Comprehensive Guide to Crusader Engine Repair

In the world of machinery, the importance of understanding the inner workings of your power units cannot be overstated. This section delves into the intricacies of maintenance and troubleshooting, providing essential insights that empower users to keep their systems running smoothly. With the right knowledge, any operator can enhance performance and prolong the lifespan of their equipment.

Through comprehensive guidelines and practical advice, this resource aims to equip users with the necessary skills to address common issues and conduct routine assessments. Whether you are a seasoned professional or a novice enthusiast, having a solid grasp of these procedures will lead to improved efficiency and reliability. With clear instructions and expert tips, this guide serves as a valuable companion for anyone involved in the upkeep of mechanical systems.

Understanding the components and functions of your machinery is crucial for effective management. By familiarizing yourself with key concepts and techniques, you can troubleshoot problems more effectively and perform essential tasks with confidence. This approach not only saves time and resources but also contributes to a safer working environment.

Understanding the Crusader Engine

This section delves into the intricate workings of a high-performance power unit commonly found in marine vessels. By exploring its fundamental components and operational principles, one can gain valuable insights into its capabilities and maintenance requirements. A comprehensive understanding of this machinery is essential for optimizing performance and ensuring longevity.

Key Components

The structure consists of several vital parts, each playing a crucial role in its overall functionality. These include the combustion chamber, fuel delivery system, and cooling mechanisms. Together, they facilitate efficient operation, ensuring that the unit delivers consistent power while maintaining reliability under various conditions.

Operational Principles

The performance of this system is largely governed by the principles of thermodynamics and fluid dynamics. When fuel combusts within the chamber, it generates a significant amount of energy, which is then converted into mechanical power. Understanding these principles helps in troubleshooting and enhances the ability to execute necessary maintenance tasks. Regular assessments of performance indicators can preempt potential issues, allowing for timely interventions.

Common Issues with Crusader Engines

When it comes to high-performance propulsion systems, certain complications tend to arise, affecting both functionality and longevity. Understanding these frequent challenges can help users maintain optimal performance and extend the life of their machinery.

Frequent Complications

- Overheating: A common concern often linked to cooling system failures.

- Fuel System Clogs: Debris accumulation can hinder fuel flow, resulting in poor performance.

- Electrical Failures: Issues with wiring or components can lead to starting difficulties.

- Oil Leaks: Worn seals or gaskets may result in lubrication loss, impacting efficiency.

Maintenance Tips

- Regularly check and replace cooling fluids.

- Inspect fuel filters for blockages and replace as needed.

- Conduct periodic electrical system assessments to identify wear.

- Monitor oil levels and inspect for leaks to ensure proper lubrication.

By addressing these issues proactively, users can enhance the reliability and performance of their systems.

Essential Tools for Engine Repair

When it comes to maintaining and restoring mechanical systems, having the right equipment is crucial. Various instruments and devices play a vital role in diagnosing issues, facilitating disassembly, and ensuring precise reassembly. Understanding which tools are necessary can significantly enhance efficiency and effectiveness during the process.

Wrenches are fundamental, offering the versatility needed for loosening and tightening bolts of various sizes. A good set typically includes both standard and metric measurements to accommodate different components.

Sockets and ratchets provide added leverage and accessibility, especially in confined spaces. These tools enable quick adjustments and can save considerable time during complex tasks.

Torque wrenches are essential for achieving the correct tightness on critical fasteners. Applying precise torque values ensures that parts are secured without risk of damage or failure.

Diagnostic tools, such as scan tools and multimeters, are invaluable for identifying electrical issues and monitoring system performance. These devices can pinpoint malfunctions, allowing for targeted interventions.

Lastly, hand tools like screwdrivers, pliers, and hammers round out the toolkit. Their versatility makes them indispensable for various tasks, from minor adjustments to more significant overhauls.

Equipped with these essential implements, individuals can approach maintenance tasks with confidence, ensuring optimal functionality and longevity of mechanical systems.

Step-by-Step Maintenance Procedures

This section outlines essential procedures to ensure optimal performance and longevity of your machinery. Following these detailed steps will help maintain efficiency and prevent potential issues. Regular upkeep is key to reliable operation.

-

Pre-Maintenance Checklist:

- Gather necessary tools and replacement parts.

- Ensure the work area is clean and safe.

- Review the operational guidelines for specific requirements.

-

Fluid Inspection:

- Check oil levels and quality.

- Inspect coolant levels and ensure there are no leaks.

- Verify fuel cleanliness and quantity.

-

Filter Replacement:

- Identify and remove old air, fuel, and oil filters.

- Install new filters according to specifications.

- Ensure all connections are secure to prevent leaks.

-

Component Examination:

- Inspect belts and hoses for wear or damage.

- Check electrical connections for corrosion or looseness.

- Examine all mounting brackets and supports for stability.

-

Performance Testing:

- Start the unit and listen for unusual noises.

- Monitor gauges for correct readings.

- Conduct a test run to ensure all systems function properly.

-

Final Review:

- Document all maintenance actions taken.

- Schedule the next service based on usage and manufacturer recommendations.

- Ensure tools are accounted for and the workspace is clean.

By adhering to these structured procedures, you can enhance the reliability and performance of your machinery while minimizing the risk of unexpected breakdowns.

Diagnosing Engine Problems Effectively

Identifying issues within a mechanical system can often feel daunting. However, a structured approach combined with keen observation can lead to accurate diagnostics. By utilizing a systematic methodology, one can uncover underlying faults that may not be immediately apparent.

Begin by noting any irregularities during operation, such as unusual noises or performance drops. Keeping a detailed log can provide valuable insights for further analysis. Understanding the symptoms is crucial; they often point to specific components that may be malfunctioning.

Next, employ a checklist to streamline the evaluation process. This ensures that no potential causes are overlooked and helps in narrowing down the scope of investigation. Below is a basic guide to assist in this assessment:

| Symptom | Possible Cause | Action |

|---|---|---|

| Unusual noises | Worn bearings or loose components | Inspect and tighten as necessary |

| Reduced power | Fuel delivery issues | Check fuel lines and filters |

| Excessive smoke | Oil consumption or fuel problems | Evaluate oil levels and quality |

| Overheating | Coolant leaks or blockages | Examine coolant system for leaks |

After identifying the symptoms and possible causes, further tests may be required to confirm suspicions. These could include pressure tests, fluid analysis, or component inspections. Documenting the findings will aid in future troubleshooting and maintenance.

Ultimately, effective diagnosis relies on a blend of methodical observation and analytical thinking. By following a structured process, one can enhance their ability to resolve mechanical issues efficiently.

Replacing Engine Components Safely

Ensuring the secure and effective replacement of vital parts within a power unit is crucial for maintaining optimal performance and longevity. Following the appropriate guidelines not only enhances functionality but also minimizes risks associated with the process. Adopting a systematic approach will provide a safer environment and foster confidence during the task.

Preparation and Safety Measures

Before starting any work, it is essential to gather the necessary tools and materials. Wearing protective gear such as gloves and safety goggles can prevent injuries. Additionally, make sure to disconnect the power supply and follow proper isolation procedures to avoid accidental activation. Familiarizing yourself with the layout of the unit will facilitate smoother operations and enhance safety.

Step-by-Step Replacement Process

Begin by carefully removing the components that need replacement. Keep track of all fasteners and small parts to ensure nothing is lost. When installing new parts, follow the manufacturer’s specifications regarding torque and alignment. Always double-check connections to guarantee everything is secure. Taking your time during this process will lead to a successful and safe replacement, minimizing the chance of future issues.

Preventive Measures for Longevity

Ensuring the durability and efficiency of machinery requires a proactive approach. By implementing regular maintenance and adopting best practices, users can significantly extend the operational lifespan of their equipment. This section outlines essential strategies for preserving functionality and minimizing wear over time.

Regular Inspections

Conducting routine evaluations is crucial for identifying potential issues before they escalate. A thorough checkup can uncover early signs of wear and tear, allowing for timely interventions. Key components to examine include:

| Component | Recommended Frequency | Actions |

|---|---|---|

| Fluid Levels | Monthly | Top up or replace as necessary |

| Belts and Hoses | Quarterly | Inspect for cracks or leaks |

| Filters | Every 500 hours | Replace to ensure optimal performance |

| Connections | Monthly | Tighten and secure as needed |

Proper Usage and Operation

Adhering to recommended operational guidelines plays a vital role in maintaining performance. Users should avoid overloading and adhere to specified limits to prevent unnecessary strain. Additionally, warming up the system before full operation can promote smoother functionality and reduce stress on components.

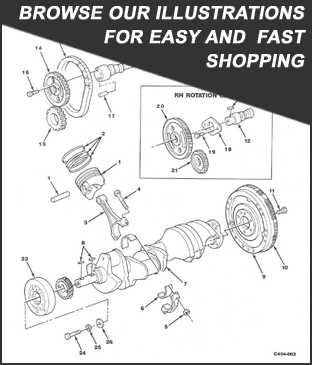

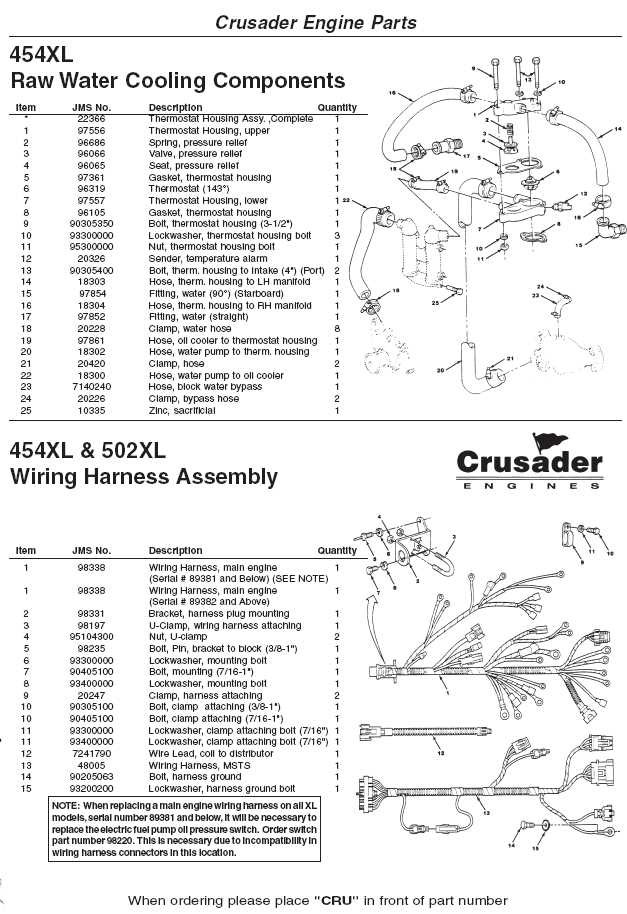

Understanding Engine Specifications and Parts

Comprehending the technical details and components of a propulsion unit is crucial for maintaining optimal performance and longevity. This section will delve into the essential characteristics and individual elements that contribute to the functionality of these systems. By familiarizing oneself with these specifications, users can make informed decisions regarding care and enhancement.

Key specifications often include measurements such as displacement, compression ratio, and horsepower ratings. Each of these attributes plays a vital role in determining how effectively the system operates under various conditions. Additionally, knowing the various components and their functions helps in diagnosing issues and implementing necessary adjustments.

| Specification | Description |

|---|---|

| Displacement | The total volume of all cylinders in the unit, affecting power and efficiency. |

| Compression Ratio | The ratio of the maximum to minimum volume in the combustion chamber, influencing performance and fuel efficiency. |

| Horsepower | A measure of the engine’s power output, impacting speed and load capacity. |

| Torque | The twisting force produced, essential for acceleration and towing capacity. |

Understanding these specifications and parts not only aids in effective management but also enhances the overall experience and reliability of the machine. Regular review of this knowledge can lead to better performance and a more enjoyable journey.

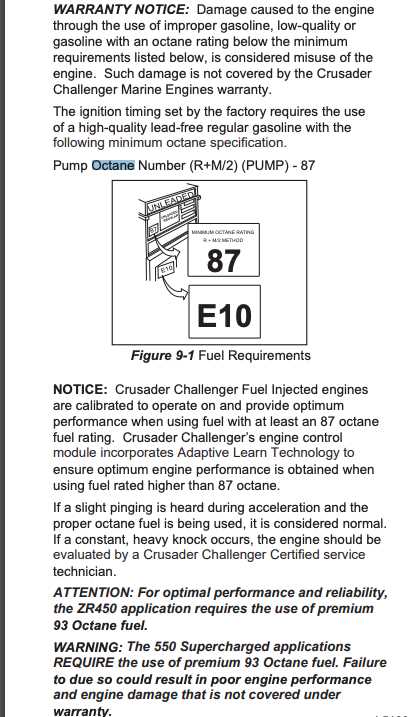

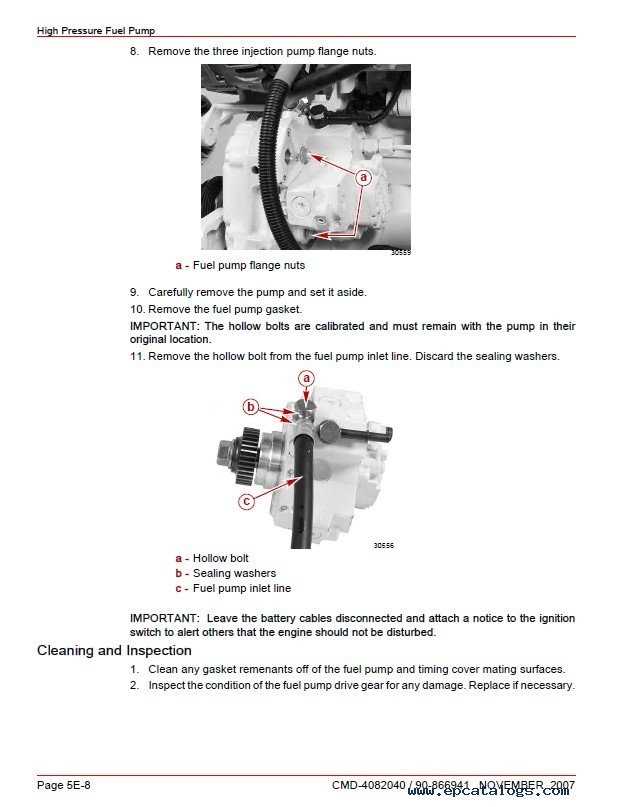

Fuel System Troubleshooting Tips

Maintaining optimal performance in your power unit involves understanding potential issues within the fuel system. Addressing these concerns promptly can help ensure reliability and efficiency. Below are some effective strategies for diagnosing common fuel-related problems.

Common Symptoms and Solutions

Identifying symptoms can lead you to the root cause of fuel system troubles. The table below outlines typical issues along with their possible solutions:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Hard starting | Clogged fuel filter | Replace the fuel filter |

| Stalling | Fuel pump failure | Check and replace the fuel pump if necessary |

| Poor acceleration | Dirty injectors | Clean or replace the fuel injectors |

| Unusual noises | Air leaks in fuel lines | Inspect and seal any leaks |

Preventive Measures

Implementing preventive strategies can help mitigate future issues. Regular inspections and maintenance of the fuel system components will prolong their lifespan and enhance overall performance. Always use quality fuel and follow the manufacturer’s guidelines for maintenance intervals.

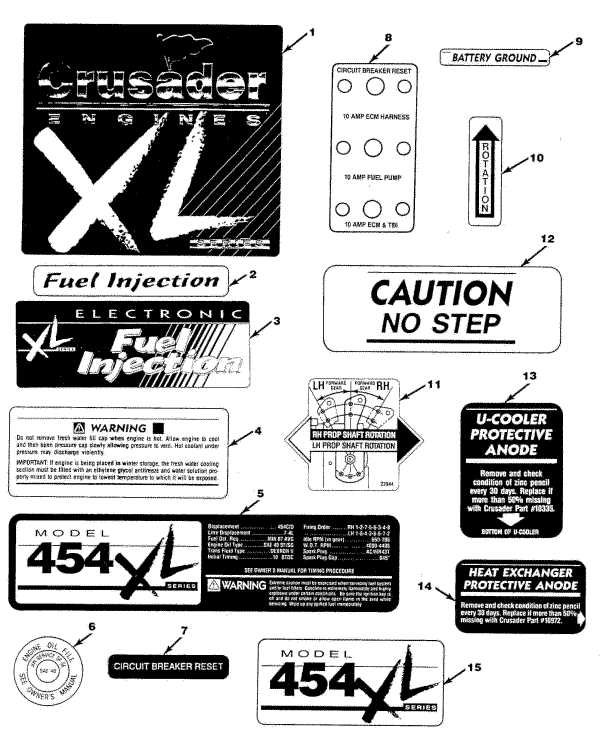

Electrical Systems in Crusader Engines

The electrical systems play a crucial role in the functionality and performance of any mechanical unit. These systems are responsible for powering various components, ensuring efficient operation, and providing essential diagnostics. Understanding how these systems operate and how to maintain them is vital for optimal performance.

Key Components

- Batteries: Serve as the primary power source, supplying energy to start the unit and run electrical accessories.

- Alternators: Generate electricity while the unit is running, recharging the batteries and powering onboard systems.

- Wiring Harnesses: Facilitate the distribution of electrical power and signals throughout the system.

- Fuses and Relays: Protect circuits from overloads and control the flow of electricity to various components.

Maintenance Tips

- Regularly inspect batteries for corrosion and ensure proper connections.

- Check the alternator’s output voltage to confirm it is functioning correctly.

- Examine wiring harnesses for signs of wear or damage.

- Replace blown fuses and test relays for proper operation.

By understanding these essential elements and adhering to maintenance guidelines, one can enhance the longevity and reliability of the electrical systems in the unit.

Cooling System Maintenance Guidelines

Maintaining the thermal regulation system is crucial for ensuring optimal performance and longevity of your machinery. Regular attention to this component helps prevent overheating and promotes efficient operation, ultimately enhancing reliability and reducing the likelihood of costly failures.

Key Maintenance Tasks

To keep the thermal regulation system in top condition, consider the following essential tasks:

| Task | Frequency | Description |

|---|---|---|

| Inspect coolant level | Monthly | Ensure the coolant is at the recommended level to prevent overheating. |

| Check for leaks | Monthly | Examine hoses and connections for signs of leaks that could compromise efficiency. |

| Flush the system | Annually | Remove old coolant and debris to maintain optimal thermal transfer. |

| Inspect the thermostat | Every two years | Ensure the thermostat opens and closes correctly to regulate flow. |

| Clean radiator | Annually | Remove debris from the radiator fins to enhance airflow and cooling efficiency. |

Tips for Effective Care

To enhance the lifespan of the thermal management system, adhere to these additional recommendations:

- Use the manufacturer-recommended coolant type to ensure compatibility and effectiveness.

- Avoid operating under extreme conditions without adequate coolant levels.

- Monitor performance and watch for any unusual changes, such as temperature fluctuations.

Repairing Engine Seals and Gaskets

Maintaining the integrity of sealing components is crucial for optimal performance and longevity of any machinery. Properly functioning seals and gaskets prevent leaks, ensuring that fluids remain contained within their designated pathways. Addressing issues with these components not only enhances efficiency but also minimizes the risk of damage to surrounding parts.

Before beginning any work, it is essential to identify the specific areas where leakage may be occurring. Signs such as fluid stains, unusual noises, or pressure drops can indicate potential failures. Once identified, the first step is to remove the faulty components carefully, ensuring that no debris contaminates the surrounding areas.

When selecting replacements, it is vital to choose high-quality materials that match the specifications of the original parts. Installing new seals or gaskets should be done with precision, ensuring a snug fit to prevent future leaks. It is also advisable to apply a suitable sealant, where necessary, to enhance the effectiveness of the new components.

After installation, perform thorough checks to ensure everything is properly seated and secured. A test run can help identify any remaining issues, allowing for timely adjustments. Regular inspection and maintenance of these crucial parts will contribute significantly to the overall health of the system.