Comprehensive Guide to Repairing Your 1990 Ford F150

Owning a classic vehicle presents unique challenges and rewards. For enthusiasts and everyday users alike, understanding how to properly maintain and troubleshoot these machines is essential. This section aims to provide in-depth insights and valuable information that can help owners keep their vehicles running smoothly for years to come.

From routine checks to more complex issues, this guide covers a wide range of topics to assist individuals in their automotive journeys. Whether you’re a seasoned mechanic or a curious novice, having access to practical tips and detailed procedures will empower you to tackle any situation with confidence.

Equipped with the right knowledge, vehicle owners can enhance performance, ensure safety, and ultimately prolong the life of their beloved rides. Join us as we delve into essential techniques and expert advice tailored for those dedicated to preserving the legacy of their cherished automobiles.

Overview of the 1990 Ford F150

This section provides a comprehensive look at a classic pickup that has made its mark in automotive history. Known for its durability and versatility, this vehicle appeals to both everyday drivers and enthusiasts alike. With a blend of functionality and performance, it has become a staple in the world of trucks.

Key Features

- Robust engine options offering a range of power for various needs.

- Spacious cabin with comfortable seating, making it suitable for both work and leisure.

- Enhanced towing capacity, allowing for the transport of heavy loads.

- Various trim levels providing customization to meet individual preferences.

Performance and Handling

The performance of this model stands out, thanks to its powerful drivetrain and balanced handling. It is designed to tackle a variety of terrains, whether on highways or rugged paths.

- Responsive steering that provides confidence on the road.

- Solid suspension system ensuring a smooth ride even under challenging conditions.

This pickup remains a popular choice for those seeking a reliable vehicle that combines tradition with modern capabilities.

Common Issues with the 1990 F150

Every vehicle has its unique set of challenges, and this particular model is no exception. Owners often report recurring problems that can affect performance, safety, and overall reliability. Understanding these issues can help in effective maintenance and troubleshooting.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Hesitation | Drivers may experience a lack of power or rough acceleration. | Check the fuel system and ignition components; replace filters if necessary. |

| Transmission Slipping | Shifting can become erratic, leading to poor driving experience. | Inspect fluid levels and consider a transmission service. |

| Brake Issues | Unresponsive or spongy brakes can pose serious safety risks. | Examine brake lines and pads; replace worn components promptly. |

| Electrical Problems | Malfunctions in the electrical system can cause various issues, including starting problems. | Inspect wiring and battery connections; test the alternator. |

| Suspension Wear | Uneven tire wear and poor handling are common indicators. | Check shock absorbers and bushings for wear; align the wheels if needed. |

Essential Tools for F150 Repairs

When maintaining or fixing a vehicle, having the right equipment is crucial for efficiency and safety. Each task requires specific instruments to ensure that everything runs smoothly and effectively. Here’s a comprehensive list of the most vital tools to keep in your workshop.

- Wrenches: A variety of sizes, including both metric and standard, are essential for loosening and tightening bolts.

- Sockets: A socket set with extensions will help reach tight spaces, making it easier to work on the engine and chassis.

- Ratchet: This tool simplifies the process of applying torque to nuts and bolts, saving time and effort.

- Jacks and Stands: Hydraulic jacks and jack stands provide safe access to the underside of the vehicle for inspection and maintenance.

- Screwdrivers: A set of flathead and Phillips screwdrivers is necessary for various tasks, from dashboard adjustments to exterior fixes.

- Pliers: Both needle-nose and standard pliers are helpful for gripping, bending, and cutting wires or other materials.

- Torque Wrench: This precision tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: An essential instrument for diagnosing electrical issues, helping to test voltage and continuity.

Equipping yourself with these tools will enhance your ability to handle a variety of challenges, ensuring that you can perform maintenance and fixes effectively.

Step-by-Step Maintenance Procedures

Proper upkeep of your vehicle is essential for optimal performance and longevity. This section outlines essential procedures that will help ensure your truck remains in excellent condition. By following these organized steps, you can address common issues and enhance the overall functionality of your automobile.

| Procedure | Description | Frequency |

|---|---|---|

| Oil Change | Replace the engine oil and filter to ensure smooth operation. | Every 3,000 miles |

| Tire Rotation | Swap tires to promote even wear and extend tire life. | Every 5,000 miles |

| Brake Inspection | Check brake pads, rotors, and fluid levels for safety. | Every 10,000 miles |

| Battery Check | Inspect battery terminals and charge levels to avoid starting issues. | Every 6 months |

| Fluid Levels | Monitor coolant, transmission, and brake fluid levels for optimal performance. | Monthly |

Adhering to these maintenance tasks will not only enhance the reliability of your vehicle but also contribute to a safer driving experience. Regular checks and timely interventions can prevent more significant issues from arising, saving both time and money in the long run.

Engine Troubleshooting Tips

When dealing with engine issues, a systematic approach can save both time and money. Identifying the root cause of a malfunction requires careful observation and methodical testing. By following a few straightforward guidelines, you can effectively diagnose and address common problems that may arise with your vehicle’s powertrain.

Start with a visual inspection. Look for any signs of leaks, wear, or loose connections. Pay attention to the condition of belts and hoses, as these components can often lead to significant issues if not maintained properly. Listen for unusual noises during operation, which can indicate potential malfunctions.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine Won’t Start | Dead battery or faulty starter | Check battery connections and test starter functionality |

| Loss of Power | Clogged fuel filter or air intake issues | Inspect and replace filter; clean air intake |

| Overheating | Low coolant or malfunctioning thermostat | Check coolant levels and replace thermostat if necessary |

| Excessive Smoke | Oil leak or worn piston rings | Investigate for leaks and assess engine condition |

Utilizing these troubleshooting tips can help pinpoint the issue, allowing for more effective repairs and maintaining optimal performance.

Transmission Repair Guidelines

Maintaining the functionality of a vehicle’s transmission is crucial for optimal performance. This section outlines essential procedures and tips for addressing common issues associated with this vital component. Understanding the mechanics and having a systematic approach can greatly enhance the longevity and efficiency of the transmission system.

Common Symptoms of Transmission Issues

Identifying problems early can prevent extensive damage. Look for the following signs:

- Slipping gears

- Unusual noises (grinding, whining)

- Fluid leaks under the vehicle

- Delayed engagement when shifting

- Warning lights on the dashboard

Basic Troubleshooting Steps

Before delving into complex repairs, consider these initial diagnostic measures:

- Check the transmission fluid level and quality.

- Inspect for visible leaks and assess fluid condition.

- Examine electrical connections related to the transmission.

- Run a diagnostic scan to identify error codes.

By following these guidelines, you can effectively address transmission issues, ensuring smoother operation and enhancing the overall driving experience.

Electrical System Diagnostics

The effective functioning of an automobile’s electrical framework is crucial for its overall performance. Proper diagnostics are essential to identify any issues that may arise within this intricate network of components. By understanding how to evaluate the electrical system, one can ensure that all parts operate harmoniously and efficiently.

Common Issues in Electrical Systems

Several problems can affect the electrical system, including faulty wiring, malfunctioning sensors, and weak connections. Symptoms such as dim lights, non-responsive accessories, or trouble starting the engine often indicate underlying electrical faults. Recognizing these signs early can prevent more significant issues from developing.

Diagnostic Tools and Techniques

Utilizing specialized diagnostic tools, such as multimeters and oscilloscopes, is vital for accurate assessments. Multimeters help measure voltage, current, and resistance, while oscilloscopes provide visual representations of electrical signals. Employing these instruments allows for precise identification of problems, enabling timely repairs and maintenance.

In addition to tools, following a systematic approach to testing circuits and components can streamline the diagnostic process. Begin by verifying power supply and grounding connections, then proceed to check individual components for functionality. This methodical evaluation aids in isolating issues efficiently.

Brake System Maintenance Strategies

Ensuring the reliability and performance of the braking system is essential for vehicle safety. Regular upkeep not only extends the lifespan of components but also enhances overall driving experience. Implementing effective maintenance practices can help identify potential issues before they escalate, ultimately preventing costly repairs and ensuring optimal functionality.

Key Maintenance Practices

Several fundamental strategies contribute to the effective management of the braking system. These include routine inspections, timely replacements, and the use of quality materials. Each practice plays a crucial role in maintaining the efficiency and safety of the braking mechanism.

| Practice | Description | Frequency |

|---|---|---|

| Visual Inspection | Check for wear on brake pads and discs, and ensure no leaks in the hydraulic system. | Every 6 months |

| Fluid Check | Monitor brake fluid levels and quality; replace if contaminated or below the minimum mark. | Every 6 months |

| Brake Pad Replacement | Change brake pads when they reach the manufacturer’s recommended thickness. | As needed |

| Brake Fluid Flush | Replace old fluid to prevent moisture contamination and ensure optimal braking performance. | Every 2 years |

Signs of Trouble

Being aware of warning signs can greatly assist in maintaining the braking system. Unusual noises, decreased responsiveness, or vibrations during braking should prompt immediate investigation. Addressing these symptoms promptly can prevent further damage and ensure a safe driving experience.

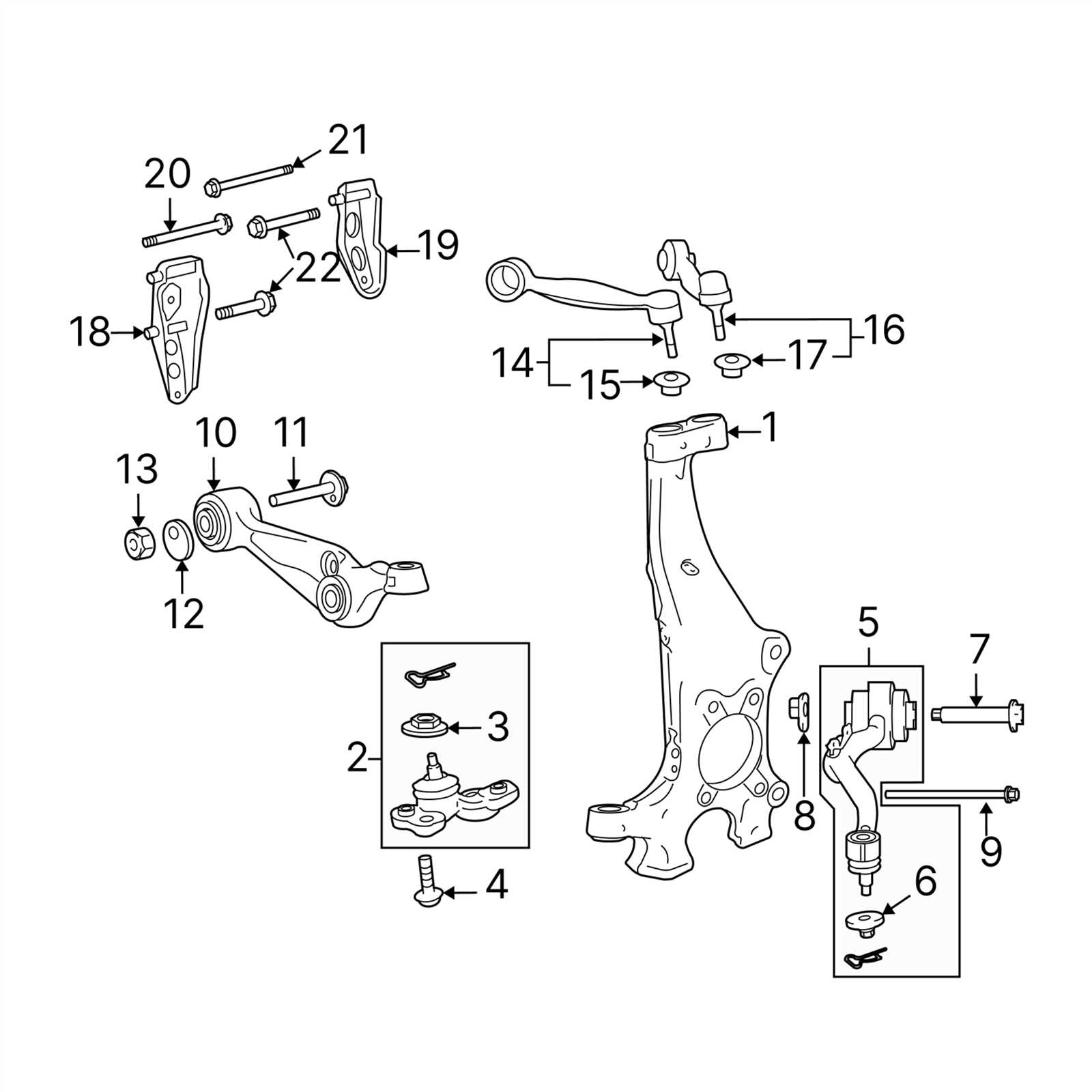

Suspension and Steering Insights

The suspension and steering systems are vital components that significantly impact vehicle performance and handling. These systems work together to provide a smooth ride, enhance stability, and ensure responsive maneuverability. Understanding their mechanics is essential for maintaining optimal functionality and addressing potential issues effectively.

Suspension plays a crucial role in absorbing shocks from the road, helping to maintain tire contact and improve traction. Key elements, such as shocks, suspension arms, and springs, must be regularly inspected for wear and tear. Any degradation can lead to an uncomfortable ride and diminished control.

Steering systems allow the driver to guide the vehicle precisely. This involves components like steering columns, racks, and linkages. Ensuring these parts are in good condition is essential for maintaining a safe and responsive driving experience. Regular checks for alignment and fluid levels can prevent major steering issues down the line.

Both systems require attention to detail and routine maintenance. Keeping them in peak condition not only enhances performance but also extends the lifespan of the vehicle, ensuring safety and comfort on every journey.

Bodywork and Exterior Repairs

Maintaining the integrity of a vehicle’s exterior is crucial for both aesthetics and functionality. From minor dents to significant surface damage, addressing these issues promptly can prevent further complications. This section focuses on essential techniques and considerations for restoring the body of your automobile to its original condition.

Common Issues and Solutions

Several typical problems may arise with a vehicle’s exterior, including rust, scratches, and dents. Each issue requires specific methods to ensure a long-lasting fix.

| Issue | Solution |

|---|---|

| Rust | Sand affected areas, apply rust-inhibiting primer, and repaint. |

| Scratches | Use touch-up paint or a rubbing compound to blend with surrounding surfaces. |

| Dents | Utilize a hairdryer and aluminum foil or a specialized dent puller to restore shape. |

Preparation and Tools

Before initiating any work, proper preparation is vital. Gather necessary tools such as sanders, fillers, and painting supplies. Ensure the workspace is clean and well-ventilated to facilitate effective repairs and maintain safety standards.