Comprehensive Guide to the 2003 Ford Ranger Repair Manual

Maintaining your vehicle is essential for ensuring its longevity and optimal performance. Whether you are an experienced mechanic or a novice enthusiast, having access to detailed instructions and insights can greatly enhance your repair skills. This resource aims to provide invaluable information to assist you in tackling various maintenance and troubleshooting tasks, making the process more manageable and efficient.

Understanding the intricacies of your automobile allows you to address common issues proactively. With a wealth of knowledge at your fingertips, you can navigate through repairs with confidence, avoiding unnecessary expenses and downtime. This guide covers essential topics, offering step-by-step procedures, safety precautions, and tips for successful execution.

From engine diagnostics to electrical systems, this resource serves as a reliable companion for any vehicle owner. By familiarizing yourself with the underlying mechanics and specifications, you empower yourself to keep your automobile in top shape. Prepare to dive into a world of practical advice that will elevate your hands-on experience.

Understanding the 2003 Ford Ranger

This section provides an in-depth look at a versatile pickup truck known for its durability and reliability. Designed for both everyday use and challenging conditions, this model has earned a reputation among drivers for its performance and practicality. The following insights will help you appreciate its features, functionality, and the maintenance needed to keep it in optimal condition.

Engineered with a robust powertrain, this vehicle offers various options catering to different driving needs. From its efficient fuel consumption to its capable handling, this model stands out in the competitive truck market. It blends power with agility, making it suitable for both urban and off-road adventures.

Understanding the components that contribute to its performance is essential for any owner. Knowledge about the engine specifications, transmission types, and suspension system enhances the driving experience. Familiarity with the dashboard layout and controls can significantly improve usability and comfort.

Regular upkeep is crucial for longevity. Knowing how to address common issues, perform basic maintenance tasks, and recognize warning signs can prevent more significant problems. A proactive approach to care ensures that this truck remains a dependable companion for years to come.

Ultimately, this pickup is not just a vehicle; it represents a blend of utility, comfort, and style. Understanding its design and functionality empowers drivers to maximize their experience on the road, whether for work or leisure.

Common Issues with the 2003 Ranger

This section highlights frequently encountered problems that may arise with this particular vehicle model. Understanding these issues can help owners maintain performance and safety, ensuring a reliable driving experience.

Engine and Performance Concerns

Many users report specific challenges related to engine performance, which can manifest in various ways. Common symptoms include reduced power, stalling, and unusual noises. These issues often stem from a combination of wear and tear, fuel system problems, and electrical component failures.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Poor Acceleration | Clogged fuel filter, faulty spark plugs | Replace fuel filter, check and replace spark plugs |

| Engine Stalling | Fuel pump failure, ignition system issues | Inspect fuel pump, check ignition components |

| Unusual Noises | Loose belts, worn bearings | Tighten or replace belts, lubricate or replace bearings |

Transmission Issues

Transmission problems can significantly impact drivability. Drivers may notice difficulty in shifting gears, slipping, or unusual vibrations. Addressing these concerns promptly is crucial to avoid more severe damage.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Slipping Gears | Low transmission fluid, worn clutch | Check fluid levels, replace clutch if necessary |

| Difficulty Shifting | Linkage issues, low fluid levels | Inspect and adjust linkage, top off fluid |

| Vibration During Operation | Imbalanced driveshaft, worn mounts | Balance driveshaft, replace worn mounts |

Essential Tools for Repairs

Having the right instruments at your disposal can significantly enhance the efficiency and success of any maintenance task. Whether you’re tackling minor adjustments or more extensive modifications, a well-equipped toolkit is fundamental for achieving desired outcomes.

Basic Tools

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: A mix of flathead and Phillips for different types of screws.

- Socket set: Essential for reaching fasteners in tight spaces.

Specialized Equipment

- Torque wrench: Ensures proper tightness to avoid damage.

- Multimeter: Useful for diagnosing electrical issues.

- Jack and stands: Necessary for safely lifting the vehicle.

Step-by-Step Maintenance Procedures

Regular upkeep of your vehicle is essential for ensuring optimal performance and longevity. By following systematic processes, you can address common issues and maintain the efficiency of your transportation. This section outlines key maintenance tasks that can be performed with basic tools and a little know-how.

Start by checking the engine oil levels. It’s crucial to ensure that the oil is clean and at the appropriate level, as this prevents wear and tear on engine components. Remove the dipstick, wipe it clean, reinsert it, and then pull it out again to assess the oil’s condition.

Next, inspect the air filter. A clogged filter can restrict airflow and reduce fuel efficiency. Locate the air intake housing, open it, and examine the filter for dirt and debris. If necessary, replace it with a new one to enhance engine performance.

Don’t overlook the importance of tire maintenance. Regularly check tire pressure using a gauge and ensure it matches the manufacturer’s recommendations. Additionally, inspect the tread depth and look for any signs of uneven wear, which might indicate alignment issues.

Brake inspection is another critical task. Examine the brake pads for wear and listen for any unusual noises while driving. If you notice any signs of reduced performance, consider replacing the pads or consulting a professional.

Lastly, keep an eye on fluid levels, including coolant, transmission fluid, and brake fluid. Regularly topping off these fluids helps maintain the vehicle’s systems and prevent overheating or failure. Remember to check for leaks under the vehicle as well.

Engine Troubleshooting Techniques

Diagnosing issues within an engine requires a systematic approach to identify potential problems accurately. Understanding the symptoms and using effective methods can save time and resources. This section will explore various techniques to help pinpoint malfunctions and facilitate the repair process.

Common Symptoms to Observe

- Unusual noises, such as knocking or rattling sounds

- Decreased power or sluggish acceleration

- Excessive smoke from the exhaust

- Increased fuel consumption

- Check engine light activation

Diagnostic Steps

- Visual Inspection: Examine the engine and surrounding components for signs of wear or damage.

- Listen for Noises: Pay attention to any irregular sounds that may indicate a mechanical failure.

- Check Fluid Levels: Ensure that oil, coolant, and other essential fluids are at the appropriate levels.

- Use Diagnostic Tools: Employ OBD-II scanners to read error codes and assess electronic systems.

- Perform Tests: Conduct compression tests, leak-down tests, and other evaluations to assess engine health.

By following these techniques, one can systematically address engine issues, leading to more effective solutions and prolonged vehicle performance.

Transmission Care and Repairs

Maintaining the functionality of your vehicle’s transmission is crucial for optimal performance and longevity. Regular attention to this complex system can prevent costly issues and ensure a smoother driving experience. Understanding basic maintenance practices and common problems will empower you to keep your vehicle in top shape.

Routine Maintenance Practices

To extend the life of the transmission, it’s essential to perform regular checks and fluid changes. Fluid quality plays a significant role in the system’s operation; old or contaminated fluid can lead to overheating and wear. It is advisable to check the fluid level periodically and replace it according to the manufacturer’s recommendations. Additionally, inspecting the transmission filter can help prevent debris buildup that could impair functionality.

Common Issues and Troubleshooting

Even with diligent maintenance, transmission problems can arise. Symptoms such as slipping gears, unusual noises, or warning lights should not be ignored. Diagnosing the issue early can save time and money. Common solutions may involve adjusting linkage, replacing seals, or, in more severe cases, rebuilding the transmission. Always consult a professional if unsure about the necessary steps to take.

Electrical System Diagnostics

Diagnosing electrical systems is crucial for maintaining optimal performance and ensuring safety. Understanding the components and their interactions allows for efficient troubleshooting and problem resolution.

Common Issues

- Battery problems

- Wiring faults

- Fuses and relays failures

- Grounding issues

Diagnostic Steps

- Inspect the battery and connections for corrosion.

- Check fuses and replace any that are blown.

- Use a multimeter to test voltage and continuity in wiring.

- Examine ground connections for reliability.

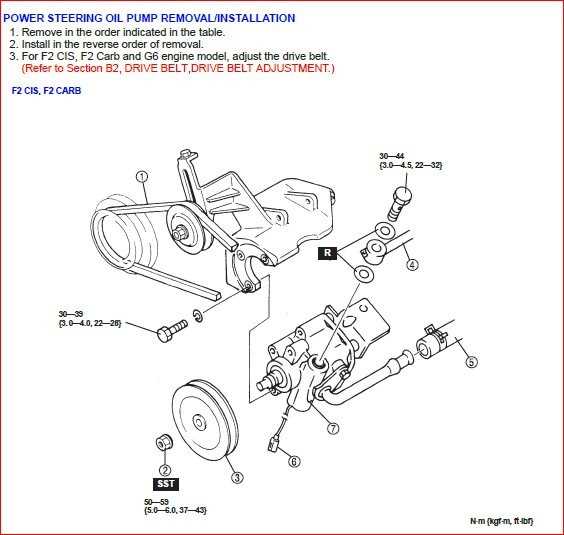

Suspension and Steering Components

This section delves into the essential elements that contribute to a vehicle’s handling and ride quality. The interplay between suspension and steering components is crucial for maintaining stability, comfort, and responsiveness while navigating various terrains. Understanding these parts is vital for effective maintenance and performance optimization.

| Component | Function | Common Issues |

|---|---|---|

| Shock Absorbers | Dampen oscillations to improve ride comfort. | Leakage, excessive wear, and noise. |

| Struts | Support vehicle weight and maintain alignment. | Weakness, bending, and mounting failures. |

| Control Arms | Connect suspension to the frame, allowing movement. | Cracks, bushings wear, and misalignment. |

| Ball Joints | Facilitate pivoting motion between suspension and steering. | Excessive play, wear, and noise. |

| Steering Rack | Convert rotational motion into lateral movement. | Leaking fluid, stiffness, and noise. |

| Power Steering Pump | Assists in steering by providing hydraulic pressure. | Noise, leaking fluid, and loss of assistance. |

Regular inspection and timely replacement of these components can significantly enhance the driving experience, ensuring safety and performance over time.

Brake System Maintenance Tips

Regular upkeep of your vehicle’s braking components is crucial for ensuring safety and performance. Proper attention to these systems can prevent costly repairs and enhance the overall driving experience. Below are essential tips to maintain the integrity and functionality of your braking system.

Inspect Components Regularly

Frequent examination of brake pads, rotors, and lines is vital. Look for signs of wear, such as thinning pads or scoring on the rotors. Replacing worn-out parts before they fail can prevent accidents and costly damage.

Maintain Proper Fluid Levels

The brake fluid should be checked regularly to ensure optimal performance. If levels are low, it may indicate a leak or worn components. Flushing the brake fluid at recommended intervals helps remove contaminants and maintain effective braking action.

Cooling System Service Guidelines

The cooling system is vital for maintaining optimal engine performance and preventing overheating. Proper maintenance ensures longevity and efficiency, while neglect can lead to serious mechanical issues. Regular checks and servicing are essential to keep the system functioning smoothly.

Begin by inspecting the coolant levels regularly. Low coolant can lead to inadequate heat dissipation, causing the engine to run hotter than desired. Always use the recommended coolant type, as it is designed to protect against corrosion and maintain the system’s integrity.

Next, examine the hoses and connections for any signs of wear or leaks. Cracks, bulges, or soft spots can indicate that a hose is nearing failure and should be replaced promptly. Ensure that all clamps are secure to prevent any coolant loss.

It is also important to check the radiator for debris and obstructions that can impede airflow. A clean radiator allows for better heat exchange, which is crucial during high-temperature operation. Flush the radiator periodically to remove sediment and prevent clogging.

Inspect the thermostat and water pump for proper functionality. A malfunctioning thermostat can cause erratic temperature readings, while a failing water pump may not circulate coolant effectively. Replacing these components as needed can prevent overheating issues.

Finally, consider performing a pressure test on the cooling system. This can help identify hidden leaks and ensure that the entire system is sealed properly. Following these guidelines will help maintain a healthy cooling system, contributing to the overall performance and reliability of the vehicle.

Fuel System Inspection Methods

Inspecting the fuel system is crucial for ensuring optimal engine performance and longevity. Proper evaluation techniques help identify potential issues, enhance fuel efficiency, and maintain overall vehicle reliability. Various inspection methods can be employed to diagnose problems within the fuel delivery and storage components.

| Inspection Method | Description | Tools Required |

|---|---|---|

| Visual Inspection | Check for leaks, damaged lines, and corrosion on components. | Flashlight, Inspection Mirror |

| Pressure Testing | Measure fuel pressure to ensure it meets specifications. | Fuel Pressure Gauge |

| Flow Testing | Evaluate the fuel flow rate to identify restrictions. | Flow Meter |

| Electrical Testing | Test fuel pump operation and circuit integrity. | Multimeter, Wiring Diagrams |

| Fuel Quality Assessment | Analyze fuel for contaminants and octane levels. | Sample Jar, Tester Kit |

Regular inspections using these methods can prevent major failures and contribute to the smooth operation of the engine. Adopting a systematic approach ensures that every aspect of the fuel system is evaluated comprehensively.

Bodywork and Interior Repairs

This section focuses on the essential techniques and guidelines for addressing external and internal issues of a vehicle. Maintaining both the body and interior is crucial for preserving the overall aesthetic and functionality of any automobile. From minor dents to upholstery wear, understanding the repair processes can enhance both safety and comfort.

Exterior Damage Repair

When dealing with scratches, dents, or rust, it’s important to assess the extent of the damage before proceeding. Minor scratches can often be treated with polishing compounds, while deeper dents may require tools such as a dent puller. In cases of significant rust, proper treatment includes removing the affected area and applying protective coatings to prevent future corrosion. Always ensure a smooth finish by sanding and repainting affected surfaces for a seamless look.

Interior Maintenance

For interior repairs, start by evaluating the condition of seats, carpets, and dashboard components. Stains on upholstery can usually be treated with specialized cleaners, while cracked dashboards may need patching kits or covers. Regular maintenance, such as vacuuming and conditioning materials, helps to prolong the life of the interior. Additionally, keeping all surfaces clean not only enhances appearance but also prevents deterioration.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Following certain guidelines can significantly reduce risks and create a secure working environment. Here are essential precautions to consider.

- Personal Protective Equipment (PPE): Always wear appropriate gear such as gloves, goggles, and steel-toed boots to protect yourself from potential hazards.

- Ventilation: Work in a well-ventilated area to avoid inhaling harmful fumes and gases. If necessary, use fans or exhaust systems.

- Work Surface Stability: Ensure that your work area is clean and organized. Use sturdy workbenches and ensure vehicles are securely elevated when necessary.

- Tool Safety: Regularly inspect tools for damage and ensure they are suitable for the task. Use tools according to the manufacturer’s instructions.

- Electrical Safety: Disconnect the battery before performing any electrical work to prevent shocks or short circuits.

By adhering to these guidelines, you can maintain a safe and efficient atmosphere while performing necessary tasks. Prioritizing safety not only protects you but also enhances the quality of your work.