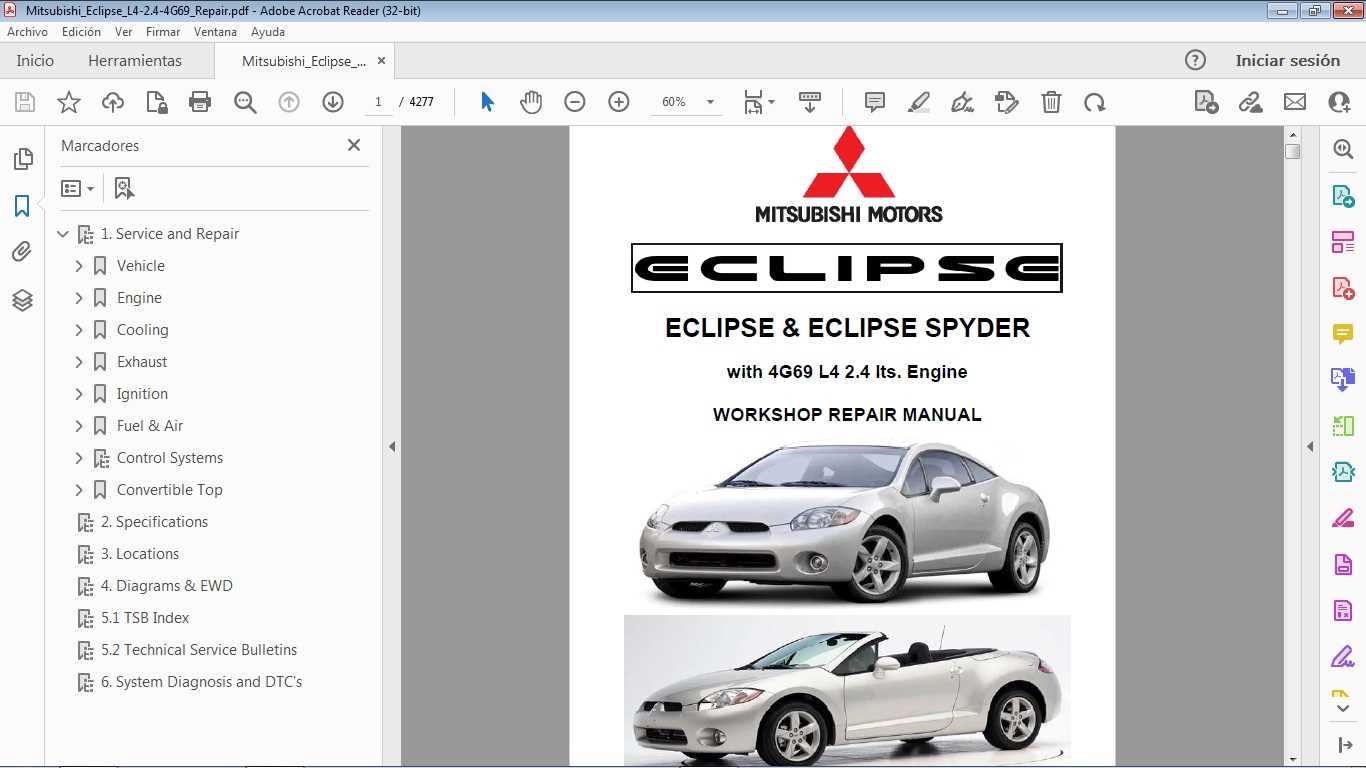

Mitsubishi 4G69 Engine Repair Guide

This section serves as a valuable resource for individuals seeking to enhance their understanding of vehicle performance and upkeep. Focusing on a specific type of power unit, it aims to provide detailed insights and actionable guidance to ensure optimal functionality.

With a thorough examination of common issues and practical solutions, readers will gain knowledge essential for troubleshooting and enhancing the longevity of their automotive systems. By delving into the intricacies of the specified model, this guide will empower users to confidently address various challenges.

Emphasizing the importance of regular care, the information presented will facilitate a deeper connection between owners and their vehicles. This will not only promote efficient operation but also contribute to a safer driving experience.

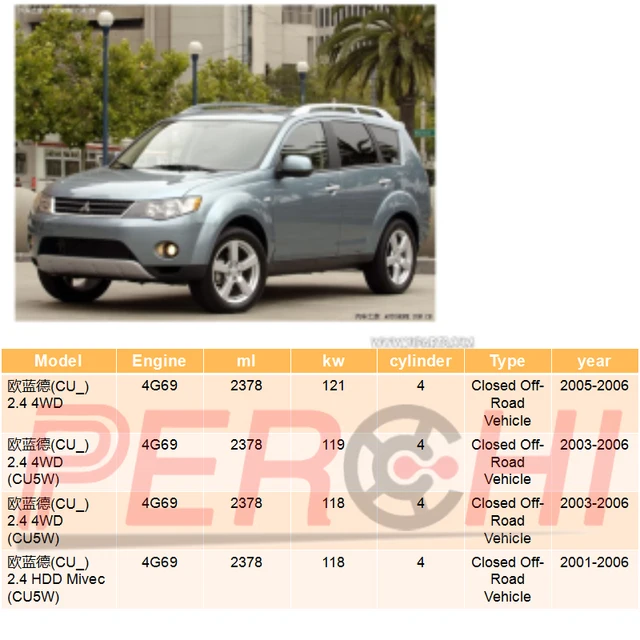

This section will provide a comprehensive overview of a specific automotive power unit, focusing on its key features, functionality, and common applications. Understanding the fundamentals of this component will aid enthusiasts and technicians in recognizing its significance in vehicle performance and maintenance.

Key Specifications and Features

This part will delve into the essential specifications that define the operational capabilities of the power unit, including displacement, horsepower, and torque ratings.

Common Applications in Vehicles

Exploring various vehicles that utilize this power unit, this section will highlight its adaptability and performance across different automotive platforms.

Maintenance Tips for Optimal Performance

Regular upkeep is vital for ensuring efficiency. This section will cover essential maintenance practices to prolong the lifespan of the power unit.

Potential Issues and Solutions

Every component can encounter challenges. Here, we will discuss frequent problems faced and offer practical solutions for resolution.

In conclusion, this overview aims to equip readers with foundational knowledge about the power unit, enhancing their understanding and ability to address related challenges effectively.

Common Issues with the 4G69 Engine

Various challenges may arise with this particular power unit, affecting its performance and reliability. Understanding these common complications can assist in maintaining optimal functionality and enhancing longevity.

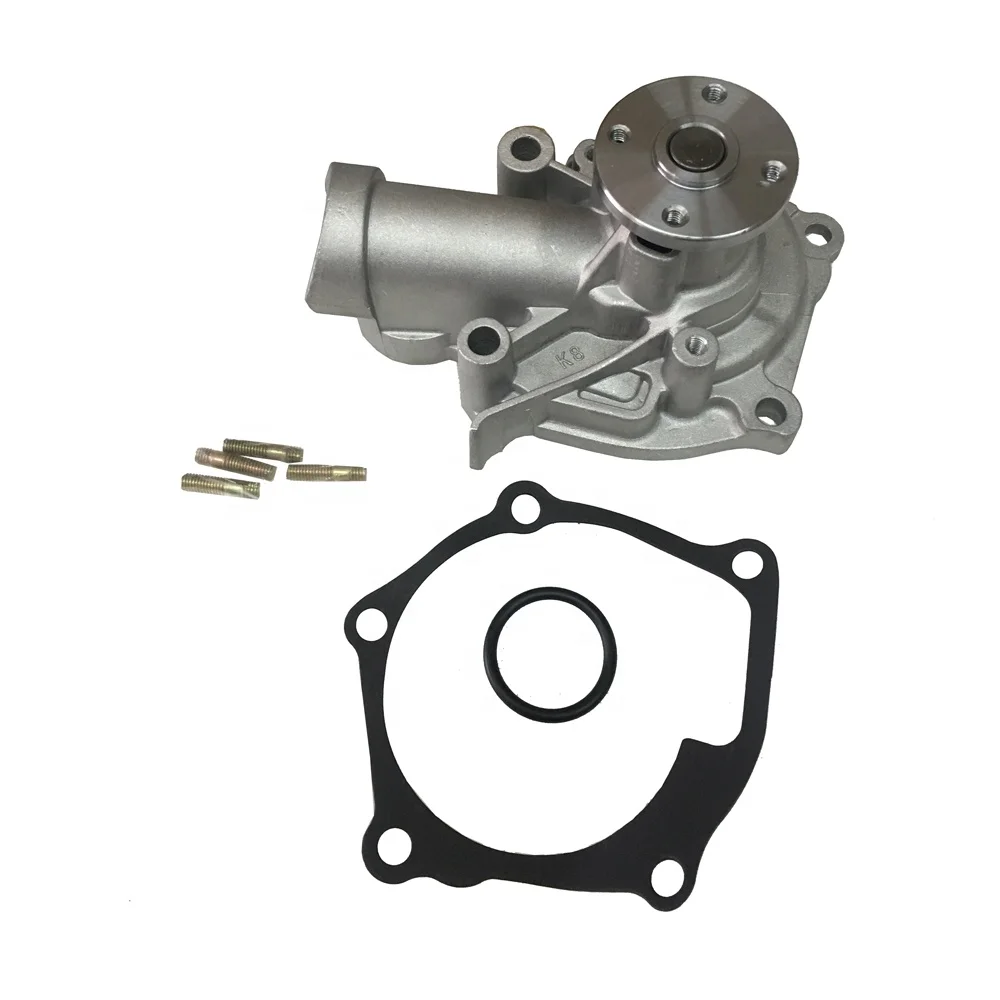

- Overheating: Excessive heat can lead to severe damage if not addressed promptly. It is often caused by a malfunctioning cooling system or insufficient coolant levels.

- Oil Leaks: Seals and gaskets may wear over time, resulting in oil escaping from the system, which can lead to lower lubrication efficiency.

- Loss of Power: A noticeable decrease in power output can indicate issues such as fuel delivery problems or exhaust restrictions.

- Rough Idling: Irregular engine behavior during idle can stem from a variety of factors, including air intake issues or ignition system failures.

- Strange Noises: Unusual sounds, such as knocking or tapping, often signal internal problems that require immediate investigation.

Addressing these issues early can prevent more significant problems down the line and ensure smooth operation.

Essential Tools for Engine Repair

When undertaking maintenance on a vehicle’s powertrain, having the right instruments is crucial for achieving optimal results. A well-equipped toolkit ensures that tasks can be performed efficiently and effectively, minimizing the risk of errors and enhancing the overall experience.

Basic Hand Tools

Among the fundamental items, various hand tools are indispensable. These tools allow for precise adjustments and facilitate the disassembly and assembly of components with ease.

Specialized Equipment

In addition to standard tools, certain specialized instruments may be required for specific tasks. These instruments cater to unique functions and contribute significantly to the successful completion of maintenance projects.

| Tool Type | Purpose |

|---|---|

| Wrenches | Used for loosening or tightening bolts and nuts. |

| Sockets | Provide better grip and leverage for fasteners. |

| Torque Wrench | Ensures that bolts are tightened to specified tension. |

| Oil Filter Wrench | Facilitates the removal of the oil filter. |

| Multimeter | Measures voltage, current, and resistance for electrical diagnostics. |

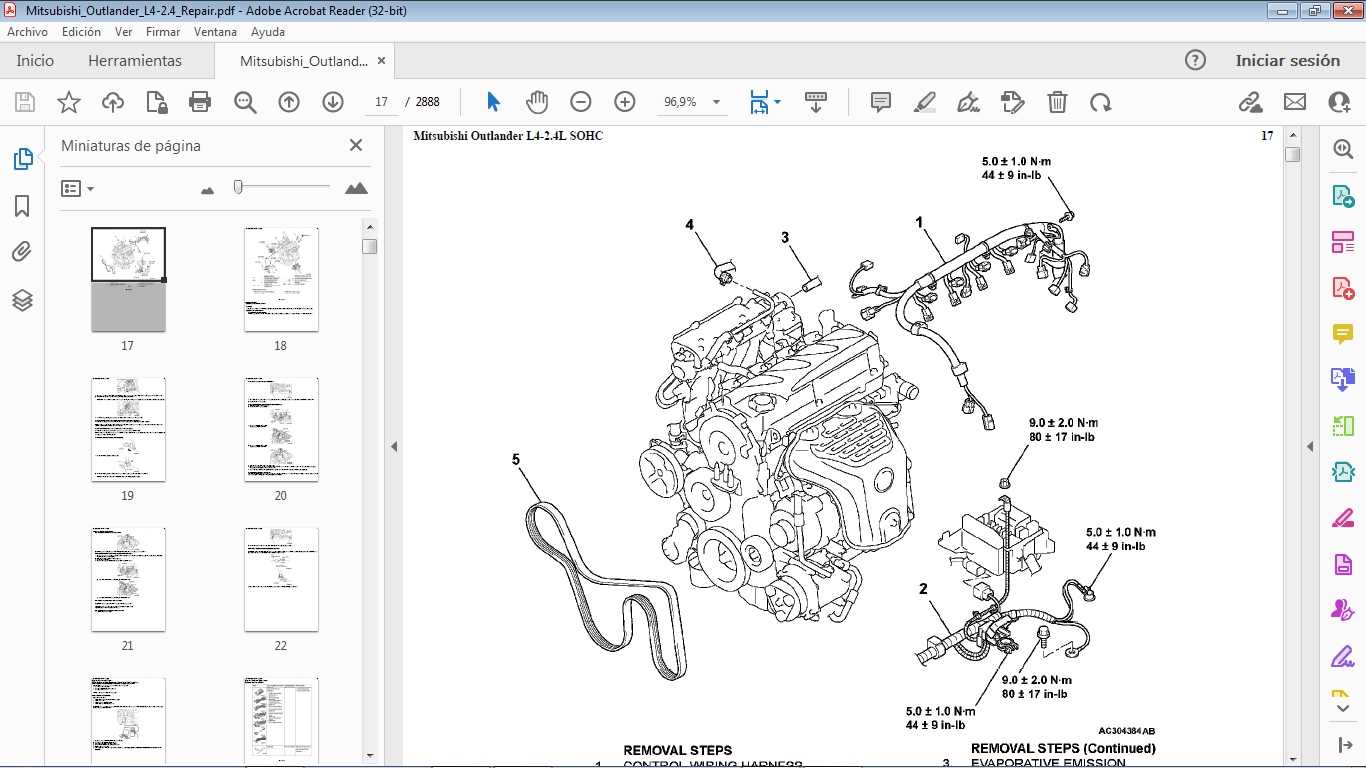

Step-by-Step Disassembly Process

This section provides a detailed overview of the systematic approach needed to dismantle a specific type of power unit. Following a structured disassembly process is essential for ensuring that all components are carefully removed without causing damage. This guide aims to simplify the task by breaking it down into manageable steps, allowing for efficient reassembly later.

Preparation and Safety Measures

Before beginning the disassembly, it is crucial to prepare the workspace and gather the necessary tools. Ensuring a clean and organized environment can prevent mishaps during the process. Additionally, taking safety precautions such as wearing protective gear will safeguard against potential hazards.

Disassembly Steps

The disassembly process can be divided into several key stages, each focusing on different components. Below is a summary of the steps involved:

| Step | Description |

|---|---|

| 1 | Remove any external covers or shields to gain access to internal components. |

| 2 | Detach the intake and exhaust systems, carefully noting their positions for reinstallation. |

| 3 | Unfasten the fasteners holding the main parts in place, using the appropriate tools. |

| 4 | Carefully lift and separate the components, ensuring no parts are left attached. |

| 5 | Inspect the disassembled parts for wear or damage to facilitate effective maintenance. |

Inspecting Engine Components

Thorough examination of various parts is crucial for maintaining optimal performance and longevity of the vehicle’s power unit. By carefully assessing these components, one can identify potential issues that may affect functionality. Regular inspections allow for timely interventions, preventing more severe problems from developing.

Common Parts to Assess

During the inspection, focus on key components such as the pistons, cylinders, and valves. These elements play a significant role in ensuring smooth operation. Look for signs of wear, cracks, or any irregularities that could lead to inefficiency.

Tools and Techniques

Utilizing appropriate tools is essential for accurate assessment. A compression tester and a borescope can provide valuable insights into the condition of internal parts. Ensure to follow safety protocols while performing these checks, as they involve accessing sensitive areas of the vehicle.

Replacing Gaskets and Seals

Properly functioning gaskets and seals are essential for maintaining the integrity of any mechanical assembly. Over time, these components can wear out or become damaged, leading to leaks and performance issues. This section will outline the steps necessary for effectively replacing these crucial elements, ensuring optimal operation and longevity of the machinery.

Before starting the replacement process, it’s important to gather all necessary tools and materials. Ensure that the work area is clean to prevent any contaminants from entering the assembly. Begin by carefully removing the old gaskets and seals, taking note of their positioning for accurate reinstallation. It’s advisable to inspect the surfaces where the gaskets will be placed, making sure they are free from debris and damage.

Once the surfaces are prepared, position the new gaskets and seals correctly, ensuring they align with any guiding features. Apply any recommended sealant if required, and follow the specified torque settings when reassembling the components. Finally, perform a thorough inspection to confirm that everything is installed correctly and securely to avoid future complications.

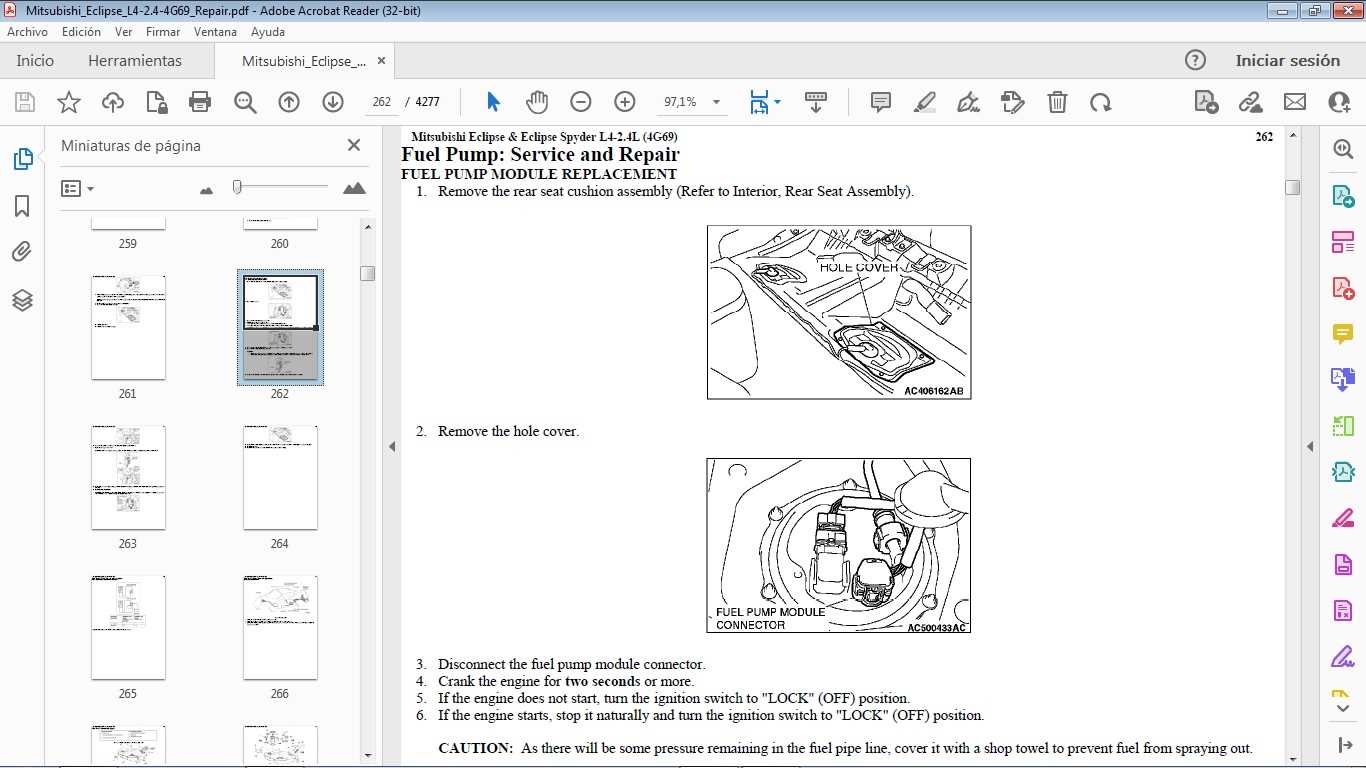

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for ensuring optimal performance and longevity of the vehicle. Regular attention to this critical component can prevent issues such as poor fuel efficiency and rough operation. Here are some effective maintenance strategies to keep the fuel system functioning smoothly.

Regular Fuel Filter Replacement

Changing the fuel filter at recommended intervals helps to maintain clean fuel delivery. A clogged filter can restrict fuel flow, leading to engine performance problems.

- Check the owner’s manual for the recommended replacement schedule.

- Inspect the filter regularly for any signs of damage or wear.

- Ensure the replacement filter matches the specifications of the vehicle.

Keep the Fuel Tank Clean

Maintaining a clean fuel tank is crucial to prevent contaminants from entering the fuel system. Regularly inspecting and cleaning the tank can help avoid potential blockages and failures.

- Monitor fuel levels to avoid running low, which can stir up sediment.

- Use fuel additives that help keep the tank and fuel lines clean.

- Consider periodic professional cleaning if necessary.

Electrical System Diagnostics

This section focuses on the assessment and troubleshooting of electrical components in the vehicle. Understanding the electrical system is essential for ensuring optimal performance and preventing potential issues that may arise from faulty connections or components.

Common Electrical Issues

Electrical problems can manifest in various ways, often resulting in symptoms such as dim lights, unresponsive electronics, or starting difficulties. Identifying the root cause requires a systematic approach, including the examination of wiring, connections, and voltage levels.

Diagnostic Procedures

To effectively diagnose electrical issues, follow these steps:

| Step | Description |

|---|---|

| 1 | Check the battery voltage and condition to ensure it meets the required specifications. |

| 2 | Inspect all fuses and relays for signs of damage or malfunction. |

| 3 | Examine wiring harnesses for wear, corrosion, or loose connections. |

| 4 | Utilize a multimeter to measure voltage at critical points within the system. |

| 5 | Perform continuity tests to ensure there are no breaks in the circuit. |

Reassembly of the Engine

The process of putting the power unit back together requires careful attention to detail and systematic organization. Each component must be positioned accurately to ensure optimal performance and longevity. It is essential to follow a methodical approach to avoid any potential issues during operation.

Start by gathering all necessary parts and tools, ensuring everything is clean and free of debris. Begin with the assembly of the lower section, carefully fitting each piece and applying the appropriate sealing materials. Follow the manufacturer’s specifications for torque settings to prevent any damage.

Next, proceed to the upper assembly, where components like the cylinder head and valve train are installed. Ensure all gaskets are correctly placed to prevent leaks. It’s crucial to check the alignment of parts during this stage to maintain balance and functionality.

After everything is in place, double-check all connections and fittings. A thorough inspection will help identify any potential errors before the final installation. Completing this stage with precision will contribute significantly to the reliability of the power unit.

Testing Engine Performance

Evaluating the functionality of a power unit is crucial for ensuring optimal operation and longevity. This process involves a systematic approach to assess various parameters that influence the overall efficiency and responsiveness of the system. By employing specific diagnostic techniques, one can identify any underlying issues that may hinder performance.

Key aspects of performance testing include analyzing power output, fuel consumption, and emissions levels. Utilizing specialized instruments allows for precise measurements that can reveal discrepancies from expected values. Regular assessment not only helps in maintaining peak functionality but also aids in preemptive identification of potential faults.

Moreover, conducting performance tests in controlled environments can provide valuable insights into how the system behaves under different conditions. This information is vital for making informed decisions regarding maintenance and adjustments needed for enhanced efficiency. Ultimately, thorough testing ensures reliability and helps to prolong the lifespan of the unit.

Regular Maintenance Practices

Routine upkeep is essential for ensuring the longevity and optimal performance of your vehicle’s components. Adhering to a consistent maintenance schedule can prevent potential issues and enhance efficiency. This section outlines key practices that can help maintain the overall health of the machinery.

Essential Tasks for Longevity

Regularly scheduled inspections and servicing can make a significant difference in performance. Here are some crucial tasks to incorporate into your maintenance routine:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace old oil with fresh lubricant to ensure smooth operation. |

| Filter Replacement | Every 10,000 miles | Change air and fuel filters to prevent contaminants from entering the system. |

| Fluid Levels Check | Monthly | Inspect and replenish essential fluids such as coolant and brake fluid. |

Signs of Potential Issues

Being aware of warning signs can help identify problems early. Look out for the following indicators:

- Unusual noises during operation.

- Decreased power or responsiveness.

- Fluid leaks underneath the vehicle.

Resources for Further Assistance

When tackling complex mechanical issues, having access to reliable resources can significantly enhance your troubleshooting and maintenance efforts. Various tools, guides, and community support systems are available to assist you in resolving challenges effectively and efficiently.

Online Forums and Communities

Joining online platforms dedicated to automotive discussions can be immensely beneficial. These communities provide a wealth of shared experiences, tips, and solutions from fellow enthusiasts and professionals alike.

Technical Support Services

For more specialized inquiries, consider reaching out to technical support services. These experts can offer tailored guidance based on your specific needs, ensuring that you receive accurate and reliable information.

| Resource Type | Description | Website/Contact |

|---|---|---|

| Online Forums | Platforms for discussion and advice from fellow users. | www.auto-forum.com |

| Technical Support | Expert assistance for detailed inquiries. | www.techsupport.com |

| DIY Guides | Step-by-step instructions for common tasks. | www.diyauto.com |