LCT Engine Repair Guide for Optimal Performance

The world of small machinery is intricate, filled with various components that require proper attention for optimal performance. Whether you’re a hobbyist or a professional, mastering the nuances of these mechanical systems is crucial. This section delves into the essential practices that ensure longevity and efficiency of these vital machines.

Comprehending the intricacies of these mechanisms is paramount for anyone looking to maintain or enhance their functionality. From troubleshooting common issues to executing routine checks, having a solid foundation of knowledge empowers you to tackle potential challenges with confidence. This guidance is designed to help you navigate the complexities of small machinery care.

Additionally, familiarizing yourself with the specific elements involved will enable you to implement effective solutions and perform necessary adjustments. By understanding the operational principles and typical pitfalls, you can ensure that your equipment remains in peak condition, ready to handle any task at hand.

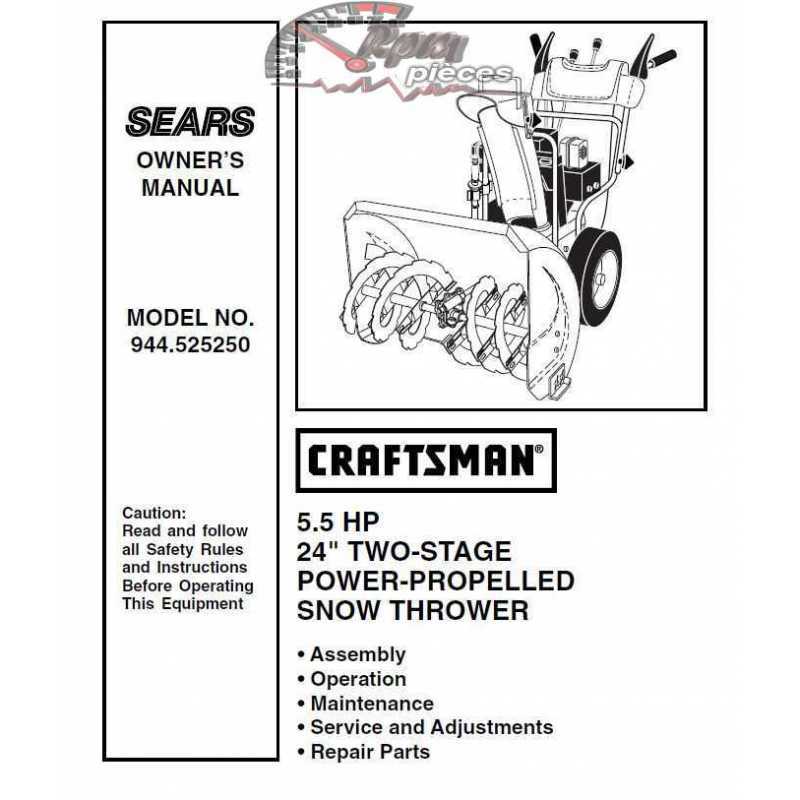

LCT Engine Repair Manual Overview

This section provides a comprehensive guide designed to assist users in maintaining and troubleshooting their machinery. It covers essential aspects to ensure optimal performance and longevity of the units.

Key components included in this guide are:

- Fundamentals of operation

- Common issues and diagnostic procedures

- Step-by-step disassembly and reassembly instructions

- Maintenance schedules and best practices

- Safety precautions to consider during service

Each topic is detailed with clear illustrations and straightforward explanations to enhance understanding, making it accessible even for those with minimal technical background.

In summary, this guide serves as an invaluable resource for both novice users and experienced technicians, empowering them to address challenges effectively and maintain their equipment in peak condition.

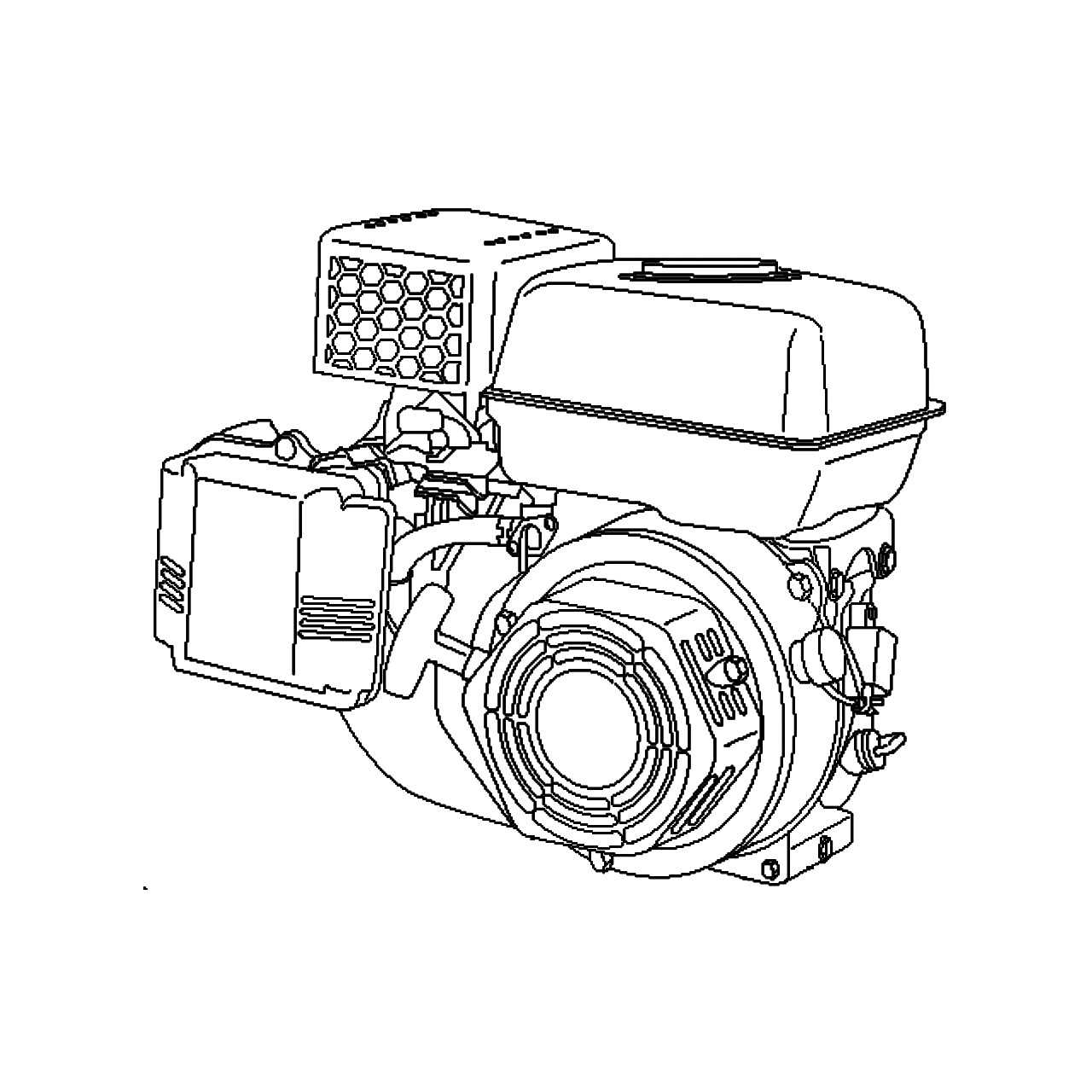

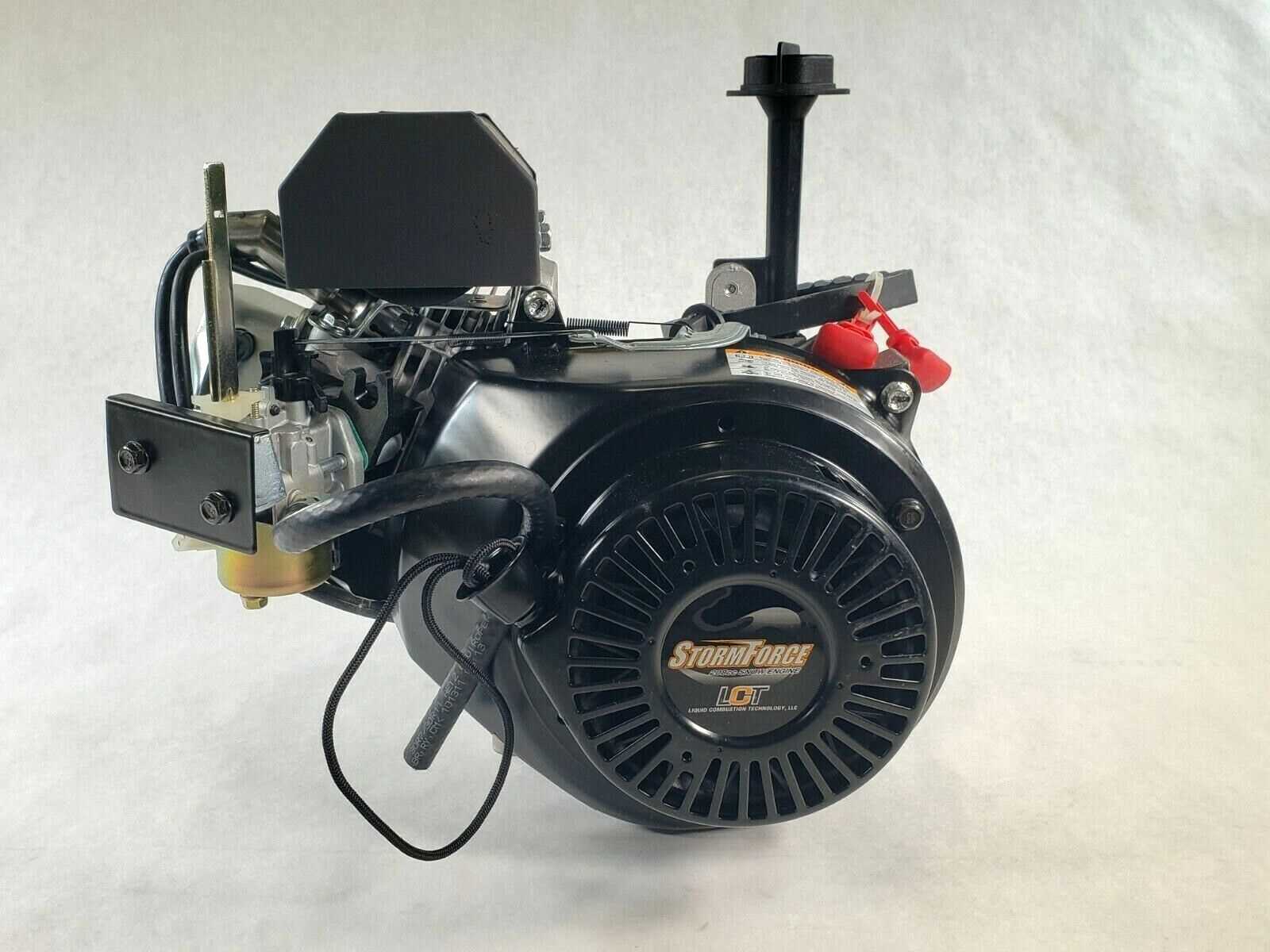

Understanding LCT Engine Components

Gaining insight into the various parts of a power unit is crucial for effective maintenance and functionality. Each element plays a specific role in the overall performance and reliability of the machinery. Familiarity with these components allows operators to troubleshoot issues and enhance the longevity of the equipment.

Main Parts Overview

- Crankshaft: This is a pivotal part that converts linear motion into rotational motion, driving the entire system.

- Piston: This component moves within a cylinder, compressing the mixture for combustion and generating power.

- Cylinder: Houses the piston and is essential for creating the conditions necessary for combustion.

- Valves: Control the intake of air and the expulsion of exhaust gases, ensuring optimal operation.

Additional Components

- Fuel System: Responsible for delivering the necessary fuel for combustion.

- Ignition System: Initiates combustion by generating a spark at the right moment.

- Cooling System: Maintains optimal operating temperatures to prevent overheating and damage.

- Lubrication System: Reduces friction between moving parts, enhancing efficiency and lifespan.

Common Issues with LCT Engines

When dealing with small power units, several frequent complications can arise that may hinder performance and efficiency. Understanding these common problems can help users maintain optimal functionality and extend the lifespan of their machinery.

- Starting Difficulties:

Many users report issues with initiating operation, often linked to fuel delivery or ignition problems.

- Overheating:

Excessive temperatures can result from inadequate cooling or blocked airflow, leading to potential damage if not addressed promptly.

- Unusual Noises:

Strange sounds during operation may indicate internal wear or loose components, which should be investigated immediately.

- Poor Performance:

Decreased power output or efficiency can stem from various factors, including fuel quality or carburetor malfunctions.

- Vibration Issues:

Excessive shaking during operation often suggests misalignment or worn-out parts that need attention.

Addressing these issues promptly not only improves functionality but also enhances the overall longevity of the equipment. Regular maintenance checks can prevent many of these complications from arising in the first place.

Tools Required for Engine Repair

Effective maintenance and troubleshooting require a selection of essential instruments. Having the right gear not only streamlines the process but also ensures safety and precision in every task undertaken.

Below is a list of vital tools that are commonly needed for various maintenance tasks:

- Wrenches: A variety of sizes, including adjustable and socket types, are crucial for loosening and tightening components.

- Screwdrivers: Both flat-head and Phillips types are necessary for handling different fasteners.

- Pliers: Needle-nose and regular pliers help in gripping and manipulating small parts.

- Torque wrench: This ensures that bolts are tightened to the correct specifications, preventing damage.

- Oil filter wrench: Essential for removing and installing oil filters without causing damage.

- Multimeter: Useful for diagnosing electrical issues and measuring voltage, current, and resistance.

In addition to these, consider the following items for more specialized tasks:

- Compression tester

- Fuel pressure gauge

- Timing light

- Feeler gauge

Equipping yourself with these instruments can greatly enhance your ability to conduct thorough assessments and perform necessary adjustments, leading to improved performance and longevity of your machinery.

Step-by-Step Disassembly Process

This section outlines a comprehensive approach to systematically dismantling a mechanical unit. Following a methodical procedure is crucial to ensure that all components are handled carefully, preventing damage and facilitating reassembly. Each step is designed to guide you through the process, making it straightforward and efficient.

Begin by gathering all necessary tools and materials, ensuring everything is within reach. Labeling containers for small parts can save time and avoid confusion later on. Start with the outer casing, carefully removing any screws or fasteners using the appropriate tools. Keep track of each part as it is taken off to maintain organization.

Once the exterior is removed, proceed to the internal components. Take note of how each piece is positioned before disassembly, as this will assist in putting everything back together. Utilize a step-by-step approach to detach each section, starting with larger parts and moving to smaller, more delicate components. If applicable, document the process with photographs for future reference.

As you disassemble, be mindful of any seals, gaskets, or electrical connections that may require special attention. Avoid applying excessive force to prevent bending or breaking parts. If you encounter resistance, reassess the previous steps to ensure no fasteners were overlooked.

Finally, once all components are separated, conduct a thorough inspection. Cleaning parts can also be beneficial, preparing them for reassembly or replacement. This meticulous approach not only aids in understanding the unit’s structure but also contributes to a successful reassembly process.

Inspecting Engine Parts for Damage

Evaluating components for wear and potential issues is a crucial aspect of maintaining optimal performance and longevity. This process involves a thorough examination to identify any signs of deterioration or malfunction that could affect functionality. Regular checks can help prevent more significant problems down the line.

Common Signs of Wear

When assessing various components, watch for the following indicators of damage:

- Cracks: Look for visible fractures or breaks on surfaces.

- Corrosion: Check for rust or oxidation, especially on metallic parts.

- Wear Marks: Observe for unusual abrasions or scoring that may signal excessive friction.

- Deformation: Inspect for any bending or warping that deviates from the original shape.

Inspection Techniques

Utilizing proper techniques can enhance the effectiveness of your evaluation:

- Visual Inspection: Conduct a thorough visual check under good lighting conditions.

- Use of Tools: Employ magnifying glasses or borescopes for detailed views of hard-to-reach areas.

- Measurement: Take precise measurements to identify deviations from standard specifications.

- Functional Testing: Perform operational checks to ensure each component performs as expected.

Regular inspections help maintain peak performance and extend the lifespan of critical parts. Prioritize consistent assessments to safeguard against unexpected failures.

Cleaning and Maintenance Techniques

Regular upkeep and thorough cleansing are essential for optimal performance and longevity of machinery. Implementing effective strategies not only enhances functionality but also prevents costly issues down the line.

Here are some vital techniques to consider:

- Routine Inspection: Frequently check components for wear and tear.

- Debris Removal: Clear away dirt and grime to maintain efficiency.

- Fluid Changes: Regularly replace oils and other fluids to ensure smooth operation.

- Filter Maintenance: Clean or replace filters as needed to enhance air and fluid flow.

- Component Lubrication: Apply appropriate lubricants to minimize friction and wear.

Incorporating these practices into a regular schedule will help preserve the overall functionality and reliability of your machinery.

Reassembly Guidelines for LCT Engines

Reassembling complex machinery requires careful attention to detail and a systematic approach. Properly following guidelines not only ensures optimal performance but also enhances longevity. Here are essential steps to consider during the reassembly process.

- Preparation:

- Gather all necessary tools and components.

- Review the disassembly notes to understand the sequence and orientation of parts.

- Clean all components thoroughly to remove debris and contaminants.

- Inspect Components:

- Check for wear and tear on seals, gaskets, and critical surfaces.

- Replace any damaged or worn-out parts to avoid future issues.

- Lubrication:

- Apply appropriate lubricant to moving parts to ensure smooth operation.

- Use recommended oils and greases for specific components.

- Assembly Sequence:

- Start with the main components, ensuring a secure fit.

- Follow with auxiliary parts, adhering to the original layout.

- Pay close attention to torque specifications for bolts and fasteners.

- Final Checks:

- Double-check all connections and fittings.

- Ensure that no tools or foreign objects are left inside the assembly.

- Test the assembled unit for proper functionality before use.

Adhering to these guidelines will significantly contribute to the successful reassembly of your machinery, leading to improved performance and reliability.

Lubrication Best Practices

Ensuring optimal performance and longevity of mechanical systems requires careful attention to lubrication. Proper application of lubricants not only minimizes wear and tear but also enhances efficiency. This section outlines essential practices to achieve effective lubrication, promoting smoother operation and reducing the risk of damage.

Essential Lubrication Techniques

- Choose the Right Lubricant: Select a lubricant that meets the specifications for the machinery in question. Consider factors such as viscosity, temperature range, and type (synthetic vs. mineral).

- Apply Adequately: Avoid over-lubrication, which can lead to excessive buildup and attract contaminants. Follow manufacturer guidelines for the correct amount.

- Regular Maintenance: Establish a schedule for checking and replenishing lubricants. Frequent inspections can identify potential issues before they escalate.

Common Mistakes to Avoid

- Using Incorrect Lubricants: Always verify compatibility; using the wrong type can lead to system failure.

- Neglecting Contaminant Control: Ensure that the lubrication points are clean to prevent dirt and debris from entering.

- Ignoring Environmental Conditions: Be mindful of operating environments; extreme temperatures or humidity can affect lubricant performance.

Troubleshooting Performance Problems

When facing issues with efficiency and functionality, it is essential to systematically identify and address the underlying causes. Various factors can contribute to subpar operation, ranging from mechanical faults to fuel supply inconsistencies. A thorough examination can help pinpoint the specific area requiring attention.

Begin by assessing the fuel system, as inadequate fuel flow can severely impact performance. Check for blockages in fuel lines and ensure that filters are clean. Additionally, inspect the fuel quality; contaminated fuel can lead to poor combustion and reduced power output.

Next, examine the air intake system. Restricted airflow due to dirty or damaged filters can hinder optimal performance. Regular maintenance of air filters is crucial to ensure efficient airflow and proper mixing with fuel.

Ignition components also play a vital role in overall efficiency. Worn-out spark plugs or faulty ignition coils can lead to misfiring, causing noticeable drops in power. Replacing these components as part of routine upkeep can enhance performance significantly.

Lastly, consider the overall condition of moving parts. Regular lubrication and inspection of bearings and connections can prevent wear and ensure smooth operation. By maintaining each system carefully, one can achieve reliable functionality and enhance the longevity of the unit.

Upgrading LCT Engine Parts

Enhancing the performance of your power unit can lead to significant improvements in efficiency, speed, and overall functionality. By carefully selecting and installing superior components, you can achieve desired results and extend the lifespan of your machinery. This section focuses on various enhancements that can be made to achieve optimal performance.

When considering upgrades, it’s essential to evaluate the compatibility and quality of the parts. Here are some common modifications that can elevate the performance of your system:

| Part | Upgrade Option | Benefits |

|---|---|---|

| Cylinder | High-compression variant | Increased power output |

| Carburetor | Performance carb | Improved fuel efficiency |

| Exhaust | Performance exhaust system | Better airflow and reduced weight |

| Ignition system | High-performance coil | Enhanced spark and throttle response |

| Air filter | High-flow filter | Increased air intake and better filtration |

By investing in these upgrades, you can maximize the potential of your machinery, ensuring it performs at its best under various conditions. Regular assessments and strategic enhancements will contribute to sustained performance and reliability.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for preventing accidents and injuries. Adhering to specific safety measures not only protects the individual but also preserves the integrity of the machinery being serviced.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep a fire extinguisher nearby in case of emergencies.

- Disconnect the power source before starting any work to prevent accidental activation.

- Use proper lifting techniques or equipment to handle heavy components safely.

Work Area Organization

- Maintain a clutter-free workspace to reduce the risk of tripping or accidents.

- Label tools and materials clearly to avoid confusion during the process.

- Store hazardous substances in designated areas, away from work surfaces.

- Have a first aid kit readily accessible in case of minor injuries.

By following these guidelines, individuals can significantly enhance their safety and efficiency during maintenance tasks, ensuring a smoother and more secure working experience.

Resources for Further Learning

Expanding your knowledge in the field of machinery and maintenance can greatly enhance your skills and confidence. Numerous resources are available to help enthusiasts and professionals alike deepen their understanding and refine their techniques. From comprehensive guides to online forums, there are various ways to access valuable information.

Books and Publications

Textbooks focused on mechanical systems provide foundational knowledge, covering principles of operation, troubleshooting methods, and practical applications. Look for titles authored by industry experts to ensure reliable information. Additionally, specialized magazines often feature articles on the latest technologies and best practices, keeping you updated with current trends.

Online Courses and Tutorials

Many platforms offer online courses that cater to different skill levels, ranging from beginner to advanced. These courses often include video lectures, interactive quizzes, and practical exercises. Furthermore, video tutorials on platforms like YouTube can provide step-by-step instructions and visual demonstrations, making complex concepts easier to grasp.