Comprehensive Guide to Dt466 Engine Repair

Maintaining the performance and longevity of heavy machinery requires a thorough understanding of its intricate systems. This section delves into the essential practices for ensuring optimal functionality and reliability. By focusing on key components and their interrelations, operators can better manage their equipment and prevent unexpected issues.

It is crucial to familiarize oneself with various aspects of the mechanical systems, including routine assessments and potential complications. Understanding these elements allows for more effective troubleshooting and enhances overall efficiency. This guide provides insights into critical procedures that can aid in maintaining peak performance.

Equipped with knowledge about standard practices and common pitfalls, individuals will find themselves better prepared to tackle challenges. This information empowers users to take proactive measures, ensuring that their machinery operates smoothly for years to come. The following sections will outline vital techniques and tips for successful maintenance.

This section aims to provide a comprehensive overview of a powerful power unit widely used in various applications, highlighting its key features, specifications, and overall functionality. Understanding the fundamental aspects of this unit can assist users in better appreciating its design and operation, which is crucial for effective maintenance and troubleshooting.

| Feature | Description |

|---|---|

| Configuration | This unit is designed with a robust structure, offering exceptional durability and performance. |

| Cylinders | Typically, it incorporates six cylinders, allowing for a balanced power output. |

| Displacement | The total displacement is significant, providing enhanced torque and efficiency. |

| Fuel Type | It operates on diesel fuel, ensuring efficient energy conversion. |

| Cooling System | Equipped with an effective cooling mechanism, it maintains optimal operating temperatures. |

Common Issues and Symptoms

Understanding the typical problems and indicators associated with these power units is essential for maintaining optimal performance and longevity. Many issues can arise due to various factors, including wear and tear, inadequate maintenance, or environmental conditions. Recognizing these symptoms early can prevent more significant complications down the line.

| Issue | Symptoms | Potential Causes |

|---|---|---|

| Overheating | High temperature gauge, steam from cooling system | Low coolant levels, faulty thermostat |

| Loss of Power | Reduced acceleration, sluggish performance | Clogged air filter, fuel delivery issues |

| Strange Noises | Knocking, grinding, or hissing sounds | Worn bearings, loose components |

| Excessive Smoke | Visible smoke from exhaust | Improper fuel mixture, oil leaks |

| Vibration | Unusual shaking during operation | Imbalanced components, worn mounts |

Required Tools for Repairs

When undertaking maintenance on complex machinery, having the right set of instruments is crucial for ensuring efficiency and effectiveness. The correct tools not only facilitate the task at hand but also contribute to the longevity and performance of the equipment. In this section, we will outline the essential instruments needed for successful upkeep.

Basic Hand Tools: A collection of hand tools is fundamental for any maintenance job. This includes wrenches, pliers, screwdrivers, and sockets. These instruments allow for easy access to various components and enable secure fastening.

Specialized Equipment: Certain tasks may require specialized tools, such as torque wrenches and alignment tools. These are designed to meet specific requirements, ensuring that all adjustments are precise and adhere to the necessary specifications.

Diagnostic Instruments: To effectively troubleshoot issues, diagnostic tools are indispensable. Items like multimeters and pressure gauges help in assessing the functionality of different systems, providing valuable insights into potential problems.

Safety Gear: Personal protective equipment should not be overlooked. Safety glasses, gloves, and appropriate footwear protect individuals from potential hazards during maintenance activities.

By gathering these necessary tools, individuals can approach their tasks with confidence, ensuring that each procedure is performed accurately and safely.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your machinery. By following a structured maintenance routine, you can identify potential issues early and prevent costly repairs.

Start by regularly checking fluid levels, including oil, coolant, and fuel. Ensure that each fluid is at the recommended level and free of contaminants. This simple task can significantly impact the overall functionality of your system.

Next, inspect all filters, such as air and fuel filters, for cleanliness and effectiveness. Replacing dirty filters at recommended intervals will enhance efficiency and protect vital components from wear and tear.

Pay attention to belts and hoses, checking for signs of wear, cracks, or leaks. Timely replacement of these parts can prevent unexpected breakdowns and keep your operations running smoothly.

Finally, perform regular inspections of electrical connections and components. Clean terminals and ensure that connections are secure to avoid electrical issues that could lead to operational failures.

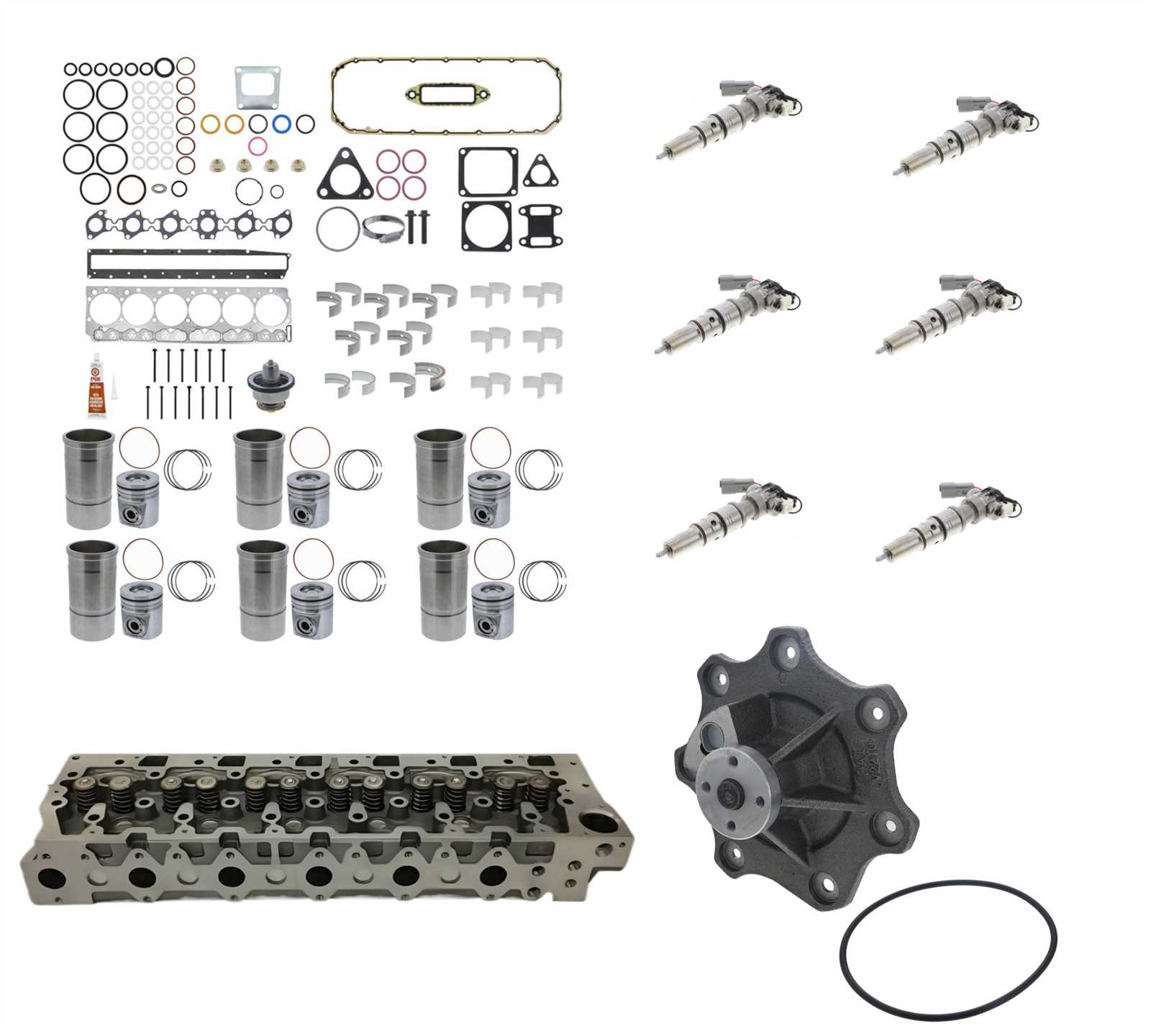

Replacing Engine Components

Maintaining the performance of a vehicle often necessitates the replacement of key elements within the power unit. This process involves careful evaluation and substitution of worn or malfunctioning parts to ensure optimal functionality and reliability. Understanding the significance of these components and the steps required for their exchange is crucial for successful maintenance.

The initial step involves a thorough assessment of the affected parts. Identifying the symptoms of wear or damage will guide the selection of components that require replacement. Once the necessary parts are determined, it’s important to gather the appropriate tools and equipment to facilitate a smooth transition during the process.

When replacing the components, ensure that each part is compatible with the system to maintain efficiency. Attention to detail is vital, as proper installation can prevent future complications. It is also advisable to refer to specifications for torque settings and other critical measurements to guarantee accuracy during reassembly.

Finally, after completing the replacements, a comprehensive inspection should be conducted to verify that all components function harmoniously. Regular monitoring and timely replacements can significantly enhance the longevity and performance of the entire system.

Fuel System Diagnostics

The effectiveness of a vehicle’s performance heavily relies on the functionality of its fuel system. Accurate diagnostics play a crucial role in identifying issues that may affect fuel delivery, combustion efficiency, and overall power output. This section focuses on various techniques and methods employed to assess the integrity and performance of fuel-related components, ensuring optimal operation.

Common Symptoms of Fuel System Issues

Recognizing the signs of a malfunctioning fuel system is essential for timely intervention. Some prevalent indicators include inconsistent acceleration, reduced fuel efficiency, and difficulty starting. Additionally, abnormal noises from the fuel pump or a noticeable decrease in power during operation may suggest underlying problems. Monitoring these symptoms can guide technicians in diagnosing and addressing potential failures effectively.

Diagnostic Tools and Techniques

Utilizing specialized tools enhances the accuracy of diagnostics. Pressure gauges can measure fuel pump output, while multimeters can assess electrical connections and component functionality. Furthermore, visual inspections of fuel lines and filters can reveal leaks or clogs. Employing these techniques ensures comprehensive evaluation and targeted repairs, promoting reliable performance and longevity of the vehicle.

Electrical System Troubleshooting

Troubleshooting the electrical system involves systematically diagnosing and resolving issues that affect performance. A thorough understanding of components and their interactions is essential for effective problem-solving. This section will guide you through common symptoms, potential causes, and recommended solutions, enabling you to restore functionality efficiently.

Begin by examining the power supply, as many issues stem from inadequate voltage or poor connections. Check the battery for proper voltage levels and ensure terminals are clean and tight. If the battery is functional, investigate the wiring harness for any signs of wear or damage that could interrupt the flow of electricity.

Next, assess the various sensors and actuators within the system. These components are critical for monitoring and adjusting operations. Verify that all sensors are connected properly and test their outputs using a multimeter. Faulty sensors can lead to inaccurate readings and erratic performance.

Additionally, inspect the fuses and relays within the electrical panel. A blown fuse can interrupt the circuit, leading to system failures. Replace any blown fuses and test the relays to ensure they are functioning correctly. If necessary, consult the wiring diagrams to trace the circuits and pinpoint any underlying issues.

Finally, utilize diagnostic tools to identify any trouble codes stored in the control module. These codes provide valuable insights into potential problems, allowing for a targeted approach to repairs. By systematically addressing each aspect of the electrical system, you can effectively troubleshoot and resolve issues, ensuring optimal performance.

Cooling System Efficiency

The efficiency of a cooling system is critical for maintaining optimal performance in various machinery. A well-functioning cooling apparatus ensures that temperatures remain within acceptable limits, preventing overheating and associated damage. Understanding the components and processes involved in heat dissipation is essential for maximizing effectiveness.

Key Components of Cooling Systems

A robust cooling system comprises several essential elements, including radiators, pumps, and thermostats. Each part plays a vital role in regulating temperature and promoting fluid circulation. For instance, radiators dissipate heat absorbed by the coolant, while pumps maintain the necessary flow to transport the coolant efficiently throughout the system.

Factors Affecting Cooling Performance

Several factors can influence the overall performance of cooling systems. Fluid quality is paramount; using the right coolant can enhance heat transfer and reduce corrosion. Additionally, environmental conditions such as ambient temperature and airflow around the components can significantly impact the system’s efficiency. Regular maintenance and timely replacements of worn components also contribute to sustained performance.

Oil Change Procedures

Regular maintenance of the lubrication system is crucial for ensuring optimal performance and longevity of your vehicle’s power source. This section outlines the essential steps involved in replacing the lubricant, highlighting the importance of using the correct products and techniques.

Preparation

- Gather necessary tools: wrenches, oil filter wrench, oil catch pan, funnel.

- Select the appropriate lubricant and filter based on manufacturer specifications.

- Ensure the vehicle is parked on a level surface and the engine is warm to promote better oil drainage.

Procedure

- Start the vehicle briefly to warm the lubricant, then turn it off.

- Place the oil catch pan under the oil pan and remove the drain plug carefully.

- Allow the old lubricant to fully drain into the pan.

- Replace the drain plug securely after all oil has been drained.

- Remove the old filter using an oil filter wrench; lubricate the rubber gasket of the new filter with fresh oil before installation.

- Install the new filter and tighten it by hand, ensuring a snug fit.

- Pour the new lubricant into the filler opening using a funnel, checking the level with the dipstick.

- Run the vehicle for a few minutes and check for leaks around the filter and drain plug.

- Dispose of the old lubricant and filter properly, following local regulations.

Following these steps will help maintain the integrity of the lubrication system and contribute to the overall efficiency of your machinery.

Performance Upgrades Options

Improving the capabilities of your vehicle can greatly enhance its overall driving experience. Various modifications can be made to boost power output, improve efficiency, and enhance responsiveness. These enhancements not only contribute to a more enjoyable ride but also may improve the longevity of the system.

One popular approach is optimizing the fuel delivery system. Upgrading injectors or installing high-performance fuel pumps can increase the amount of fuel supplied, leading to improved combustion and increased horsepower. Additionally, a remap of the vehicle’s control unit can fine-tune fuel and air mixtures for maximum performance.

Another option is to enhance the airflow into and out of the system. Installing a high-flow air intake can help the system breathe better, allowing for more efficient air entry. Pairing this with an upgraded exhaust system can significantly reduce back pressure and enhance the expulsion of exhaust gases, resulting in a noticeable power increase.

Consider also upgrading the intercooler if applicable. A larger or more efficient intercooler can help reduce intake air temperatures, improving density and enhancing performance. Furthermore, suspension upgrades can provide better handling and stability, allowing for the full utilization of any power gains achieved through modifications.

Lastly, regular maintenance and the use of high-quality fluids can contribute to overall performance. Ensuring that all components are in optimal condition is essential for maximizing the benefits of any upgrades made.

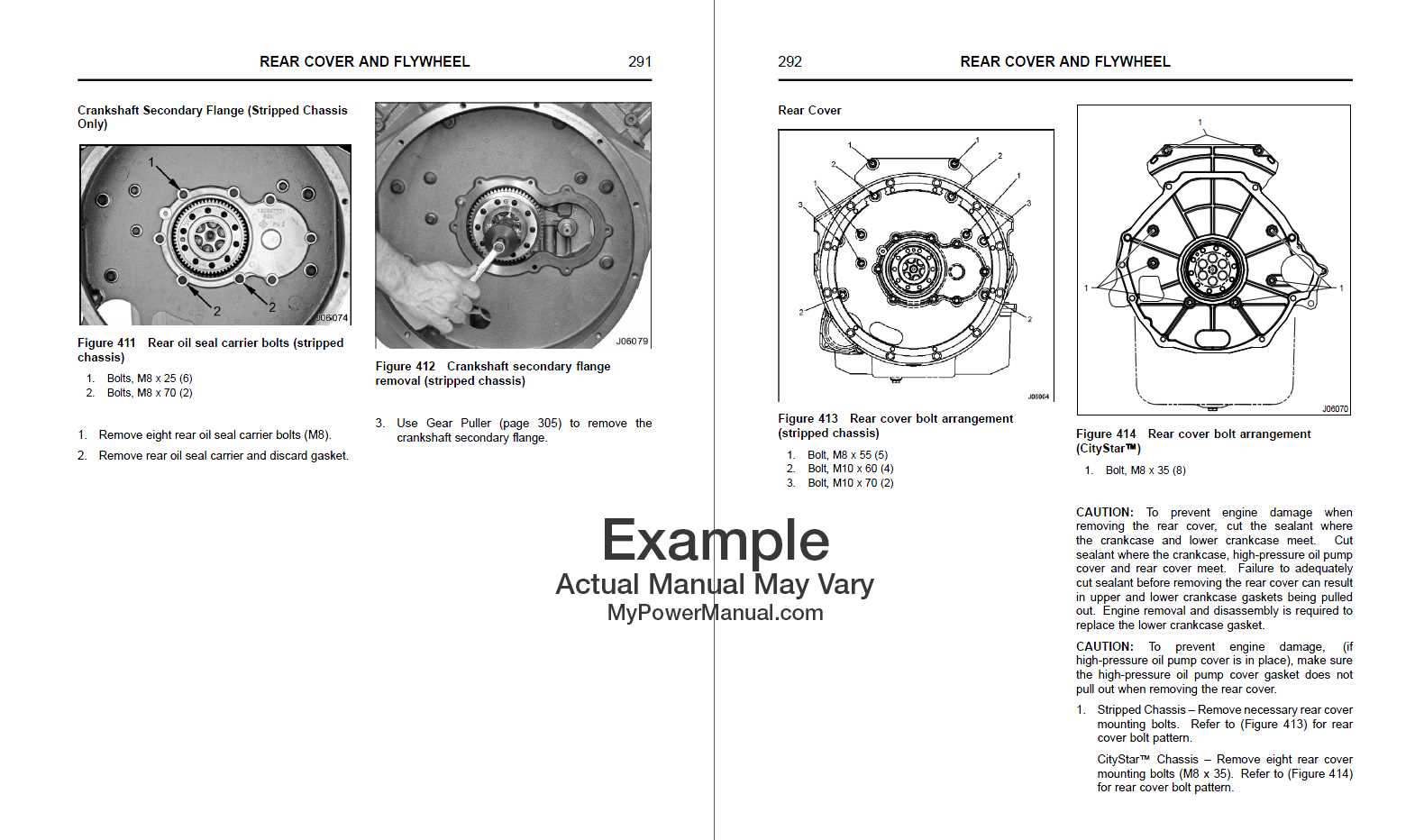

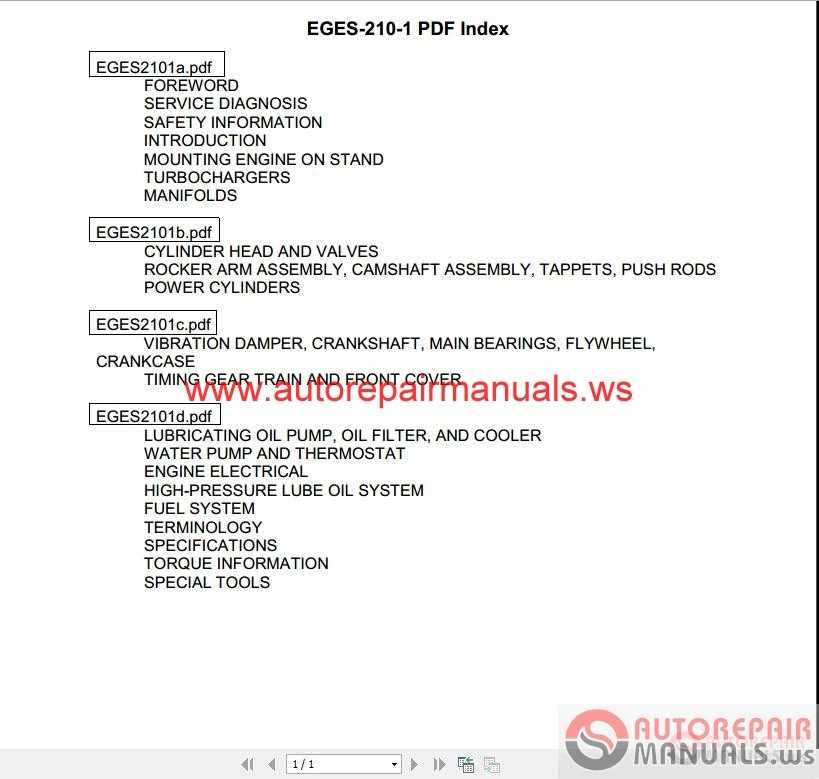

Engine Assembly and Disassembly

The process of assembling and disassembling a power unit is crucial for maintenance and overhaul tasks. Proper techniques and attention to detail ensure optimal performance and longevity. This section outlines the fundamental steps involved in reassembling components after servicing or inspection, as well as the methodical approach to disassembling parts for thorough examination and repairs.

When disassembling, it is essential to follow a structured approach to avoid damage and ensure all parts can be reassembled correctly. Here are the key stages:

| Step | Description |

|---|---|

| 1 | Remove external components such as belts, hoses, and electrical connections. |

| 2 | Drain all fluids to prevent spills and contamination. |

| 3 | Carefully detach the main assembly from the supporting structure, ensuring stability. |

| 4 | Take apart subassemblies systematically, labeling parts for easier reassembly. |

| 5 | Inspect components for wear, damage, or contamination during disassembly. |

Once disassembly is complete, the assembly process begins by reversing the steps. Attention to torque specifications and sequences is vital to ensure integrity and performance. Here are the main stages:

| Step | Description |

|---|---|

| 1 | Clean all parts thoroughly before reassembly to prevent contamination. |

| 2 | Apply appropriate lubricants to moving surfaces to facilitate operation. |

| 3 | Assemble subcomponents in a logical order, following manufacturer specifications. |

| 4 | Reconnect all external elements, ensuring secure and proper connections. |

| 5 | Refill fluids and perform final checks before starting the unit. |

By adhering to these guidelines, technicians can ensure the successful assembly and disassembly of the power unit, resulting in enhanced functionality and reliability.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance work is paramount to prevent accidents and injuries. Proper precautions not only protect the individual performing the task but also safeguard the surrounding environment and equipment. Familiarizing oneself with safety measures is essential for a successful and secure experience.

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and steel-toed boots.

- Ensure that the work area is well-ventilated to avoid inhalation of harmful fumes.

- Keep the workspace organized and free of clutter to prevent trips and falls.

- Disconnect all power sources before beginning any service to avoid accidental activation.

- Use tools and equipment that are in good condition and suitable for the tasks at hand.

- Be aware of your surroundings and keep all unnecessary personnel out of the work area.

- Follow manufacturer instructions carefully to prevent misuse of components and systems.

Taking these precautions seriously can significantly reduce the risk of incidents and contribute to a more efficient maintenance process.

FAQs About DT466 Engine

This section addresses common inquiries regarding a specific type of heavy-duty power unit, focusing on its features, maintenance, and troubleshooting. Understanding these aspects can greatly enhance the longevity and performance of the unit.

What are common issues with this power unit?

Many users report challenges such as overheating, fuel system complications, and electrical malfunctions. Regular maintenance and timely inspections can help mitigate these problems, ensuring optimal performance.

How often should maintenance be performed?

It is recommended to conduct routine checks every 3,000 to 5,000 miles, depending on usage. Key areas to focus on include fluid levels, filter conditions, and overall component integrity. Regular upkeep is crucial for preventing larger, costly repairs.