Complete Guide to Repairing Briggs and Stratton Engines

Maintaining the longevity and performance of your machinery is essential for optimal functionality. This section delves into the intricacies of upkeep and troubleshooting for small power units, ensuring they operate efficiently. Understanding the essential components and their roles can significantly enhance the user experience.

Detailed insights into common issues faced by these power sources will empower you with the knowledge needed to address potential challenges. Whether it’s routine checks or tackling unexpected malfunctions, being equipped with the right information is crucial for any operator.

In this guide, we will explore various aspects of upkeep, from identifying signs of wear to implementing effective solutions. With a focus on practical techniques and insightful tips, you’ll gain the confidence to handle your machinery with ease.

Understanding Briggs & Stratton Engines

When it comes to small power units, a certain brand stands out due to its reliability and performance. These power sources are widely utilized in various applications, from lawn care to industrial equipment, making them a crucial component in the toolkit of many professionals and DIY enthusiasts alike.

The design and functionality of these motors are engineered to provide optimal efficiency and durability. Recognizing the key features and specifications can help users maximize their experience and ensure longevity.

| Feature | Description |

|---|---|

| Power Output | Typically ranges from 3 to 25 horsepower, catering to different needs. |

| Fuel Type | Usually operates on gasoline, though some models may support alternative fuels. |

| Cooling System | Air-cooled designs are common, promoting efficient temperature management during operation. |

| Starting Mechanism | Most units feature recoil starters, with some advanced models offering electric start options. |

| Maintenance | Regular upkeep includes oil changes, air filter replacements, and spark plug checks. |

Understanding these characteristics empowers users to choose the right power unit for their specific tasks while ensuring proper usage and care for optimal performance.

Common Engine Types Overview

Understanding the various categories of power units is essential for anyone looking to maintain or enhance the performance of their machinery. Each type of motor is designed with specific features that cater to different applications, resulting in a diverse array of choices for users.

Two-Stroke Engines: These units are known for their simplicity and lightweight design. They complete a power cycle in just two strokes of the piston, making them ideal for portable equipment. However, they may consume more fuel and produce higher emissions compared to their four-stroke counterparts.

Four-Stroke Engines: Characterized by their efficiency and lower emissions, these systems require four strokes of the piston to complete a cycle. They are commonly found in lawn mowers, generators, and various other machinery, offering a balance between power and fuel economy.

Rotary Engines: Also known as Wankel engines, these unique systems utilize a triangular rotor that moves in an eccentric pattern. They are valued for their compact design and smooth operation, often seen in specialized applications such as sports cars and small aircraft.

Diesel Engines: Renowned for their durability and fuel efficiency, these power units operate on compression ignition. They are widely used in heavy machinery, commercial vehicles, and marine applications, delivering robust performance under demanding conditions.

Electric Motors: With the rise of sustainable technology, electric power units are gaining popularity. They provide quiet operation and zero emissions, making them an excellent choice for indoor applications and environmentally conscious users.

Each type of power unit has its own set of advantages and drawbacks, and selecting the right one depends on the specific requirements of the task at hand. Familiarity with these common types can significantly enhance decision-making when it comes to equipment selection and maintenance.

Essential Tools for Engine Repair

Having the right instruments at your disposal is crucial for successfully addressing mechanical issues. Properly selected tools not only enhance efficiency but also ensure safety while working on complex systems. A well-equipped toolkit can make the difference between a straightforward task and a frustrating challenge.

1. Socket Set: A comprehensive socket set is fundamental for loosening and tightening various fasteners. It allows for a wide range of sizes, making it versatile for different components.

2. Wrench Set: Both open-end and box-end wrenches are essential for accessing tight spaces. They provide the leverage needed to handle stubborn bolts.

3. Screwdriver Set: A diverse selection of screwdrivers, including flathead and Phillips, is necessary for removing and securing screws. Ergonomic designs can improve comfort during extended use.

4. Pliers: A good pair of pliers can grasp, twist, and cut various materials. Needle-nose pliers are especially helpful for reaching into confined areas.

5. Torque Wrench: Ensuring that bolts are tightened to the correct specifications is vital. A torque wrench helps achieve the necessary tension without over-tightening.

6. Multimeter: For diagnosing electrical issues, a multimeter is invaluable. It allows for accurate measurement of voltage, current, and resistance.

7. Oil Drain Pan: Keeping the workspace clean is important. An oil drain pan collects fluids during maintenance, preventing spills and ensuring proper disposal.

8. Work Light: Adequate lighting is essential for precision. A bright, portable work light helps illuminate dark areas, making tasks easier and safer.

Equipping yourself with these tools will facilitate efficient handling of various challenges, leading to more successful outcomes in your mechanical endeavors.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a systematic approach can help you maintain its efficiency and prevent unexpected issues.

-

Gather Necessary Tools and Supplies:

- Wrench set

- Screwdrivers

- Oil and filter

- Fuel stabilizer

- Cleaning brushes

-

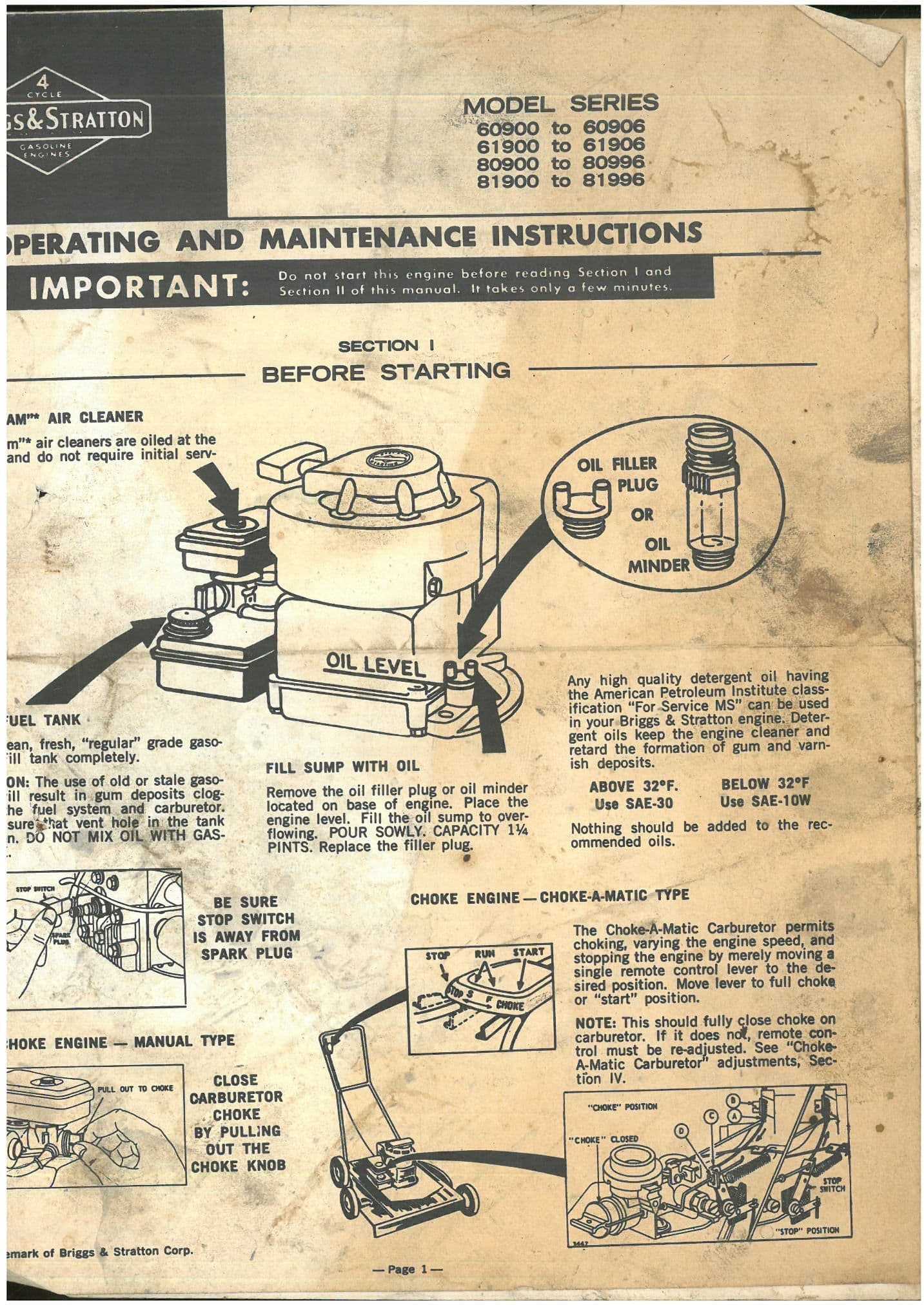

Check and Change Oil:

- Warm up the unit slightly to help the oil flow.

- Drain old oil into a suitable container.

- Replace with fresh oil according to specifications.

-

Inspect and Replace Air Filter:

- Remove the air filter cover.

- Inspect the filter for dirt and damage.

- Replace if necessary or clean if it is reusable.

-

Examine Fuel System:

- Check fuel levels and quality.

- Replace old fuel with fresh fuel if needed.

- Inspect fuel lines for leaks or wear.

-

Sharpen Blades (if applicable):

- Remove the blades carefully.

- Use a sharpening tool to restore edges.

- Reinstall blades securely.

-

Clean External Components:

- Remove debris from the exterior.

- Use a brush or compressed air for hard-to-reach areas.

- Ensure all vents are clear of obstructions.

By adhering to these procedures, you can significantly enhance the functionality and lifespan of your equipment, ensuring it runs smoothly for years to come.

Troubleshooting Common Engine Issues

Identifying and addressing frequent complications in small machinery can significantly enhance performance and longevity. Understanding the symptoms and potential causes allows users to take informed actions, ensuring smoother operation and minimizing downtime.

Common Symptoms and Their Causes

- Engine Won’t Start:

- Insufficient fuel supply

- Defective spark plug

- Blocked air filter

- Rough Running:

- Dirty carburetor

- Incorrect fuel mixture

- Worn ignition components

- Overheating:

- Poor ventilation

- Low oil levels

- Clogged cooling fins

Steps to Diagnose Issues

- Check fuel levels and quality.

- Inspect the ignition system for wear or damage.

- Examine the air intake and exhaust systems for blockages.

- Assess oil levels and condition.

- Run a visual check for loose or damaged components.

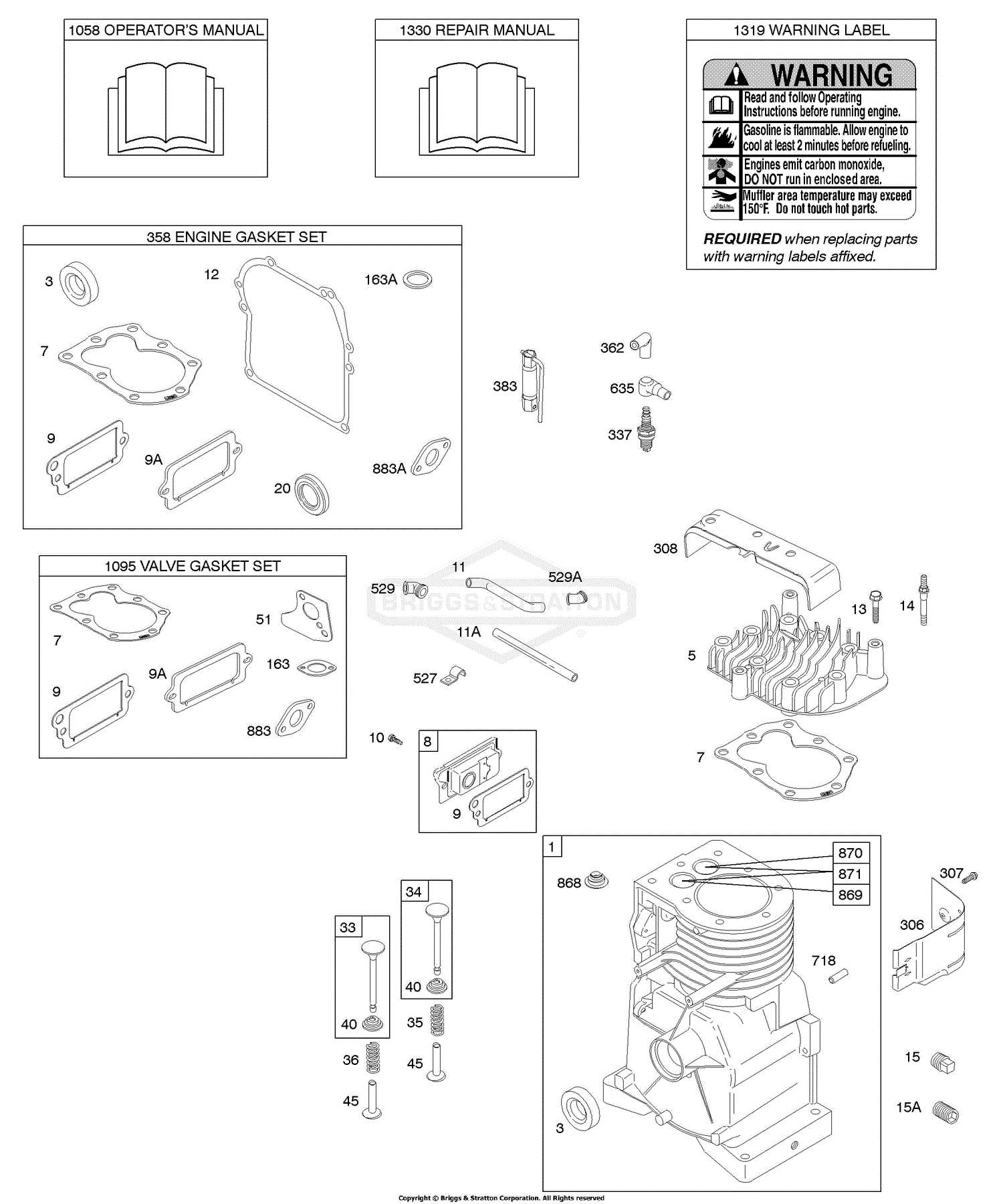

Replacing Engine Components Effectively

Efficiently swapping out parts within a power unit is essential for maintaining optimal performance and longevity. This process requires careful attention to detail and a systematic approach to ensure each component is fitted correctly. Understanding the essential steps and best practices will streamline this task and enhance the overall functionality of the machinery.

Before initiating the component exchange, it’s crucial to gather all necessary tools and materials. Having everything at hand minimizes downtime and allows for a more fluid workflow. Here’s a brief overview of the key elements involved in the replacement process:

| Step | Description |

|---|---|

| Assessment | Evaluate the condition of the components to determine which need replacement. |

| Preparation | Gather tools, new parts, and any required safety equipment before starting. |

| Disassembly | Carefully take apart the unit to access the components that require replacement. |

| Installation | Place the new parts in position, ensuring proper alignment and fit. |

| Testing | Run the unit to confirm that the new components are functioning as intended. |

Adhering to these steps will not only simplify the process but also help in achieving the desired outcomes. Proper care during each stage ensures that the machinery operates efficiently and reliably in the long term.

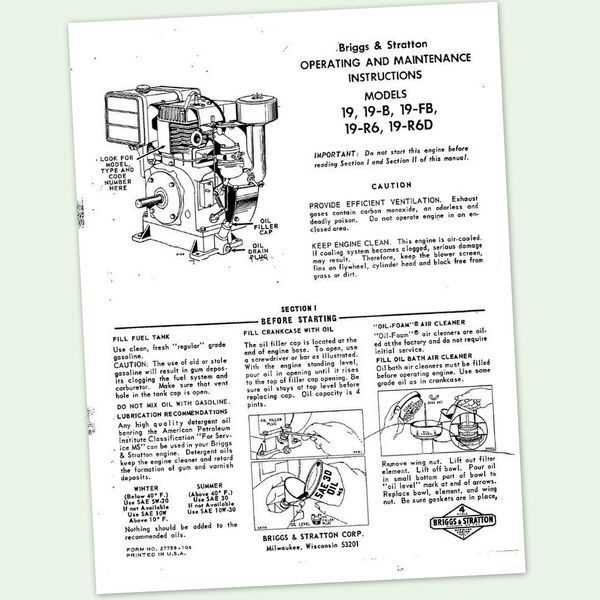

Oil Change: Best Practices Explained

Regular maintenance of your power unit’s lubrication system is essential for optimal performance and longevity. Changing the lubricant at appropriate intervals ensures that the internal components are protected from wear and tear, while also promoting efficient operation. This section highlights effective strategies for executing this critical task, ensuring that you maintain the health of your machinery.

Preparation and Tools

Before starting the process, gather all necessary tools and materials. You’ll need a suitable lubricant, an oil pan for collection, a funnel, and a wrench for the drain plug. Ensuring that you have everything on hand will streamline the process and minimize downtime. Always consult the specifications to select the right type and amount of lubricant for your unit.

Step-by-Step Procedure

Begin by warming up the unit for a few minutes to help the lubricant flow more easily. Once warmed, turn off the power and allow it to cool slightly. Position the oil pan beneath the drain plug and carefully remove the plug to let the old lubricant drain completely. After draining, replace the drain plug securely. Then, using a funnel, pour the new lubricant into the designated fill hole, ensuring not to overfill. Finally, run the unit for a short period to circulate the new lubricant, checking for any leaks around the drain plug.

Cleaning Carburetors: A Complete Guide

Maintaining optimal performance in small combustion units often hinges on the cleanliness of their fuel delivery components. Ensuring that the fuel system operates smoothly not only enhances efficiency but also extends the life of the unit. This guide will provide step-by-step instructions on effectively cleaning these essential parts.

Before starting the cleaning process, gather the necessary tools and materials. A clean workspace is crucial, as it helps avoid contamination during maintenance. Below is a list of required items:

| Tools | Purpose |

|---|---|

| Socket Wrench | To remove the carburetor from the unit |

| Screwdriver Set | For unscrewing components |

| Cleaning Solution | To dissolve built-up deposits |

| Soft Brush | To gently scrub surfaces |

| Compressed Air | To blow out debris from small passages |

| Safety Gear | To protect eyes and skin during cleaning |

Start by safely disconnecting the power source and removing the fuel line. Once the carburetor is detached, disassemble its components carefully, taking note of the order to ensure proper reassembly. Soaking parts in a suitable cleaning solution will help break down stubborn grime. After soaking, use the soft brush to remove any remaining residue.

Attention to detail is vital when cleaning small passages. Utilize compressed air to clear any blockages, ensuring that fuel can flow freely once reassembled. After cleaning, reassemble the carburetor in the reverse order of disassembly, making sure all connections are secure.

Regular maintenance of fuel delivery components can prevent performance issues and costly repairs. By following this guide, you can keep your small equipment running efficiently for years to come.

Recognizing Signs of Engine Wear

Identifying the symptoms of deterioration in mechanical systems is crucial for maintaining optimal performance. Various indicators can signal that components are experiencing excessive wear and may require attention. Early detection can prevent more significant issues and extend the lifespan of the machinery.

Common Indicators

There are several key signs to monitor that may indicate wear and tear. Understanding these can help in assessing the condition of the components and deciding on necessary actions.

| Indicator | Description |

|---|---|

| Excessive Smoke | Visible smoke during operation may suggest that seals or gaskets are compromised, leading to oil leakage. |

| Noisy Operation | Unusual sounds, such as knocking or grinding, can indicate that parts are not functioning smoothly. |

| Decreased Power | A noticeable reduction in output may signify internal friction or other performance issues. |

| Vibration | Increased vibration levels may be a result of unbalanced components or failing parts. |

Maintenance Tips

Regular inspections and maintenance can mitigate the risks associated with wear. Keeping an eye on the aforementioned indicators will aid in making informed decisions regarding necessary interventions. Addressing minor issues promptly can help maintain functionality and efficiency.

Safety Precautions During Repairs

Ensuring safety while working on machinery is of utmost importance. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. This section outlines essential measures to follow, promoting a secure environment during maintenance tasks.

Wear Appropriate Personal Protective Equipment (PPE): Always don safety glasses, gloves, and sturdy footwear. This gear protects against potential hazards such as flying debris and sharp components.

Work in a Well-Ventilated Area: Proper airflow minimizes the accumulation of harmful fumes and ensures a healthier workspace. If working with fuel or chemicals, ensure adequate ventilation to avoid inhalation of toxic substances.

Disconnect Power Sources: Before starting any task, disconnect the power supply to prevent unexpected starts. This precaution is crucial when handling electrical components or working near moving parts.

Use Tools Safely and Properly: Familiarize yourself with the correct usage of all tools. Using the right tool for the job not only enhances efficiency but also minimizes the risk of accidents.

Keep the Workspace Organized: A tidy environment reduces the likelihood of tripping hazards and misplaced tools. Ensure that all items are stored properly after use, contributing to a safer work area.

Be Aware of Surroundings: Always stay alert to your surroundings. Be mindful of others in the vicinity and communicate effectively to avoid distractions or misunderstandings during tasks.

Follow Manufacturer Guidelines: Adhering to specific instructions provided by the manufacturer can prevent mishaps. Understanding the equipment’s features and limitations is key to maintaining safety.

By observing these precautions, individuals can foster a secure atmosphere, enabling efficient and safe execution of maintenance duties.

Finding Genuine Replacement Parts

Ensuring optimal performance of your machinery requires the use of authentic components. Sourcing these items can significantly affect the longevity and functionality of your equipment. It’s essential to prioritize quality and compatibility when searching for parts, as counterfeit alternatives may lead to premature failures or safety hazards.

To locate original components, start by identifying the model number and specifications of your device. This information can often be found on the unit itself or in accompanying documentation. Once you have the necessary details, explore authorized dealers or reputable online retailers that specialize in selling genuine parts.

Additionally, consider joining forums or communities dedicated to equipment maintenance. These platforms often provide valuable insights and recommendations from experienced users who can guide you towards trustworthy sources. By investing time in finding authentic components, you not only protect your machinery but also enhance its overall efficiency and reliability.

Tips for Long-Term Engine Care

Maintaining optimal performance over time requires consistent attention and proper strategies. By following a few essential practices, you can ensure longevity and efficiency, allowing your machinery to serve you well for years to come.

Here are some key recommendations to keep your power source running smoothly:

| Tip | Description |

|---|---|

| Regular Oil Changes | Frequent oil replacements help reduce wear and tear, ensuring internal components remain lubricated. |

| Clean Air Filter | A clean air filter prevents dirt and debris from entering, promoting better combustion and efficiency. |

| Fuel Quality | Using high-quality fuel can prevent deposits and maintain optimal performance. |

| Check Spark Plug | Regular inspections and replacements of the spark plug help maintain ignition efficiency. |

| Monitor Cooling System | Ensuring the cooling system is functioning properly prevents overheating and extends lifespan. |

By adhering to these simple yet effective guidelines, you can significantly enhance the durability and functionality of your machinery. Consistency is key to achieving the best results.