Guide to Repairing Volvo Truck Engines

The efficient operation of heavy-duty vehicles relies heavily on their complex powertrain systems. Understanding the intricacies of these mechanisms is essential for ensuring optimal performance and longevity. This section aims to provide comprehensive insights into the maintenance and troubleshooting processes that are crucial for enhancing the reliability of such vehicles.

Effective upkeep involves recognizing potential issues before they escalate into significant problems. Familiarity with the various components and their functions will empower operators and technicians alike to carry out necessary interventions. By following structured procedures and utilizing appropriate tools, one can achieve the desired outcomes in performance and safety.

Whether you’re a seasoned professional or a newcomer to vehicle maintenance, having access to reliable information is invaluable. This section will delve into practical advice and techniques that facilitate efficient servicing, ensuring that your heavy-duty vehicle continues to operate at its best.

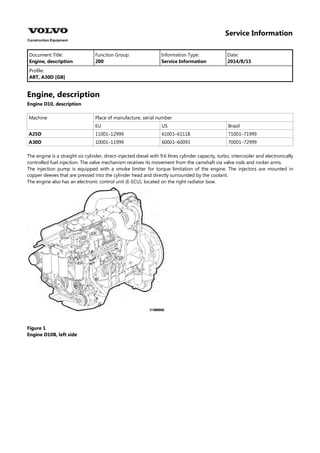

Overview of Volvo Truck Engines

This section provides an insight into the power units utilized in heavy-duty vehicles, highlighting their essential features and characteristics.

These power systems are designed to deliver robust performance and efficiency. They come in various configurations, tailored to meet diverse operational demands. Here are some key aspects:

- Performance: Engine units are engineered for high torque and horsepower, suitable for transporting heavy loads.

- Fuel Efficiency: Advanced technology enhances combustion processes, resulting in lower fuel consumption.

- Durability: Constructed with high-quality materials to withstand harsh conditions and prolonged usage.

- Emissions Control: Equipped with systems that comply with environmental regulations, minimizing harmful outputs.

Understanding these systems is crucial for ensuring optimal functionality and longevity. Regular assessments and appropriate maintenance strategies are essential for sustaining their performance over time.

Common Engine Issues and Solutions

This section addresses frequent problems encountered in power units, along with practical solutions. Understanding these issues can help in maintaining optimal performance and prolonging the lifespan of the machinery.

Overheating Problems

One of the most common challenges is excessive temperature rise, which can lead to severe damage if not addressed promptly. This issue often stems from coolant leaks, malfunctioning thermostats, or blocked radiators.

Starting Difficulties

Another frequent concern is trouble starting the machinery. This can be attributed to battery failures, fuel system obstructions, or electrical malfunctions. Regular checks and maintenance can prevent such occurrences.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Overheating | Coolant leaks, thermostat failure, blocked radiator | Inspect and repair leaks, replace thermostat, clean radiator |

| Starting Difficulties | Battery issues, fuel obstructions, electrical faults | Test battery, clear fuel lines, check wiring |

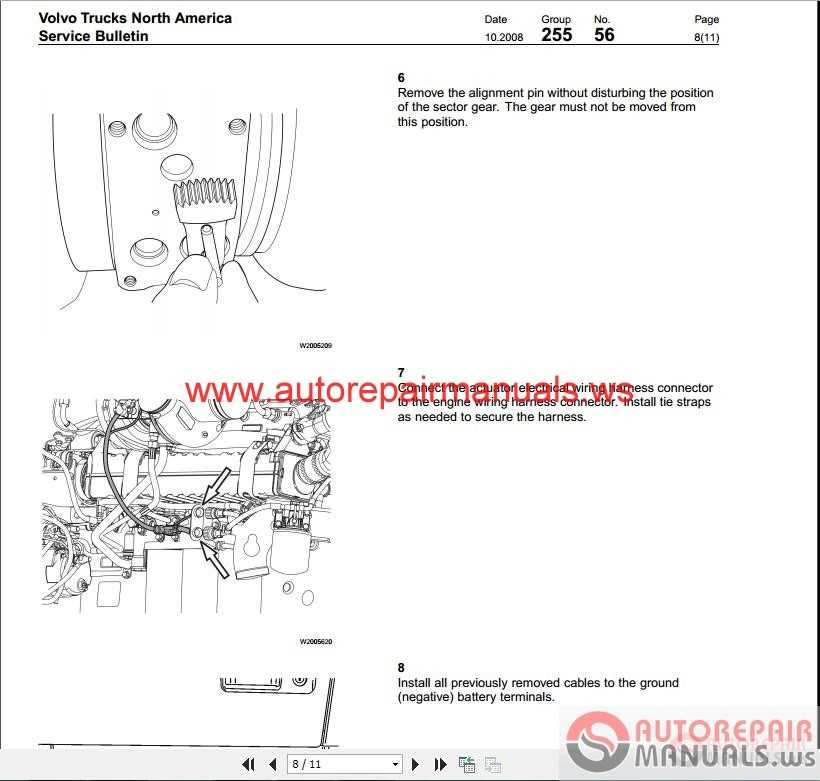

Steps for Engine Disassembly

Disassembling a complex power unit involves a series of methodical steps to ensure that each component is carefully removed and documented. This process requires meticulous attention to detail to avoid damage and ensure efficient reassembly.

Preparation and Safety Measures

Before beginning the disassembly, ensure the workspace is clean and organized. Gather all necessary tools and safety equipment, including gloves and goggles. Disconnect the power source to prevent accidental activation during the process.

Sequential Disassembly Steps

Follow these steps to systematically disassemble the unit:

| Step | Description |

|---|---|

| 1 | Remove external components such as covers and belts. |

| 2 | Disconnect any fluid lines and electrical connections. |

| 3 | Loosen and remove fasteners securing major assemblies. |

| 4 | Carefully lift out larger sections, taking care to support them adequately. |

| 5 | Continue removing smaller components in a logical order. |

Key Tools for Engine Repair

When addressing the complexities of automotive power units, having the right instruments is essential for effective maintenance and service. This section will outline crucial implements that facilitate diagnostics and modifications, ensuring optimal performance.

Essential Instruments

- Socket Set: A comprehensive set of sockets is vital for loosening and tightening various fasteners.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specified torque, preventing damage.

- Diagnostic Scanner: Useful for identifying issues through error codes and real-time data.

- Compression Gauge: Allows for the assessment of the internal pressure within cylinders, indicating their condition.

- Oil Filter Wrench: Aids in the removal of oil filters, making oil changes more manageable.

Additional Helpful Tools

- Multimeter: Essential for testing electrical components and diagnosing electrical issues.

- Pliers and Screwdrivers: Various types of pliers and screwdrivers are fundamental for various tasks, from removing clips to adjusting components.

- Shop Manual: Although not a tool in the traditional sense, having a detailed guide aids in understanding specific procedures and specifications.

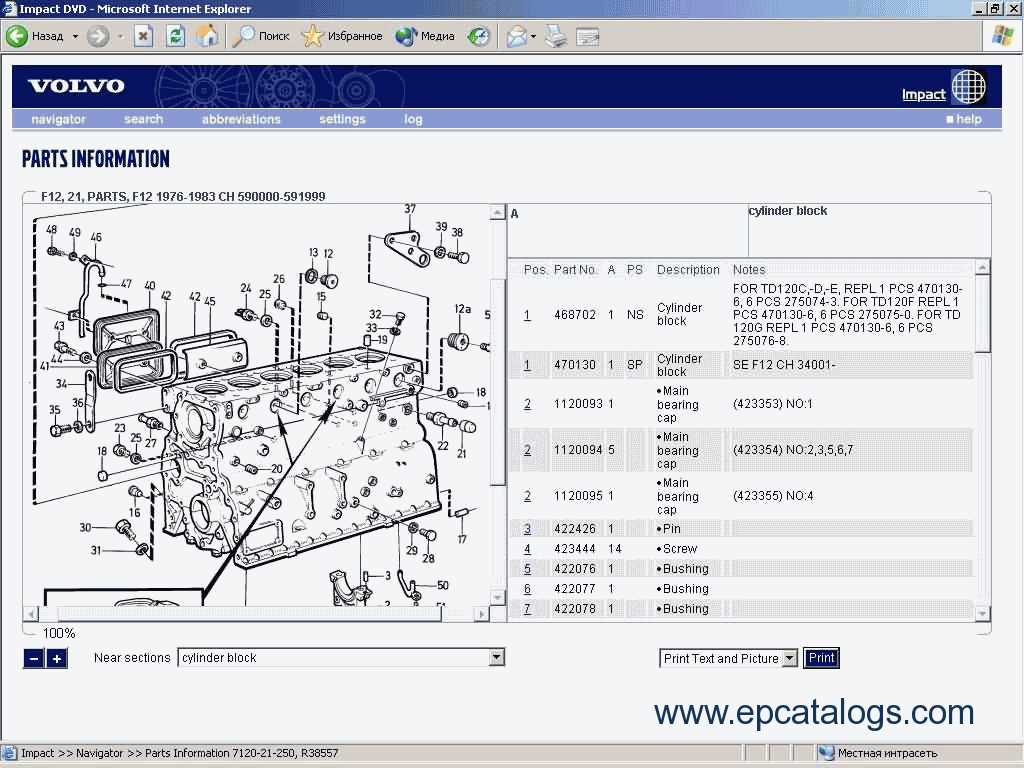

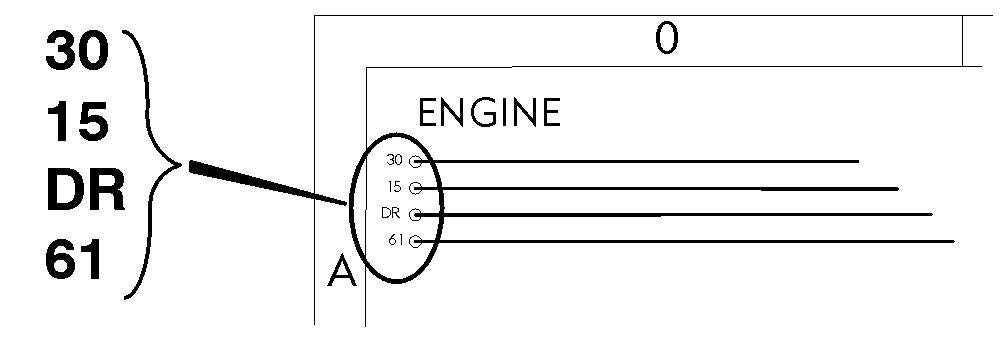

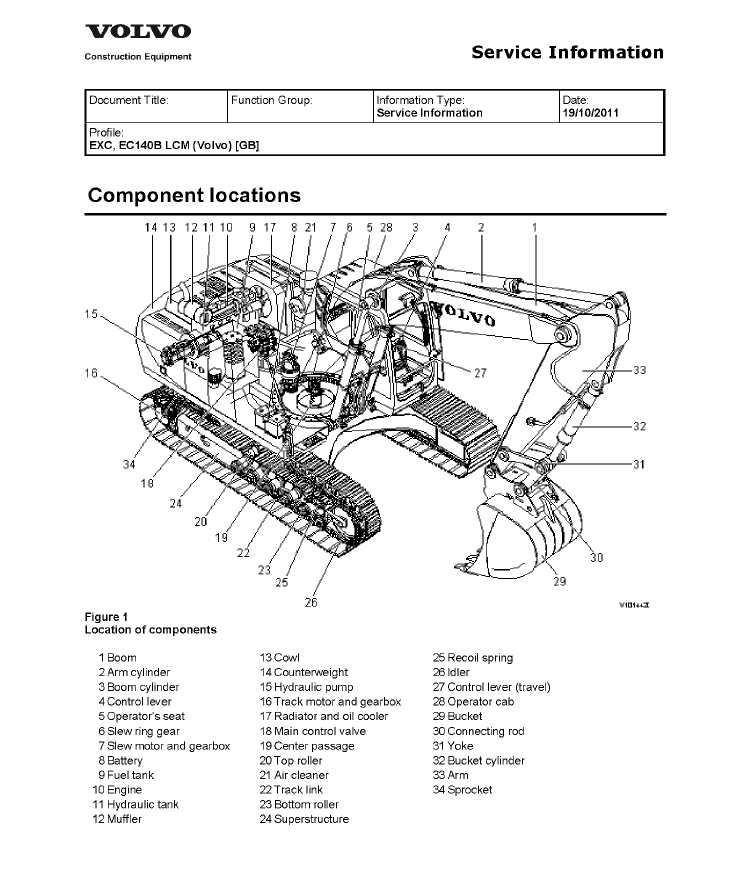

Understanding Engine Components

Comprehending the essential parts of a power unit is crucial for effective maintenance and performance optimization. Each component plays a specific role in the overall function, contributing to the unit’s efficiency and longevity.

The core parts include those responsible for combustion, energy conversion, and mechanical movements. Their interaction is vital, as a malfunction in any single part can lead to diminished performance or failure of the entire system.

Among the primary elements are the fuel delivery system, which ensures the correct mixture of fuel and air, and the cooling system, vital for maintaining optimal operating temperatures. Additionally, the ignition assembly is essential for initiating the combustion process, while the lubrication system reduces friction and wear on moving parts.

Regular inspections and understanding the role of each component can prevent potential issues and enhance the lifespan of the entire assembly. Familiarity with these parts empowers operators to make informed decisions regarding upkeep and troubleshooting.

Safety Precautions During Repairs

Ensuring a secure environment is paramount when performing maintenance tasks. Taking necessary precautions can prevent accidents and enhance the efficiency of the work process. Understanding potential hazards and implementing safety measures can significantly reduce the risk of injury.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This includes safety goggles, gloves, and steel-toed boots. These items protect against flying debris, chemical exposure, and heavy objects. Additionally, wearing durable clothing that covers the arms and legs is advisable to minimize skin exposure to hazardous materials.

Work Environment Safety

Maintaining a clean and organized workspace contributes to safety. Clutter can lead to slips and falls, while tools left unattended may cause injuries. Ensure proper ventilation when dealing with chemicals and always have a first aid kit accessible. Following these guidelines fosters a safer atmosphere for everyone involved in the maintenance activities.

Reassembly Techniques for Optimal Performance

Effective reassembly processes are crucial for ensuring the longevity and efficiency of complex machinery. Proper techniques not only enhance performance but also minimize the risk of future issues. This section will explore various methods and best practices that contribute to successful reassembly, emphasizing the importance of precision and attention to detail.

Precision Alignment

Achieving accurate alignment during reassembly is essential for optimal functionality. Components must fit together seamlessly to avoid unnecessary wear and tear. Using alignment tools can greatly assist in positioning parts correctly, ensuring that all elements work harmoniously. Regular checks throughout the assembly process help maintain this precision, preventing potential malfunctions.

Proper Lubrication

Applying the right lubricants at appropriate points is vital for reducing friction and promoting smooth operation. Different components may require specific types of lubricants, and understanding these requirements can significantly impact overall performance. Consistent lubrication not only protects parts but also enhances their durability, leading to improved efficiency in the long run.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged performance of any heavy machinery. By following a structured maintenance routine, you can significantly enhance the lifespan and reliability of your equipment. This section outlines key practices that contribute to optimal functionality and durability.

Regular Inspections

Conducting frequent inspections helps identify potential issues before they escalate. Check for signs of wear, fluid levels, and any unusual sounds during operation. Timely detection of minor problems can prevent major repairs, saving time and resources.

Proper Lubrication

Ensuring all moving parts are adequately lubricated is crucial for smooth operation. Use high-quality lubricants and follow the manufacturer’s recommendations regarding intervals and quantities. Proper lubrication minimizes friction and reduces the risk of premature wear.

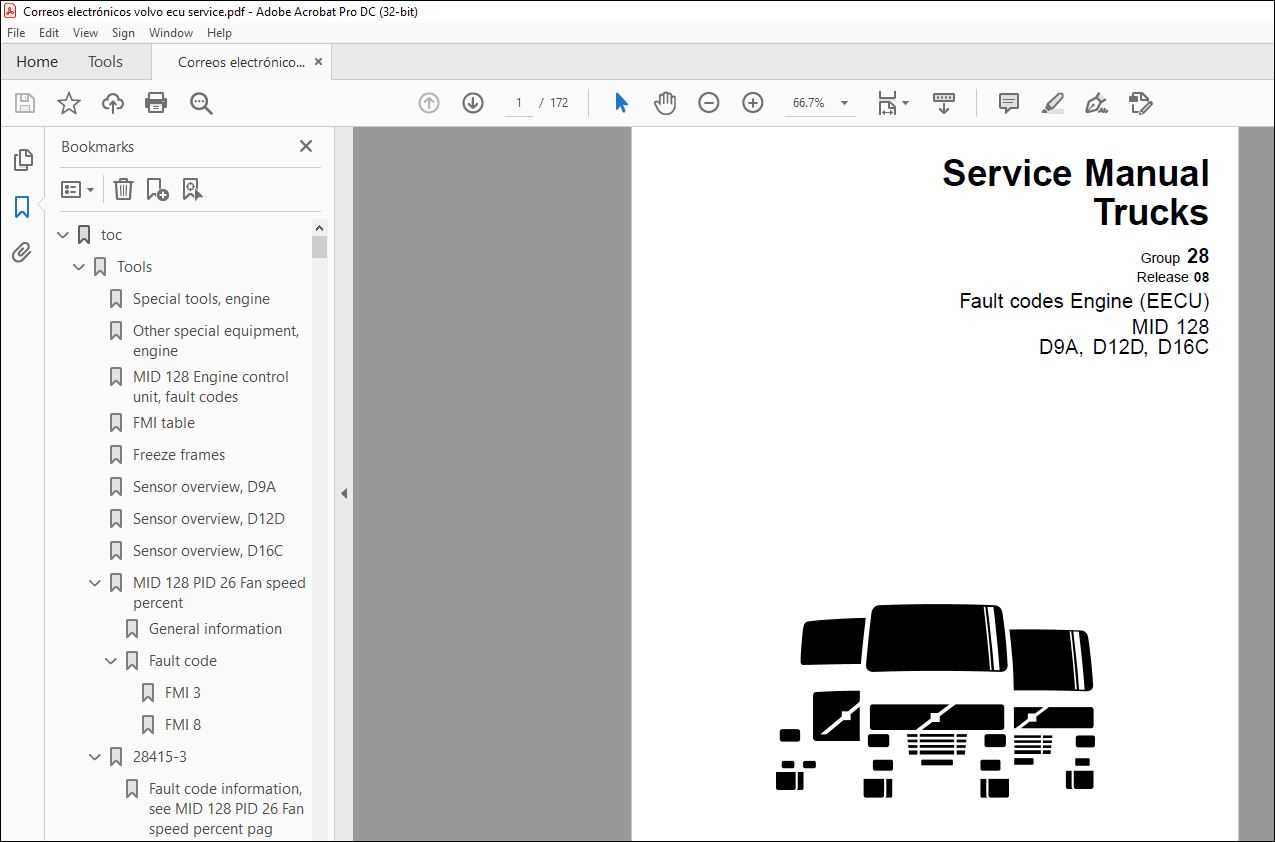

Diagnostic Procedures for Engine Problems

Effective troubleshooting of mechanical issues is crucial for maintaining optimal performance and longevity. This section outlines systematic approaches to identify and resolve various malfunctions that may arise, ensuring that all potential faults are addressed methodically.

Initial assessments should involve comprehensive inspections to detect visible signs of distress. Pay attention to unusual sounds, vibrations, or emissions, which can serve as indicators of underlying complications. Utilizing specialized diagnostic tools can provide valuable data, enabling a clearer understanding of performance deviations.

Once initial evaluations are complete, further testing may involve analyzing fluid levels, pressure readings, and temperature variations. These metrics can highlight inconsistencies that warrant deeper investigation. By following a structured process, one can accurately pinpoint the root cause of the issue, facilitating targeted interventions.

Documentation of all findings and actions taken is essential. This not only aids in the current analysis but also serves as a reference for future maintenance activities. Maintaining clear records enhances the efficiency of subsequent diagnostics, fostering a proactive approach to mechanical health.

Upgrading Engine Performance Features

Enhancing the capabilities of a vehicle’s powertrain can lead to improved efficiency, responsiveness, and overall driving experience. This section explores various methods to elevate performance characteristics, ensuring optimal functionality and longevity.

Key Performance Enhancements

- Improved fuel delivery systems

- Enhanced air intake mechanisms

- Upgraded exhaust systems for better airflow

- Reprogramming electronic control units (ECUs)

Considerations for Modifications

When contemplating enhancements, it is essential to consider compatibility with existing components. Ensure that any upgrades align with regulatory standards and maintain vehicle reliability.

- Research compatibility with current setups

- Consult with professionals for expert advice

- Monitor performance post-upgrade

Resources for Further Assistance

For those seeking additional support, a variety of resources are available to enhance understanding and troubleshooting capabilities. These platforms offer valuable insights and expert guidance tailored to specific needs.

Consider exploring online forums where enthusiasts and professionals share their experiences and solutions. Engaging in discussions can provide practical tips and foster connections within the community.

Furthermore, accessing educational websites dedicated to maintenance and service topics can prove beneficial. These sites often include detailed articles, videos, and tutorials that cover a range of issues, helping to deepen knowledge.

Lastly, do not overlook the value of local workshops and training sessions. Participating in hands-on experiences with skilled instructors can significantly improve skills and confidence in handling complex tasks.