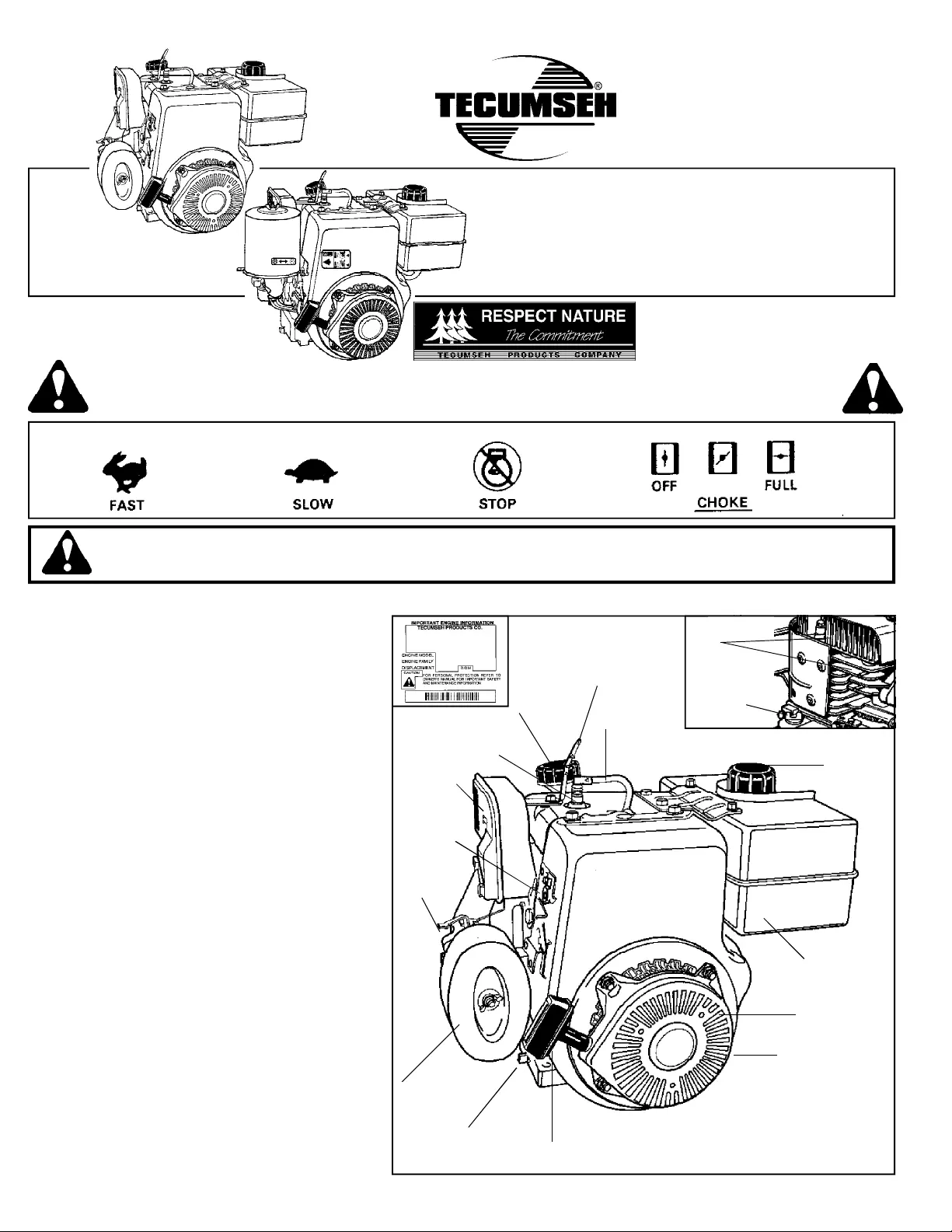

Tecumseh Small Engine Repair Guide

Maintaining and troubleshooting mechanical units is essential for ensuring optimal performance and longevity. This section provides valuable insights into various techniques and best practices for enhancing the functionality of compact power sources commonly used in outdoor equipment.

Understanding the fundamental components and their roles is crucial for effective management. This resource outlines key procedures that can assist in diagnosing issues, performing routine maintenance, and implementing corrective measures, thereby empowering users to tackle common challenges.

With the right knowledge and tools, individuals can enhance the efficiency of their machinery, reducing downtime and increasing reliability. By following the guidance presented here, users can confidently address potential problems and achieve a higher level of operational excellence.

This section will explore the fundamental concepts related to compact power sources commonly used in various outdoor equipment. Understanding these essentials is crucial for anyone looking to enhance their knowledge of these mechanisms and ensure their longevity.

Compact power units are designed for a wide range of applications, from lawn maintenance to snow removal. Each component plays a significant role in the overall functionality. By familiarizing oneself with the parts and their interactions, users can better maintain and troubleshoot issues that may arise.

Key Components:

- Fuel System: Essential for providing the necessary energy.

- Ignition System: Responsible for initiating combustion.

- Lubrication System: Ensures smooth operation and reduces wear.

- Cooling System: Prevents overheating during operation.

By understanding these vital elements, users can develop a comprehensive approach to maintaining their compact power sources effectively.

Common Engine Issues and Solutions

Maintaining a power unit can often present challenges that affect its performance and reliability. Understanding these prevalent problems and their remedies is essential for ensuring smooth operation. Below are some frequent complications encountered and effective strategies to address them.

Difficulty Starting

One of the most widespread issues is trouble initiating the unit. This may stem from various factors, including fuel delivery problems, battery issues, or spark plug malfunctions. To resolve this: ensure the fuel is fresh and properly mixed, check the battery for charge, and inspect the spark plug for wear or corrosion.

Overheating

Overheating can lead to severe damage if not addressed promptly. Common causes include blocked cooling fins, insufficient oil levels, or a malfunctioning cooling system. To combat overheating: regularly clean the cooling fins, maintain proper oil levels, and verify that the cooling components are functioning correctly.

Essential Tools for Repairs

When tackling maintenance tasks on compact power units, having the right equipment is crucial for achieving effective outcomes. A well-equipped toolkit not only streamlines the process but also ensures safety and precision during the work.

Start with basic hand tools, including wrenches and screwdrivers, which are fundamental for loosening and tightening various components. A quality socket set can enhance efficiency, allowing for quicker access to fasteners in tight spaces. Additionally, pliers and cutters are invaluable for manipulating wires and other materials.

Investing in diagnostic tools, such as multimeters and compression testers, provides insight into the operational status of the unit. These devices help identify issues that may not be immediately visible, ensuring a thorough approach to troubleshooting.

Finally, safety gear should not be overlooked. Gloves, goggles, and ear protection are essential to safeguard against potential hazards during maintenance activities. With these tools at your disposal, you’ll be well-prepared to undertake various tasks with confidence and competence.

Understanding Engine Components

The intricate workings of power units hinge on various integral parts that collaborate seamlessly to generate motion and energy. Grasping the roles of these components is essential for effective diagnostics and maintenance. Each segment contributes to the overall functionality, ensuring that the system operates smoothly and efficiently.

Core Parts encompass the vital elements that facilitate combustion and energy transformation. These include the chamber where the mixture ignites, the apparatus that compresses the mixture, and the system that expels exhaust. Understanding these functions allows for better troubleshooting and optimization of performance.

Fuel Delivery Systems play a crucial role in ensuring that the correct mixture reaches the combustion chamber. This involves a series of pumps, filters, and pathways that manage the flow of fuel, directly affecting efficiency and responsiveness. Proper maintenance of these systems can prevent significant operational issues.

Ignition Mechanisms are pivotal for initiating the combustion process. They encompass various devices that generate the necessary spark at the precise moment, influencing both power output and operational reliability. Recognizing the types and functions of these mechanisms aids in maintaining optimal performance.

In summary, a comprehensive understanding of these fundamental components is vital for anyone involved in the upkeep of mechanical systems. Knowledge of how each part operates and interacts contributes significantly to longevity and efficiency.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your power apparatus. Regular upkeep not only enhances efficiency but also minimizes the risk of unexpected failures.

Essential Tools Required

Before commencing maintenance tasks, gather the following instruments:

- Wrench set

- Screwdriver assortment

- Oil filter wrench

- Fuel stabilizer

- Clean rags

Maintenance Procedures

Follow these structured steps for effective upkeep:

| Task | Description | Frequency |

|---|---|---|

| Change Oil | Replace old lubricant to prevent wear. | Every 25 hours of use |

| Check Air Filter | Inspect and clean or replace as needed. | Every 50 hours of use |

| Inspect Spark Plug | Examine for corrosion; replace if damaged. | Every 100 hours of use |

| Fuel System Maintenance | Clean fuel lines and ensure proper fuel quality. | At the start of each season |

Diagnosing Performance Problems

Identifying issues that affect operational efficiency is crucial for maintaining optimal functionality. A thorough assessment can help pinpoint the source of the problem, ensuring timely resolutions and enhanced performance.

Common symptoms that may indicate underlying issues include:

- Unusual noises during operation

- Inconsistent power output

- Difficulty starting or frequent stalling

- Excessive vibration

- Visible leaks or fluid loss

To effectively diagnose these challenges, consider the following steps:

- Visual Inspection: Examine all accessible components for signs of wear, damage, or loose connections.

- Test Performance: Observe the unit’s operation under various loads to identify specific failure points.

- Check Fuel System: Ensure fuel quality and flow are adequate, looking for blockages or contamination.

- Examine Air Intake: Verify that air filters are clean and unobstructed to promote efficient combustion.

- Inspect Electrical Components: Test wiring and connections for faults that may disrupt power delivery.

Following these guidelines can lead to a more precise understanding of performance issues, facilitating effective solutions.

Fuel System Troubleshooting Techniques

Diagnosing issues within the fuel system is essential for optimal performance and longevity. A systematic approach can help identify common problems that hinder functionality. Understanding the various components and their roles is the first step in resolving these concerns.

Identifying Common Symptoms

Before delving into specific techniques, it’s vital to recognize the signs of fuel-related issues. Some prevalent indicators include:

- Difficulty starting the unit

- Irregular or inconsistent operation

- Reduced power output

- Unusual noises during operation

Step-by-Step Troubleshooting

Utilize the following steps to effectively troubleshoot fuel system problems:

- Inspect Fuel Quality: Ensure that the fuel is fresh and free from contaminants. Old or degraded fuel can lead to performance issues.

- Check Fuel Lines: Examine hoses for cracks, leaks, or blockages that may impede fuel flow.

- Examine the Filter: A clogged filter can restrict fuel supply. Replace it if necessary.

- Assess the Carburetor: Clean or rebuild the carburetor to eliminate any obstructions affecting fuel delivery.

- Verify Fuel Pump Functionality: Ensure that the pump is operating correctly and delivering fuel at the required pressure.

Electrical System Repairs Explained

The functionality of any machinery heavily relies on its electrical components. Understanding the various aspects of these systems is crucial for effective maintenance and troubleshooting. This section delves into common issues, diagnostic approaches, and essential techniques to ensure optimal performance.

Regular inspections of wiring and connections can prevent unexpected malfunctions. Check for signs of wear, corrosion, or loose fittings that might compromise the system’s integrity. A comprehensive approach includes testing voltage levels and continuity to pinpoint faulty components.

When addressing power supply concerns, it’s vital to understand the role of batteries and charging systems. Ensuring proper voltage output and examining the condition of terminals can significantly enhance reliability. Replacing outdated or damaged parts can restore functionality and prolong the lifespan of the equipment.

Lastly, familiarity with ignition systems is essential. Problems in this area often lead to starting difficulties. Diagnosing issues related to spark plugs, coils, and safety switches can clarify whether repairs or replacements are necessary to maintain seamless operation.

Replacing Engine Parts Safely

Ensuring safety while replacing components is essential for effective maintenance and longevity of your machinery. Proper preparation, understanding of the parts involved, and adherence to guidelines can significantly reduce risks during the process.

Before beginning, gather the necessary tools and personal protective equipment to shield yourself from potential hazards. Always disconnect power sources to prevent accidental starts and secure the workspace to avoid distractions. Familiarize yourself with the specifications and requirements for each part you plan to replace.

During the replacement process, handle components carefully, ensuring you follow the manufacturer’s instructions for installation. Double-check connections and secure fasteners appropriately to maintain operational integrity. Finally, conduct a thorough inspection after reassembly to confirm that everything functions correctly and safely.

Safety Precautions During Repairs

When undertaking maintenance on machinery, ensuring personal safety is paramount. This section outlines essential guidelines to help individuals minimize risks while performing tasks on mechanical devices.

Proper preparation and awareness of hazards can significantly reduce the likelihood of accidents. Always utilize the appropriate safety gear and tools, and familiarize yourself with the machinery before proceeding.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use safety goggles, gloves, and sturdy footwear to protect against potential injuries. |

| Ensure Proper Ventilation | Work in a well-ventilated area to avoid inhaling harmful fumes or gases. |

| Disconnect Power Sources | Always disconnect electrical supplies before starting any work to prevent accidental activation. |

| Keep Workspace Organized | A tidy workspace reduces clutter, minimizing the risk of slips and falls. |

| Read Manuals and Instructions | Consult relevant documentation to understand specific procedures and safety measures. |

By adhering to these precautions, individuals can work more confidently and effectively, reducing the potential for harm while enhancing the overall maintenance experience.

Seasonal Maintenance Checklist

Proper upkeep of your outdoor machinery is essential for optimal performance and longevity. A seasonal maintenance checklist serves as a valuable guide to ensure that each component is functioning correctly and efficiently. Regular evaluations can prevent minor issues from escalating into significant problems, ultimately saving time and costs.

Spring Preparation

As the warmer months approach, it is crucial to inspect various elements to prepare for the active season:

- Fuel System: Check for any stale fuel and replace it with fresh gasoline to avoid starting difficulties.

- Air Filter: Clean or replace the air filter to ensure proper airflow and enhance performance.

- Belts and Cables: Examine for wear and tear; replace any frayed or damaged components to prevent malfunction.

Fall Readiness

Before the cold weather sets in, completing a few key tasks will protect your equipment:

- Oil Change: Change the oil to remove contaminants and maintain the internal components in good condition.

- Battery Maintenance: Disconnect the battery and store it in a cool, dry place to extend its lifespan.

- Storage Preparation: Clean the exterior and cover the machinery to safeguard it from harsh elements during downtime.

Tips for Preventing Engine Failures

Maintaining optimal performance and longevity of a power unit requires attention to various factors that can lead to operational issues. By implementing a few simple practices, one can significantly reduce the risk of breakdowns and ensure smooth functionality.

- Regular Maintenance: Schedule periodic check-ups to identify potential problems before they escalate.

- Check Fluid Levels: Ensure that all fluids, including oil and coolant, are at appropriate levels to avoid overheating and excessive wear.

- Clean Air Filter: Replace or clean the air filter regularly to maintain proper airflow and efficiency.

- Inspect Fuel Quality: Use fresh fuel and store it correctly to prevent degradation and contamination.

- Monitor Spark Plug Condition: Regularly check and replace spark plugs as needed to ensure reliable ignition and performance.

- Avoid Overloading: Do not exceed the recommended capacity of the unit to prevent undue stress on components.

By adhering to these preventive measures, users can enhance the reliability and lifespan of their machinery, minimizing the likelihood of unexpected failures.

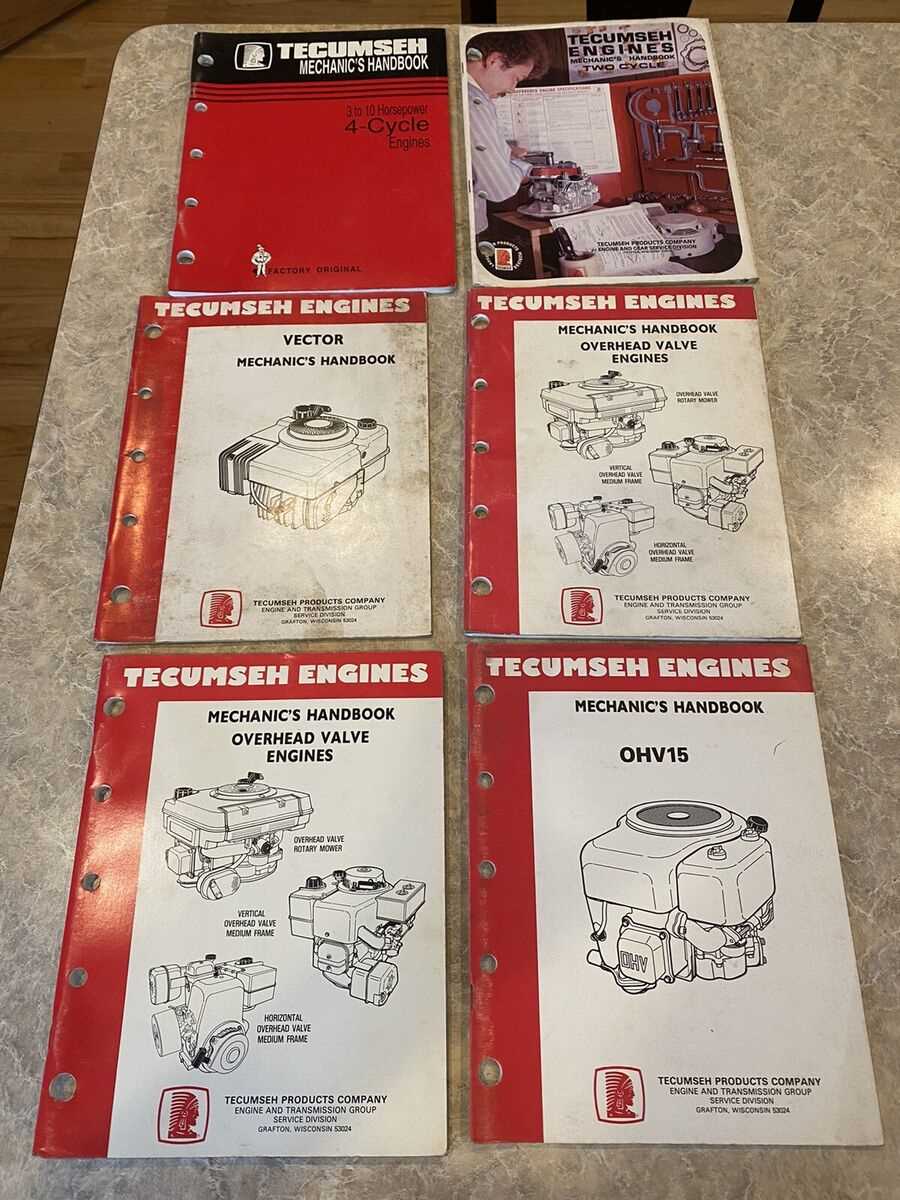

Resources for Further Learning

Enhancing your knowledge and skills in maintenance and troubleshooting can significantly improve your proficiency in handling various mechanical devices. Numerous resources are available that cater to both beginners and experienced enthusiasts, providing insights, tips, and practical advice for effective practices.

Online Platforms

Websites dedicated to mechanics often offer instructional videos, articles, and forums where users can exchange experiences. YouTube is an excellent source for visual learners, showcasing detailed tutorials on a wide range of topics. Additionally, specialized forums and communities foster discussions and provide solutions to common challenges.

Books and Publications

Investing in literature related to mechanical systems can deepen your understanding. Look for comprehensive guides that cover essential techniques and best practices. Many manuals focus on specific models or types, ensuring you have access to targeted information that can enhance your skills.