Comprehensive Guide to Repairing Your 1968 Ford F100

Maintaining a vintage pickup truck requires a thorough understanding of its unique mechanics and systems. Enthusiasts often seek resources that provide clear instructions and insights, ensuring their beloved vehicles remain in peak condition. Such guides not only assist in routine upkeep but also offer troubleshooting advice for common issues that may arise over time.

Within the realm of automotive care, it is essential to have access to detailed information regarding the various components and functions of the vehicle. This knowledge empowers owners to perform essential tasks with confidence, from basic inspections to more intricate repairs. A well-structured reference can illuminate the intricacies of older models, making the maintenance process less daunting and more rewarding.

For those passionate about preserving the charm of their classic rides, having a reliable source of guidance can transform the experience. By following methodical instructions and utilizing practical tips, truck aficionados can enjoy a deeper connection with their machines while ensuring longevity and performance. In this exploration, we delve into essential practices that every owner should consider for effective vehicle stewardship.

Essential Tools for F100 Repair

When working on classic vehicles, having the right equipment is crucial for ensuring efficiency and effectiveness in maintenance tasks. A well-equipped workspace not only enhances the quality of the work but also makes the process more enjoyable.

Here are some indispensable items for anyone looking to dive into vehicle maintenance:

- Socket Set: A comprehensive set will allow you to tackle various nuts and bolts with ease.

- Wrenches: Both standard and metric sizes are necessary for different fasteners.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Jack and Stands: Essential for lifting the vehicle safely for underbody access.

- Screwdrivers: A variety of sizes and types (flathead and Phillips) are important for diverse tasks.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending wires.

- Multimeter: Great for diagnosing electrical issues and checking voltage levels.

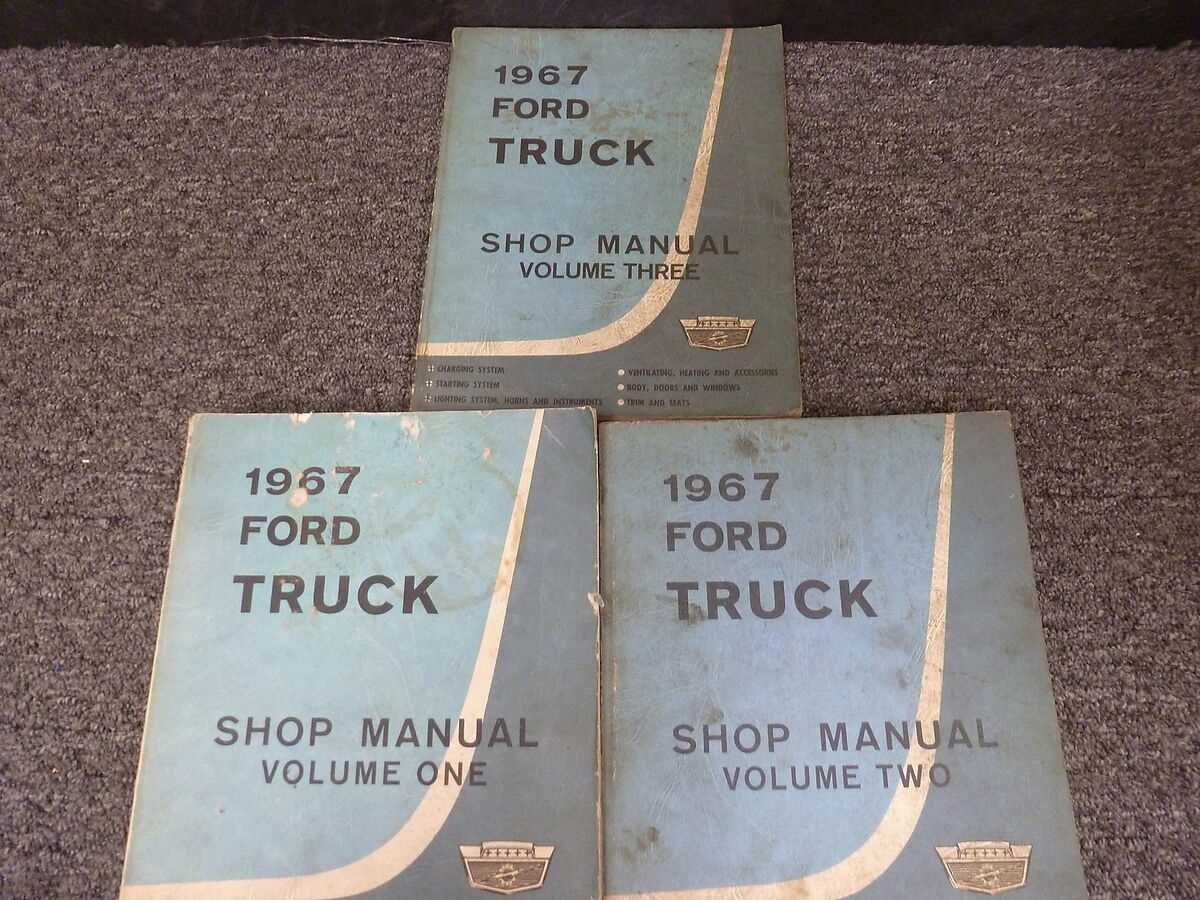

- Shop Manual: A guide specific to your model can provide valuable insights and instructions.

Investing in quality tools not only pays off in the short term but also supports long-term maintenance projects. With the right gear, you can tackle a wide range of tasks and keep your classic ride running smoothly.

Common Issues with the 1968 F100

Classic vehicles often exhibit a range of challenges due to their age and the wear on components. Understanding these frequent problems can help enthusiasts maintain and restore their cherished rides effectively. Here are some of the typical issues that may arise with this particular model, along with potential solutions.

| Issue | Description | Solution |

|---|---|---|

| Rust | Corrosion can develop in various areas, particularly around wheel wells and the frame. | Regular inspections and rust treatment are essential, along with applying protective coatings. |

| Electrical Problems | Malfunctions in the wiring and electrical systems can cause lights or the ignition to fail. | Inspecting wiring for frays or shorts and replacing faulty components will help restore functionality. |

| Leaking Fluids | Leaks from the engine or transmission are common and can lead to significant damage if not addressed. | Regular checks of fluid levels and prompt repair of seals or gaskets can prevent further issues. |

| Suspension Wear | The suspension system may experience wear, affecting ride quality and handling. | Inspecting and replacing worn shocks, springs, or bushings will enhance stability. |

| Overheating | Cooling system inefficiencies can lead to engine overheating. | Flushing the radiator and checking for blockages or leaks in hoses is advisable. |

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your classic truck in optimal condition. Regular upkeep not only enhances performance but also extends the vehicle’s lifespan. Following a systematic procedure ensures that every aspect of the vehicle is thoroughly checked and maintained, preventing future issues and preserving its value.

Routine Checks

Seasonal Maintenance

Understanding the Engine Specifications

Grasping the details of an engine’s specifications is essential for effective maintenance and performance enhancement. This knowledge allows enthusiasts and mechanics to make informed decisions regarding upgrades, repairs, and troubleshooting. Recognizing key attributes helps ensure optimal functioning and longevity of the vehicle.

Engines are typically characterized by various parameters, including displacement, horsepower, torque, and fuel type. Displacement, measured in cubic inches or liters, indicates the engine’s size and is a significant factor influencing its power output. Horsepower represents the engine’s capability to perform work over time, while torque measures its twisting force, crucial for acceleration and towing capacity.

Understanding fuel requirements is equally vital, as different engines operate efficiently on specific types of fuel. This aspect not only affects performance but also impacts emissions and overall environmental footprint. Regularly consulting technical documents that outline these specifications can guide users in optimizing engine performance and addressing any issues that arise.

Ultimately, familiarity with these characteristics not only enhances the driving experience but also promotes better vehicle care. Whether for routine maintenance or extensive modifications, a comprehensive grasp of engine specifications is indispensable for any automotive enthusiast.

Electrical System Troubleshooting Tips

Troubleshooting the electrical system of a vehicle can often be a daunting task, yet it is essential for ensuring reliable performance. A systematic approach can help identify and resolve issues efficiently. By focusing on key components and employing effective diagnostic techniques, you can restore functionality and enhance overall safety.

Check the Battery and Connections

Start by examining the battery and its connections. Ensure the terminals are clean and tight, as corrosion or loose connections can impede electrical flow. Use a multimeter to measure voltage; a fully charged battery should read around 12.6 volts. If the voltage is low, consider recharging or replacing the battery.

Inspect Fuses and Relays

Next, inspect the fuses and relays. A blown fuse is often a straightforward fix, but it may indicate an underlying issue. Replace any faulty fuses with the correct amperage rating. Check relays by swapping them with similar ones in the circuit; if the problem resolves, you may need to replace the faulty relay.

Transmission Repair and Adjustment

This section focuses on the intricacies of maintaining and fine-tuning the vehicle’s gear-shifting system. Proper attention to this critical component ensures optimal performance and longevity, allowing for smoother transitions between gears and improved driving experience.

Common Issues

Drivers may encounter various symptoms indicating problems within the transmission system. These include unusual noises, slipping gears, or difficulty in shifting. Identifying these issues early can prevent further complications and enhance overall vehicle reliability.

Diagnostic Steps

Begin with a thorough inspection of fluid levels and condition. Low or dirty fluid can lead to a host of transmission troubles. Ensure that all connections and cables are secure and undamaged. Utilize diagnostic tools to check for error codes that may pinpoint specific malfunctions.

Adjustment Techniques

After diagnosing the issues, adjustments may be necessary to restore functionality. This often involves calibrating the linkage to ensure precise gear engagement. Follow the manufacturer’s specifications closely to achieve the desired settings. Proper adjustments can significantly enhance responsiveness and efficiency.

Maintenance Tips

Regular maintenance is crucial for the longevity of the transmission system. Changing the transmission fluid at recommended intervals and inspecting the system for wear can mitigate potential problems. Additionally, keeping an eye on the cooling system is essential, as overheating can lead to severe damage.

By adhering to these guidelines, owners can maintain a reliable and efficient transmission, ensuring a seamless driving experience.

Suspension and Steering Components

The efficiency and stability of a vehicle heavily rely on its suspension and steering systems. These components work together to ensure a smooth ride, enhance handling, and provide the driver with precise control. Understanding their functionalities and maintenance needs is essential for optimal performance and safety on the road.

Key Components

Various elements contribute to the overall functionality of suspension and steering systems. Each plays a crucial role in maintaining vehicle stability and ride comfort. Below is a table summarizing the primary components and their functions:

| Component | Function |

|---|---|

| Shock Absorbers | Control the impact and rebound movement of the vehicle’s springs. |

| Struts | Support the weight of the vehicle and absorb road shocks. |

| Sway Bars | Reduce body roll during cornering to improve handling. |

| Control Arms | Connect the vehicle’s chassis to the wheels, allowing for controlled movement. |

| Steering Rack | Converts the rotational motion of the steering wheel into linear motion of the wheels. |

Maintenance Tips

Regular inspection and maintenance of these components are vital to prevent premature wear and ensure safe operation. Checking for leaks in shock absorbers, inspecting bushings, and ensuring proper alignment can greatly enhance vehicle performance and longevity.

Brake System Inspection Procedures

Regular examination of the braking system is crucial for ensuring vehicle safety and performance. This process involves assessing various components to identify wear, damage, or any potential issues that could compromise functionality. By following systematic inspection steps, vehicle owners can maintain optimal braking efficiency and prevent unexpected failures.

Begin the assessment by visually inspecting the brake pads and shoes for signs of wear or contamination. Look for uneven wear patterns, which may indicate alignment issues or the need for replacement. Next, examine the rotors and drums for cracks, warping, or grooves that could affect braking performance.

Check the brake lines and hoses for leaks, abrasions, or deterioration. Ensure that all connections are secure and that there are no signs of fluid leakage. Additionally, inspect the master cylinder and brake fluid reservoir, making sure the fluid level is adequate and that the fluid appears clean and free of debris.

Test the operation of the brake pedal. It should feel firm and responsive, with minimal travel. If the pedal feels spongy or sinks to the floor, this could indicate air in the system or a leak. Conduct a road test to evaluate braking effectiveness, paying attention to any unusual noises or vibrations during operation.

Finally, ensure that the brake warning light functions correctly. If it illuminates, further investigation is necessary to diagnose the issue. Consistent and thorough inspections will help maintain the integrity of the braking system and enhance overall driving safety.

Bodywork and Paint Restoration Techniques

Restoring the exterior of a vintage vehicle requires a blend of skill and attention to detail. The process often involves assessing the condition of the body and determining the best methods to revive its original charm. Effective techniques can rejuvenate not just the aesthetics, but also the overall value of the automobile.

Assessment and Preparation are crucial first steps. Before diving into repairs, thoroughly inspect for rust, dents, and other imperfections. Cleaning the surface to remove dirt and grease ensures better adhesion of materials used during restoration. A well-prepared workspace is essential for achieving a professional finish.

Rust Repair is a common challenge. Treating rust involves removing affected areas and applying a suitable primer. Patching can be done using metal sheets or fillers designed for automotive applications. It’s vital to ensure a smooth transition between the repaired sections and the original surface.

Body Filler Application plays a significant role in achieving a flawless look. After rust repair, applying a high-quality filler can help smooth out imperfections. Use a spreader for even application and sand it down once cured, achieving a seamless blend with the surrounding metal.

Painting Techniques are equally important in restoration. Selecting the right type of paint and applying it with precision can drastically enhance the vehicle’s appearance. Techniques like spray painting allow for an even coat, while careful layering can produce a deep, lustrous finish. Always allow proper drying time between coats to avoid issues.

Final Touches include polishing and waxing to protect the newly painted surface. This not only enhances the shine but also adds a layer of protection against environmental elements. Regular maintenance of the paint job will help preserve its beauty for years to come.

By following these techniques, enthusiasts can successfully restore the bodywork and paint of classic vehicles, ensuring they stand out for generations to come.

Upgrading Your F100: Performance Mods

Enhancing the performance of your classic truck can be a rewarding endeavor. With the right modifications, you can significantly improve horsepower, torque, and overall driving experience. From engine upgrades to suspension improvements, there are numerous ways to make your vehicle more responsive and enjoyable on the road.

Engine Enhancements

One of the most effective ways to boost your vehicle’s performance is by upgrading the engine. Consider installing a high-performance intake manifold and a quality carburetor. These components can greatly increase airflow, resulting in better combustion and increased power. Additionally, an aftermarket exhaust system can enhance exhaust flow, further improving engine efficiency.

Suspension and Handling Upgrades

Improving handling is just as crucial as increasing power. Upgrading to a better suspension system can provide superior stability and control. Consider adding performance shocks and struts, as well as sway bars to minimize body roll during turns. Tires also play a vital role; investing in high-quality, performance-oriented tires can greatly enhance grip and overall driving dynamics.

By focusing on these key areas, you can transform your classic truck into a more powerful and responsive machine, making every drive an exhilarating experience.

Safety Features of the 1968 Model

The automotive landscape of the late 1960s marked a significant shift in the incorporation of safety measures into vehicle design. Manufacturers began to recognize the importance of protecting occupants and improving overall driving security. This era saw the introduction of various innovations aimed at reducing the risk of accidents and enhancing passenger safety.

| Feature | Description |

|---|---|

| Seat Belts | Standardized seat belts became increasingly common, providing crucial restraint during collisions. |

| Energy-Absorbing Steering Column | This design reduced the risk of injury to the driver during impact by allowing the steering column to collapse upon collision. |

| Rigid Body Construction | Sturdier frames and reinforced body panels contributed to better crashworthiness, helping to protect passengers in the event of an accident. |

| Dual Circuit Brake System | This system enhanced braking reliability, ensuring that if one circuit failed, the other would still function, providing added safety. |

| Windshield Design | Safety glass was used to reduce the risk of shattering, minimizing injury from flying glass in the event of an accident. |

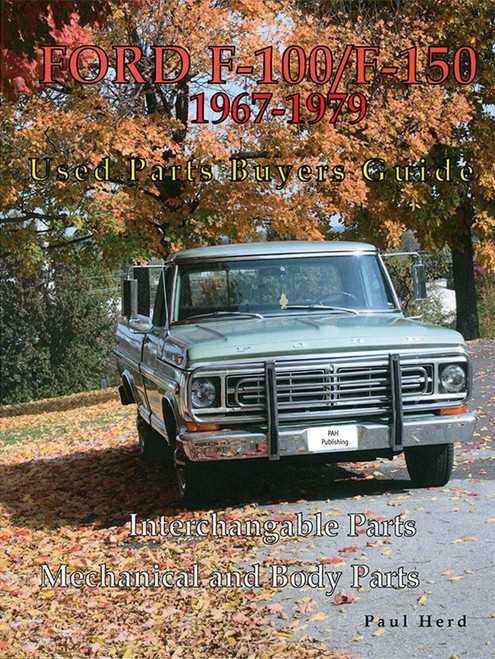

Finding Replacement Parts Efficiently

Locating suitable components for vintage vehicles can be a daunting task. The key to success lies in a strategic approach that maximizes resources and minimizes frustration. With the right tools and knowledge, enthusiasts can uncover the necessary pieces to restore their cherished automobiles without excessive hassle.

Start by exploring various online platforms that specialize in classic vehicle parts. Websites dedicated to vintage car enthusiasts often have extensive inventories and user-friendly search functions. It’s essential to utilize multiple sources to ensure a comprehensive search, as availability can vary greatly.

| Resource Type | Examples | Benefits |

|---|---|---|

| Online Marketplaces | eBay, Craigslist | Wide variety, often at competitive prices |

| Specialty Retailers | Classic Parts, RockAuto | Expert advice, quality assurance |

| Local Salvage Yards | Auto recycling centers | Cost-effective, opportunity for unique finds |

| Community Forums | Online discussion groups | Advice from fellow enthusiasts, potential leads |

Networking within enthusiast communities can yield valuable information regarding hard-to-find parts. Engaging in discussions and sharing experiences can lead to recommendations for reliable suppliers or even direct sales from fellow hobbyists. Leveraging social media platforms can also enhance connections within these circles.

Finally, don’t overlook the possibility of reproductions. Many companies specialize in producing high-quality replicas of vintage components. This option can often save time and provide a reliable solution when originals are scarce. Always compare quality and pricing to ensure you make the best choice for your restoration project.