Comprehensive Guide to Gy6 Engine Repair

In the world of compact motorized vehicles, ensuring optimal performance is essential for longevity and efficiency. These systems require careful attention and a foundational knowledge of their components to maintain their functionality. Regular upkeep can prevent minor issues from escalating into major concerns, thereby safeguarding your investment.

Whether you’re a seasoned enthusiast or a newcomer to this realm, grasping the basics of how these units operate can greatly enhance your experience. Familiarity with the various parts and their roles allows for more effective troubleshooting and enhances your confidence in handling maintenance tasks. With the right approach, you can navigate the complexities of small power units with ease.

Embarking on this journey not only empowers you with practical skills but also deepens your appreciation for the mechanics involved. By learning how to properly care for these systems, you contribute to their reliability and performance, ensuring enjoyable rides for years to come.

This section discusses frequent problems encountered in small motorized vehicles. Understanding these challenges can help owners maintain optimal performance and prolong the lifespan of their machinery.

- Overheating: Excessive heat can lead to severe damage, often caused by low coolant levels or a malfunctioning radiator.

- Starting Difficulties: Issues with ignition systems or battery failures can prevent the vehicle from starting efficiently.

- Fuel Leaks: Inadequate seals or damaged lines may result in fuel escaping, posing safety hazards and reducing efficiency.

- Vibration Problems: Imbalanced components or loose parts can create excessive vibrations, impacting overall stability and comfort.

- Exhaust Smoke: Unusual smoke emissions may indicate underlying issues, such as burning oil or fuel inefficiencies.

Addressing these common concerns promptly can help ensure smooth operation and avoid costly repairs in the future.

Essential Tools for Engine Repair

Having the right instruments is crucial for successfully tackling mechanical projects. These items enhance efficiency and ensure precision during the process, making it easier to handle various tasks effectively.

| Tool | Description |

|---|---|

| Wrench Set | A variety of sizes to accommodate different bolts and nuts. |

| Screwdriver Set | Essential for fastening and loosening screws in various components. |

| Torque Wrench | Ensures proper tightness without damaging parts. |

| Socket Set | Allows for quick removal and installation of fasteners. |

| Pliers | Useful for gripping and manipulating wires and small parts. |

Step-by-Step Maintenance Guide

This section outlines essential practices for keeping your scooter in optimal condition. Regular upkeep ensures longevity and peak performance, allowing you to enjoy a smooth ride every time.

Essential Tools and Materials

- Wrench set

- Screwdriver kit

- Oil and oil filter

- Cleaning supplies

- Air filter replacement

Maintenance Steps

- Start with a visual inspection of the vehicle, checking for any signs of wear or damage.

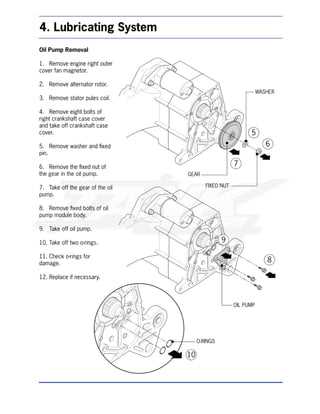

- Change the oil and replace the oil filter to ensure optimal lubrication.

- Inspect and clean the air filter to maintain proper airflow.

- Check tire pressure and tread condition, adjusting as necessary.

- Examine brake pads for wear and replace if needed.

How to Diagnose Engine Problems

Identifying issues within a mechanical system requires a systematic approach. Understanding symptoms and using appropriate techniques can greatly aid in pinpointing the source of malfunction.

Common Symptoms to Look For

- Unusual noises during operation

- Decreased performance or power loss

- Difficulty starting or stalling

- Excessive smoke or strange smells

- Vibration or instability while running

Diagnostic Steps

- Observe and note any abnormal behaviors.

- Check fluid levels and look for leaks.

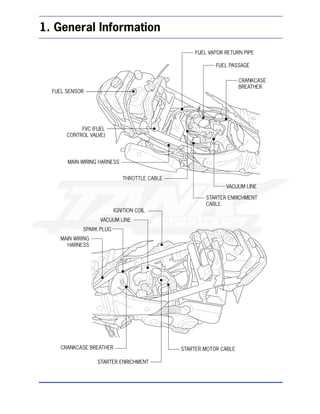

- Inspect electrical connections and wiring.

- Utilize diagnostic tools to retrieve error codes.

- Test individual components for functionality.

Rebuilding the Gy6 Engine Explained

Revamping a small propulsion unit requires a thorough understanding of its components and systems. This process not only enhances performance but also prolongs the lifespan of the machinery. A careful approach ensures that each part is inspected, cleaned, and, if necessary, replaced to achieve optimal functionality.

Essential Tools and Materials

Before diving into the overhaul, gathering the right tools and materials is crucial. Key items include a variety of wrenches, screwdrivers, gaskets, and lubricants. Having a detailed parts list at hand will facilitate a smoother reassembly, minimizing potential issues.

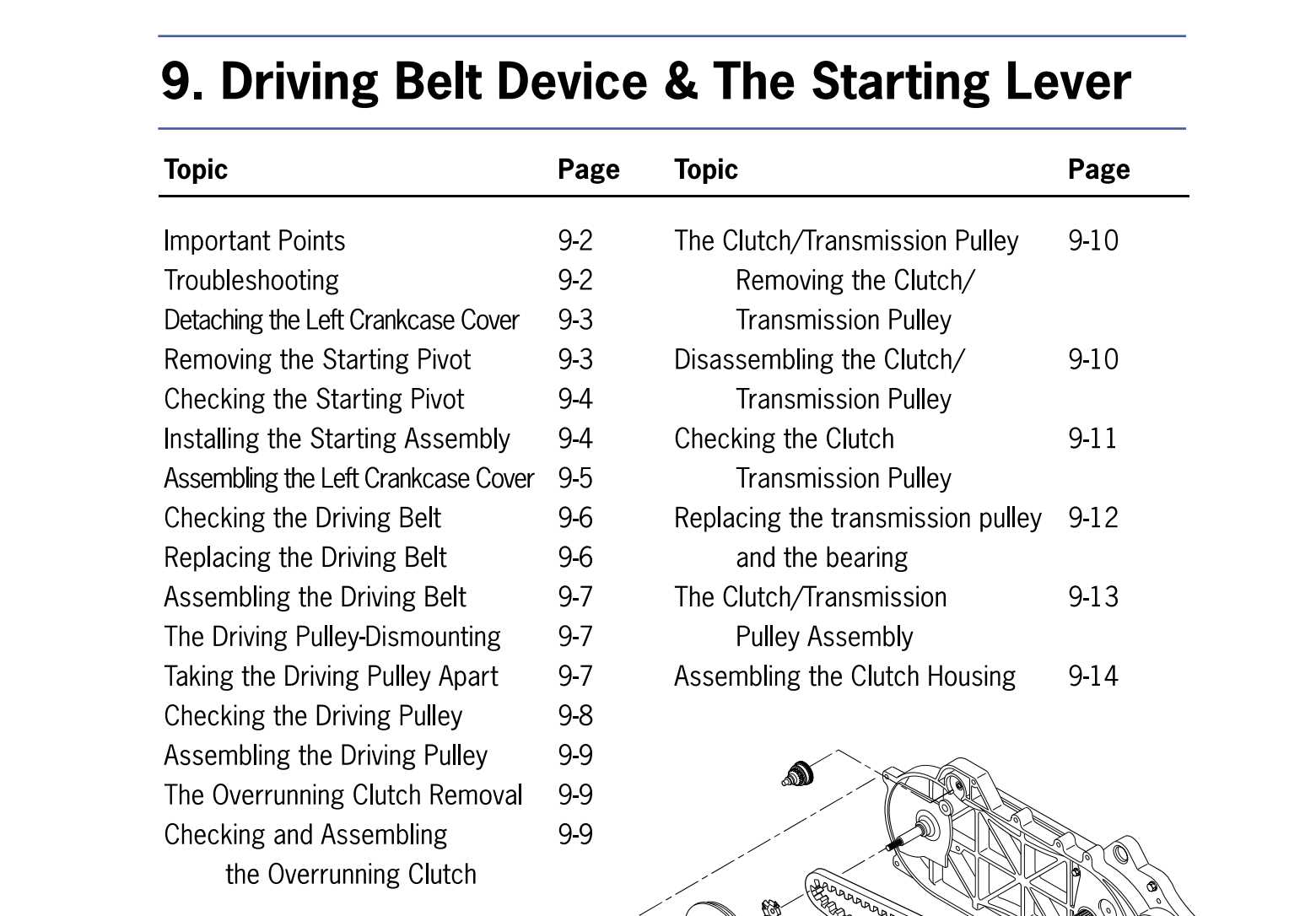

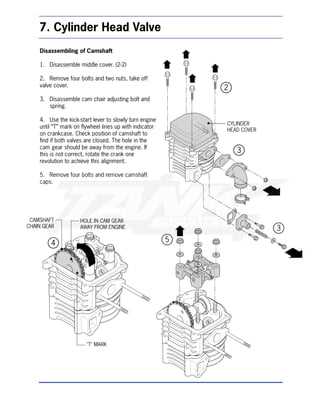

Step-by-Step Process

The rebuilding process involves disassembling the unit methodically. Start by removing outer casings, followed by inspecting internal components for wear or damage. After cleaning all parts, carefully reassemble them, ensuring each piece is properly aligned and secured. Regular checks during this stage help prevent future malfunctions.

In summary, a meticulous approach to revamping small propulsion systems not only enhances their efficiency but also contributes to overall longevity. A well-executed process can lead to significant improvements in performance.

Replacing Engine Components Safely

When undertaking the task of swapping out various parts of a motor, it is crucial to prioritize safety and ensure proper procedures are followed. Understanding the correct techniques can help prevent accidents and damage to the system. This section outlines essential practices for handling component changes with care.

Preparation and Tools

Before beginning, gather all necessary tools and materials. Having everything organized minimizes distractions and enhances efficiency. Always wear appropriate protective gear, such as gloves and goggles, to safeguard against potential hazards.

Step-by-Step Process

Follow a systematic approach to component replacement. Start by disconnecting the power source to avoid unintended activations. Carefully remove the old part, ensuring no debris is left behind that could interfere with the installation of the new one. Once in place, double-check all connections and secure fastenings before reactivating the system.

Tuning Tips for Better Performance

Enhancing the efficiency and power of your two-wheeled vehicle can be achieved through various modifications and adjustments. These tuning techniques focus on optimizing performance, improving acceleration, and maximizing speed without compromising reliability. Implementing these tips can lead to a noticeable difference in your ride’s overall capability.

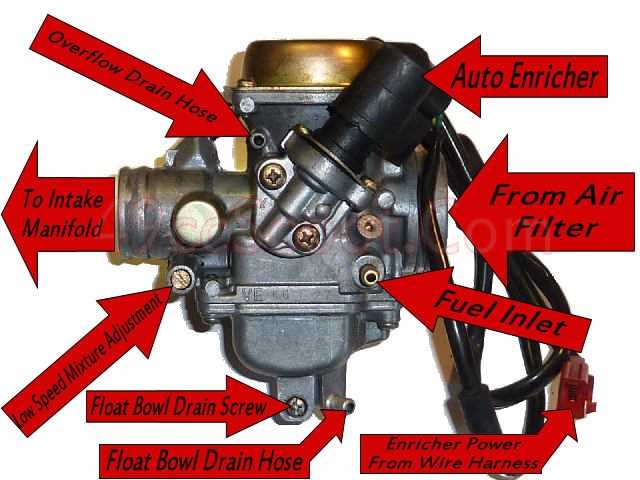

Air Intake Modifications

Improving the airflow into the combustion chamber is crucial for better performance. Upgrading to a high-flow air filter can increase the amount of air entering the system, resulting in a more efficient fuel-air mixture. Additionally, consider adjusting the intake system to reduce any restrictions that may hinder airflow.

Exhaust System Upgrades

Upgrading the exhaust system is another effective way to enhance performance. A performance exhaust can reduce back pressure and improve the expulsion of exhaust gases. This not only increases power but also can enhance the overall sound of your vehicle, giving it a more aggressive tone.

Cleaning the Engine for Longevity

Maintaining the internal components of your vehicle is crucial for its optimal performance and lifespan. Regular cleaning helps to prevent the buildup of debris and contaminants, ensuring smooth operation and reducing the likelihood of future issues.

Importance of Regular Maintenance

Frequent upkeep is essential to keep your machine running efficiently. Here are some benefits:

- Enhances overall performance

- Increases lifespan of components

- Reduces the risk of breakdowns

- Improves fuel efficiency

Steps for Effective Cleaning

Follow these steps for a thorough cleaning process:

- Gather Materials: Collect necessary cleaning supplies such as brushes, detergents, and cloths.

- Remove Covers: Carefully take off any protective coverings to access internal parts.

- Clean Components: Use brushes to scrub surfaces and remove any dirt or grease.

- Rinse and Dry: Rinse off any cleaning agents and dry the components completely before reassembly.

- Reassemble: Replace covers and ensure everything is secured properly.

By following these steps, you can contribute to the longevity of your vehicle’s internal parts, leading to a smoother and more reliable ride.

Safety Precautions During Repairs

Ensuring a secure working environment is essential when performing maintenance on mechanical systems. Adopting appropriate safety measures can prevent accidents and enhance efficiency during the process.

Always wear protective gear, including gloves, goggles, and a mask, to shield against potential hazards such as chemicals and debris. Maintaining a clean workspace is crucial; clutter can lead to mishaps and impede movement.

Before starting any work, disconnect the power source to eliminate the risk of electrical shock. Familiarize yourself with the tools you will be using and ensure they are in good condition. Following the manufacturer’s guidelines and safety recommendations will help mitigate risks effectively.

It’s also advisable to work in a well-ventilated area to avoid inhaling harmful fumes. If you experience any discomfort or uncertainty while working, take a break and reassess the situation. Prioritizing safety will contribute to a smoother and more successful maintenance experience.