equipping users with the knowledge needed to tackle common issues and enhance functionality.

From basic troubleshooting to more complex interventions, understanding the mechanisms behind these machines can significantly impact their operation. Whether you’re a novice or an experienced enthusiast, this resource aims to demystify the processes involved in keeping your equipment running smoothly.

With a focus on practical advice and step-by-step guidance, you’ll learn to identify problems and implement effective solutions. Emphasizing safety and precision, this guide provides valuable insights that empower users to take charge of their machinery, ensuring it performs at its best for years to come.

Essential Tools for Engine Repair

Having the right instruments at your disposal is crucial for maintaining and fixing any machinery. A well-equipped toolkit not only enhances efficiency but also ensures precision and safety during the process. Below are key items that every mechanic should consider for effective maintenance tasks.

Basic Hand Tools

- Wrenches: Various sizes, including adjustable, for loosening and tightening bolts.

- Screwdrivers: A set of flathead and Phillips types to handle different fasteners.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: Essential for reaching fasteners in tight spaces.

Specialized Equipment

- Torque Wrench: Ensures bolts are tightened to the correct specifications, preventing damage.

- Compression Tester: Helps assess the health of the combustion chamber.

- Multimeter: For checking electrical systems and diagnosing issues.

- Fuel Pressure Gauge: Assists in verifying the proper fuel delivery to the system.

Equipping yourself with these fundamental tools will significantly enhance your capability to tackle various tasks with confidence and competence.

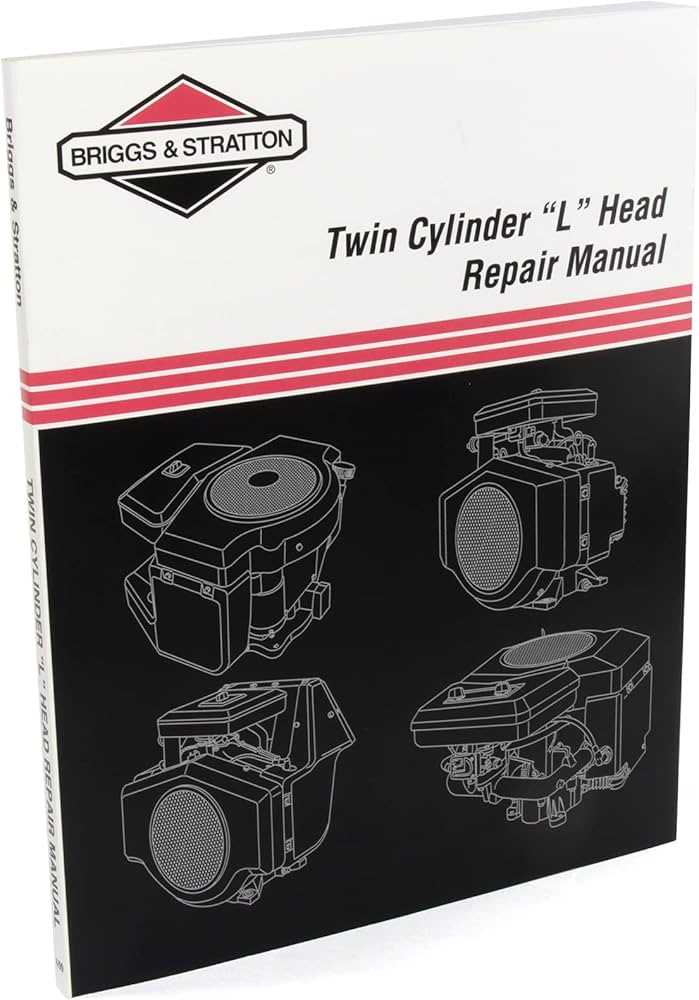

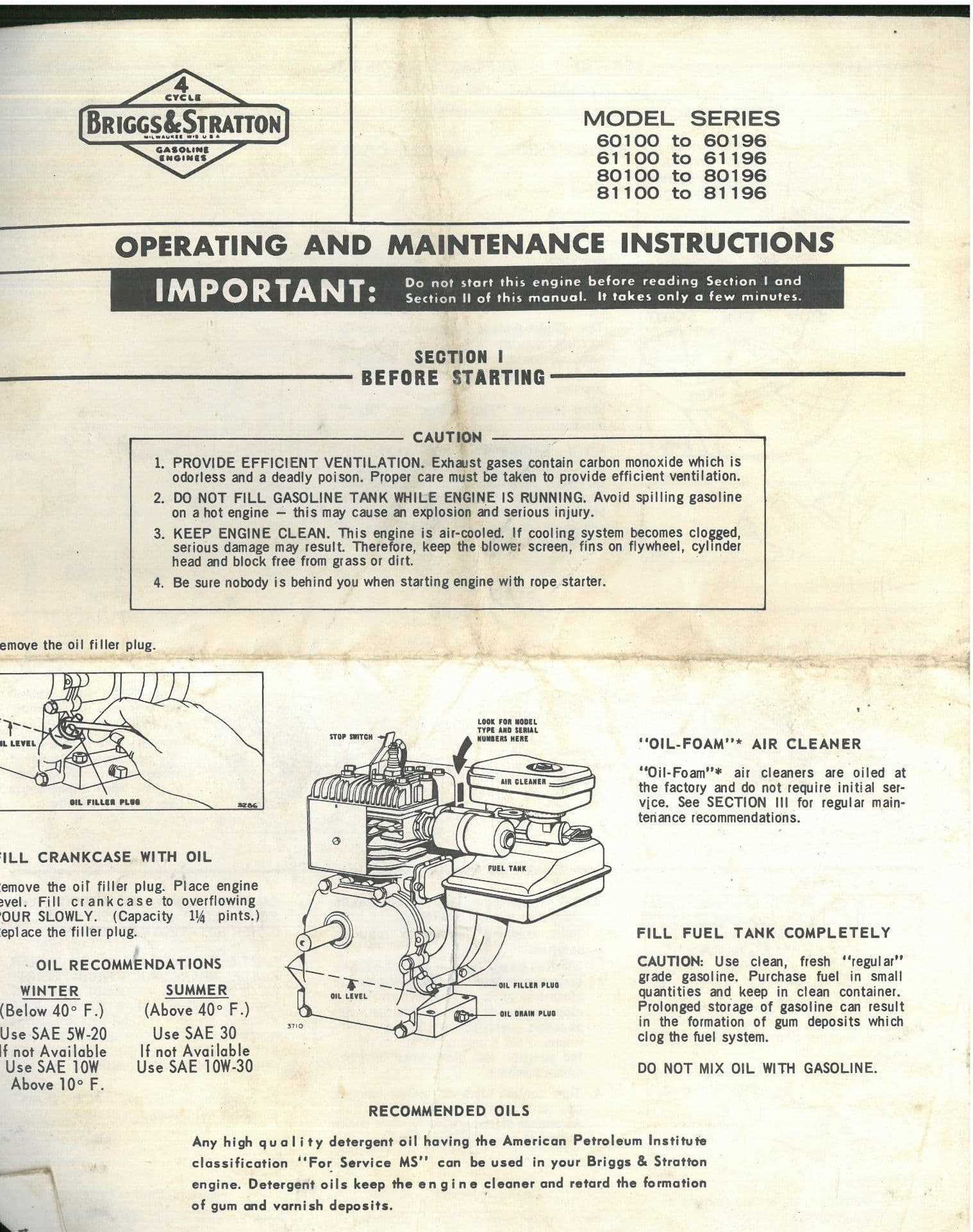

Understanding Briggs & Stratton Engines

This section delves into the fundamental principles of these popular power units. Recognized for their durability and reliability, they serve a variety of applications, from lawn maintenance to outdoor power tools. Grasping the intricacies of their design and functionality can enhance your ability to maintain and optimize performance.

Key features to consider include:

- Configuration and design variations

- Fuel types and efficiency

- Cooling systems and their importance

- Common issues and troubleshooting methods

Understanding how these power sources operate involves familiarizing yourself with several components:

- Fuel System: The mechanism that ensures proper combustion.

- Ignition System: Responsible for starting the unit and ensuring smooth operation.

- Lubrication System: Key to reducing friction and prolonging lifespan.

- Exhaust System: Important for expelling gases and maintaining efficiency.

By mastering these elements, you can ensure optimal functionality and longevity of your equipment. Knowledge of their workings allows for proactive maintenance and effective problem-solving, ultimately leading to a more satisfying experience with your machinery.

Common Issues in Small Engines

Understanding the frequent problems that can arise in compact power units is crucial for effective maintenance and longevity. Many users encounter similar challenges, which can often be resolved with basic troubleshooting techniques. Recognizing these issues can save time and resources.

Fuel-Related Problems: One of the most prevalent concerns is related to fuel quality and delivery. Stale or contaminated fuel can lead to starting difficulties and erratic performance. Regularly checking the fuel system, including filters and lines, is essential.

Inefficient Ignition: Another common challenge involves the ignition system. Worn spark plugs or faulty ignition coils can result in misfires or failure to start. Regular inspection and timely replacement of these components are vital for optimal functionality.

Airflow Restrictions: Proper airflow is necessary for effective combustion. Clogged air filters can significantly reduce performance and efficiency. It is advisable to clean or replace air filters periodically to ensure unobstructed airflow.

Overheating: Overheating can lead to severe damage if not addressed promptly. Causes may include low oil levels, blocked cooling fins, or malfunctioning cooling systems. Monitoring temperature and ensuring adequate lubrication are key preventive measures.

Vibration Issues: Excessive vibrations can indicate loose or damaged parts. This can affect performance and lead to further complications if left unchecked. Regular inspections and tightening of loose components can help mitigate this risk.

Step-by-Step Repair Process

This section outlines a comprehensive procedure for troubleshooting and restoring functionality to various types of mechanical devices. By following these detailed steps, users can systematically identify issues and apply appropriate solutions, ensuring optimal performance and longevity.

Step 1: Diagnosis

Begin by assessing the situation. Gather information on the symptoms presented, including any unusual noises or performance issues. This initial evaluation is crucial for pinpointing the root cause of the malfunction.

Step 2: Preparation

Before diving into any maintenance tasks, ensure you have the necessary tools and replacement parts on hand. Organizing your workspace will streamline the process and minimize disruptions.

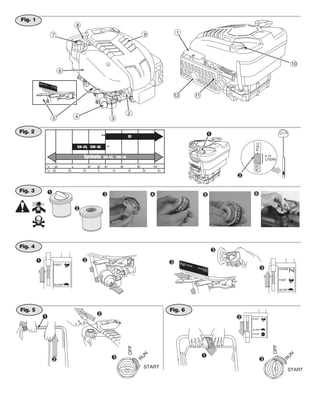

Step 3: Disassembly

Carefully disassemble the components, noting the order and orientation of each part. Utilize a systematic approach to avoid misplacing any pieces, which can complicate reassembly.

Step 4: Inspection

Thoroughly examine all parts for wear and damage. Look for signs of corrosion, cracks, or other abnormalities. This step is essential to determine what needs to be replaced or repaired.

Step 5: Replacement

If any components are found to be defective, replace them with high-quality alternatives. Ensure that all replacements are compatible with the existing system to avoid future complications.

Step 6: Reassembly

Once all repairs have been made, carefully reassemble the device. Refer back to your notes from the disassembly phase to ensure accuracy in placement and orientation.

Step 7: Testing

After reassembly, conduct a thorough test to confirm that everything operates smoothly. Monitor for any signs of malfunction during this phase, as it may indicate further adjustments are necessary.

Step 8: Maintenance

Implement a regular maintenance schedule to keep the system in optimal condition. This proactive approach can help prevent future issues and extend the life of the device.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and efficient performance of your outdoor equipment. Regular attention to various components not only prevents unexpected breakdowns but also enhances overall functionality. Here are some valuable practices to consider.

Routine Inspections

- Check the fuel levels and ensure it’s fresh.

- Examine the air filter for dirt and debris; clean or replace as necessary.

- Inspect all hoses and belts for signs of wear or damage.

Scheduled Maintenance

- Change the oil regularly to keep internal parts lubricated.

- Sharpen cutting blades to maintain efficiency and reduce strain.

- Clean the spark plug and replace it if it shows signs of corrosion.

By adhering to these simple yet effective maintenance tips, you can significantly prolong the lifespan of your machinery, ensuring it remains reliable for years to come.

Safety Precautions During Repairs

When engaging in mechanical maintenance, it is crucial to prioritize safety to prevent accidents and ensure effective work. Adhering to proper guidelines can minimize risks associated with handling tools and machinery, thereby protecting both the individual and the equipment involved.

First and foremost, always wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and sturdy footwear. This gear acts as a barrier against potential hazards like sharp objects, flying debris, or chemical exposure.

Additionally, ensure that the workspace is organized and free from clutter. A clean environment not only enhances visibility but also reduces the likelihood of tripping or misplacing tools, which can lead to injuries. Furthermore, always work in a well-ventilated area to avoid inhaling harmful fumes or dust particles.

Before beginning any task, disconnect the power source to eliminate the risk of accidental starts. Familiarize yourself with the tools and their proper usage to prevent mishandling. Regularly inspect tools for wear and damage, replacing any that are not in optimal condition.

Lastly, if you are unsure about any procedure, consult relevant documentation or seek assistance from a knowledgeable individual. Taking the time to understand the task at hand can prevent costly mistakes and ensure a safer working experience.

Identifying Engine Parts and Functions

Understanding the components of a power unit is essential for effective maintenance and troubleshooting. Each part plays a vital role in the overall functionality, ensuring smooth operation and longevity. By familiarizing yourself with these elements, you can diagnose issues more accurately and perform necessary interventions with confidence.

1. Cylinder: This component houses the piston and is crucial for the combustion process. The design and condition of the cylinder significantly impact performance.

2. Piston: Moving within the cylinder, the piston compresses the air-fuel mixture, creating the power necessary for operation. Its integrity is vital for optimal efficiency.

3. Crankshaft: This part converts the linear motion of the piston into rotational motion, ultimately driving the output shaft. Any misalignment can lead to significant issues.

4. Carburetor: Responsible for mixing air and fuel in the correct proportions, the carburetor is essential for proper combustion. Blockages or misadjustments can hinder performance.

5. Ignition System: Comprising components such as the spark plug and ignition coil, this system ignites the air-fuel mixture at the appropriate time, ensuring efficient power delivery.

6. Valves: These control the intake of air-fuel mixture and the exhaust of gases. Proper functioning is crucial for maintaining the cycle of operation.

7. Cooling System: This system prevents overheating by dissipating heat generated during operation. Components like the cooling fins or fans play a critical role in maintaining optimal temperature.

By comprehensively understanding these parts and their functions, you will be better equipped to maintain and optimize performance, ensuring the longevity of your equipment.

Troubleshooting Engine Starting Problems

When a power unit fails to initiate, it can be a frustrating experience. Identifying the underlying causes is essential for efficient resolution. Common factors influencing ignition include fuel delivery, electrical systems, and air intake. By systematically examining these components, users can often pinpoint the issue and restore functionality.

Checking Fuel Supply

Insufficient or contaminated fuel is a frequent culprit in starting issues. Begin by ensuring that the tank is filled with fresh fuel, free from impurities. Additionally, inspect the fuel lines for clogs or leaks. If the fuel appears discolored or has an unusual odor, it may need to be replaced. Proper filtration can also prevent debris from obstructing flow.

Inspecting Electrical Components

Electrical malfunctions can impede starting as well. Verify that the battery is charged and the connections are secure. Look for corroded terminals or frayed wires that may disrupt the electrical circuit. If equipped, the ignition switch should be tested for functionality. A faulty spark plug may also prevent ignition; replacing it can often resolve the issue.

Upgrading vs. Repairing Your Engine

When it comes to maintaining your machinery, the decision between enhancing performance and fixing existing issues can be a challenging one. Each option offers its own set of benefits and considerations, impacting both functionality and longevity. Understanding these factors is essential for making an informed choice that aligns with your goals.

Benefits of Upgrading

Opting for an upgrade can provide significant improvements in efficiency and power. By incorporating advanced components, you may experience better fuel consumption and increased output. Moreover, modern upgrades often come with enhanced technology that improves reliability and reduces maintenance needs. Investing in enhancements can ultimately lead to a longer lifespan for your unit, making it a worthwhile consideration.

Advantages of Repairing

On the other hand, focusing on repairs allows for a cost-effective approach, particularly when dealing with minor issues. Often, fixing specific parts can restore optimal functionality without the expense of a complete overhaul. Additionally, maintaining original components can preserve the integrity and value of your equipment. This approach is especially beneficial for those who wish to retain familiarity with their tools while extending their usable life.

In conclusion, whether you choose to upgrade or repair will depend on your individual circumstances, budget, and long-term goals. Weighing the pros and cons of each option can help ensure your decision aligns with your operational needs.

Where to Find Replacement Parts

When it comes to maintaining outdoor power equipment, sourcing the right components is essential for optimal performance. There are various avenues available for finding the necessary parts, ensuring your machinery runs smoothly and efficiently.

- Authorized Dealers: Visiting a certified dealer is one of the most reliable methods. These establishments often stock original parts and can provide expert guidance.

- Online Retailers: Numerous websites specialize in replacement components. Popular platforms often have user-friendly interfaces to help locate specific items.

- Local Hardware Stores: Many community hardware shops carry a selection of essential parts. It’s worth checking their inventory, especially for common components.

- Salvage Yards: For those seeking budget-friendly options, salvage yards may have used parts in good condition. This can be a cost-effective solution for older models.

- Manufacturer Websites: Directly visiting the manufacturer’s website can yield valuable information about compatible parts and where to purchase them.

By exploring these options, you can ensure that your machinery remains in excellent working order for years to come.