Comprehensive Guide to Repairing the 2005 Ford F150

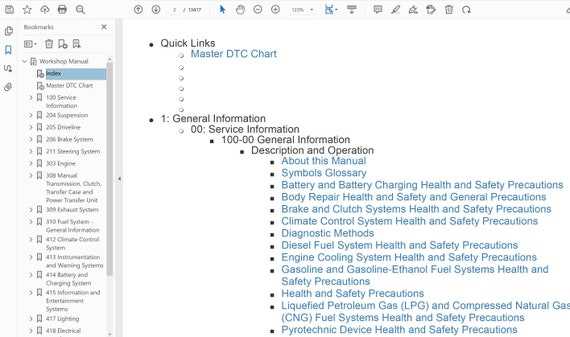

The significance of having a comprehensive reference for vehicle upkeep cannot be overstated. Whether you are an experienced enthusiast or a casual driver, understanding the intricacies of your automobile enhances not only its longevity but also its performance. This section serves as a vital resource, equipping you with the necessary insights and methodologies to address various challenges that may arise during ownership.

With the right information at your fingertips, tackling issues becomes a more manageable task. From routine inspections to more complex repairs, the details outlined in this guide provide clarity on procedures, specifications, and recommended practices. Such knowledge empowers owners to make informed decisions, ultimately leading to a more satisfying and reliable driving experience.

Moreover, familiarity with your vehicle’s components and systems fosters a deeper appreciation for engineering. It transforms the relationship between the owner and the machine into one of partnership and understanding. By utilizing this resource, you can confidently navigate the journey of maintenance and repair, ensuring that your vehicle remains in optimal condition for years to come.

This section provides a comprehensive overview of the vehicle in question, focusing on its key features, specifications, and overall performance. By examining various aspects, readers will gain insight into the unique characteristics that set this model apart from its contemporaries.

Key Features

- Powerful engine options that enhance performance

- Advanced safety features ensuring driver and passenger protection

- Spacious interior designed for comfort and utility

- Cutting-edge technology integrated into the dashboard

Specifications

Understanding the specifications is crucial for potential owners or enthusiasts. Here are some essential aspects to consider:

- Engine types available, including V6 and V8 configurations

- Transmission options that offer flexibility in driving

- Towing capacity suitable for various tasks

- Fuel efficiency ratings providing insight into cost-effectiveness

This overview aims to highlight the significant elements of the vehicle, preparing readers for a deeper exploration into maintenance and troubleshooting guidelines in subsequent sections.

Common Issues and Their Solutions

When it comes to maintaining a vehicle, several frequent problems may arise that can affect performance and safety. Identifying these challenges early on is crucial for effective management and prolonging the lifespan of the vehicle. Below are some typical concerns along with practical solutions to address them.

Engine Overheating: One common issue is the engine overheating, which can be caused by low coolant levels or a malfunctioning thermostat. To resolve this, regularly check the coolant level and replace any damaged hoses. If the thermostat is stuck, it should be replaced to restore proper circulation.

Transmission Slipping: Another prevalent problem is slipping transmission, which can lead to a decrease in power and responsiveness. This issue can often be rectified by checking and changing the transmission fluid, as well as inspecting for leaks that could lead to low fluid levels.

Brake Noise: Unusual sounds from the brakes are often indicative of worn brake pads or rotors. Regular inspection and timely replacement of these components can ensure safe stopping and prevent further damage to the braking system.

Battery Issues: Battery failure is a frequent occurrence, especially in extreme weather conditions. Regularly cleaning the battery terminals and ensuring a secure connection can help maintain battery health. If the battery is old or showing signs of weakness, consider replacing it to avoid unexpected breakdowns.

By staying aware of these common issues and implementing the suggested solutions, owners can enhance the reliability and performance of their vehicles.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring that your vehicle operates at peak efficiency. Adhering to a structured maintenance timetable can prolong its lifespan, enhance fuel economy, and reduce the likelihood of unexpected failures. This section outlines a comprehensive schedule designed to keep your automobile in prime condition.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles or 6 months |

| Air Filter Replacement | Every 15,000 miles |

| Tire Rotation | Every 5,000 miles |

| Brake Inspection | Every 10,000 miles |

| Fluid Levels Check | Every 3,000 miles |

| Battery Condition Check | Every 12 months |

| Spark Plug Replacement | Every 30,000 miles |

Following this schedule will help maintain the vehicle’s reliability and performance. Always consult with a professional mechanic for specific advice tailored to your model.

Tools Required for Basic Repairs

Having the right equipment is crucial for successfully tackling minor maintenance tasks. Whether you are addressing a simple issue or performing routine upkeep, a well-stocked toolbox can significantly enhance your efficiency and effectiveness. Below are essential instruments that every vehicle owner should consider keeping on hand to facilitate common tasks.

Basic Hand Tools

A solid set of hand tools forms the foundation for any maintenance job. Essential items include wrenches, pliers, and screwdrivers in various sizes. A socket set is also invaluable, allowing for easy access to fasteners in tight spaces. Additionally, a sturdy hammer can help with minor adjustments or re-alignments during the process.

Diagnostic Equipment

Understanding the condition of your vehicle is key to effective troubleshooting. A code reader can quickly identify issues by retrieving diagnostic trouble codes from the onboard computer. In addition, a multimeter is useful for checking electrical systems and ensuring proper functioning of components. Keeping these tools handy can save time and prevent unnecessary frustrations when addressing issues.

Step-by-Step Engine Troubleshooting Guide

This guide provides a comprehensive approach to diagnosing engine issues effectively. Whether facing performance drops, unusual noises, or warning lights, a systematic examination can help pinpoint the source of the problem. Following these steps will ensure a thorough evaluation and facilitate the identification of potential fixes.

Initial Checks

Start by conducting a visual inspection of the engine compartment. Look for any obvious signs of wear, such as frayed belts, leaks, or disconnected hoses. Pay attention to fluid levels; low oil or coolant can lead to severe damage. Additionally, ensure that all electrical connections are secure and free from corrosion.

Diagnostic Steps

Once the initial checks are complete, proceed to test drive the vehicle to gather more data. Pay attention to any unusual sounds or vibrations. Use an onboard diagnostic scanner to read error codes that can provide valuable insights into specific issues. If necessary, check the fuel system, ignition components, and air intake for potential blockages or failures. This methodical approach will aid in isolating the engine’s malfunction.

Electrical System Diagnostics and Repairs

The electrical system of a vehicle is critical for its overall functionality, requiring meticulous attention and systematic analysis for any issues. This section focuses on identifying faults, performing necessary adjustments, and ensuring all components operate seamlessly together. A sound understanding of electrical principles and diagnostic techniques is essential for efficient troubleshooting and maintenance.

Common Electrical Issues

Several prevalent electrical problems can arise, including issues with wiring, connections, and components such as batteries and alternators. Symptoms may include dimming lights, difficulty starting, or malfunctioning accessories. Addressing these concerns promptly can prevent further complications and enhance vehicle reliability.

Diagnostic Procedures

To effectively diagnose electrical faults, employing a multimeter is vital for measuring voltage, current, and resistance. Begin by checking the battery voltage and ensuring all connections are secure and free from corrosion. Follow up by testing individual components to isolate the source of the issue. Regular inspections and prompt repairs are crucial in maintaining the integrity of the vehicle’s electrical system.

Brake System Inspection and Replacement

Ensuring the optimal performance of a vehicle’s stopping mechanism is crucial for safety. Regular evaluation and maintenance of this system are necessary to prevent potential failures and enhance driving confidence. This section outlines the key aspects of assessing and replacing components related to the braking function.

Inspection Procedures: Begin by examining the brake pads for wear. A thickness of less than 1/4 inch typically indicates the need for replacement. Additionally, inspect the rotors for any signs of scoring or warping. Uneven surfaces can lead to reduced braking efficiency and should be addressed promptly.

Check the brake fluid level in the reservoir; low fluid may signify a leak or worn brake components. Ensure that the fluid is clear and free of contaminants. If the fluid appears dark or has particles, consider flushing the system.

Replacement Steps: When replacing brake pads, start by removing the wheel and caliper. Carefully detach the old pads and clean the caliper bracket. Install the new pads, ensuring they fit snugly and correctly align with the rotor. Reattach the caliper and wheel, then lower the vehicle.

For rotor replacement, remove the caliper and wheel, then take off the old rotor. Install the new rotor and ensure it is properly secured before reattaching the caliper. Finally, bleed the brake lines to eliminate any air pockets, ensuring consistent brake performance.

Regular checks and timely replacements of components are vital to maintain the efficiency of the braking system. Prioritize these procedures to enhance safety and prolong the lifespan of the system.

Transmission Care and Maintenance Tips

Proper upkeep of the transmission system is essential for ensuring smooth operation and extending the lifespan of your vehicle. Regular attention to this critical component can prevent costly repairs and enhance overall performance. Understanding the basics of transmission maintenance can empower you to keep your vehicle in optimal condition.

Fluid Checks and Changes

Regularly checking the transmission fluid level and quality is a fundamental practice. Fluid should be clear and free of contaminants. If it appears dark or has a burnt smell, it’s time for a change. Generally, it is advisable to replace the fluid every 30,000 to 60,000 miles, but always consult your vehicle’s specifications for the most accurate intervals.

Inspection of Components

In addition to fluid maintenance, periodic inspections of related components are crucial. Look for signs of wear or damage in the transmission seals, gaskets, and hoses. Addressing minor issues early can prevent them from escalating into significant problems, ensuring the longevity of the transmission system.

Bodywork and Paint Touch-Up Techniques

Maintaining the exterior appearance of your vehicle is crucial for both aesthetics and protection against environmental factors. This section delves into effective methods for addressing minor imperfections in the bodywork and enhancing the finish with precise paint applications. Understanding these techniques can help extend the lifespan of the vehicle’s surface and restore its original charm.

Before starting any touch-up work, it is essential to gather the right tools and materials. A clean workspace, appropriate brushes, and quality touch-up paint that matches the original color are key components. Begin by thoroughly cleaning the affected area to remove dirt, grime, and any wax residues. This ensures proper adhesion of the new paint.

For minor dents and scratches, consider using a dent repair kit or a heat gun to gently reshape the affected area. Once the surface is smooth, apply a primer if necessary, especially for deep scratches that expose bare metal. This step promotes better paint adhesion and helps prevent rust formation.

When applying touch-up paint, use small, controlled strokes to avoid over-saturation. Multiple thin layers are preferable to a single thick one, allowing for a smoother finish. Allow each layer to dry completely before applying the next. After achieving the desired coverage, a clear coat can be applied to protect the paint and enhance its shine.

Finally, buff the area gently after the paint has cured to blend it seamlessly with the surrounding surface. Regular maintenance and timely touch-ups not only improve the vehicle’s appearance but also protect it from further damage.

Understanding the Fuel System Components

The fuel system is a critical aspect of vehicle operation, playing a vital role in delivering the necessary energy for efficient engine performance. Comprehending its various components helps in diagnosing issues and maintaining optimal functionality.

Key Components of the Fuel System

- Fuel Tank: The primary reservoir where fuel is stored until needed.

- Fuel Pump: Responsible for transferring fuel from the tank to the engine, ensuring proper pressure for efficient combustion.

- Fuel Filter: Removes impurities from the fuel, protecting engine components and enhancing performance.

- Fuel Injectors: Atomize fuel and spray it into the combustion chamber, allowing for precise delivery and improved efficiency.

- Fuel Lines: Transport fuel from the tank to the engine, designed to withstand high pressure and prevent leaks.

Importance of Regular Maintenance

Maintaining the fuel system is essential for longevity and performance. Regular checks and timely replacements of components, such as filters and pumps, can prevent costly repairs and ensure a smooth driving experience.

Understanding the fuel system’s intricacies enables effective troubleshooting and enhances overall vehicle reliability.

Safety Precautions During Repairs

Ensuring a secure environment while undertaking maintenance tasks is essential for both personal safety and the longevity of the vehicle. Adhering to fundamental safety practices helps minimize risks associated with mechanical work, thereby fostering a safer workspace and enhancing overall efficiency.

Before commencing any work, it is crucial to prepare adequately and understand the necessary precautions. Below are some key safety guidelines to follow:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, safety goggles, and a sturdy pair of shoes to shield yourself from potential hazards. |

| Work in a Well-Ventilated Area | Ensure adequate airflow to prevent inhalation of harmful fumes and maintain a comfortable working environment. |

| Disconnect Battery | Prior to any electrical work, disconnect the battery to avoid electrical shocks or accidental short circuits. |

| Use Proper Tools | Utilize the appropriate tools for each task to avoid injury and damage to components. |

| Keep Workspace Organized | Maintain a tidy work area to prevent accidents caused by clutter or misplaced tools. |

| Follow Manufacturer Instructions | Refer to guidelines provided by the manufacturer for specific safety protocols relevant to the vehicle. |

By prioritizing these essential safety measures, individuals can ensure a more secure and efficient experience while performing maintenance on their vehicles.