Comprehensive Guide to Repairing the 2003 Ford Windstar

Ensuring the longevity and efficiency of your automobile requires a solid understanding of its inner workings. This section delves into essential insights and practical advice for maintaining your vehicle, covering various aspects from routine checks to more intricate troubleshooting techniques. A well-informed owner is empowered to tackle issues proactively, minimizing potential breakdowns and costly repairs.

Within these pages, you will discover detailed information aimed at enhancing your knowledge about vehicle upkeep. Whether you’re a seasoned enthusiast or a novice looking to gain confidence, this guide offers invaluable tips to help you navigate the complexities of automotive care. From engine performance to electrical systems, we’ll explore the nuances of maintaining a dependable ride.

Each chapter is designed to equip you with the tools necessary for successful intervention and routine servicing. With clear explanations and step-by-step instructions, you can approach your vehicle’s needs with assurance. Join us as we embark on a journey to master the art of vehicle maintenance, transforming potential challenges into manageable tasks.

Overview of 2003 Ford Windstar

This section provides a comprehensive look at a well-regarded minivan known for its spaciousness and versatility. Designed to cater to families and individuals seeking comfort and functionality, this vehicle combines practicality with essential features that enhance the driving experience.

Key Features

The model boasts an array of amenities aimed at improving passenger comfort and convenience. Its roomy interior accommodates multiple passengers, with adjustable seating configurations that allow for optimal space management. Additionally, advanced safety features contribute to peace of mind on the road.

Performance and Handling

Under the hood, this vehicle is equipped with a robust engine that delivers reliable performance. Its handling is characterized by a smooth ride and responsive steering, making it suitable for both city commuting and long-distance travel. This combination of power and agility ensures a pleasant driving experience for all users.

Common Issues with the Windstar

Many owners experience a variety of challenges with their vehicles over time. Understanding these common concerns can aid in effective maintenance and improve overall performance. Here are some frequent issues reported by users:

- Transmission Problems: Slipping gears or difficulty shifting can occur, often due to fluid leaks or wear.

- Electrical Issues: Malfunctions in lighting or dashboard indicators may arise from faulty wiring or blown fuses.

- Cooling System Failures: Overheating engines are often linked to radiator leaks or malfunctioning thermostats.

- Suspension Wear: Noise while driving or uneven tire wear might indicate worn-out shocks or struts.

- Brake System Concerns: Squeaking or grinding sounds could signify worn brake pads or damaged rotors.

Addressing these issues promptly can prevent further damage and ensure a smoother driving experience. Regular inspections and maintenance checks are advisable to mitigate these common problems.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance tasks. Whether you are a seasoned mechanic or a novice enthusiast, possessing a well-organized toolkit can make all the difference in your experience and efficiency. Below are some key implements that every automotive enthusiast should consider having on hand.

- Socket Set: A versatile collection of sockets in various sizes is essential for loosening and tightening bolts.

- Wrenches: Both standard and adjustable wrenches are necessary for gripping and turning fasteners.

- Screwdriver Set: A variety of screwdrivers, including flathead and Phillips, are vital for different types of screws.

- Pliers: Needle-nose and slip-joint pliers provide excellent grip for reaching into tight spaces.

- Jack and Jack Stands: Lifting the vehicle safely is critical, and having a quality jack along with sturdy stands is non-negotiable.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Multimeter: An invaluable tool for diagnosing electrical issues, helping to measure voltage, current, and resistance.

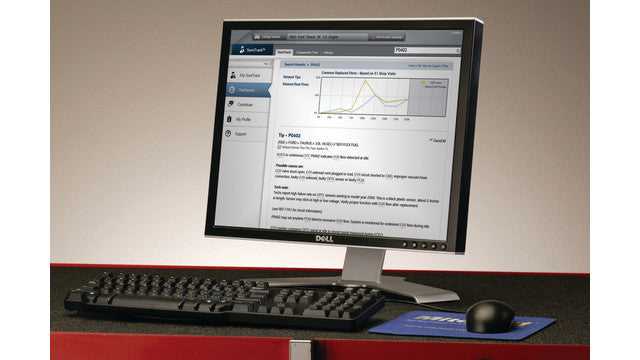

- Diagnostic Scanner: A scanner can read error codes from the vehicle’s computer, aiding in troubleshooting and repairs.

Equipping yourself with these essential tools will not only enhance your ability to perform various tasks but will also foster confidence in handling automotive challenges.

Engine Specifications and Maintenance

This section provides essential information regarding the engine’s characteristics and necessary upkeep practices to ensure optimal performance and longevity. Understanding these specifications is vital for anyone looking to maintain their vehicle effectively.

Engine Specifications

- Type: V6 engine configuration

- Displacement: Approximately 3.8 liters

- Power Output: Around 200 horsepower

- Torque: About 240 lb-ft

- Fuel System: Multi-port fuel injection

Maintenance Recommendations

- Regularly check and replace engine oil to maintain lubrication and reduce wear.

- Inspect and replace the air filter as needed to ensure proper airflow.

- Monitor coolant levels and inspect the cooling system for leaks or corrosion.

- Replace spark plugs according to the manufacturer’s schedule for optimal ignition efficiency.

- Perform routine inspections of belts and hoses to identify signs of wear or damage.

Adhering to these specifications and maintenance guidelines will contribute significantly to the reliability and performance of the vehicle’s engine.

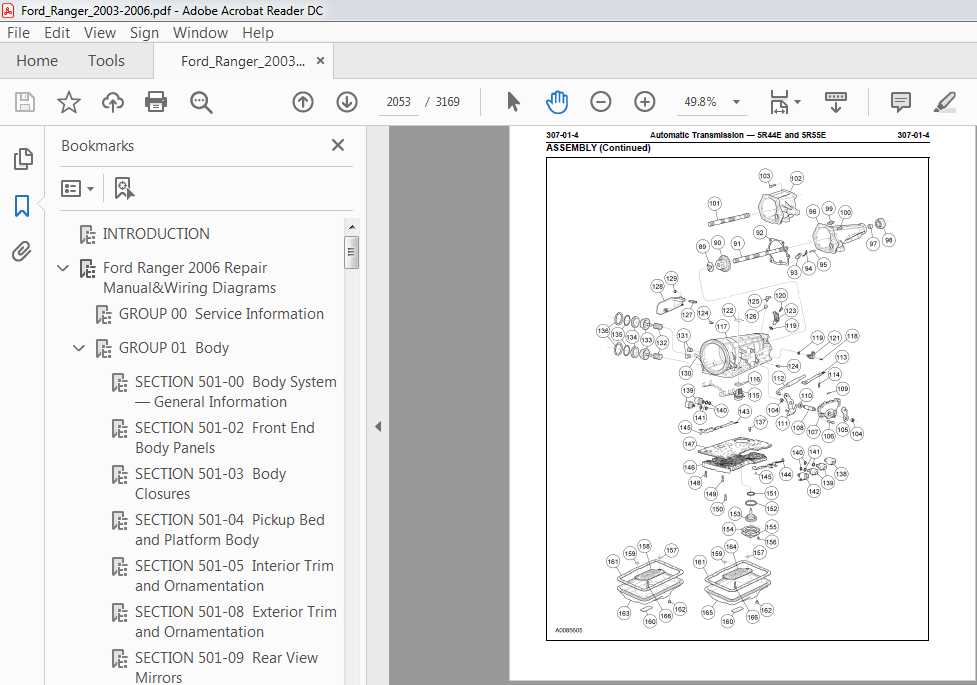

Transmission Troubleshooting Tips

When experiencing issues with your vehicle’s transmission, a systematic approach to diagnosing the problem can save time and prevent unnecessary expenses. Understanding common symptoms and their potential causes is essential for effective troubleshooting. This guide offers key insights to help you identify and address transmission-related concerns.

1. Check Fluid Levels

One of the first steps in troubleshooting transmission problems is to inspect the fluid levels. Low fluid can lead to slipping and overheating. Ensure that the transmission fluid is at the appropriate level and is clean, as dirty fluid can indicate contamination or degradation.

2. Listen for Unusual Noises

Pay attention to any strange sounds while driving, such as grinding or whining. These noises can signify mechanical issues within the transmission. Identifying when these sounds occur can help pinpoint the problem.

3. Observe Shifting Behavior

Monitor how the vehicle shifts between gears. Hesitation, rough transitions, or failure to engage can indicate internal problems. Noting these patterns can assist in determining whether the issue is mechanical or electronic.

4. Scan for Error Codes

Utilizing a diagnostic scanner can reveal error codes stored in the vehicle’s computer. These codes can provide specific information about faults within the transmission system, guiding your troubleshooting efforts.

5. Inspect for Leaks

Visual inspection for fluid leaks around the transmission can be critical. Puddles or stains under the vehicle often point to seal or gasket failures that need immediate attention.

6. Test the Torque Converter

A malfunctioning torque converter can cause significant performance issues. If the vehicle stalls or struggles to accelerate, this component may require testing or replacement.

By following these troubleshooting tips, you can better understand potential transmission issues and take informed steps toward resolution. Regular maintenance and prompt attention to problems can help ensure the longevity and reliability of your vehicle’s transmission system.

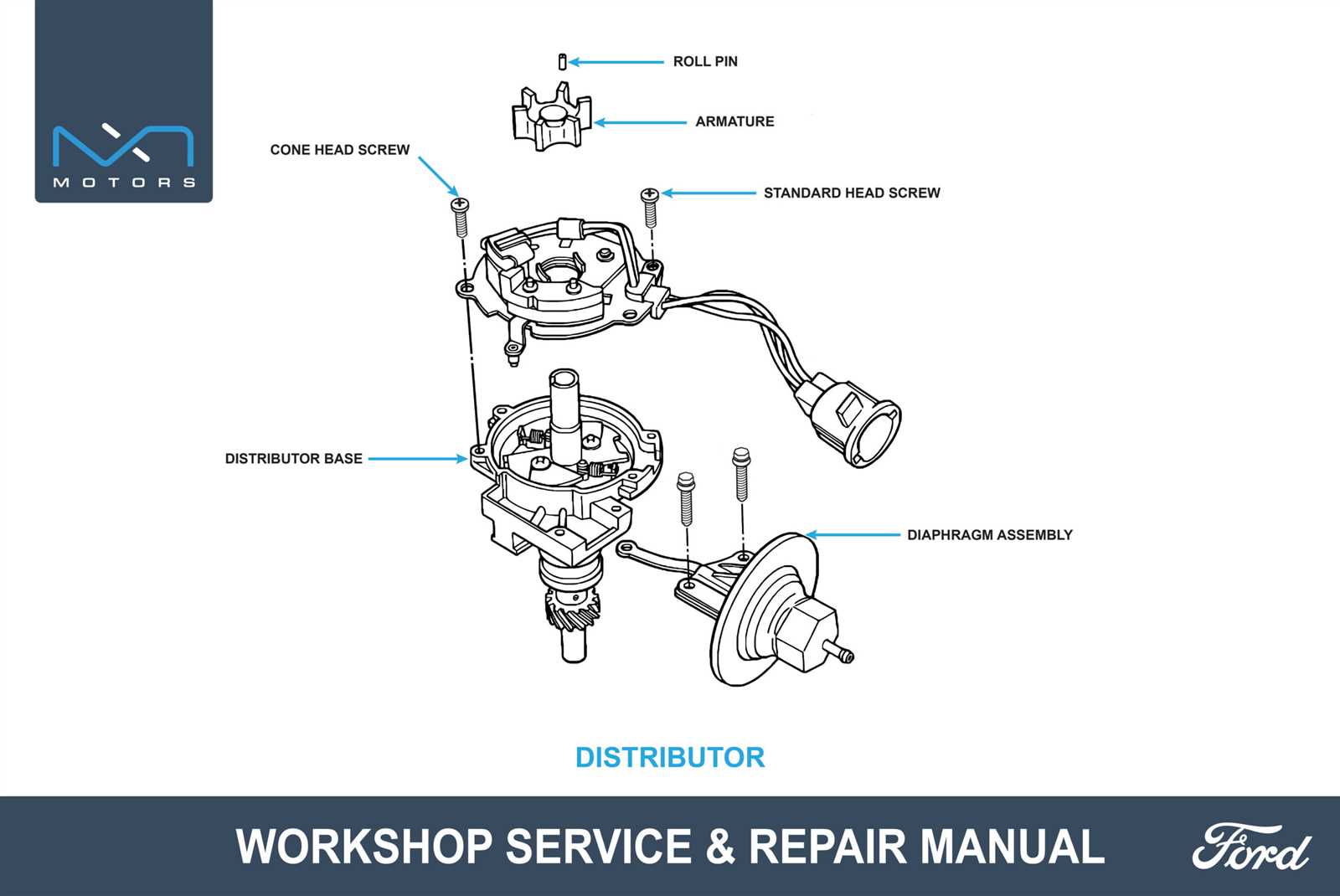

Electrical System Diagnostics

The ability to effectively diagnose electrical issues is crucial for maintaining optimal performance in any vehicle. Understanding the intricacies of the electrical system can help identify problems that may lead to malfunctioning components. This section outlines key approaches and techniques to troubleshoot common electrical failures, ensuring reliability and safety on the road.

Common Symptoms of Electrical Issues

Identifying symptoms early can save time and resources. Common indicators of electrical problems include dim lights, unresponsive dashboard gauges, and starting difficulties. Additionally, frequent blown fuses or intermittent functionality of accessories may signal underlying issues. Recognizing these signs can prompt timely investigations and repairs.

Diagnostic Techniques

Utilizing a multimeter is an effective method for assessing electrical continuity and voltage levels. Begin by checking battery voltage to ensure adequate power supply. Next, inspect connections and wiring for any signs of corrosion or damage. Employing a systematic approach, such as following the wiring diagram, can aid in pinpointing the source of the problem. Regular maintenance and thorough inspections can greatly enhance the longevity of the electrical system.

Suspension and Steering Adjustments

The proper calibration of suspension and steering components is essential for maintaining vehicle stability and enhancing driving comfort. Adjustments ensure optimal performance, allowing for a smoother ride and improved handling. Regular inspections and precise modifications can prevent premature wear and improve overall safety on the road.

Alignment Procedures

Correct wheel alignment is crucial for even tire wear and accurate steering response. Misalignment can lead to pulling to one side and decreased fuel efficiency. To achieve proper alignment, technicians typically check the camber, caster, and toe angles. Adjustments are made using specialized equipment to bring these angles within manufacturer specifications.

Suspension Component Inspection

Routine inspection of suspension components, such as shocks, struts, and springs, is vital. Worn or damaged parts can significantly affect handling and comfort. Technicians should examine these components for signs of wear, such as leaking fluid or unusual noises. Replacing defective parts promptly can prevent further damage and ensure a safe driving experience.

Brake System Repair Guidelines

The brake system is a critical component of vehicle safety, requiring regular inspection and maintenance to ensure optimal performance. This section provides essential procedures and considerations for addressing various issues that may arise within the braking mechanism.

- Inspection Procedures:

- Check brake fluid levels regularly.

- Examine brake pads and shoes for wear.

- Inspect rotors and drums for damage or warping.

- Ensure all brake lines are intact and free from leaks.

- Replacement Guidelines:

- Replace brake pads when they show signs of thinning.

- Consider replacing rotors if they are below the manufacturer’s specifications.

- Use quality components to ensure reliability.

- Bleeding the Brake System:

- Start with the wheel furthest from the master cylinder.

- Ensure no air is trapped in the lines to maintain brake effectiveness.

- Follow a systematic bleeding order for optimal results.

- Testing and Adjustments:

- Conduct a test drive to assess brake response.

- Adjust brake balance if necessary to ensure even stopping power.

- Monitor for unusual noises or sensations during braking.

Regular attention to the brake system not only enhances safety but also extends the lifespan of components, contributing to overall vehicle reliability.

Heating and Cooling System Insights

The effectiveness of a vehicle’s thermal management is crucial for comfort and performance. This section explores key components and considerations that ensure optimal functionality of the climate control system.

- Components: The heating and cooling system comprises several essential parts, including the radiator, heater core, compressor, and various sensors.

- Functionality: Understanding how these components work together can help in diagnosing issues. The system circulates coolant to regulate temperatures, providing both heating in colder months and cooling during warmer periods.

- Common Issues: Drivers may encounter problems such as:

- Inadequate heating or cooling.

- Strange noises from the system.

- Coolant leaks, which can lead to overheating.

- Blocked air filters affecting airflow.

- Inspect and replace coolant as needed.

- Check and clean air filters regularly.

- Ensure that hoses and connections are secure.

- Test the thermostat and sensors for proper operation.

By staying informed about the heating and cooling system’s components and maintenance needs, vehicle owners can enhance comfort and prevent potential failures.

Interior and Exterior Components Maintenance

Proper upkeep of vehicle elements plays a crucial role in ensuring longevity and performance. Regular attention to both the inside and outside parts can prevent minor issues from escalating into significant problems. A comprehensive approach to maintenance not only enhances aesthetics but also improves safety and functionality.

Interior Maintenance Tips

- Cleaning Upholstery: Use appropriate cleaners for different materials, ensuring they are gentle yet effective.

- Dashboard Care: Wipe down with a soft cloth regularly to prevent dust buildup and fading.

- Check Electronics: Regularly inspect audio and climate control systems for proper operation.

- Inspect Safety Features: Ensure seat belts and airbags are functioning correctly.

Exterior Maintenance Tips

- Regular Washing: Keep the exterior clean to protect paint and prevent rust.

- Waxing: Apply wax periodically to shield the surface from environmental damage.

- Tire Inspection: Monitor tire pressure and tread depth for safety and performance.

- Lighting Checks: Regularly test headlights, taillights, and turn signals for functionality.

Consistent care of these components not only improves the overall experience but also preserves the value of the vehicle over time.

Fuel System Checks and Repairs

The fuel system plays a crucial role in the overall performance of a vehicle. Ensuring that it functions optimally is essential for smooth operation and longevity. Regular inspections and maintenance can prevent potential issues, saving time and money in the long run. This section outlines key procedures for assessing and addressing common fuel system concerns.

Inspection Procedures

Before delving into repairs, it’s vital to conduct a thorough inspection of the fuel system components. This includes the fuel pump, filter, injectors, and lines. Identifying any irregularities early can help avoid more significant problems later.

| Component | Check for | Action if Faulty |

|---|---|---|

| Fuel Pump | Strange noises, poor pressure | Replace or repair |

| Fuel Filter | Clogs, leaks | Change regularly |

| Fuel Injectors | Misfiring, uneven idle | Clean or replace |

| Fuel Lines | Cracks, leaks | Replace damaged sections |

Repair Techniques

When problems are detected, employing the correct techniques for repairs is essential. Depending on the issue, some repairs may require specialized tools and knowledge. Understanding the specific requirements for each component will ensure effective resolution of any issues encountered.

Using the Repair Manual Effectively

Utilizing a comprehensive guide can significantly enhance your ability to troubleshoot and maintain your vehicle. A well-structured resource provides essential information that can help you diagnose issues, understand component functions, and execute repairs with confidence. Mastering the use of this resource will empower you to address problems more efficiently and improve your overall experience with vehicle upkeep.

Key Strategies for Effective Use

- Familiarize Yourself with the Structure: Understand how the information is organized. Typically, you will find sections for troubleshooting, specifications, and procedures. Knowing where to look will save you time.

- Use the Index and Table of Contents: These tools can guide you to specific topics quickly. They help you navigate directly to the section relevant to your current needs.

- Read Before You Begin: Before starting any task, read through the entire procedure. This will give you a clear idea of what to expect and what tools you may need.

- Take Notes: As you work through the instructions, jot down important points or any modifications you make. This practice will create a personal reference for future tasks.

Safety and Preparation

- Gather Necessary Tools: Ensure you have all the tools required for the job before you start. This prevents interruptions during the repair process.

- Follow Safety Guidelines: Always prioritize safety by adhering to recommended practices and using protective gear.

- Consult Multiple Sections: Some repairs may involve various systems. Don’t hesitate to check related sections for comprehensive guidance.

Resources for Additional Help

When tackling vehicle maintenance and troubleshooting, having access to a variety of resources can significantly enhance your understanding and effectiveness. Whether you’re a novice or an experienced enthusiast, leveraging multiple platforms can provide valuable insights and solutions.

Here are some recommended avenues to explore:

- Online Forums: Communities of automotive enthusiasts often share their experiences and solutions to common issues.

- Video Tutorials: Platforms like YouTube host countless instructional videos that demonstrate various repair techniques step-by-step.

- Automotive Websites: Specialized sites provide detailed articles, guides, and user-generated content to assist with specific challenges.

- Local Libraries: Many libraries offer access to repair databases and manuals for different vehicle models.

- Social Media Groups: Join groups on platforms such as Facebook or Reddit to connect with others who share your interest in automotive care.

By utilizing these resources, you can enhance your knowledge, gain practical skills, and tackle any challenges that may arise with greater confidence.