Comprehensive Guide to 9N Ford Tractor Repair Manual

Maintaining agricultural machinery is essential for ensuring optimal performance and longevity. This section aims to provide valuable insights into the upkeep and troubleshooting of a specific model that has gained a reputation for reliability and efficiency in the field. Understanding the intricacies of this equipment can empower operators to handle common issues and perform routine checks effectively.

In-depth knowledge of machinery components and their functions is crucial for any user. This guide will explore various aspects of maintenance, including preventive measures and troubleshooting techniques. Whether you are a seasoned professional or a newcomer to the world of agricultural equipment, the information provided will enhance your confidence and skills.

With a focus on practical applications and user-friendly approaches, this resource serves as an indispensable tool for anyone looking to optimize their machinery’s performance. From basic adjustments to more complex diagnostics, mastering these skills will ensure that your equipment remains in peak condition throughout its operational life.

Overview of 9N Ford Tractors

The 9N model represents a significant advancement in agricultural machinery, embodying innovative design and engineering principles. Developed in the early 20th century, this equipment was designed to enhance productivity on farms, offering versatility and reliability for various tasks.

Key Features

This machinery is characterized by its robust construction and user-friendly design. The introduction of a three-point hitch system revolutionized the way implements were attached, making it easier for operators to switch between tasks. Additionally, the compact size allows for maneuverability in tight spaces, making it an ideal choice for smaller plots of land.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Four-cylinder gasoline |

| Horsepower | 22 HP |

| Transmission | 4-speed manual |

| Weight | 2,500 lbs |

| Production Years | 1939 – 1942 |

This model has stood the test of time, appreciated by enthusiasts and collectors alike for its historical significance and mechanical simplicity. Understanding its features and specifications is essential for those looking to maintain or restore these iconic machines.

Importance of Repair Manuals

Having access to comprehensive guides is crucial for anyone involved in maintenance and troubleshooting of machinery. These resources serve as essential references, providing detailed insights into the workings and components of equipment. Their value extends beyond simple fixes; they foster a deeper understanding of operational principles and enhance efficiency.

First and foremost, such documentation offers step-by-step instructions, ensuring that users can follow established protocols without the risk of oversight. This not only helps in performing tasks accurately but also reduces the likelihood of errors that could lead to further complications.

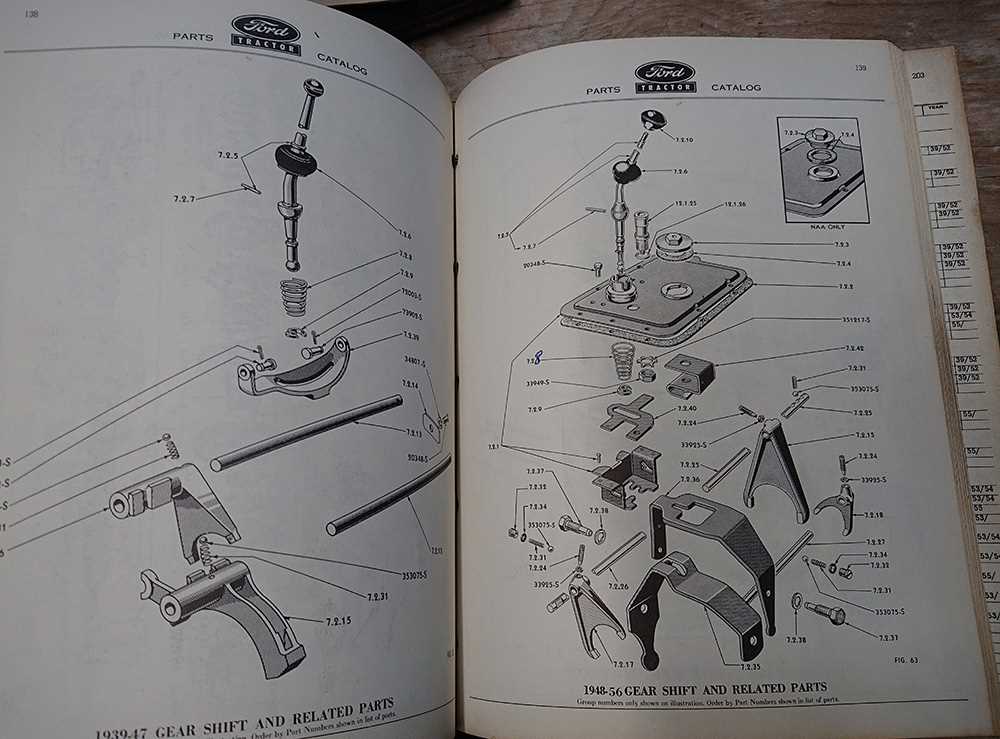

Moreover, these guides often include diagrams and illustrations, which can be invaluable for visual learners. A clear depiction of parts and assemblies aids in identifying issues quickly and effectively, ultimately saving time and resources during the troubleshooting process.

In addition, having a structured reference can significantly improve safety. Understanding the correct procedures and potential hazards associated with certain tasks helps prevent accidents and injuries. This aspect is vital for both amateur and professional users alike.

Lastly, a well-organized resource fosters self-sufficiency. By equipping users with the knowledge to handle various situations, it empowers them to undertake maintenance tasks independently, leading to increased confidence and skill development over time.

Common Issues with 9N Tractors

Operating vintage machinery can often present unique challenges. Understanding the typical problems that arise can help enthusiasts maintain their equipment effectively and prolong its lifespan. This section will explore some frequent complications encountered with these classic machines.

Starting Difficulties

Many owners report issues related to starting, which can stem from various factors. A weak battery, faulty ignition system, or poor connections often contribute to these challenges. Regularly checking the electrical components can prevent frustration during the crucial moments of operation.

Hydraulic System Failures

Hydraulic malfunctions are another common concern. Leaks in hoses, worn seals, or issues with the pump can hinder performance. Routine inspections and timely maintenance of the hydraulic components can help ensure smooth operation and avoid more serious repairs down the line.

Tools Needed for Repairs

Proper maintenance of equipment requires a selection of essential implements that ensure efficiency and safety during the process. Having the right tools on hand not only streamlines tasks but also helps in achieving high-quality results. This section outlines the necessary instruments that are fundamental for effective upkeep.

Essential Hand Tools

Hand tools form the backbone of any maintenance toolkit. They provide the versatility needed for various tasks, from simple adjustments to more complex disassemblies.

| Tool | Purpose |

|---|---|

| Wrenches | For loosening or tightening bolts and nuts. |

| Screwdrivers | For driving screws into different surfaces. |

| Pliers | For gripping and manipulating objects. |

| Socket Set | For applying torque to fasteners. |

Power Tools

In addition to hand tools, power tools can significantly enhance efficiency, especially for larger projects. These instruments are designed to reduce manual effort and expedite tasks.

| Tool | Purpose |

|---|---|

| Drill | For creating holes in various materials. |

| Impact Wrench | For delivering high torque output for tightening. |

| Angle Grinder | For cutting, grinding, and polishing surfaces. |

| Air Compressor | For powering pneumatic tools and cleaning. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing mechanical issues through a systematic method. By following these outlined procedures, you can ensure that each phase of the process is executed effectively, leading to optimal performance of your equipment.

Step 1: Identify the Issue

Begin by conducting a thorough examination to pinpoint the specific malfunction. Look for unusual sounds, leaks, or performance drops. Take notes on symptoms to aid in diagnosis.

Step 2: Gather Tools and Parts

Once the problem is identified, assemble the necessary tools and replacement components. Having everything on hand before starting will streamline the workflow and minimize downtime.

Step 3: Disassemble Components

Carefully take apart the relevant sections. Keep track of screws and small parts to ensure easy reassembly. Use labeled containers if necessary to avoid misplacement.

Step 4: Inspect for Damage

Examine the disassembled parts for wear and tear. Look for cracks, rust, or other signs of deterioration. Replace any damaged components with high-quality alternatives to ensure longevity.

Step 5: Clean the Parts

Thoroughly clean all components to remove dirt and debris. This will not only improve performance but also prevent future issues. Use appropriate cleaning agents that are safe for the materials involved.

Step 6: Reassemble Carefully

Rebuild the equipment by carefully following your notes from the disassembly phase. Ensure that each part is secured properly and that all fasteners are tightened to the manufacturer’s specifications.

Step 7: Test the Equipment

After reassembly, conduct a series of tests to verify that the issue has been resolved. Monitor for any irregularities during operation and address them promptly if they arise.

Step 8: Document the Process

Finally, record the entire process, including the problems encountered and solutions implemented. This documentation will serve as a valuable reference for future maintenance and troubleshooting.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of any mechanical equipment. Regular attention not only enhances performance but also prevents costly breakdowns. Adopting a systematic approach to care can significantly increase the reliability and efficiency of your machinery.

Routine Inspections

Conducting frequent examinations is crucial. Check fluid levels, belts, and hoses to identify any signs of wear or leaks early on. This proactive measure allows for timely interventions, ensuring that all components operate smoothly and effectively.

Lubrication and Cleaning

Regular lubrication of moving parts minimizes friction and wear, which is vital for optimal performance. Additionally, keeping the surfaces clean from dirt and debris helps maintain functionality and can prevent unnecessary damage. Establish a schedule for both lubrication and cleaning to keep your equipment in peak condition.

Finding Replacement Parts

Locating suitable components for machinery can be a straightforward process when you know where to look and what to consider. Whether you are in need of specific items for maintenance or upgrades, understanding your options is crucial for ensuring optimal performance and longevity of your equipment.

Where to Search

There are various avenues to explore when seeking out necessary parts. Both online and offline resources can provide valuable options. Here are some key places to consider:

| Source | Description |

|---|---|

| Local Dealers | Authorized dealers often carry a range of parts and can provide expert advice. |

| Online Retailers | Websites specializing in machinery components offer convenience and a wider selection. |

| Second-Hand Market | Used parts can be found through auctions or classified ads, often at a reduced cost. |

| Manufacturer Websites | Direct purchase from manufacturers ensures authenticity and compatibility. |

Considerations When Choosing Parts

When selecting components, it is essential to keep several factors in mind. Quality, compatibility, and price should all be carefully evaluated to make informed decisions. Investing in high-quality parts can save time and money in the long run, ensuring your equipment operates smoothly and efficiently.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for preventing accidents and injuries. Adopting safety measures protects both the individual and the equipment involved. This section outlines essential guidelines to follow, ensuring a safe and efficient work process.

Personal Protective Equipment

Utilizing appropriate personal protective gear is vital. Items such as gloves, goggles, and steel-toed boots significantly reduce the risk of injuries. Wearing a hard hat is recommended in environments where overhead hazards may exist. Ensure that all equipment is in good condition and fits properly to provide maximum protection.

Work Area Organization

Maintaining an organized workspace is key to safety. Keep tools and materials neatly arranged to prevent tripping hazards. Ensure that all areas are well-lit, and remove any clutter that may obstruct movement. Implementing these practices not only enhances safety but also improves overall efficiency during maintenance tasks.

DIY vs. Professional Repairs

When it comes to addressing mechanical issues, enthusiasts often face a choice between tackling the problem themselves or seeking the assistance of a skilled technician. Each option presents its own set of advantages and challenges, making it essential to weigh the factors carefully before proceeding.

Do-It-Yourself efforts can be highly rewarding. They allow individuals to gain hands-on experience and foster a deeper understanding of the machinery involved. Additionally, this approach often results in significant cost savings, as it eliminates labor fees associated with hiring professionals. However, it also requires a certain level of expertise, access to tools, and a commitment of time that not everyone may have.

On the other hand, enlisting the help of a professional brings a wealth of knowledge and experience to the table. Technicians are equipped with specialized tools and can diagnose problems more efficiently. Their work often comes with guarantees, providing peace of mind regarding the quality of service. Nevertheless, the financial investment in professional services can be substantial, leading some to reconsider their options.

Ultimately, the decision hinges on individual circumstances, such as budget, time constraints, and the complexity of the task at hand. Balancing personal capabilities with the potential benefits of expert assistance is key to achieving the best outcome.

Upgrading Your 9N Tractor

Enhancing your vintage machinery can breathe new life into its performance and efficiency. By focusing on key improvements, you can ensure a smoother operation and extend its longevity.

- Evaluate the engine: Consider a tune-up or replacing old components for better power.

- Improve the transmission: Upgrading gears can lead to smoother shifting and improved responsiveness.

- Enhance the electrical system: Installing a modern battery or wiring can prevent common issues.

- Optimize the cooling system: A more efficient radiator can help maintain optimal temperatures.

Each upgrade not only enhances functionality but also brings the equipment closer to modern standards, making it an ultimate investment for long-term use.