D4cb Engine Repair Guide

Understanding the intricacies of mechanical systems is essential for ensuring longevity and optimal performance. This section delves into the essentials of upkeep and problem-solving techniques for various components, providing readers with the knowledge to address issues effectively. Whether you are a seasoned professional or a passionate hobbyist, having a reliable resource at your disposal can make all the difference.

Key aspects of this guide include detailed instructions, troubleshooting steps, and insights into common challenges that may arise during operation. By following a systematic approach, users can enhance their skills and boost their confidence in handling technical tasks. The information presented here aims to empower individuals to tackle repairs with assurance and precision.

As you navigate through the intricacies of the subject matter, you will find valuable tips and techniques that facilitate efficient interventions. Emphasis is placed on safety and best practices, ensuring that all endeavors are conducted with caution and expertise. This knowledge not only aids in immediate resolutions but also contributes to a deeper understanding of the mechanics involved.

D4CB Engine Overview

This section provides a comprehensive insight into a specific power unit known for its reliability and performance. The design and functionality of this machinery cater to various applications, making it a popular choice in multiple industries.

Key features of this power unit include:

- Durability: Built to withstand demanding conditions.

- Efficiency: Optimized fuel consumption for better performance.

- Compact Design: Space-saving architecture enhances versatility.

- Advanced Technology: Incorporates modern innovations for improved output.

This unit is particularly noted for its adaptability, making it suitable for both light and heavy-duty tasks. Regular maintenance ensures longevity and optimal functionality, allowing users to benefit from consistent performance over time.

In summary, this power unit represents a blend of robustness and efficiency, providing users with a reliable solution for their operational needs.

Common Issues with D4CB Engines

Understanding the typical problems associated with this specific power unit can greatly assist in maintaining optimal performance and longevity. Various factors can lead to a decline in efficiency, affecting both functionality and reliability.

1. Overheating: One prevalent issue is overheating, which can stem from a malfunctioning cooling system. This can lead to severe damage if not addressed promptly.

2. Oil Leaks: Another common concern is the occurrence of oil leaks, often resulting from worn seals or gaskets. Regular inspections can help identify these leaks before they escalate into more significant problems.

3. Fuel Inefficiency: Decreased fuel efficiency can indicate underlying issues, such as clogged injectors or air filters. These components should be regularly cleaned or replaced to maintain optimal fuel economy.

4. Poor Performance: A noticeable drop in performance may be due to various factors, including issues with the ignition system or fuel supply. Diagnosing these problems early can prevent more extensive damage.

5. Noise and Vibration: Unusual noises or vibrations during operation can signal internal wear or component failure. Identifying and addressing these symptoms is crucial for maintaining smooth operation.

By staying vigilant for these common issues, one can ensure better reliability and efficiency in the long run.

Essential Tools for Engine Repair

Having the right equipment is crucial for anyone looking to undertake maintenance or troubleshooting tasks. A well-equipped workspace not only enhances efficiency but also ensures safety while working on complex machinery.

Below is a list of indispensable instruments that every enthusiast should consider:

- Wrenches: A variety of sizes is essential for loosening and tightening bolts.

- Sockets and Ratchets: These tools facilitate quick adjustments and can reach tight spaces effectively.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage.

- Plier Set: Versatile for gripping, bending, and cutting tasks.

- Screwdrivers: Both flat-head and Phillips types are necessary for different screws.

In addition to the basic tools, consider adding the following specialized instruments to your toolkit:

- Compression Gauge: Used to measure cylinder pressure and diagnose issues.

- Multimeter: Essential for electrical troubleshooting and testing components.

- Oil Filter Wrench: Makes replacing filters easier and less messy.

- Diagnostic Scanner: Helps in identifying issues by reading error codes.

Investing in high-quality tools will pay off in the long run, making tasks more manageable and ensuring that work is performed efficiently and safely.

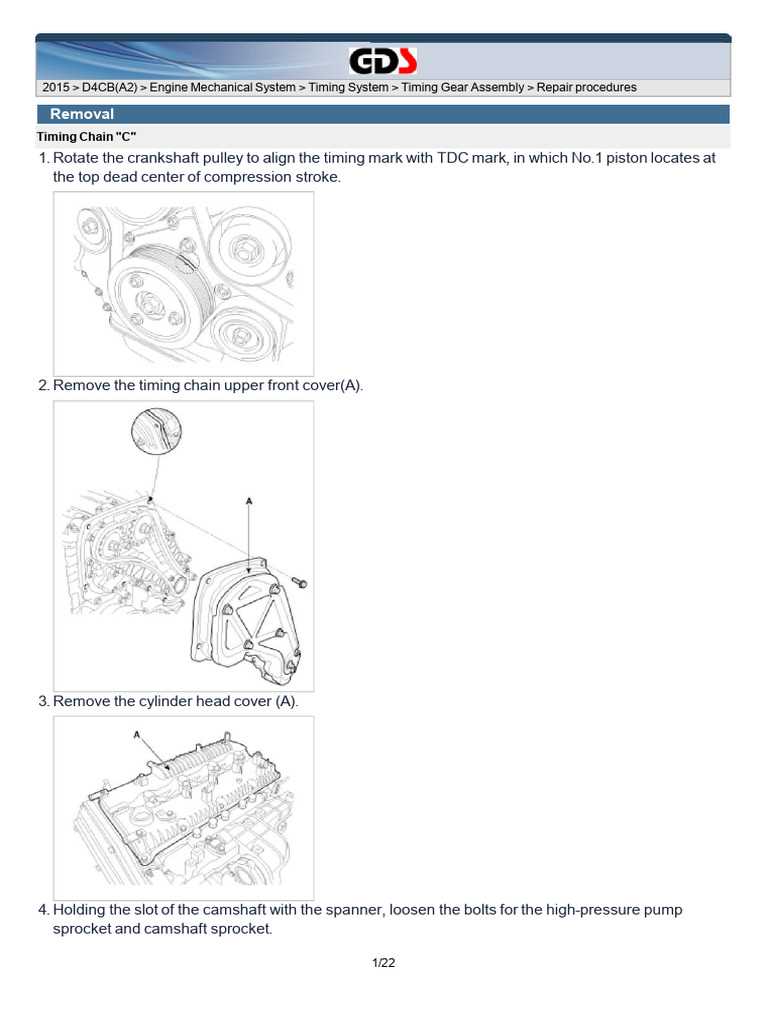

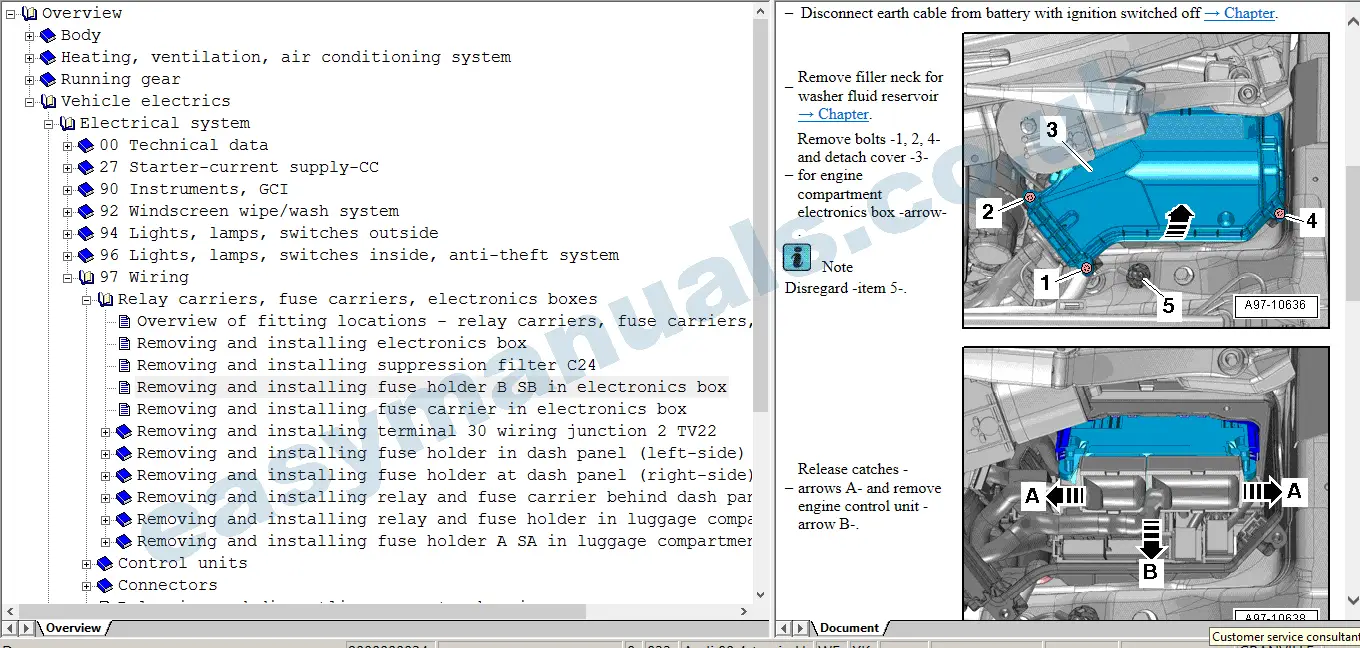

Step-by-Step Disassembly Process

Disassembling a complex machinery unit requires careful attention and systematic procedures to ensure each component is removed safely and effectively. This section outlines a detailed approach to dismantling, emphasizing the importance of organization and precision at every stage.

Preparation and Initial Steps

Begin by gathering all necessary tools and safety equipment. Ensure a clean workspace to avoid losing small parts. Remove any external accessories and components that may obstruct access to the main assembly. Label each part as it is removed to facilitate reassembly later.

Sequential Dismantling

Proceed with disassembly in a logical sequence, starting with the outer layers before moving inward. Carefully detach each component, inspecting for any wear or damage that may need attention. Keep track of fasteners and small items in designated containers to maintain organization throughout the process.

Diagnostic Procedures for D4CB

This section outlines essential methods for identifying issues in the specified power unit. Systematic approaches enable technicians to pinpoint malfunctions effectively, ensuring optimal performance and longevity. Following these protocols aids in recognizing symptoms early, thus preventing more severe complications.

Visual Inspection

Initiate the process with a thorough visual examination of the assembly. Look for any signs of wear, leaks, or physical damage. Check connections and wiring for corrosion or fraying, which could indicate potential failures. This preliminary step is crucial, as it often reveals obvious problems that can be addressed immediately.

Diagnostic Testing

Subsequently, employ diagnostic tools to assess functionality. Utilize specialized equipment to monitor parameters such as pressure and temperature. Electrical systems should be evaluated for continuity and resistance. Document findings carefully, as this data will assist in determining the root cause of any irregularities and guide subsequent actions.

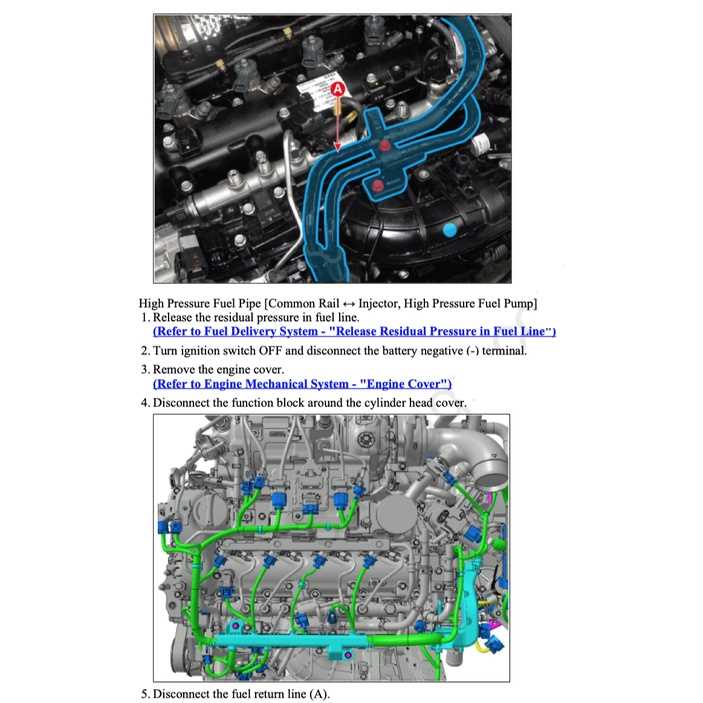

Replacing Engine Components Safely

When it comes to the process of swapping out crucial parts within a mechanical unit, ensuring safety is paramount. Proper techniques and precautions can prevent accidents and damage, promoting a smoother workflow and better outcomes. This section outlines essential practices to follow during such replacements.

Preparation and Planning

Before beginning any replacement task, thorough preparation is vital. Start by gathering all necessary tools and replacement parts. Read the specific guidelines related to the components being addressed, as understanding the layout and functionality will aid in executing the task efficiently. Wear appropriate safety gear, such as gloves and goggles, to protect against potential hazards.

Execution and Disposal

During the replacement process, maintain a clean and organized workspace. This minimizes the risk of losing small components and keeps the area safe from clutter. Take your time and follow a systematic approach to avoid mistakes. Once the task is complete, ensure that old parts are disposed of properly. Recycling and responsible disposal not only help the environment but also prevent clutter in your workspace.

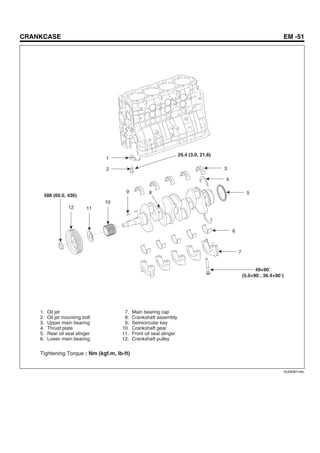

Torque Specifications for D4CB Parts

Understanding the proper tightening values for various components is crucial for optimal performance and longevity. These specifications ensure that all parts are securely fastened without the risk of damage or failure, which can result from improper installation. This section outlines the essential torque settings necessary for specific elements associated with the system.

Key Components and Their Torque Values

Each part requires a unique torque value to maintain the integrity of the assembly. For instance, critical fasteners like bolts and nuts must be tightened to precise measurements to prevent issues such as leaks or mechanical failure. It’s important to consult the specifications for each component, as variations may occur depending on the design and materials used.

Best Practices for Tightening

When applying torque, utilizing a calibrated torque wrench is essential for accuracy. Additionally, following a specific tightening sequence can help distribute the load evenly across the assembly, further preventing potential failures. Regularly checking and maintaining these settings can contribute significantly to the reliability and efficiency of the entire setup.

Reassembly Tips and Best Practices

Putting components back together can be as crucial as the disassembly process. Ensuring that everything is reassembled correctly not only enhances performance but also extends the lifespan of the entire system. Below are essential strategies and guidelines to follow during this phase.

Preparation Steps

- Clean all parts thoroughly to remove any debris or contaminants.

- Organize your workspace to prevent misplacement of components.

- Refer to documentation or notes taken during disassembly to track each part’s position and orientation.

Reassembly Techniques

- Start with larger components before moving on to smaller parts to maintain structure stability.

- Apply appropriate lubricants where necessary to reduce friction and ensure smooth operation.

- Use torque wrenches to tighten fasteners to the specified settings, avoiding over-tightening.

- Double-check alignment and fitment of all parts to prevent future issues.

Following these guidelines will help ensure a successful reassembly process, leading to improved functionality and durability of the unit.

Regular Maintenance Recommendations

Consistent upkeep is essential for ensuring optimal performance and longevity of your machinery. By adhering to a structured maintenance routine, you can prevent unexpected failures and enhance efficiency. This section outlines key practices to maintain your equipment in peak condition.

Key Maintenance Tasks

Implementing a series of regular checks can significantly impact the overall functionality. The following table summarizes vital tasks to incorporate into your maintenance schedule:

| Task | Frequency | Description |

|---|---|---|

| Fluid Level Check | Weekly | Inspect and top off all necessary fluids to ensure proper operation. |

| Filter Replacement | Every 500 hours | Change air and fuel filters to maintain optimal performance. |

| Belt Inspection | Monthly | Examine belts for wear and tension; replace if necessary. |

| Visual Inspection | Daily | Check for leaks, loose connections, and any visible damage. |

| Cleaning | Every 100 hours | Remove debris and contaminants from critical areas. |

Best Practices

In addition to the tasks outlined, following these best practices can further enhance reliability:

- Maintain a detailed log of all maintenance activities.

- Utilize quality parts and fluids recommended by the manufacturer.

- Schedule professional inspections periodically for comprehensive assessments.

Upgrades for Enhanced Engine Performance

Improving the efficiency and power of your vehicle’s machinery is essential for achieving a thrilling driving experience. Various enhancements can be implemented to elevate overall performance, providing both speed and responsiveness. Below are some effective modifications that can lead to significant gains.

Key Modifications to Consider

- Intake Systems: Upgrading to a high-performance air intake can increase airflow, resulting in better combustion and enhanced power output.

- Exhaust Systems: A less restrictive exhaust system allows for improved gas flow, which can lead to higher horsepower and torque.

- ECU Tuning: Reprogramming the electronic control unit can optimize fuel delivery and ignition timing, improving efficiency and responsiveness.

Additional Enhancements

- High-Performance Fuel Injectors: These components provide a more precise fuel spray, enhancing combustion efficiency.

- Upgraded Turbochargers: Installing a more efficient turbo can significantly boost power without compromising reliability.

- Lightweight Components: Replacing stock parts with lighter materials can improve acceleration and handling.

Implementing these modifications can transform your vehicle, making it more enjoyable to drive while ensuring reliability and longevity. Each upgrade serves a purpose, contributing to an overall enhanced performance package.

Troubleshooting Post-Repair Problems

After completing maintenance work, it’s common to encounter unexpected issues that can affect performance. Identifying and resolving these complications is essential for ensuring optimal functionality and longevity of the machinery. This section outlines key considerations and methods to diagnose and address any lingering challenges.

One of the first steps in troubleshooting is to conduct a thorough inspection. Listen for unusual noises and monitor for any irregular vibrations that may indicate underlying issues. Additionally, reviewing the work performed can help pinpoint potential areas that may have been overlooked.

Next, check all connections and components to ensure they are secure and properly aligned. Loose or misaligned parts can lead to operational inefficiencies. If any electrical systems are involved, inspect wiring for signs of wear or damage, as these can cause intermittent failures or malfunctions.

Monitoring performance metrics post-maintenance is crucial. If there are discrepancies in power output or efficiency, it may indicate deeper issues that need addressing. Using diagnostic tools can aid in pinpointing specific faults and providing clearer insights into what needs to be fixed.

Finally, if problems persist despite your efforts, consulting with a specialist can provide valuable insights. They may identify problems that are not immediately obvious and suggest effective solutions based on their expertise and experience.

Resources for Further Learning

Expanding your knowledge in the field of mechanical systems can be both rewarding and essential for enhancing your skills. Various resources are available to support your journey, whether you are a novice or an experienced technician. This section highlights some valuable materials and platforms to deepen your understanding and expertise.

Books and Publications: Consider exploring technical literature that covers theoretical and practical aspects of machinery. Comprehensive guides, textbooks, and specialized journals provide detailed insights and methodologies that can enhance your foundational knowledge.

Online Courses: Numerous educational platforms offer courses tailored to mechanical systems. These courses often include interactive modules, videos, and assessments that cater to different learning styles, allowing you to learn at your own pace.

Forums and Communities: Engaging with online communities and discussion forums can be incredibly beneficial. These platforms allow you to connect with fellow enthusiasts and professionals, exchange ideas, and seek advice on specific challenges you may encounter.

Workshops and Seminars: Attending hands-on workshops and industry seminars can provide practical experience and exposure to the latest advancements. Networking with experts and peers in these settings can also lead to valuable mentorship opportunities.

Manufacturer Resources: Many manufacturers provide technical documentation, tutorials, and support services for their products. Exploring these resources can help you gain a deeper understanding of specific components and their applications.

By utilizing these diverse resources, you can continuously improve your skills and stay updated on best practices and innovations in the field. The journey of learning never truly ends, and each new piece of knowledge brings you closer to mastery.